Abstract

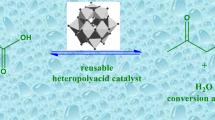

In this work, the activity of Keggin heteropolyacids (i.e., H3PW12O40, H3PMo12O40 and H4SiW12O40) and their Cesium partially exchanged salts (i.e., Cs2.5H0.5PW12O40, Cs2.5H0.5PMo12O40 and Cs3.5H0.5SiW12O40) was assessed in esterification reactions of the levulinic acid with alkyl alcohols. Among the solid catalysts investigated, Cs2.5H0.5PW12O40 was the most active and selective toward alkyl levulinates, which are efficient fuel bioadditives. The effects of main reaction variables, such as temperature, time, alcohol, and catalyst load were evaluated. The reusability of the Cs2.5H0.5PW12O40 catalyst was also evaluated.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nowadays, the use of biomass-derived resources as renewable raw materials to produce chemicals and fuels has exponentially grown due to their potential ability to gradually diminish the dependence on fossil products [1, 2]. Platform molecules such as 5-hydroxymethylfurfural, furfural, and levulinic acid are examples of biorefinery compounds classified by the US Energy Department as “top 10” [3]. They are present in carbohydrates or lignocellulosic biomass and can be converted into a series of renewable fuels or chemicals [4,5,6].

Alkyl levulinates have physicochemical properties that allow their use as bioadditives of diesel fuel and gasoline or being added to the liquid fuel in the range of 0.5 to 20 vol% [7, 8]. These esters become even more attractive when the precursor alcohol has a renewable origin likewise ethyl alcohol [9].

In the conventional esterification routes, alkyl alcohol reacts with a carboxylic acid in the presence of a Lewis or Brønsted acid in a homogeneous phase [10,11,12,13,14]. However, liquid catalysts are hard to be separated from the products, are corrosive, and generally are not easily recyclable [15]. To avoid this drawback, acid catalysts can be supported on solid matrixes such as zeolites, anchored on ionic liquids, or as sulfonic resins [16,17,18,19,20].

Keggin heteropolyacids (HPAs) have been extensively used as catalysts for esterification reactions due to their advantages such as water tolerance, high acidity, and the possibility to be used as soluble or solid-supported catalysts [21,22,23,24,25,26,27,28]. Keggin heteropolyanions are clusters of metal–oxygen, where one XO4 central tetrahedral unit (i.e., X = P5+ or Si4+) is surrounded by W6+ or Mo6+ cations in an octahedral environment [29, 30].

The protons of Keggin HPAs are mobile and easily ionized in a polar medium, allowing a facile replacement by metal cations, generating active catalysts in different reactions in the homogenous phase [31,32,33,34]. However, Keggin HPAs can be also converted into heterogeneous catalysts, when the cations that replaced their protons have large ionic radium [35,36,37,38,39]. This partial replacement allows that the salts have still an acidity strength remaining, enough to catalyze esterification reactions under heterogeneous conditions, without compromising their catalytic activity. This approach has led the cesium HPAs to be used in different reactions such as oxidation, esterification, or etherification [40,41,42,43,44,45,46].

In this work, the focus was to assess the activity of cesium partially exchanged heteropolyacid salts in esterification reactions of levulinic acid, a biomass-derived platform molecule with alkyl alcohols. Effects of main reaction variables such as time, temperature, catalyst load, and type of alcohol were investigated. Among the Keggin HPAs evaluated, Cs2.5H0.5PW12O40 was the most active and selective toward alkyl levulinates. The reusability of the catalyst was successfully demonstrated.

Experimental section

Chemicals

All the chemicals and solvents were acquired from commercial sources and used without previous treatment. Levulinic acid and all the alkyl alcohols (i.e., methyl, ethyl, propyl, butyl, isopropyl alcohols) were Sigma-Aldrich (> 99 wt%). Phosphomolybdic, phosphotungstic and silicotungstic acids, and cesium carbonate were also Sigma-Aldrich (99 wt%).

Synthesis and characterization of the cesium HPA salts catalysts

The cesium salt catalysts were synthesized in agreement with the literature [40, 47]. Typically, an amount stoichiometric of Cs2CO3 aqueous solution was added dropwise to a solution of the Keggin HPA, aiming to achieve the molar ratio desired. The addition of Cs2CO3(aq) precipitated the Cs heteropoly salts as a white solid when phosphotungstic or silicotungstic acids were the precursors. When the phosphomolybdic acid was used, the cesium heteropoly salt was a green solid. HPA. After the water evaporation at 373 K, the Cs HPA salt was dried for 6 h in an oven. The characterization of the Cesium HPA salts used in this work was previously described in two previous works recently published [45, 48].

Identification of main reaction products

The reaction products were identified in a Shimadzu GC-2010 gas chromatographer coupled with an MS-QP 2010 mass spectrometer (i.e., electronic impact 70 eV, scanning range of m/z 50–450). Additionally, the products were co-injected with authentic samples synthesized as described in previous work [49, 50].

Catalytic tests

Tests catalytic were carried out in a sealed glass tube (25 mL). Typically, levulinic acid (2.0 mmol) was dissolved in an alkyl alcohol solution (8 mL) under magnetic stirring, and heated to 393 K in an oil bath. The addition of the acid catalyst (1.2 mol%) started the reaction.

The reaction progress was followed for 6 h, analyzing aliquots in GC equipment (Shimadzu 2010, FID), fitted with a Rtx®-Wax, capillary column (30 m length, 0.25 mm i.d., 0.25 mm film thickness) the aliquots periodically collected. The temperature program of GC analyses was as follows: 80 °C (3 min), heating rate (10 °C/min) until 240 °C. Injector and detector temperatures were 250 °C and 280 °C, respectively.

Results and discussion

Catalytic tests

Initially, the effect of the Keggin anion on the activity of Cesium salt catalyst was evaluated using ethyl alcohol as model alcohol following conditions described in the literature [49, 50]. In according with the literature, Cesium salts containing 0.5 mol of H+ ions/mol of catalyst have been the most efficient catalysts in different reactions [45, 48]. Therefore, all the Cesium HPA salts evaluated were tested with this load of H+ ions. Runs in the presence of the pristine heteropolyacid catalyst were also performed aiming for a comparison (Fig. 1).

It is important to highlight that all the catalysts were used at the same load of H+ ions. Another important point is that all the Keggin heteropolyacids are soluble in the reaction, whereas the insoluble Cesium salts. The soluble HPAs-catalyzed reactions achieved a minimum conversion of 97%. Although the Cesium silico-or phosphotungstic salts have a little bite less efficient than their precursor acids, this is still a satisfactory result since they are insoluble. The Cs2.5H0.5PMo12O40 salt achieved the lowest conversion (80%). Although the Cs3.5H0.5SiW12O40 salt has achieved a high conversion, it has a higher cesium content per mol of catalyst, therefore, the Cs2.5H0.5PW12O40 salt was selected to evaluate the other effects of reaction variables. The best performance of Cs2.5H0.5PW12O40 compared to their partner salts was assigned to the combination of its high surface area with strong strength of acidity, having been also observed in etherification reactions [45].

Fig. 1 shows that the selectivity of products formed in the esterification of levulinic acid with ethyl alcohol was less impacted by the nature of the catalyst. Ethyl levulinate (EL) was always the main product, while α-angelica lactone (αAL) and pseudo ethyl levulinate (PEL) were the secondary products (Scheme 1).

Cesium phosphotungstate salts containing a variable load of H+ ions were evaluated and the main results are shown in Table 1.

In the range of concentration evaluated, the catalytic behavior of cesium exchanged partially salts were very close either in terms of conversion or selectivity toward ethyl levulinate. Although completely substituted with cesium, Cs3PW12O40 achieved still significant conversion and selectivity (Fig. 2). It suggests that this salt presents a strength of Bronsted acidity. Matachowski et al. assessed the acidity properties of a series of cesium phosphotungstate salts and assigned this remaining acidity to the hydrolysis of phosphotungstate by the hydration water molecule, which gives H+ ions [51]. This hypothesis was previously presented by Korosteleva et al. [52]. This can be the reason for the very similar activity of these salts (Table 1).

The time reaction is a key aspect of this reaction; both conversion and EL selectivity were growing along the reaction, achieving the highest value at 6 h of reaction. The pseudo ethyl levulinate (PEL) was significantly formed within the first reaction interval (1.5 h). This product is obtained from α-ALac, which is formed from the cyclization followed by water molecule realising of levulinic acid (Scheme 1). Both five-membered ring products can be intermediate to give LE.

To evaluate the effect of catalyst load, the reactions were carried out with a variable amount of Cs2.5H0.5PW12O40 for 6 h. Fig. 3 shows the main results. After 6 h of reaction in the absence of catalyst, PEL was the major product. Although omitted herein, we have followed the selectivity of this reaction and verified that when LA is reacted with an excess of ethyl alcohol at 393 K, this is the major product since the reaction's beginning, which was gradually converted to LE with the reaction progress. However, as can be seen in Fig. 3, after 6 h PEL is still the main product.

Besides increasing the conversion, the addition of the catalyst remarkably changes the reaction selectivity. Even at a minimum amount, the presence of the Cs2.5H0.5PW12O40 salt shifts the selectivity toward EL, evidence that it is essential to obtain the ester. A catalyst load higher than 0.6 mol% of H+ ions did not increase conversion or selectivity.

The impact of temperature was evaluated using the most favorable reaction conditions (0.6 mol% of H+ ions, 6 h reaction, Fig. 4). Conversion and selectivity were favoured by the increase in the reaction temperature. At higher temperatures, a greater number of reactant molecules can achieve the energy enough to overcome the activation energy of this reaction, increasing consequently its conversion. Moreover, since esterification reactions involve water molecules elimination this is an expected effect. The character endothermic of this reaction was previously demonstrated [45].

The activity of Cs2.5H0.5PW12O40 salt was also evaluated in the esterification of LA with other alkyl alcohols (Fig. 5). The size of the carbon chain had a minimum effect on the reaction conversion. Regardless of the alcohol (i.e., C1–C4), alkyl levulinate (AL) was always the main product.

Conversely, the hysteric hindrance on the carbon bound to the hydroxyl group was crucial to the reaction conversion; the secondary alcohols were the less reactive. In all the reactions, alkyl levulinate selectivity was higher than 90%.

The reusability of the Cs2.5H0.5PW12O40 catalyst was assessed (Fig. 6). After the end of the reaction, the suspension containing the solid catalyst was centrifugated, and the solid catalyst was washed with ethyl alcohol, dried in an oven, weighted and reused.

The conversion and selectivity of reactions remained almost constant after successive cycles of reuse of the Cs2.5H0.5PW12O40 catalyst. In all runs, the recovery rate was greater than 90%.

Conclusions

In this work, the activity of Cesium exchanged partially Keggin HPA salts was evaluated in the reactions of levulinic acid esterification with alkyl alcohols. Among the cesium salts of different HPAs containing 0.5 mol of H+ ions, the Cs2.5H0.5PW12O40 was the most active and selective catalyst. Investigations on the effect of H+ load per mol of phosphotungstate catalyst revealed that only the totally substituted salt (i.e., Cs3.0PW12O40) presented a conversion lower than 90%. The effect of Cs2.5H0.5PW12O40 load was also evaluated; 0.6 mol% of H+ ions was the lowest load that led to the highest conversion. The reactions achieved a satisfactory conversion only when carried at temperatures greater than 393 K and within a period equal to or higher than 6 h. When evaluated in esterification reactions of levulinic acid with primary alcohols (C1–C4 carbon atoms), the Cs2.5H0.5PW12O40 salt was also an efficient catalyst. However, the secondary alcohols were less reactive. The Cs2.5H0.5PW12O40 catalyst was successfully recovered and reused on levulinic acid esterification with ethyl alcohol without loss of activity.

References

Neves P, Antunes MM, Russo PA et al (2013) Production of biomass-derived furanic ethers and levulinate esters using heterogeneous acid catalysts. Green Chem 15:3367. https://doi.org/10.1039/c3gc41908h

Bozell JJ, Petersen GR (2010) Technology development for the production of biobased products from biorefinery carbohydrates—the US Department of Energy’s “Top 10” revisited. Green Chem 12:539. https://doi.org/10.1039/b922014c

Werpy T, Petersen G (2004) Top value added chemicals from biomass: volume I—results of screening for potential candidates from sugars and synthesis gas. US Department of Energy, Golden, CO (United States)

Lange J-P, van der Heide E, van Buijtenen J, Price R (2012) Furfural-A promising platform for lignocellulosic biofuels. Chemsuschem 5:150–166. https://doi.org/10.1002/cssc.201100648

Brodin M, Vallejos M, Opedal MT et al (2017) Lignocellulosics as sustainable resources for production of bioplastics—a review. J Clean Prod 162:646–664. https://doi.org/10.1016/j.jclepro.2017.05.209

Raspolli Galletti AM, Antonetti C, Fulignati S, Licursi D (2020) Direct alcoholysis of carbohydrate precursors and real cellulosic biomasses to alkyl levulinates: a critical review. Catalysts 10:1221. https://doi.org/10.3390/catal10101221

Christensen E, Williams A, Paul S et al (2011) Properties and performance of levulinate esters as diesel blend components. Energy Fuels 25:5422–5428. https://doi.org/10.1021/ef201229j

Teixeira MG, Natalino R, da Silva MJ (2020) A kinetic study of heteropolyacid-catalyzed furfural acetalization with methanol at room temperature via ultraviolet spectroscopy. Catal Today 314:143–149. https://doi.org/10.1016/j.cattod.2018.11.071

Nandiwale KY, Niphadkar PS, Deshpande SS, Bokade VV (2014) Esterification of renewable levulinic acid to ethyl levulinate biodiesel catalyzed by highly active and reusable desilicated H-ZSM-5. J Chem Technol Biotechnol 89:1507–1515. https://doi.org/10.1002/jctb.4228

Li YL, Pang JY, Lou JC et al (2021) Chemo- and site-selective Fischer esterification catalyzed by B(C6F5)3. Asian J Org Chem 10:1424–1427. https://doi.org/10.1002/ajoc.202100188

Démolis A, Essayem N, Rataboul F (2014) Synthesis and applications of alkyl levulinates. ACS Sustain Chem Eng 2:1338–1352. https://doi.org/10.1021/sc500082n

De Godói Silva VW, Laier LO, Da SMJ (2010) Novel H3PW12O40: catalysed esterification reactions of fatty acids at room temperature for biodiesel production. Catal Lett 135:207–211. https://doi.org/10.1007/s10562-010-0294-3

Liu Y, Lotero E, Goodwin JG (2006) A comparison of the esterification of acetic acid with methanol using heterogeneous versus homogeneous acid catalysis. J Catal 242:278–286. https://doi.org/10.1016/j.jcat.2006.05.026

Pinheiro PF, Chaves DM, da Silva MJ (2019) One-pot synthesis of alkyl levulinates from biomass derivative carbohydrates in tin(II) exchanged silicotungstates-catalyzed reactions. Cellulose 26:7953–7969. https://doi.org/10.1007/s10570-019-02665-w

Corma A, García H (2003) Lewis acids: from conventional homogeneous to green homogeneous and heterogeneous catalysis. Chem Rev 103:4307–4365. https://doi.org/10.1021/cr030680z

Song C, Liu S, Peng X et al (2016) Catalytic conversion of carbohydrates to levulinate ester over heteropolyanion-based ionic liquids. Chemsuschem 9:3307–3316. https://doi.org/10.1002/cssc.201601080

Bringué R, Ramírez E, Iborra M et al (2019) Esterification of furfuryl alcohol to butyl levulinate over ion-exchange resins. Fuel 257:116010. https://doi.org/10.1016/j.fuel.2019.116010

Sambeth JE, Romanelli G, Autino JC et al (2010) A theoretical-experimental study of Wells-Dawson phospho-tungstic heteropolyacid: an explanation of the pseudoliquid or surface-type behaviour. Appl Catal A 378:114–118. https://doi.org/10.1016/j.apcata.2010.02.011

Cirujano FG, Corma A, Llabrés I, Xamena FX (2015) Conversion of levulinic acid into chemicals: synthesis of biomass derived levulinate esters over Zr-containing MOFs. Chem Eng Sci 124:52–60. https://doi.org/10.1016/j.ces.2014.09.047

Fernandes DR, Rocha AS, Mai EF et al (2012) Levulinic acid esterification with ethanol to ethyl levulinate production over solid acid catalysts. Appl Catal A 425–426:199–204. https://doi.org/10.1016/j.apcata.2012.03.020

Badgujar KC, Badgujar VC, Bhanage BM (2020) A review on catalytic synthesis of energy rich fuel additive levulinate compounds from biomass derived levulinic acid. Fuel Process Technol 197:106213. https://doi.org/10.1016/j.fuproc.2019.106213

Bhat NS, Mal SS, Dutta S (2021) Recent advances in the preparation of levulinic esters from biomass-derived furanic and levulinic chemical platforms using heteropoly acid (HPA) catalysts. Mol Catal 505:111484. https://doi.org/10.1016/j.mcat.2021.111484

Prado RG, Bianchi ML, da Mota EG, Bruma SS, Lopes JH, da Silva MJ (2018) H3PMo12O40/agroindustry waste activated carbon-catalyzed esterification of laurica acid with methanol: a renewable catalytic support. Waste Biomass Valoriz 9:669–679. https://doi.org/10.1007/s12649-017-0012-

da Silva MJ, Liberto NA (2016) Soluble and solid supported Keggin heteropolyacids as catalysts in reactions for biodiesel production: challenges and recent advances. Curr Org Chem 20:1263–1283. https://doi.org/10.1002/chin.201636258

Rafiee E, Eavani S (2017) Polyoxometalates as heterogeneous catalysts for organic reactions. Curr Org Chem 21:752–778. https://doi.org/10.2174/1385272821666170126162936

Pathan S, Patel A (2010) Keggin-type mono lacunary silicotungstate supported onto zirconia: synthesis, characterization, and esterification reaction. J Coord Chem 63:4041–4049. https://doi.org/10.1080/00958972.2010.531274

Yan K, Wu G, Wen J, Chen A (2013) One-step synthesis of mesoporous H4SiW12O 40-SiO2 catalysts for the production of methyl and ethyl levulinate biodiesel. Catal Commun 34:58–63. https://doi.org/10.1016/j.catcom.2013.01.010

Pasquale G, Vázquez P, Romanelli G, Baronetti G (2012) Catalytic upgrading of levulinic acid to ethyl levulinate using reusable silica-included Wells-Dawson heteropolyacid as catalyst. Catal Commun 18:115–120. https://doi.org/10.1016/j.catcom.2011.12.004

Coronel NC, da Silva MJ (2018) Lacunar Keggin heteropolyacid salts: soluble, solid and solid-supported catalysts. J Clust Sci 29:195–205. https://doi.org/10.1007/s10876-018-1343-0

Kozhevnikov IV (2007) Sustainable heterogeneous acid catalysis by heteropoly acids. J Mol Catal A Chem 262:86–92. https://doi.org/10.1016/j.molcata.2006.08.072

da Silva MJ, Rodrigues AA (2020) Metal silicotungstate salts as catalysts in furfural oxidation reactions with hydrogen peroxide. Mol Catal 493:111104. https://doi.org/10.1016/j.mcat.2020.111104

Vilanculo CB, José Da Silva M (2021) Na4PMo11VO40-catalyzed one-pot oxidative esterification of benzaldehyde with hydrogen peroxide. RSC Adv 11:34979–34987. https://doi.org/10.1039/d1ra06718d

da Silva MJ, de Andrade Leles LC, Teixeira MG (2020) Lewis acid metal cations exchanged heteropoly salts as catalysts in β-pinene etherification. Reac Kinet Mech Cat 131:875–887. https://doi.org/10.1007/s11144-020-01888-4

Da Silva MJ, Rodrigues AA, Teixeira MG (2020) Iron (III) silicotungstate: an efficient and recyclable catalyst for converting glycerol to solketal. Energy Fuels 34:9664–9673. https://doi.org/10.1021/acs.energyfuels.0c01446

Santos JS, Dias JA, Dias SCL et al (2011) Mixed salts of cesium and ammonium derivatives of 12-tungstophosphoric acid: synthesis and structural characterization. Appl Catal A Gen 394:138–148. https://doi.org/10.1016/j.apcata.2010.12.034

Dias JA, Caliman E, Dias SCL (2004) Effects of cesium ion exchange on acidity of 12-tungstophosphoric acid. Microporous Mesoporous Mater 76:221–232. https://doi.org/10.1016/j.micromeso.2004.08.021

Eom HJ, Lee DW, Kim S et al (2014) Hydrocracking of extra-heavy oil using Cs-exchanged phosphotungstic acid (CsxH3-xPW12O40, x = 1–3) catalysts. Fuel 126:263–270. https://doi.org/10.1016/j.fuel.2014.02.060

Raveendra G, Rajasekhar A, Srinivas M et al (2016) Selective etherification of hydroxymethylfurfural to biofuel additives over Cs containing silicotungstic acid catalysts. Appl Catal A Gen 520:105–113. https://doi.org/10.1016/j.apcata.2016.04.017

Narasimharao K, Brown DR, Lee AF et al (2007) Structure-activity relations in Cs-doped heteropolyacid catalysts for biodiesel production. J Catal 248:226–234. https://doi.org/10.1016/j.jcat.2007.02.016

Pizzio LR, Blanco MN (2007) A contribution to the physicochemical characterization of nonstoichiometric salts of tungstosilicic acid. Microporous Mesoporous Mater 103:40–47. https://doi.org/10.1016/j.micromeso.2007.01.036

Batalha DC, Ferreira SO, da Silva RC, da Silva MJ (2020) Cesium-exchanged lacunar Keggin heteropolyacid salts: efficient solid catalysts for the green oxidation of terpenic alcohols with hydrogen peroxide. ChemistrySelect 5:1976–1986. https://doi.org/10.1002/slct.201903437

Singh S, Patel A, Prakashan P (2015) One pot oxidative esterification of aldehyde over recyclable cesium salt of nickel substituted phosphotungstate. Appl Catal A Gen 505:131–140. https://doi.org/10.1016/j.apcata.2015.07.032

Patel A, Pathan S, Prakashan P (2016) One pot oxidative esterification of benzaldehyde over a supported Cs-salt of mono nickel substituted phosphotungstate. RSC Adv 6:51394–51402. https://doi.org/10.1039/c6ra04362c

Yu Y, Sun D, Wang S et al (2019) Heteropolyacid salt catalysts for methanol conversion to hydrocarbons and dimethyl ether: effect of reaction temperature. Catalysts. https://doi.org/10.3390/catal9040320

da Silva MJ, Lopes NPG, Ferreira SO et al (2021) Monoterpenes etherification reactions with alkyl alcohols over cesium partially exchanged Keggin heteropoly salts: effects of catalyst composition. Chem Pap 75:153–168. https://doi.org/10.1007/s11696-020-01288-x

Timofeeva MN, Matrosova MM, Maksimov GM et al (2001) Esterification of n-butanol with acetic acid in the presence of heteropoly acids with different structures and compositions. Kinet Catal 42:791–795. https://doi.org/10.1023/A:1013227131728

Park HW, Park S, Park DR et al (2010) Decomposition of phenethyl phenyl ether to aromatics over CsxH3.0-XPW12O40 (X = 2.0-3.0) heteropolyacid catalysts. Catal Commun 12:1–4. https://doi.org/10.1016/j.catcom.2010.08.002

da Silva MJ, Lopes NPG, Bruziquesi CGO (2021) Furfural acetalization over Keggin heteropolyacid salts at room temperature: effect of cesium doping. Reac Kinet Mech Cat 133:913–931. https://doi.org/10.1007/s11144-021-02025-5

Vilanculo CB, de Andrade Leles LC, da Silva MJ (2020) H4SiW12O40-catalyzed levulinic acid esterification at room temperature for production of fuel bioadditives. Waste Biomass Valoriz 11:1895–1904. https://doi.org/10.1007/s12649-018-00549-x

Martins FP, Rodrigues FA, Silva MJ (2018) Fe2(SO4)3-catalyzed levulinic acid esterification: production of fuel bioadditives. Energies. https://doi.org/10.3390/en11051263

Matachowski L, Zięba A, Zembala M, Drelinkiewicz A (2009) A comparison of catalytic properties of CsxH3-xPW12O40 salts of various cesium contents in gas phase and liquid phase reactions. Catal Lett 133:49–62. https://doi.org/10.1007/s10562-009-0149-y

Ukshe EA, Leonova LS, Korosteleva AI (1989) Protonic conduction in heteropoly compounds. Solid State Ion 36:219–223. https://doi.org/10.1016/0167-2738(89)90176-8

Acknowledgements

The authors are grateful for the financial support from CNPq and FAPEMIG (Brasil). This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior - Brasil (CAPES) - Finance Code 001.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lopes, N.P.G., da Silva, M.J. Cesium partially exchanged heteropolyacid salts: efficient solid catalysts to produce bioadditives from the levulinic acid esterification with alkyl alcohols. Reac Kinet Mech Cat 135, 3173–3184 (2022). https://doi.org/10.1007/s11144-022-02310-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-022-02310-x