ABSTRACT

Purpose

To investigate the influence of solvent properties on the phase behavior and physical stability of spray-dried solid dispersions containing naproxen and PVP K 25 prepared from binary cosolvent systems containing methanol, acetone and dichloromethane.

Methods

The viscosity, polymer globular size and evaporation rate of the spray-drying feed solutions were characterized. The solid dispersions were prepared by spray-drying drug-polymer solutions in binary solvent blends containing different proportions of each solvent. The phase behavior was investigated with mDSC, pXRD, FT-IR and TGA. Further, physical stability of solid dispersions was assessed by analyzing after storage at 75% RH.

Results

The solid dispersions prepared from solvent/anti-solvent mixture showed better miscibility and physical stability over those prepared from the mixtures of good solvents. Thus, solid dispersions prepared from dichloromethane-acetone exhibited the best physicochemical attributes followed by those prepared from methanol-acetone. FT-IR analysis revealed differential drug-polymer interaction in solid dispersions prepared from various solvent blends, upon the exposure to elevated humidity.

Conclusion

Spray-drying from a cocktail of good solvent and anti-solvent with narrower volatility difference produces solid dispersions with better miscibility and physical stability resulting from the simultaneous effect on the polymer conformation and better dispersivity of drug.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Amorphous solid dispersion (ASD) of a poorly water soluble active pharmaceutical ingredient (API) in a hydrophilic polymeric carrier is one of the most commonly applied strategies to increase the solubility, dissolution rate and hence systemic availability of drugs administered through the oral route (1,2). In spite of these delivery benefits, the frequent problem with solid dispersion formulation is its higher physical and chemical instability. The solubility advantage of metastable ASD formulation often ceases due to the rapid crystallization of amorphous API, triggered upon exposure to an aqueous medium during administration or recrystallization from the supersaturated solution (3,4). The kinetically stabilized ASD with supersaturated drug loading is severely susceptible to crystallization upon storage. Molecularly dispersed systems provide maximum stabilization against crystallization (5). In this respect, understanding of polymer-drug interaction and phase behavior of the binary system is of key importance for the selection of the most suitable carrier. Moreover, the method of preparation, the range of process variables, and the drug/polymer ratio have a substantial influence on physical structure, the solid state solubility/miscibility of drug and polymer in an ASD (6,7).

Spray-drying of the mixture of a drug and a polymer from a solution/suspension in a solvent or solvent blend has been used for manufacturing ASD for many years. The morphological properties and drug release from an ASD prepared by spray-drying can be rationally correlated with the properties of dispersing solvents or solvent mixtures used during the process (8). An improved in vitro performance of solid dispersions prepared by spray-drying from multiple solvents compared to that prepared from a single solvent has been reported through control of particle morphology (http://www.aapsj.org/abstracts/AM_2009/AAPS2009-000990.PDF). The considerable difference in the solid state miscibility between polymer-polymer or drug-polymer in the film casted from different solvents has been reported (9,10). Al-Obaidi et al. pointed on the significant role of solvent composition on the stability and dissolution rate of ternary ASD prepared by spray-drying (11). Spray-drying from metastable solutions is reported to enhance miscibility of drug-polymer in solid dispersions (12). Despite recent efforts, a deeper understanding on dispersing solvent chemistry and its impact on strength of the drug-carrier interaction, phase behaviour and solid state stability is still lacking. There are no reports in the literature on how a particular spray-drying solvent mixture leads to the development of an acceptable physical structure of the spray-dried products. The marked difference in physicochemical properties between drug and excipient used in solid dispersions also creates a considerable solubility gap in different solvent mixtures. Especially, polymer architecture such as chain folding/unfolding in a particular solvent mixture provides better opportunity to establish stronger drug-polymer interaction and hence optimal miscibility (11). Hitherto, less emphasis has been given on the consequence of evaporation rate of different organic solvents used in spray-drying on molecular mixing of drug and polymer and also on the surface properties of the end products.

The present work aims to carry out a thorough investigation on the effect of initial solvent composition of the spray-drying feed solution on the phase behaviour and physical stability of the spray-dried dispersions (SDDs) of naproxen with PVP K 25 prepared from them. ASDs with two different drug loadings were prepared by spray-drying from the solutions in methanol, dichloromethane (DCM) and acetone and their binary mixtures at three different ratios. Thus, prepared SDDs were analyzed using modulated differential scanning calorimetry (mDSC), Fourier transform-infrared (FT-IR) spectroscopy and powder X-ray diffractometry (pXRD) to describe their phase behaviour/solid state miscibility/crystal growth and the strength of drug polymer interaction. The SDDs were stored at elevated humidity and analyzed by the above-mentioned techniques to gain further insight on their differential miscibility behaviour as an indicator of physical stability. The correlation of relevant solvent properties like evaporation rate, proticity, and solvent power with polymer solubility, polymeric globular size and solution viscosity was made to enlighten the mechanism underlying the observed difference in the miscibility and physical stability of the SDDs prepared from the corresponding solvent mixtures. A mechanistic explanation on the evolution of unique physical structures in SDDs prepared from a variety of solvent blends is postulated based on the observed results.

Materials and Methods

Materials

Naproxen was purchased from CERTA Ltd. (Brain-l’Allend, Belgium). PVP K 25 (Mw = 25,000 Da) was kindly donated by BASF (Ludwigshafen, Germany). Methanol (HperSolv CHROMANORM, VWR, Belgium), DCM (J.T. Baker, The Nederland) and acetone (Chem-lab, Belgium) were used single or as binary mixtures for spray-drying. The solvents used were of HPLC or analytical grade.

Methods

Spray-Drying

Volumetric combinations of methanol, DCM and acetone were prepared by mixing two solvents at 1:3, 1:1 and 3:1 ratio for each binary solvent system. Solid dispersions made up of 30%w/w and 55% w/w of naproxen in PVP K 25 were prepared by spray-drying 5%w/v solutions of drug and polymer in each solvent blend or pure solvents. The solid dispersion from acetone was not prepared due to insolubility of PVP in pure acetone. All solutions were spray-dried using a Buchi mini spray-dryer B191 (Buchi, Flawil, Switzerland) with 50°C inlet temperature, 100% aspirator rate (800 L/h heated nitrogen flow) and 12 ml/min feed rate using a peristaltic pump. The spray-dried samples were further dried to remove the residual solvent in a vacuum oven (0.2 bar) at 25°C for 1 week before analysis.

Exposure to the Elevated Relative Humidity (RH) Storage Condition

Followed by the secondary vacuum drying, approximately 100 mg of the spray-dried samples were further stored in a desiccator containing a saturated sodium chloride solution in water at room temperature (25 ± 2°C) to achieve the 75% RH condition. Samples were removed after 1 week and 1 month and subsequently dried overnight in the presence of P2O5 at 40°C before analysis to avoid the interference of the condensed water.

Thermal Analysis

mDSC was performed on a Q2000 DSC (TA Instruments, Leatherhead, U.K.) under a dry nitrogen purge at a flow rate of 50 mL/min. DSC was equipped with the refrigerated cooling system (RCS90) accessory. The data acquisition and analyses were carried out using Universal Analysis (version 4.4, TA Instruments, Leatherhead, U.K.). The enthalpy was calibrated with an indium standard, and the temperature scale was calibrated with octadecane, indium and tin. The total and reversing heat capacity signals in modulated heating mode (modulated with ±1°C amplitude every 40s) were calibrated by comparing the response of a sapphire disk with its standard values at 106.85°C. All samples were accurately weighed in aluminum pans and crimped with the aluminum lid. The samples were then heated from −20°C to 160°C at 2°C/min scan rate with the temperature modulation as that used in mDSC calibration. Glass transition temperature (Tg) was measured at half height of transition in the reversing heat flow curve. The large and broad transitions were precisely analysed in the curve of the first derivative of the reversing heat flow. The optimum linear smoothing of the derivative curves was executed to obtain better resolution against baseline noise.

Further, DSC was calibrated with indium, and samples were run at 50°C/min linear heating rate from 0°C to 160°C to distinguish the melting event due to trace crystalline content in the samples that were not prominent at slow heating rate of 2°C/min.

The moisture and volatile content in the samples were determined by heating the samples at 2°C/min from 30°C to 160°C with a dry nitrogen purge at 100 mL/min in a thermogravimetric analyzer (TGA), SDT Q600 (TA-instruments, Leatherhead, U.K.). The data were analyzed using Universal Analysis 2000 software (TA Instruments, Leatherhead, U.K.). The recorded weight loss from the starting temperature to 100°C was considered as the loss due to the solvents and water.

Evaporation Rate Measurement

The evaporation rates of spray-drying feed solutions and corresponding pure solvent mixtures were measured using TGA. Approximately 10–30 μl feed solutions were transferred into the ceramic crucible that was tared (with lid), covered with the lid and placed on the sample holder and enclosed inside the temperature-controlled furnace (23 ± 0.5°C) constantly purged with nitrogen at 100 ml/min flow rate. The weight loss was recorded every minute for 25 min. The derivative of percentage weight loss as a function of time is presented as the evaporation rate of the system.

Viscosity Measurement

Viscosity measurements of spray-drying feeds and pure PVP K 25 solution (5%w/v) were performed using a Vibration viscometer (vibration viscometer, SV-10, A & D Instruments, Oxfordshire, UK) equipped with a temperature-controlling water jacket assembly, AX-SV-37 set at 25 ± 0.1°C. The instrument consists of two sensor plates positioned at a gap of 1 mm and oscillating in opposite directions with a frequency of 30 Hz and 1 mm amplitude that were dipped in the sample solution in a glass cup. All measurements were run until there was no fluctuation in the viscosity reading at constant temperature. The calibration was done at 25°C by using water as calibrant. The data acquisitions were carried out using the RSVisco program (A & D Instruments, Oxfordshire, UK). Additionally, intrinsic viscosity measurements of the solvent blends were performed using an Ostwald viscometer (Schott AG, Mainz, Germany) at 25°C using a water bath. All measurements were performed in triplicate.

Dynamic Light Scattering

Globular size distribution of PVP K 25 in the naproxen-PVP K 25 solutions were measured using a BIC90Plus (Brookhaven Instruments Co., Holtsville, NY, USA). The measurement is based on the principle of photon correlation spectroscopy. All samples were properly filtered through 0.45 μm filter (Henke Sass Wolf, Tuttlingen, Germany) and measured at 25°C. The total solute content was always 5% w/v. The w/w ratio of naproxen to PVP K 25 was either 30/70 or 55/45. The volume-weighted mean particle diameters of the solutions were taken as the globular sizes for comparison and calculation.

Powder X-ray Diffraction (pXRD) Studies

Spray-dried products were analyzed using an automated X’pert PRO diffractometer (PANalytical, Almelo, the Netherlands) with a Cu tube and the generator set at 45 kV and 40 mA. The samples were prepared by spreading over zero background plates or by clamping between Kapton foil. The analysis was performed in a continuous scan mode from 4° to 40° 2θ with 0.0021° step size and 19.685 s counting time. The X’pert Data Viewer (PANalytical, Almelo, The Netherlands) was used for processing and analysing the data. For the samples that showed Braggs peaks, the relative degree of crystallinity was computed as the ratio of the net peak height above the amorphous halo to the total height at the same 2θ° (19.5 ± 0.5°).

Polarized Light Microscopy

Polarized light microscopy was performed with an Olympus BX60 polarizing optical microscope equipped with a LINKAM THMS600 hot stage and a LINKAM TMS93 programmable temperature controller. Sample powders were spread over a glass slide and covered with another slide. The specimens were visualized for the presence of birefringence under polarized light and pictured using a digital camera (Olympus). All images were taken at room temperature.

Fourier Transform Infrared Spectroscopy (FT-IR)

Infrared spectra of spray-dried samples were collected using a Spectrum RX I FT-IR spectrometer (Perkin Elmer, Norwalk, CT, USA). Standard KBr disk method was applied to prepare samples. Approximately 1 mg of the sample and 200 mg of dried KBr was blended uniformly in an agate mortar and pressed into a translucent disk. The samples were scanned from 400 to 4,000 cm−1 with 32 scans per spectrum and a resolution of 4 cm−1 at room temperature. The spectra were analyzed with the Spectrum v2.00 software (Perkin Elmer, Norwalk, CT, USA). The optimum points Savitsky-Golay smoothing was performed on all the spectra to remove spikes and negative peaks. The relative peak intensities at the area of interest were further taken for the calculation of the interaction.

Results

Spray-Drying Feed Solution Properties

Viscosity

As depicted in Table I, the viscosities (η) of pure solvents and their mixtures provided a measure of the interaction between the components in the solvent blends, as all the binary mixtures have higher viscosity than the corresponding calculated values. For DCM-acetone system, η is progressively increasing with the increase of DCM content with higher values as compared to the pure components at each composition. The DCM-methanol mixtures also show an evident increase in η as compared to pure components or values calculated therefrom. But the mixture containing 1:1 ratio (by volume) exhibits the largest increase in η, indicating the strongest interaction at this composition. Likewise, methanol-acetone systems are also more viscous than the pure components. Pure PVP K 25 solution in DCM has the highest viscosity and also higher in solvent blends containing DCM (Table I). The viscosity of PVP in methanol-acetone systems was reduced as compared to that in pure methanol. In the case of feed solutions, the viscosity was lower in comparison to pure PVP solution, as they contain naproxen along with PVP. But the feed solutions with methanol-acetone system have lower viscosity than the pure solvent blends. This is evidence of the synergistic building of new binodal interaction in expense of solvent-solvent interaction. Also, PVP should remain compact in this system. This was also the case in the solutions containing lower proportion of DCM.

Polymeric Globular Size

The globular sizes of PVP measured in the spray-drying feed solutions of different solvent blends are shown in Fig. 1. The mean diameter of the globules measured is higher in methanol as compared to DCM, which is in line with the viscosity results. This means that the more extended the polymeric chains are, the smaller the globular size. Moreover, the globular diameters in methanol, DCM and their binary mixtures are higher for the system containing 55% w/w naproxen compared to that of 30% w/w of naproxen. This might be due to the less inter-chain interaction of PVP at the latter composition. An increasing trend of globular size for 30% naproxen composition and decreasing trend of globular diameter for 55% naproxen content were observed with increasing proportion of methanol in DCM-methanol mixtures. This provides evidence of the composition-dependent interaction. For acetone-containing solvent blends, no marked PVP composition dependence of the globular size was observed. The trend of decreasing globular size of PVP with the decrease in acetone content in DCM-acetone as well as methanol-acetone solvent blends was observed, which is an indication of the increased PVP solubilization. Further, values of diffusion coefficient (D) of PVP globules in feed solution prepared in different solvent mixtures were calculated using Stokes-Einstein’s equation (Eq. 1). This helps to correlate the rate of solute diffusion towards the core of the droplets during spray-drying (13).

where K, T, η and r are Boltzmann’s constant, temperature, viscosity of solvent and hydrodynamic radius of polymeric globules, respectively. The D value is inversely related to the viscosity of the medium and PVP globular diameter as reflected from Table I and Fig. 1.

Rate of Solvent Evaporation from Spray-Drying Feed Solution

The miniaturized evaporation rate measurement of the feed solution is helpful in availing the insight of the relative evaporation time for different solvent blends and particle formation during spray-drying as well as the relative interaction strength. As depicted in Fig. 2a–c, the evaporation rate of acetone-containing solvent blends remains constant throughout except the linear decrease for DCM-acetone (3:1) mixture. For DCM-methanol system, the evaporation rate decreases nonlinearly, and the rate loss is more rapid with the higher DCM content.

As illustrated in Fig. 2d–i, the evaporation rate profiles of solvents from different spray-drying feed solutions appeared more complicated. As anticipated, most of the systems showed a deviation from the pure solvent evaporation rates. DCM-acetone solutions containing 30%w/w naproxen in PVP showed almost similar weight loss profiles as that of pure solvent mixtures with overall decrease in evaporation rate. The polynomial evaporation rate loss behaviours are observed in methanol-acetone and DCM-methanol solutions containing same initial drug and polymer concentration. The sudden decrease in evaporation rates of the solutions in one part methanol with one part DCM or 3 parts acetone occurs at ca. 10 min. The solutions containing 55%w/w drug in PVP showed more complicated trends. The trends of solutions in DCM-acetone were almost consistent with the preceding solutions, but overall evaporation rates increased. The average evaporation rate of solution in 1 methanol: 1 acetone was reduced the most, among the three mixtures, all showing step loss in evaporation rate after different time course. The evaporation rate trends exhibit more discrepancy in the solutions in DCM-methanol, the initial rate of 3 DCM: 1 methanol containing mixtures being higher than even that of pure DCM.

Moisture and Solvent Content in Solid Dispersions

The thermogravimetric weight loss listed in Table II and Table III reveals that the moisture and volatile content in spray-dried dispersions after 1 week of secondary drying in vacuum varied with solvent compositions from which they originated. In general, the weight loss from 30% w/w drug containing composites was higher compared to that from 55% w/w compositions. This is reasonable, as due to less PVP content, the moisture and solvent retention in the dispersions with the latter composition is less. In general, the samples obtained by spray-drying from cosolvents contained relatively less residuals, which also indicate different extent of free and bound volatile and water in these samples. For 30% w/w drug content, the dispersions prepared from DCM-methanol blends showed the least weight loss. This might be due to faster evaporation rate of this system from the end product (Fig. 2). No marked differences were observed in the weight loss of the other samples.

Phase Analysis of Spray-Dried Dispersions

The selection of the two compositions for the current investigation was based upon their positions from equilibrium solid solubility in the miscibility window of the naproxen/PVP system. The 30% w/w naproxen-containing solid dispersions are metastable heterogeneous glass solutions at which an apparent jump in the composition-dependent Tg trend was observed in our earlier exploration (14). Furthermore, the system heterogeneity increases to include two major amorphous domains and a crystalline phase at 55% drug content. So, it can be anticipated that the effect of solvent composition on the physical structures of solid dispersions with these two compositions should be representative for two different zones of miscibility.

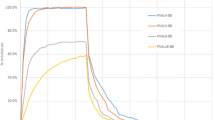

Each set of thermogram includes a reversing heat flow signal and first derivative signal of reversing heat flow as a function of temperature. Accurate and reproducible measurement of heat capacity at Tg is difficult and induces uncertainty when using it for quantitative work. Alternatively, the endothermic depth at Tg in the derivative reversing flow signal provides a clearer reflection of the relative fraction of compositions in a phase-separated system as well as visualization of the broadness of transitions. There exists a well-established relationship between the full width of the baseline shift at the Tg region measured in DSC (difference between extrapolated onset and endset temperature of transition) with the activation energy of structural relaxation and fragility of a glass (15). For a glass mixture, the span of glass transition has been merely correlated with the degree of homogeneity of the system (16). The broader Tg indicates the presence of concentration fluctuations that broaden the distribution of segmental relaxation times and also weaker interaction between the mixing components. Likewise, we consider here the width of a Tg (endset minus onset) as a measure of an individual phase homogeneity and the difference between two Tgs (midpoint values) to denote overall extent of phase separation for a system. The Tg corresponding to the drug-rich region (Tg1) with its width (ΔTg1) and that corresponding to the polymer-rich region (Tg2) with its width (ΔTg2) before and after exposure to the elevated humidity are given in Table II and Table III for spray-dried dispersions with 30% w/w and 55% w/w naproxen content, respectively. For 30% w/w drug-containing samples exposed to 75% RH for 1 month, a third Tg appeared (Tg1′). Further, Fig. 3a and b depict the Tg difference (ΔTg) between polymer-rich and drug-rich regions (Tg2-Tg1) for the spray-dried samples obtained from different solvent compositions with 30% w/w and 55% w/w naproxen content, respectively. The overlays of mDSC thermograms of spray-dried dispersions with 30% w/w naproxen content prepared from DCM before and after exposure to the elevated humidity are given in Fig. 4a, while the same for spray-dried dispersions with 55% w/w naproxen content prepared from 3 DCM: 1 methanol mixture are given in Fig. 4b.

The difference between the glass transition temperatures (midpoint values) belonging to the polymer-rich region (Tg2) and drug-rich region (Tg1) of spray-dried solid dispersions prepared from various solvent blends with 30% w/w drug content (a) and 55% w/w drug content (b), before (black bars) and after (white bars) exposure to 75% RH for 1 week.

(a) Reversing heat flow (continuous line) and derivative reversing heat flow (dashed line) versus temperature for spray-dried solid dispersions containing 30% w/w naproxen in PVP prepared from DCM (as prepared) (a), after 1 week exposure to 75% RH (b) and after 1 month exposure to 75% RH (c). (b) Reversing heat flow (continuous line) and derivative reversing heat flow (dashed line) versus temperature for spray-dried solid dispersions containing 55% w/w naproxen in PVP prepared from 3 part DCM: 1 part methanol (as prepared) (a), after 1 week exposure to 75% RH (b) and after 1 month exposure to 75% RH (c).

Solid Dispersions Containing 30%w/w Naproxen in PVP K 25

A broad glass transition event positioned between the Tg of pure naproxen (6°C) and that of pure PVP K 25 (157°C) (14) was observed in the reversing heat flow signal upon an initial analysis of the spray-dried dispersions prepared from different solvent blends. From the corresponding derivative reversing heat flow signals, it was apparent that the broad transition resulted due to the merger of two Tgs representing two different compositions. The solid dispersions prepared from pure methanol and DCM showed identical phase behavior revealing the similarity of their phase compositions. Among samples prepared from DCM-acetone blends, the sample prepared from 3 DCM: 1 acetone has a broader first Tg and a sharper second Tg both at higher temperatures, and also heterogeneity is higher as indicated with higher ΔTg (Fig. 3a). The two other compositions showed comparable miscibility. The DCM-methanol systems exhibited the first Tg at similar positions but a progressively decreasing second Tg and hence decreasing ΔTg with the increasing proportion of methanol in the blend. The extremely shallow endotherm at the second Tg position of samples derived from 1 DCM: 3 methanol in the derivate signals revealed a decreased proportion of the polymer-rich phase in this sample. In methanol-acetone systems, the phase heterogeneity decreases with an increase in the acetone content in the system. Also, the relative proportion of the two phases is opposite in the samples originating from 1:1 methanol-acetone blends compared to the extreme compositions of solvents (1:3 and 3:1).

The positions of both of the Tgs (observed in untreated samples) shifted towards higher temperature, and clearly separated phases were perceived after the exposure to 75% RH for a week. Even after the exposure to the elevated humidity for a week, the shift in Tgs, individual Tg width and ΔTg followed quite similar patterns for the samples generated from pure methanol and DCM, which is a further indication of similar solid state structure. However, the effect of exposure to the moisture for 1 week was markedly different among samples derived from the various solvent blends. The spray-dried dispersion from 1:3 and 1:1 solvent composition among that prepared from DCM: acetone system showed the least shift in Tg1 values, which points to less reorganisation of physical structure after the exposure to 75% RH. In samples from 3 DCM: 1 methanol, an abrupt increase in phase miscibility was observed as demonstrated by the discernible increase in both Tgs, decrease in ΔTg and equivalent depth at both Tgs observed in derivative signal, while the moisture-induced phase behavior was similar for the samples prepared from one part DCM with one part and three parts methanol. No considerable difference was found on the shift of Tgs among the dispersions prepared from different compositions of methanol: acetone system except slightly increasing trend of heterogeneity with an increased proportion of acetone in feed solution.

Upon exposure of samples to 75% RH further for one month, the first Tg was further split into two adjoining Tgs, while the position of the second Tg remained almost unaltered. This is supported by the recrystallization of a fraction of naproxen from saturated composition corresponding to the first Tg discussed in the succeeding sections. The dispersions formulated from DCM: acetone mixture demonstrated increased phase heterogeneity at the split zone of the first Tg. The spray-dried dispersions from 1 DCM: 3 methanol and 1 methanol: 1 acetone exhibited the highest ΔTg values in the split region, signifying the diverse effect of moisture in the group.

Solid Dispersions Containing 55%w/w Naproxen in PVP K 25

The phase behavior of solid dispersions with 55% drug content is characterized by overlays of thermograms presented in Fig. 4b. The transitions of the drug-rich and polymer-rich region are distinctly separated and also confirmed by the enthalpy recovery enotherms that appeared at the equivalent positions in non-reversing heat flow signals (data not shown). In all samples, a shallow transition corresponding to polymer-rich region (Tg2) positioned between ca. 100–110°C was observed in reversing heat flow signals. The first transitions due to drug-rich compositions within the dispersion matrix appeared at diverse positions depending upon the spray-drying solvent composition. Tg1 was lower for the solid dispersion prepared from pure DCM as compared to that prepared from pure methanol, indicating high drug loading in the amorphous drug-rich region. Likewise, the solid dispersions prepared from DCM-acetone systems showed the lowest values of Tg1 (Table III), indicating relatively higher proportion of the amorphous drug loading in the matrix. The broader glass transitions related to the polymer-rich fractions (ΔTg2) were located at lower temperature. This signifies that overall more drug is loaded in this region with higher heterogeneity. Conversely, solid dispersions generated from DCM-methanol systems showed relatively higher Tg1 and Tg2, which is indicative for lower drug loading in both regions compared to the dispersions prepared from the other solvent compositions. The samples derived from methanol-acetone showed behavior between that of DCM-acetone and DCM-methanol systems, i. e. the drug loadings in the drug-rich region were in between that of the two systems. However, the sample from 1:1 methanol: acetone system was exceptional, as was the case for its evaporation rate. It showed lower drug content in the drug-rich region as compared to that prepared from the other compositions of this solvent system.

All the spray-dried dispersions exposed for one week to 75% RH showed a shift of Tg corresponding to the drug-rich part of the mixture (Tg1) towards higher temperature, which provided an indication of the recrystallization of naproxen from the saturated region (Fig. 4b). The possibility of diffusion of naproxen from the drug-rich region to the unsaturated polymer-rich fraction was ruled out, as Tg2 was also slightly shifted towards higher temperature for most of the samples. Rather, the latter observation refers to the crystallization of a small fraction of naproxen from the polymer region also, in the corresponding dispersion. The Tg1 of the dispersion prepared from methanol was higher than that of the sample prepared from DCM. This indicates an increased conversion to the crystalline state. Among the spray-dried dispersions from solvent blends, the shift of Tg2 towards the higher temperature was the least in the set of dispersions prepared from DCM-acetone system pointing to comparatively lesser extent of crystalline conversion. The solid dispersion from 3 DCM: 1 methanol showed the highest shift in Tg1 towards lower temperature among all solvent blends. A possible explanation is that the slight decrease in Tg2 of samples from 1 DCM: 3 methanol and 1 DCM: 1 methanol might be due to the solid state diffusion of a small fraction of amorphous naproxen to the unsaturated polymer-rich region other than the major crystalline conversion. The dispersions produced from methanol-acetone also showed similar trend in increase of Tg2 except that from 1:1 solvent mixture. Surprisingly, the sample from the latter mixture exhibited similar positions of Tg as that of the corresponding untreated sample. In spite of similar ΔTg value, the relative depth of drug-rich and polymer-rich peaks observed in the derivative signal was reversed, indicating equivalent phase distributions.

Prolonging the exposure of solid dispersions with 55% naproxen content to 75% RH for one month resulted in maximum crystallization of naproxen from the supersaturated drug-rich fractions of the dispersions. The Tg1 was shifted and almost merged with Tg2, the latter also being slightly shifted to higher temperature, indicating further crystallization of a trace fraction of drug from the polymer-rich fraction.

Evaluation of Relative Crystallinity in the Solid Dispersions

The 30% naproxen-containing samples were noncrystalline phase-separated amorphous dispersions up to one week exposure to 75% RH as confirmed by the absence of Bragg peaks in pXRD and birefringence in polarized light. Conversely, small peaks due to trace crystallinity were evident in pXRD of the samples exposed to 75% RH for one month. No striking difference was visible in amorphous halo patterns of the samples prepared from different solvents. Recently, the subtle difference in halo patterns of pharmaceutical solid dispersions has been statistically treated and analyzed using partial least-square (PLS) analysis for the quantification of phase separated fractions (17). In our case, generation of the halo pattern of pure naproxen was not possible to attempt. We made an effort to obtain the pXRD pattern of molten naproxen that could be assumed to bear the structure nearly matching the amorphous halo. But no characteristic halo was observed as naproxen sublimated rapidly in the course of melting.

The crystallinity analysis was focused on the solid dispersions with 55% w/w drug content. The trace amount of small crystals spread over the polymer matrix was observed through the polarized light microscope of the initial samples and was more prevalent in the samples exposed to the elevated humidity. The micrographs of the samples prepared from methanol-acetone systems are given in Fig. 5. Bragg peaks appeared on the top of an amorphous halo in the diffractograms of the respective samples, except for the sample prepared from 3 DCM: 1 acetone. In line with the observation in the microscopic images, the relative increase in the intensity of crystalline peaks and decrease of the amorphous halo were noticed in samples exposed to 75% RH for one week and even more in that exposed for one month. The ratios of net intensity of the highest crystalline peak (2θ° = 19.5 ± 0.5°) on top of the amorphous halo to the total intensity for different samples are listed in Table IV. Although this is a not the measure of an exact crystallinity, and even the possible error due to preferred orientation cannot be ruled out, it provides an estimation of the crystallinity of a sample and enables comparison between samples. In mDSC analysis with 2°C/min heating rate, no melting event was observed in any sample, not even for the physically mixed drug-polymer composite with equivalent composition. The kinetically controlled solid-state dissolution, instead of melting of the drug, spread the polymer matrix upon slow heating of solid dispersion as reported before (18). Similar phenomenon is assumed to be prevalent in the present case that is responsible for the undetectable melting event that can be surpassed by other events or spread through a broader temperature range. Nevertheless, the melting events were prominent in the DSC thermograms of the samples recorded at heating rate of 50°C/min. Depending upon the solvent composition used to prepare solid dispersions, the thermograms of the samples before humidity treatment showed the absence or the presence of very small endotherm following glass transition of the polymer-rich region in the samples. Just as expected, the endotherms due to melting increased with an increased exposure of the samples to 75% RH indicating the progressive increase in recrystallization. The percentages of crystallinity derived from DSC data, assuming that drug-polymer interaction has ignorable impact on the heat of melting for trace crystalline content (18), are given in Table IV. As a whole, the crystallinity analysis is consistent with the positions of Tg and their shifts. The dispersion from pure methanol showed higher crystalline content than that from DCM. Solid dispersions prepared from DCM: methanol blends showed the highest initial crystalline drug content, and that from DCM: acetone systems contained the least. The exposure of samples to 75% RH for one week led to the increase of crystallinity, accordingly. But the extent of crystal growth was solvent-composition-dependent. Regardless of solvents, the exposure of samples at 75% RH for the period of one month led to a comparable extent of crystallization.

Polarized light micrographs of solid dispersions prepared from methanol: acetone systems with 55% naproxen content immediately after preparation (a), after 1 week storage at 75% RH (b) and after 1 month exposure at 75% RH (c). The notations in the parentheses correspond to the respective composition of solvent mixture where M: methanol and A: acetone.

Spectroscopic Investigation on Drug-Polymer Interaction and Hydrogen Bonding

FTIR is one of the extensively used techniques for the study of solid-state interaction between drug and polymer in solid dispersions. The intermolecular hydrogen bonding in crystalline naproxen and naproxen solution in various organic solvents (19,20) as well as its solid dispersions with PVP (21) has been well documented. The crystal structure of naproxen reveals that it exists as a trimolecular catemer instead of cyclic dimeric congener as ibuprofen (22). So, the fingerprint region in the FTIR spectrum of naproxen is mainly characterized by vibrations at 1,727 cm−1 and 1,686 cm−1 attributed to non-hydrogen-bonded –C=O stretching and hydrogen-bonded -C=O stretching of the catemer, respectively. The intensity of the vibrational band at 1,727 cm-1 is more dominant because most of the naproxen molecules are not engaged in hydrogen bonding. The bands observed at 3,206 cm−1 are assigned to the -OH stretching of –COOH group. The broad vibration band in the IR spectrum of pure PVP, with peak maximum at 1,654 cm−1, is due to –C = O stretching of amide group that is hydrogen bonded with physically adsorbed water. It also shows the corresponding vibration at 3,446 cm−1 of hydroxyl groups due to the formation of the hydrogen bonds between PVP and water.

The FTIR spectra of solid dispersions containing 30% w/w naproxen are given in Fig. 6. The carbonyl stretching region was more sensitive to the consequences of drug-polymer interaction. A new peak at 1,677 cm−1 appeared at the expense of the peak due to the hydrogen-bonded carbonyl group of pure naproxen. This is an indication of the disruption of intermolecular hydrogen bonding between naproxen molecules. In addition, the peak due to non-hydrogen-bonded carbonyl stretching decreased appreciably. Though the PVP molecules would still be unsaturated in terms of hydrogen bonding, the vibration due to non-hydrogen-bonded carbonyl group of non-interacting PVP might have been masked by the intense peaks of the aromatic skeleton stretching of naproxen appearing around the same position. Generally, hydrogen bonding causes a shift to lower wave numbers of the vibration peaks. But the phenomenon depends on the self-association and interaction between molecules (23). The percentages of hydrogen-bonded –C=O fraction between drug and polymer (% Fnaproxen-PVP) listed in Table V for solid dispersions before and after exposure to humidity were calculated from the normalized height ratio of the corresponding peaks using Eq. 2.

FTIR spectra for spray-dried solid dispersions containing 30% w/w naproxen in PVP prepared from various solvent blends after one vacuum drying (a), after 1 week exposure to 75% RH (b) and after 1 month exposure to 75% RH (c). The notations in parentheses correspond to the respective solvent mixture composition used to prepare solid dispersions where A: acetone, D: DCM and M: methanol.

where I1677 and I1727 are the normalized absorption intensity at the respective wave number in IR spectra. As total area of the carbonyl stretching region remained approximately constant for the samples derived from various solvent blends, we assume that the ratio of molar absorption coefficient of free carbonyl group of naproxen to that of inter-associated carbonyl group of PVP (with drug) equals unity in Eq. 2 (24). No distinctive difference in % Fnaproxen-PVP was apparent within solid dispersions prepared from different solvent compositions stored at identical conditions, despite their dissimilar phase behavior observed from thermal analysis. No evidence of differences in hydrogen bonding were detected by FTIR between the samples. An average 75% intermolecular hydrogen-bonded –C=O was visualized up to one week exposure to 75% RH, which reduced to 55% on average after exposure for one month. Also, the vibration band due to naproxen-PVP intermolecular hydrogen bonding broadened after one month exposure to 75% RH, which is interpreted as an indication of weakening of the interaction. This can be well correlated with the fractional recrystallization of the samples by this time.

As shown in Fig. 7, the spectral patterns of 55% w/w naproxen containing solid dispersions in the carbonyl stretching region were strikingly different from those with 30% w/w naproxen content. An appearance of an extra vibration band at 1,632 cm−1 with the highest intensity was observed in the carbonyl region of the spectra of samples independent of solvent composition. This is assigned to the stronger intermolecular hydrogen bonding between naproxen and PVP molecules in the drug-rich region of solid dispersions. A shift to lower wave numbers of –C=O stretching band of PVP to a similar extent has been reported to be attributable to the –COOH group hydrogen bonded with the –C=O group of the amide functionality of PVP (25). It is logical to hypothesize that the hydrogen bonding distance would be decreased with stoichiometrically increasing amount of interacting group. However, the peak observed at 1,677 cm−1 in spectra of 30% w/w drug containing dispersions is still present in dispersions with 55% w/w drug content, reflecting the presence of the polymer-rich phase with identical hydrogen bonding strength. Thus, in this case, the relative percentage of hydrogen-bonded –C=O belonging to drug-rich and polymer-rich region with respect to the non-hydrogen-bonded –C=O stretching of drug was calculated using Eq. 3a–c. Here also, the ratio of molar extinction coefficient of free carbonyl group of drug and inter-molecularly hydrogen-bonded –C=O of the amide group of PVP was assumed to be unity. The values are listed in Table VI.

FTIR spectra for spray-dried solid dispersions containing 55% w/w naproxen in PVP prepared from various solvent blends after one vacuum drying (a), after 1 week exposure to 75% RH (b) and after 1 month exposure to 75% RH (c). The notations in parentheses correspond to the respective solvent mixture composition used to prepare solid dispersions where A: acetone, D: DCM and M: methanol.

where the symbols carry their usual meanings. Analysis of as prepared samples showed the highest percentage of –C=O hydrogen-bonded fraction belonging to the drug-rich region in samples derived from all solvent compositions, and no marked differences in the intensity ratio was observed among the samples. After stressing samples for one week at 75% RH, the scenario was different. All samples prepared from DCM-acetone showed a higher percentage of –C=O hydrogen-bonded fraction belonging to the drug-rich region as compared to that of the polymer-rich region, which was reverse in the case of all samples prepared from DCM-methanol system. The increase in peak intensity due to non-hydrogen-bonded –C=O compared to untreated samples also indirectly reflects an increase of crystallinity in the samples. The lesser percentage of non-hydrogen-bonded –C=O in samples from one part acetone with one part and three parts DCM indicates their higher amorphicity. Samples after storage at 75% RH for one month showed a marked decrease in the percentage of –C=O hydrogen-bonded fraction belonging to the drug-rich region accompanied with an increase in the intensity of the vibration band attributed to non-hydrogen-bonded –C=O. This as a whole indicates an increased crystallinity in the samples comparable to that of the physical mixtures. The observations in FT-IR are in line with the phase behavior obtained from mDSC analysis. The intermolecular hydrogen bonding interaction between naproxen and PVP led to the shift to lower wave numbers of the hydroxyl band of naproxen up to 100 cm-1 in solid dispersions containing 55% w/w naproxen.

Discussion

Solution Dynamics of Drug and Polymer Systems in Spray-Drying Feed Solutions

A variety of molecular interactions among the components, viz., drug, polymer and solvents, can be expected in the spray-drying feed solution. In a binary solvent mixture, there is potential opportunity for interaction as solvents can relatively behave as a proton donor and/or a proton acceptor. The interaction results in the deviation of the experimentally obtained physical attributes of the mixtures from the calculated values for their ideal solution. The extent and type of deviation depend upon the strength of interaction and composition of the solution. The methanol molecules undergo self association in presence of DCM due to the lack of mutual intermolecular hydrogen bonding. The methanol and acetone can interact through intermolecular hydrogen bonding as acetone is a weak proton acceptor. Thus, the binary mixtures of methanol with DCM and acetone show strong positive deviation from ideality (26,27). The formation of electron donor-acceptor complexes and the absence of association in the pure components, and thereby the negative deviation from ideality, have been documented for the DCM-acetone system throughout a broad composition range (28). The Kamlet–Taft (KT) polarity scale separately measures hydrogen bond donor acidity (α), hydrogen bond acceptor basicity (β), and polarizability of a solvent (29). The α and β values for pure solvents, functional groups of naproxen and PVP used in this study were taken from literature (30). The progressive increase in η of DCM-acetone system with the increase of DCM content could be the consequence of electron donor-acceptor complex formation as reported by Nath et al. (31).

The solution dynamics of naproxen in various organic solvents has been extensively studied (19,20). This information is relevant to understand the solution state interaction and also the physical state of the solid form resulting from the corresponding solution. The reported negative deviation from ideality (activity coefficient <1) of the naproxen solutions in methanol, DCM and acetone is evidence of its favourable interaction with these solvents. The solubility of naproxen in acetone is four times higher than that in methanol and DCM, in spite of the strength of hydrogen bonding being the highest in methanol (19). The higher solubility of naproxen in acetone has been described as strongly dispersive with polar interactions (32). According to Tomasko et al., naproxen majorly forms dimers in a proton-donating solvent and monomers in a proton-accepting solvent and both dimer/monomer are prevalent in the 1:1 mixtures of these solvent blends (19). In our context, it should form dimers in DCM, monomers in acetone and both in the amphiprotic methanol, and apparently the effect should be synchronous in the solvent blends. Another interesting finding has been reported on the existence of intramolecular hydrogen bonding of naproxen in DCM, which is absent in methanol (20).

Solvents have vital influence on the conformation of the polymer in its solutions (11). The solvent properties that provide an idea about the strength of polymer-solvent interaction can also provide the measure of a power of polymer solvation. The solvent polarity has been generally used as a correlating property to the polymer solvation in corresponding solution (30). The benefit of better solvation should be reflected through the transport of drug molecules to the nearest proximity of PVP chain that provides a chance for stronger interaction. The viscosity of a polymer in solution is considered as a good indicator of solvent power. The higher viscosity of PVP in DCM and DCM-containing blends could be due to the presence of weak hydrogen-donating power in DCM as well as the higher dispersive interaction with the hydrocarbon backbone of PVP. With methanol, there is propensity for hydrogen bonding with amide carbonyl function of PVP, but self association is also equally possible as the β value for methanol ((α = 0.98, β = 0.66) itself is comparable with that of n-methyl pyrrolidone (NMP) (α = 0.00, β = 0.77), a small molecular analogue of PVP. There is no possibility of any type of donor-acceptor interaction between acetone (α = 0.08, β = 0.43) and PVP, as both are proton acceptors. Rather, the PVP chain should get more coiled due to self association through the pyrrolidone moiety. Hence, acetone is a typical anti-solvent for PVP. This can be visualized by the reduced viscosity of PVP in methanol-acetone systems. The lower viscosity of feed solutions in methanol-acetone system than the pure solvent blends is evidence of the synergistic building of new binodal interaction in expense of solvent-solvent interaction. Also, PVP should remain compact in this system. This was also the case in the solutions containing lower proportion of DCM.

The polymeric globular size provides additional information on ternary interaction in solution. This higher globular size of PVP in DCM could be because the more extended the polymeric chains are, the smaller the globular size. This higher globular diameter of PVP for the system containing 55% w/w naproxen compared to that of 30% w/w for naproxen in methanol, DCM and their binary mixtures might be due to the less inter-chain interaction of PVP at the latter composition. However, an increasing trend was observed. Moreover, the trend of increasing globular size for 30% naproxen composition and decreasing trend of globular diameter for 55% naproxen content with increasing proportion of methanol in DCM-methanol mixtures provides evidence of the composition-dependent interaction. The absence of marked difference in composition-dependent difference of the PVP globular size in acetone-containing solutions could be due to the acetone, being an anti-solvent for PVP but the best solvent for naproxen, which might give rise to the selective binodal interactions. However, the observed trend of decreasing globular size of PVP with the decrease in acetone content in DCM-acetone as well as methanol-acetone blends is an indication of the increased PVP solubilization. As the diffusion of small naproxen particles would be the fastest, the system producing smaller PVP globules that create the higher flux should provide the most intimate mixing between drug and polymer.

Diverse Evaporation Rate Profiles of Feed Solutions in Solvent Blends

The evaporation rate profiles of pure solvent blends are in line with the relative volatility and binary composition. The methanol-acetone mixture is reported to form an azeotropic mixture at 88% w/w acetone content (27). The relative volatilities of acetone and DCM decrease with increasing amount in methanolic solutions. The nonlinear decrease in the evaporation rate of DCM-methanol system could be due to the combination of the solvents with larger difference in volatility. The marked deviation in evaporation rate of feed solution from the pure solvent should be majorly contributed to the interaction of solvents with PVP in the solution as the vapour pressure of the polymeric solutions shows distinct concentration dependence (33). The rapidly changing liquid composition in the binary solvents mixture during evaporation alters analogously the polymer concentration with respect to each solvent that leads to the nonlinear drop in the evaporation rate. Also, there exists a competitive hydrogen bonding among naproxen, PVP, and solvents. The abrupt drop in evaporation rates of the feed solutions might be due to the spontaneous vitrification of PVP at this stage. The overall increase in evaporation rates of feed solution with 55% naproxen content as compared to 30% drug content provided evidence of the disruption of the donor-acceptor-type solvent-solvent interaction by introducing drug-polymer solution in this system, which increases the relative volatilities of the solvents.

Spray-Drying Solvent-Induced Variation in Phase Behaviour

The difference in physical structure of the solid dispersions prepared from diverse solvent compositions should be correlated with the relevant solvent properties. The major part of difference in the solid state architecture depends upon the type and extent of molecular chaos a solvent produces within the growing particles during the drying process. An entire pattern of inter-component interaction in solution state cannot be dictated exactly in solid state as molecular vicinity, type of interaction, especially nature of hydrogen bonding, drastically changes from solution to solid state. The main factors influencing the resulting solid structure are polymer conformation in the solvent and the rate of evaporation of the feed solution. These two factors can contribute favourably or unfavourably regarding the drug-polymer miscibility. For example, the solvent composition which results into better polymer chain conformation with smaller globular size thus producing higher flux could evaporate exceedingly fast so that particle formation occurs far before the drug-polymer interaction is established. Solvent evaporation from drug-polymer solution, which itself is an interplay between intra-droplet diffusion and gas phase mass transfer to drying air, is highly dependent upon the droplet size, drying gas flow rate, solution feed rate and other parameters. For a constant set of process parameters, the evaporation rate is related with the rate of vitrification of the polymer from the solution and also with the interaction potential between solutes and solvents. An abrupt drop in evaporation rate should indicate the vitrification of the polymer in the growing particle.

Solutions containing 30% w/w drug in PVP in DCM-acetone showed an increase in globular size with the increase in acetone, an anti-solvent for PVP. Also, these systems showed relatively lower initial diffusional flux that avail sufficient span for polymer to stay in the right conformation for the interaction with the drug molecules. This is in line with higher miscibility observed in the solid dispersion prepared from these solvent mixtures. However, the higher heterogeneity in the sample prepared from 3 DCM: 1 acetone might be due to an increased dimerization of naproxen molecules with higher DCM content. The samples obtained by spray-drying drug-polymer solutions in methanol-acetone showed comparable miscibility as samples prepared from DCM-acetone. The same explanation fits for the increase in PVP globular size with the increase in acetone content in the feed solution for this system also. The phase heterogeneity decreases with an increase in acetone content. As methanol is an amphiprotic solvent, both monomer and dimer of naproxen can exist. But, with an increase in acetone, the monomer would again be prevalent, leading to increased possibility of interaction with PVP in the solid state. Drug-polymer solutions in DCM-methanol are different from aforementioned systems. As compared to acetone, both solvents are good solvents for PVP but poorer solvents for naproxen. The increase in globular size with an increase in methanol content could be due to increased self-aggregation of ethyl pyrrolidone groups of PVP. There is a potential chance in co-operativity in intermolecular hydrogen bonding between naproxen-PVP and methanol, as the latter can act as proton donor to the lone pair electron of the hydroxyl group of naproxen. This increases the strength of drug-polymer inter-association as an inter-molecular hydrogen bonding –COOH with the amide group is stronger than with the alcohol functionality (34). But, at the same time, both solvents induce dimerization of naproxen, which is against drug-polymer miscibility. The dimerization would be less prevalent with an increase of methanol, hence leading to increased miscibility.

The effect of solvent composition is also viewed in terms of miscibility and crystallinity of resulting solid dispersions containing 55% naproxen. The drug-polymer solution in DCM-acetone systems exhibited an increasing trend of globular size with increase in acetone content. The solid dispersions prepared from this solvent system showed higher drug content in the drug-rich domain, which was mainly amorphous. The same explanation as that given for the 30% w/w solid dispersions prepared from this solvent system holds for this system as well. The size of the PVP globules is smaller in the feed solutions in methanol-acetone blend, hence higher diffusion flux. So, there would be a balance between shrinking of droplets and receding solute transport to the core that generates higher crystallinity but comparable miscibility. The globular size decreases with increased methanol content, which is an opposite effect as compared to the solution containing 30% w/w drug in the same solvent system. This can be explained based upon the concentration dependency of polymer solvation with solvents in the presence of a hydrophobic drug (30). The slower diffusional flux and faster evaporation rate can induce more crystallization as well as poor miscibility reflected by the phase behavior of the samples prepared by this solvent system.

As a whole, the presence of anti-solvent for the polymer in the spray-drying feed solution increases miscibility and decreases the crystalline content as compared to systems prepared from a binary mixture of good solvents. The latter can potentially generate radial demixing between naproxen and PVP during particle formation during spray-drying. Due to low affinity between the non-solvent and the polymer, the amorphicized drug can be rapidly embedded in the precipitating polymer, resulting in dispersions showing relatively low residual crystallinity. Recently, an increase in the strength of non-covalent interaction of a PVP-containing solid dispersion in the presence of a bad solvent for PVP in the feed solution has been discussed (11). Addition of acetone in DCM or methanol possibly provides better interaction through solubilisation of a maximum amount of drug in the acetone fraction. Conversely, a competing effect on solubility of drug and polymer in DCM-methanol blend would exist. Hence, more chance of self-aggregation of the individual component is possible. The solvent blend with lesser difference between the volatility of solvent and anti-solvent is preferable for better miscibility as the change of solvent composition in the course of drying could be more constant. Additionally, the consequence of solvent drug interaction is also important to decide the type of molecular chaos the solvent blend can impart on the end product. The solvent effect is also dependent upon the drug polymer ratio in the solution. The presence of a higher amount of hydrophobic drug in solution leads to an early and inhomogeneous precipitation of polymer during spray-drying, with decreasing miscibility as witnessed for 55% w/w solid dispersions. The straightforward correlation between dielectric constant and dipole moment of the solvents with the dispersion efficiency in the solid dispersion is rather complicated as the polarity scale of solvent blends is not the weighted values of an individual solvent. Even so, simply correlating these properties has serious limitations, as they only account for the electrostatic solvent-solute interactions without considering whether the effective alignments of the solvent dipoles for the maximum interaction with the solute molecule are expected. Naproxen is reported to show oscillatory stereo-conversion from S to R in various solvents including methanol and DCM (35,36). It is likely that the efficiency of molecular mixing is also sterically favoured for one enantiomer over the other due to the reduced streric hindrance for interaction for chiral molecules like naproxen. This is the topic of our current investigation.

Physical Stability of Solid Dispersions Inherited from Spray-Drying Solvents

Adsorption of moisture by solid dispersions initiates favourable water-PVP interaction in expense of non-covalent interactions between naproxen-PVP. The molecular mobility of the energetically trapped glassy phase increases with the weakening of intermolecular hydrogen bonding. The reorganisation of the mixtures due to involvement of water is responsible for such behavior. The evolution of the new structure might be due to an increased mobility of the naproxen molecules below the activation energy of crystallization that led to an occurrence of solid state interdiffusion across the concentration gradient existing in the mixture. The diffusion of small molecules through the polymer matrix would indeed be very slow, even for non-interacting molecules. However, this process can be accelerated by water. The conformation change of the pyrrolidone ring from perpendicular with respect to the hydrocarbon backbone in hydrated PVP to the folded assembly in anhydrous PVP and the decrease in cohesion force between PVP chains due to H2O molecules can enhance diffusivity of the drug between the domains (37).

A distinct polymer-rich region might be generated as a moisture-induced surface binodal phase decomposition (38) that results into precipitation of PVP with a relatively low fraction of hydrophobic drug loading at the surface when exposed to the moisture. In this way, other than the strength of drug polymer interaction, the difference created in solid state physical stability among solid dispersions prepared from different solvent blends should be attributed to the surface composition and hydrophilicity, wettability, specific surface area and, of course, equilibrium moisture gain by the samples. In many instances, it is considered that the decrease in Tg in the presence of trace amounts of solvent is due to plasticization of the system by the same. It is not logical to believe the phenomena wherein the solvent present as a liquid in the sample is well above its melting temperature. So, the vitrification of the solvent is hard to extrapolate at this temperature. Thus, the lower value of Tg1 in 30% w/w naproxen containing spray-dried samples indicates that the specifically interacting composite is richer in drug content. The shift of Tg to higher temperature is due to reorganization in the presence of moisture with the change in polymer conformation as discussed above. The extent of phase separation would indeed be correlated with the different initial structure induced by solvent composition in the feed solution. The considerable shift of Tg1 in dispersions prepared from 3 DCM: 1 acetone and 3 methanol: 1 acetone after humidification for one week could be due to weaker stabilizing interaction between drug and PVP due to solution state properties resulting in diffusion of a higher fraction of naproxen towards the polymer-rich surface. Moreover, after one month exposure to 75% RH, further phase separation occurred at the saturated drug-rich region to give three amorphous phases overall along with trace crystallinity observed in pXRD. As Tg2 was at the same position, the mass balance between phases could be possibly explained through recrystallization from the saturated region followed by the reorganization through water upon prolonged contact with moisture.

The increased vitrification of naproxen from naproxen-PVP K 30 physical mixture (1:1 composition) upon humidification has been reported due to the favourable conformation of PVP for interaction induced by water molecules (37). The phenomenon is opposite in the solid dispersions as humidity led to the manifestation of crystal growth. The dispersions containing 55% w/w of naproxen exhibit a more precise picture. The lower extent of crystallization in samples prepared from DCM-acetone blends is due to the lesser availability of PVP for interaction with water when exposed to humidity. Hence, more drug molecules were rendered amorphous. Further, dimeric orientation of naproxen was so interrupted in the samples prepared by this solvent blends that it was hard to regain even after increase in molecular mobility in presence of water. In samples prepared from DCM-methanol, it is likely that more PVP was available (due to co-operativity between naproxen, PVP and methanol in solution state) for interaction with water so that the drug-rich matrix can easily be weakened to initiate recrystallization. Further, dimeric orientation could be more preferential for naproxen to evolve towards crystals from the samples prepared from these solvent systems. The samples prepared from methanol-acetone show intermediate behavior, which is a reflection of the intermediary physical structure too. Moreover, the crystallization induction until one week of exposure to 75% RH might also be related with the initial crystalline content. This means more seeds in the initial sample, faster onset of crystallization and hence more crystallinity at the same time point. But after one month of humidification, it would already reach the secondary crystalline state that samples lose the memory of initial physical structures due to spray-drying solvents. Overall, this resulted in identical crystallinity in the samples spray-dried from all solvent blends. Their mDSC behavior almost matches that of the physically mixed naproxen and PVP mixture (data not shown) with equivalent composition, which in fact reflects an exhaustive crystallization.

Conclusion

The dependency of the phase behavior and physical stability of spray-dried solid dispersions between drug and polymer to the solvent properties was explored from the present investigation. The results showed that all complex supramolecular solution state interactions are not innately transferred to the solid state. The effects of solvent composition are different at different zone of miscibility. For the present system containing a hydrophobic drug, naproxen, in a hydrophilic polymer, PVP, addition of an anti-solvent for PVP creates systems with better miscibility, lesser crystallinity and also higher physical stability. Nonetheless, it is more preferential that the anti-solvent is chosen to have favourable impact on solubility of the drug so that drug molecules can reach the nearest vicinity of interacting groups of the polymer in the right conformation. Based on all the results, the favourable solvent systems for manufacturing naproxen and PVP K 25 with improved physical attributes is in the order of DCM-acetone > methanol-acetone > DCM-methanol. In solvent mixtures containing the anti-solvent for PVP, acetone, 25% v/v content is favourable to produce the best mixing effect, amorphicity and physical stability.

REFERENCES

Nagapudi K, Jona J. Amorphous active pharmaceutical ingredients in preclinical studies: preparation, characterization, and formulation. Curr Bioact Compd. 2008;4(4):213–24.

Leuner C, Dressman J. Improving drug solubility for oral delivery using solid dispersions. Eur J Pharm Biopharm. 2000;50(1):47–60.

Rumondor AC, Taylor LS. Effect of polymer hygroscopicity on the phase behavior of amorphous solid dispersions in the presence of moisture. Mol Pharm. 2010;7(2):477–90.

Alonzo DE, Zhang GG, Zhou D, Gao Y, Taylor LS. Understanding the behavior of amorphous pharmaceutical systems during dissolution. Pharm Res. 2010;27(4):608–18.

Khougaz K, Clas SD. Crystallization inhibition in solid dispersions of MK-0591 and poly(vinylpyrrolidone) polymers. J Pharm Sci. 2000;89(10):1325–34.

Janssens S, De Zeure A, Paudel A, Van Humbeeck J, Rombaut P, Van den Mooter G. Influence of preparation methods on solid state supersaturation of amorphous solid dispersions: a case study with itraconazole and eudragit e100. Pharm Res. 2010;27(5):775–85.

Guns S, Dereymaker A, Kayaert P, Mathot V, Martens JA, Van den Mooter G. Comparison between hot-melt extrusion and spray-drying for manufacturing solid dispersions of the graft copolymer of ethylene glycol and vinylalcohol. Pharm Res. 2011;28(3):673–82.

Rizi K, Green RJ, Donaldson M, Williams AC. Production of pH-responsive microparticles by spray drying: investigation of experimental parameter effects on morphological and release properties. J Pharm Sci. 2011;100(2):566–79.

Bank M, Leffingwell J, Thies C. The influence of solvent upon the compatibility of polystyrene and poly (vinyl methyl ether). Macromolecules. 1971;4(1):43–6.

Ansari MT, Sunderland VB. Solid dispersions of dihydroartemisinin in polyvinylpyrrolidone. Arch Pharm Res. 2008;31(3):390–8.

Al-Obaidi H, Brocchini S, Buckton G. Anomalous properties of spray dried solid dispersions. J Pharm Sci. 2009;98(12):4724–37.

Janssens S, Anné M, Rombaut P, Van den Mooter G. Spray drying from complex solvent systems broadens the applicability of Kollicoat IR as a carrier in the formulation of solid dispersions. Eur J Pharm Sci. 2009;37(3–4):241–8.

Tsapis N, Bennett D, Jackson B, Weitz DA, Edwards DA. Trojan particles: large porous carriers of nanoparticles for drug delivery. Proc Natl Acad Sci USA. 2002;99(19):12001–5.

Paudel A, Van Humbeeck J, Van den Mooter G. Theoretical and experimental investigation on the solid solubility and miscibility of naproxen in poly(vinylpyrrolidone). Mol Pharm. 2010;7(4):1133–48.

Moynihan CT. Correlation between the width of the glass transition region and the temperature dependence of the viscosity of high Tg glasses. J Am Ceram Soc. 1993;76(5):1081–7.

Song M, Hammiche A, Pollock HM, Hourston DJ, Reading M. Modulated differential scanning calorimetry: 4. Miscibility and glass transition behaviour in poly (methyl methacrylate) and poly (epichlorohydrin) blends. Polymer. 1996;37(25):5661–5.

Rumondor AC, Taylor LS. Application of partial least-squares (PLS) modeling in quantifying drug crystallinity in amorphous solid dispersions. Int J Pharm. 2010;398(1–2):155–60.

Tao J, Sun Y, Zhang GG, Yu L. Solubility of small-molecule crystals in polymers: D-mannitol in PVP, indomethacin in PVP/VA, and nifedipine in PVP/VA. Pharm Res. 2009;26(4):855–64.

Tomasko DL, Timko MT. Tailoring of specific interactions to modify the morphology of naproxen. J Cryst Growth. 1999;205(1–2):233–43.

Velazquez MM, Valero M, Rodriguez LJ, Costa S, Santos MA. Hydrogen bonding in a non-steroidal anti-inflammatory drug–Naproxen. J Photochem Photobio B Biol. 1995;29(1):23–31.

Nair R, Nyamweya N, Gönen S, Martinez-Miranda LJ, Hoag SW. Influence of various drugs on the glass transition temperature of poly (vinylpyrrolidone): a thermodynamic and spectroscopic investigation. Intl J Pharm. 2001;225(1–2):83–96.

Bogdanova S, Pajeva I, Nikolova P, Tsakovska I, Müller B. Interactions of poly (vinylpyrrolidone) with ibuprofen and naproxen: experimental and modeling studies. Pharm Res. 2005;22(5):806–15.

Painter PC, Park Y, Coleman MM. Thermodynamics of hydrogen bonding in polymer blends. 1. The application of association models. Macromolecules. 1989;22(2):570–9.

Meaurio E, Velada JL, Cesteros LC, Katime I. Blends and complexes of poly (monomethyl itaconate) with polybases poly (N, N-dimethylacrylamide) and poly (ethyloxazoline). association and thermal behavior. Macromolecules. 1996;29(13):4598–604.

Senatore D, Berix MJA, Laven J, van Benthem RATM, de With G, Mezari B, et al. Miscibility and specific interactions in blends of poly (N-vinyl-2-pyrrolidone) and acid functional polyester resins. Macromolecules. 2008;41(21):8020–9.

Maria C, Martin MJC, Mato F. Vapor-liquid equilibrium data at 25°C for six binary systems containing methyl acetate or methanol, with dichloromethane, chloroform, or 1,2-trans-dichloroethylene. J Solution Chem. 1991;20(1):87–95.

Campbell AN, Anand SC. Phase Equilibria in the systems acetone–methanol, acetone–cyclohexane, methanol–cyclohexane, and acetone–methanol–cyclohexane. Can J Chem. 1972;50(4):479–89.

Nath J, Prakash Dixit A. Total vapour pressures for binary liquid mixtures of acetone with tetrachloroethylene, trichloroethylene, methylene chloride, 1, 2-dichloroethane and cyclohexane at 273.15 K. Fluid Phase Equilibr. 1990;60(1–2):205–12.

Kamlet MJ, Abboud JLM, Abraham MH, Taft RW. Linear solvation energy relationships. 23. A comprehensive collection of the solvatochromic parameters,* and, and some methods for simplifying the generalized solvatochromic equation. J Org Chem. 1983;48:2877–87.

Malavolta L, Oliveira E, Cilli EM, Nakaie CR. Solvation of polymers as model for solvent effect investigation: proposition of a novel polarity scale. Tetrahedron. 2002;58(22):4383–94.

Nath J, Dixit AP. Binary systems of acetone with tetrachloroethylene, trichloroethylene, methylene chloride, 1, 2-dichloroethane, and cyclohexane. 2. Viscosities at 303.15 K. J Chem Eng Data. 1984;29(3):317–9.

Tsivintzelis I, Economou IG, Kontogeorgis GM. Modeling the phase behavior in mixtures of pharmaceuticals with liquid or supercritical solvents. J Phys Chem B. 2009;113(18):6446–58.

Maria Bercea JE, Wolf BA. Vapor pressure of polymer solutions and the modeling of their composition dependence. Ind Eng Chem Res. 2009;48(9):4603–6.

Kireeva PE, Shandryuk GA, Kostina JV, Bondarenko GN, Singh P, Cleary GW, et al. Competitive hydrogen bonding mechanisms underlying phase behavior of triple poly (N vinyl pyrrolidone)–poly (ethylene glycol)–poly (methacrylic acid co ethylacrylate) blends. J Appl Polym Sci. 2007;105(5):3017–36.

Sajewicz M, Matlengiewicz M, Leda M, Gontarska M, Kronenbach D, Kowalska T, et al. Spontaneous oscillatory in vitro chiral conversion of simple carboxylic acids and its possible mechanism. J Phys Org Chem. 2010;23(11):1066–73.

Sajewicz M, Pietka R, Pienak A, Kowalska T. Application of thin-layer chromatography to investigate oscillatory instability of the selected profen enantiomers in dichloromethane. J Chromatogr Sci. 2005;43(10):542–8.

Malaj L, Censi R, Mozzicafreddo M, Pellegrino L, Angeletti M, Gobetto R, et al. Influence of relative humidity on the interaction between different aryl propionic acid derivatives and poly (vinylpyrrolydone) k30. Evaluation of the effect on drug bioavailability. Intl J Pharm. 2010;398(1–2):61–72.

Van de Witte P, Dijkstra PJ, Van den Berg JWA, Feijen J. Phase separation processes in polymer solutions in relation to membrane formation. J Membr Sci. 1996;117(1–2):1–31.

ACKNOWLEDGMENTS & DISCLOSURES

The department of pharmaceutical analysis, K.U. Leuven, is acknowledged for providing facility for the FT-IR. Special thanks to Danny Winant (Department of Metallurgy and Materials Engineering, K.U. Leuven) for help with the TGA measurements. Patrick Rombaut and Pieterjan Kayaert are duly acknowledged for assisting with the pXRD measurements. AP acknowledges D.B.O.F. for providing a PhD grant. FWO-Vlaanderen is acknowledged for financial support (G.0741.09).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Paudel, A., Van den Mooter, G. Influence of Solvent Composition on the Miscibility and Physical Stability of Naproxen/PVP K 25 Solid Dispersions Prepared by Cosolvent Spray-Drying. Pharm Res 29, 251–270 (2012). https://doi.org/10.1007/s11095-011-0539-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-011-0539-x