Abstract

Amorphous solid dispersions (ASDs) are inherently unstable because of high internal energy. Evaluating physical and chemical stability during the process and storage is essential. Numerous researches have demonstrated how polymers influence the drug precipitation and physical stability of ASDs, while the influence of polymers on the chemical stability of ASDs is often overlooked. Therefore, this study aimed to investigate the effect of polymers on the physical and chemical stability of spray-dried ASDs using dipyridamole (DP) as a model drug. Proper polymers were selected by assessing their abilities to inhibit drug recrystallization in supersaturated solutions. HPMC E5, Soluplus®, HPMCP-55, and HPMCAS-LP were shown to be effective stabilizers. The optimized formulations were further stored at a high temperature (60 °C) and high humidity (40 °C, 75% RH) for 2 months, and their physical and chemical stability was evaluated using polarizing optical microscopy, FTIR, HPLC, and mass spectrometry (MS). In general, crystallization was observed in all samples, which indicated the physical instability under stressed storage conditions. Also, it was noted that the polymers in ASDs rather than physical mixtures, induced a dramatic drug degradation after being exposed to a high temperature (HPMCP-55 > 80% and HPMCAS-LP > 50%) and high humidity (HPMCP-55 > 40% and HPMCAS-LP > 10%). The MS analysis further confirmed the degradation products, which might be generated from the reaction between dipyridamole and phthalic anhydride decomposed from HPMCP-55 and HPMCAS-LP. Overall, the exposure of ASDs to stressed conditions resulted in recrystallization and even the chemical degradation induced by polymers.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

Various new compounds emerge from pharmaceutical pipelines showing low solubility and unsatisfied dissolution rates in aqueous solutions, leading to low oral bioavailability and limited clinical applications. Amorphous solid dispersion (ASD) technology is being widely used to increase the bioavailability of such drug candidates by improving their solubility, wettability, and dissolution rates (1,2).

In an ASD, the active pharmaceutical ingredient (API) possesses a high Gibbs free energy, which induces a high tendency to precipitate as a more stable crystalline form, hence undermining the advantages of increased solubility (3). Drug precipitation from supersaturated solutions (4) and physical aging during the storage (5,6) are two primary concerns involved in ASDs.

Specifically, when ASDs are exposed to the gastrointestinal fluids, the drug concentration exceeds the equilibrium state and a supersaturated solution is formed, leading to the precipitation of drugs subsequently. In this case, the drug is thermodynamically unstable and energetically tends to return to the equilibrium via precipitation. Physical aging is typically related to the recrystallization or drug-polymer phase separation during storage, especially upon stressed conditions, such as a high humidity and high temperature.

Many researchers have highlighted the importance of drug precipitation and physical aging. Great efforts have been paid to either minimize the drug precipitation during dissolution or improve the physical stability during storage. Up to now, drug precipitation has been successfully mitigated by using precipitation inhibitors in supersaturated formulations, including polymers (7) or polymer blends (8), polymer-surfactant complexes (9,10), and cyclodextrins (11). Likewise, studies on the physical aging have been extensively undertaken, such as improving the physical stability of ASD through proper polymers (3), predicting the propensity for crystallization (12), underlying the factors influencing physical stability (13), and developing analytical approaches to evaluate ASD miscibility after storage under different conditions (14,15,16).

However, there is still a lack of researches considering the integral performance of polymers on drug precipitation and physical aging. Moreover, it is noted that previous stability studies only highlighted the physical aging, but not chemical changes of drugs. The occurrence of drug impurities from degradation could be dangerous and cause serious safety problems. Accordingly, it is critical to synchronously prevent drug precipitation, physical aging, and chemical degradation of ASDs when developing a successful ASD formulation.

Therefore, the objective of this study was to investigate the effect of polymers on the physical and chemical stability of spray-dried ASDs using dipyridamole (DP) as a model drug. The influences of water-soluble polymers and enteric polymers on the physical and chemical properties of DP-ASDs were evaluated because DP was a weak base drug and potential ionic interactions could exist between DP and enteric polymers.

MATERIALS AND METHODS

Materials

DP was purchased from Jinan Ruixing Pharmaceutical Technology Co., Ltd. (99.1%; Jinan, China). Hydroxypropyl methyl cellulose E5 (HPMC E5) was kindly donated by Colorcon, and Eudragit® L100-55 by Evonik Degussa. Kollicoat® MAE, poly vinyl pyrrolidne K30 (PVP K30), polyvinylpyrrolidone vinyl acetate (PVPVA 64), and Soluplus® were gifted from BASF AG. Hydroxypropyl methyl-cellulose phthalate NF (HPMCP-55; Shin Etsu Chemical, Tokyo, Japan), and Hydroxypropyl methylcellulose acetate succinate LF (HPMCAS LF; Shin Etsu Chemical, Tokyo, Japan) were obtained as gifts from Dalian Construction Industry Trade Co., Ltd. Other chemicals were used as received.

Solubility Measurement

An excess amount of the drug was added to 5 ml of pH 1.2 HCl, pH 4.5 and pH 5.5 acetate buffer, pH 6.8 and pH 7.4 phosphate buffer (PBS), and the pH 6.8 PBS containing polymer in 10-ml capped tubes. Each polymer was kept at the same concentration (0.15%, w/v). The samples were vortexed for 30 s and shaken in an air bath (THZ-82BA, Jintan, China) for 2 days at 37 ± 0.5 °C. Then, the samples were taken from the supersaturation solution and filtered through a 0.22-μm filter. The drug concentration was determined by the HPLC system and equated to the drug solubility in the solution medium.

Preparation of Solid Dispersions

Spray-drying was used to prepare solid dispersions (SDs). The polymers acting as matrix were water-soluble polymers (HPMC E5, PVP K30, PVPVA 64, and Soluplus®) and enteric polymers (Eudragit® L100, Kollicoat® MAE, HPMCP, and HPMCAS). The polymer and drug at the weight ratio of 1:3 were dissolved in 80% (v/v) ethanol (60% v/v ethanol for HPMC E5 and DP) to achieve the solution with solid content of 2.5% (w/v). Then, the solution was spray-dried using a laboratory-scale spray-dryer (SD-1000, Eyela SD-1000, Japan) under the following conditions: inlet temperature 130 °C, outlet temperature 80 °C, drying flow rate 0.6 m3/min, atomization air pressure 10 MPa, feeding rate 10 mg/min. The spray-dried powders were collected from the cyclone separator and stored in a dryer for further studies.

Solid-state Characterization

Differential Scanning Calorimetry

The physical status of DP raw material and DP in the fresh SDs was characterized by a differential scanning calorimetry (DSC)-SP thermal analyzer (STA 409PC, Netzsch, Germany). Approximately 5–10 mg of sample was sealed in the aluminum pan with one pin holes in the lid, and an empty hermetic pan was used as a reference. The samples were purged with pure nitrogen at a flow rate of 10 ml/min and analyzed at a heating rate of 10 °C/min from 40 to 300 °C to record the thermograms.

Powder X-ray Diffraction

Powder X-ray diffraction (PXRD) was used as a complementary technique to determine the physical status of the DP raw material and DP in the fresh SDs. PXRD analysis was conducted by using an X-ray powder diffractometer (D8 Quest, Bruker, Germany). The samples were loaded onto a sample holder and leveled with a glass slide before inserting into the equipment. The X-ray pattern was collected in the angle range of 5° ≤ 2θ ≤ 40° in the step scan mode at a step rate of 3°/min, voltage of 30 kV, and current of 10 mA.

In Vitro Supersaturation Dissolution Test

The dissolution of solid dispersions containing 47.5 mg DP was performed on a ZRS-8G dissolution tester (TDTF, Tianjin, China) using the paddle method at the rotation speed of 100 rpm. The dissolution medium was 750 ml gastric fluid (pH 1.2) for 2 h and was adjusted to the intestinal fluid (pH 6.8) by adding 250 ml 0.2 M sodium phosphate solution for another 3 h. The medium was maintained at 37 ± 0.5 °C. The samples were withdrawn after 120, 125, 150, 240, and 300 min and filtered through a 0.22-μm filter. The drug concentration was analyzed using HPLC to obtain the supersaturation dissolution curve.

Stability Studies

Since the stability of commercial products must be evaluated at 40 °C/75% RH/open (high humidity) and 60 °C/closed (high temperature) for quality control, the stability studies of optimized SDs were stored under these conditions for 2 months. The physical and chemical properties of SDs were evaluated in terms of drug solid-state characterization, residual drug content, and degradation products. The samples or corresponding physical mixtures (PMs) stored under the same environment were used for comparative evaluation.

Polarized Light Microscopy

Polarized light microscopy (PLM) is considered to be a quite sensitive method to detect the crystalline state of drug. Therefore, the crystalline state of the stability samples was evaluated using PLM (LV100POL, Olympus, Japan) and observed at × 10 magnification. The specimens were spread over a glass slide and covered with another slide. The presence of birefringence under polarized light was considered as an indication of crystallization from polymeric matrices.

HPLC Analysis

The high humidity and high temperature during storage may lead to chemical degradation of the drug. Therefore, HPLC analysis was performed on the stability samples of SDs to determine drug content and potential chemical degradation, which were compared to those of the corresponding PMs.

The drug content was analyzed using phenomenex Kinetx C18 (4.6 × 250 mm, 5 μm) column with a mobile phase containing methanol and phosphate solution in the ratio of 75:25 at a flow rate of 1.0 ml/min. The phosphate solution was obtained by dissolving 1.0 g of Na2HPO4 in 1 l of deionized water, followed by adjusting pH to 4.6 with phosphate. A 10 μl volume was applied to the column. Drug concentration in the solid dispersions was determined based on linear concentration versus peak area generated at 288 nm. The remaining drug content of the reference samples was considered as 100%, while that of the test samples was calculated as the percentage of the reference samples. Each sample was performed in triplicate.

To get a more thorough separation of the drug and potential chemical degradation products, the mobile phase comprising 65:35 (v/v) of methanol and acetate buffer at a flow rate of 1.0 ml/min was used. The acetate buffer comprised 6.8 mg sodium acetate per milliliter and was adjusted to pH 5.0 using acetic acid. The force degradation products of DP, including acid stressed product (DP was subjected to 0.1 N HCl for 4 h), peroxide stressed product (DP was subjected to 6% hydrogen peroxide solution and maintained at 70 °C for 4 h), and thermal stressed product (DP was subjected to 105 °C for 3 h), were compared with those of the fresh and stability samples.

Mass Spectrometry

To provide the molecular information on the degradation products, the accurate mass spectrometric experiments were performed on a TripleTOF®4600 system with a DuoSpray™ ion source operated in positive ion mode (AB SCIEX, CA, USA). The DP-HPMCP SDs stored at high temperature for 2 months were taken as an example. Ten milligram of the sample was accurately weighted and dissolved in 5 ml of 50% methanol. Then, 2 ml of the solution was added to the dialysis bag (molecular weight cutoff, 3500 Da) in 50% methanol to isolate the polymer so that the influence of polymer on the mass analysis was excluded. The raw DP powder was used as a control.

Statistical Analysis

Data were reported as mean ± standard deviations (SD). One-way analysis of variance (ANOVA) followed by Bonferroni’s test was conducted using Graphpad Prism 5.0 software to compare the statistical significance of DP solubility in different medium. P value < 0.05 was considered statistically significant.

RESULTS AND DISCUSSION

Solubility

The solubility of DP in different medium is shown in Fig. 1. DP shows pH-dependent solubility and has a solubility more than 900 times in acid medium (pH = 4.5 and pH = 1.2, P < 0.001) than that in alkaline medium since it is a weak base compound. Additionally, the solubility of DP in the pH 6.8 PBS was significantly improved with the addition of Soluplus® (P < 0.001), HPMC E5 (P < 0.001), HPMCAS (P < 0.01), and PVPVA 64 (P < 0.01), which followed the order of Soluplus® > HPMC E5 > HPMCAS ≈ PVPVA 64. There was no statistical difference for the other polymers even they all showed enhancement in the solubility of DP.

Solid-state Characterization

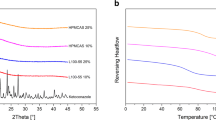

The DSC results of DP and spray-dried DP-SDs are displayed in Fig. 2a. The drug powder showed a distinctive endothermic event at 165~166 °C, corresponding to the melting of DP (17). The melting peak was absent and a single Tg was observed in all DP-SDs, suggesting that the crystalline drug was successfully transformed into amorphous form after spray-drying.

The XRD patterns of DP and spray-dried DP-SDs are shown in Fig. 2b. Compared to the pure drug, no diffraction peaks were detected in the DP-SDs, further confirming that DP existed in an amorphous state in the SD system.

In Vitro Supersaturation Dissolution Test

Figure 3 shows the supersaturated dissolution curves of DP-SDs. It was found that in the acidic medium of pH 1.2, all DP-SDs exhibited a relatively high drug dissolution with released drug amount above 80% at 120 min, followed by a sharp decline in the drug concentration at 125 min. The initial surge of high DP dissolution was mainly caused by the protonation and high solubility of DP in the acid environment, while the subsequent decline in DP concentration was triggered by the crystallization owing to the rapid build-up of high supersaturation and decreased DP solubility upon pH shift to 6.8 (18). Upon the precipitation of DP, the release of protons and decrease in pH would simultaneously occur, which could last for several minutes and in turn increased the dissolution of DP (19). Therefore, an increasing trend in DP dissolution from 125 min to 180 min was observed in the presence of HPMC E5 and Soluplus®. However, the other formulations showed a further decrease or constant level in the DP concentration, probably due to their inferior ability to maintain the supersaturation of DP.

Based on the dissolution result, the rank of polymers to stabilize DP supersaturation was HPMC E5 ≈ Soluplus® > HPMCAS > HPMCP ≈ PVP K30 > PVP VA64 ≈ Eudragit® L100 > Kollicoat® MAE, which was related to the solubilizing ability of polymers to some extent.

For the water-soluble polymers with pH-independent solubility, HPMC E5 and Soluplus® have the greatest ability to inhibit DP precipitation, while their mechanisms were slightly different as observed from Fig. 3. HPMC E5 was more capable to maintain the degree of supersaturation (the released DP amount was higher in HPMC E5 than in Soluplus® from 125 min to 180 min, followed by a constant decrease), while Soluplus® benefited the maintenance of the duration of supersaturation (the dissolved DP amount in Soluplus® was maintained at a constant level from 125 min to 360 min). HPMC E5 behaved as a precipitation inhibitor for DP by delaying both the precipitation initiation time and precipitation rate (7). Soluplus® inhibited DP precipitation by acting as a matrix polymer in the SD and an active solubilizer with the ability to enhance the solubility of DP due to its amphiphilic chemical structure (20). The inferior ability of PVP K90 to HPMC in maintaining supersaturation has been previously reported (7). Therefore, the precipitation inhibition effect may be further lessened in PVP K30 since PVP K30 has a smaller molecular weight and less effective polymer chain to prohibit DP crystallization compared to PVP K90. PVP VA64 was less effective as a precipitation inhibitor than PVP K30 since the interaction between DP and PVP monomer may be decreased due to a steric hindrance of the PVA monomer (21).

For the enteric polymers which start to dissolve at pH of 5.5 and higher, recrystallization of DP at pH 6.8 could be further aggravated due to the enhanced solubility of polymers comparable to water-soluble polymers. HPMCAS was shown to be the most effective stabilizer among enteric polymers (HPMCAS > HPMCP > Eudragit® L100 > Kollicoat® MAE) to maintain the supersaturation of DP-SDs. HPMCAS performed the functions to increase the degree and extent of dissolution of DP from two ways: firstly, HPMCAS is partially ionized above pH 5.0, which stabilizes drug/polymer aggregates and prevents them merge into larger aggregates by the steric stabilization. Additionally, it promotes the free drug release from the composition into the solution (22); secondly, HPMCAS, as an amphiphilic polymer, could provide sites to enhance the solubility of DP by the hydrophobic regions and improve the formation of stable hydrated colloidal structures in aqueous media by the hydrophilic regions (23). The greater ability of HPMCAS to stabilize DP supersaturation than that of HPMCP might be related to the increased solubilization capacity. HPMCAS has a two- to threefold solubility in the enteric pH range of 6.8–8.0 than Eudragit® L, which may explain the lower AUCintestine of the Eudragit® L during the dissolution (24). Kollicoat® MAE is the counterpart of Eudragit® L100 and was the least effective stabilizer to inhibit DP precipitation.

It is concluded that the ability of polymers in precipitation inhibition is a result of multiple factors, including the drug-polymer interaction, polymer molecular weight, and solubilization ability. HPMC E5, Soluplus®, HPMCP, and HPMCAS were shown to be the effective stabilizers of DP-SDs and thus were selected for further stability studies.

Stability Studies

PLM Analysis

The representative pictures taken by the PLM are shown in Fig. 4. Humidity and temperature are two factors inducing the drug recrystallization, while the degree of recrystallization depends on the polymers. Under high humidity, the extent of recrystallization degree was ranked as HPMCP ≈ Soluplus® (complete recrystallization, fine needle-like crystal) > HPMCAS (partial recrystallization, rode-like crystal) > HPMC E5 (invisible recrystallization). Under high temperature, the extent of recrystallization degree followed the order of Soluplus® (complete recrystallization, fine needle-like crystal) > HPMC (partial recrystallization, rode-like crystal) > HPMCAS (partial recrystallization, rode-like crystal) > HPMCP (minor recrystallization).

Under a high humidity, water residue and water activity can be two main factors affecting the stability of amorphous form. Water can act as a plasticizer for the polymer to lower the Tg or increase molecular mobility and weaken the drug-polymer interactions (as shown in the FTIR spectra). This leads to the phase separation that may cause nucleation and crystal growth (25). Therefore, the differences in moisture absorption rates among polymers may affect drug recrystallization as a result of plasticization and hydrogen bonding competition. Soluplus® is more hygroscopic than HPMC, resulting in obviously higher degree of recrystallization. HPMCP and HPMCAS are both hydrophobic polymers with less hygroscopicity, while HPMCP is more susceptible to hydrolysis and hence generated aggravated recrystallization.

Likewise, partial or complete crystallization of SDs occurred at a high temperature due to increased molecular mobility, where both the primary and secondary relaxation times can decrease with increasing temperature (26). Complete recrystallization was observed in the DP-Soluplus® SDs, which may be explained by the low Tg of Soluplus® and hence lower Tg for the SD compositions (27).

To sum up, drug recrystallization was susceptible to stressed conditions and dependent on the polymers used in matrices. The occurrence of needle-shaped crystals indicated the inherent physical instability of amorphous DPs. HPMC was the most resistant polymer to recrystallization induced by humidity, while HPMCP was the most resistant to the recrystallization induced by temperature. Soluplus® was the least effective stabilizer against recrystallization of DP since the complete recrystallization was observed under both stressed conditions. In general, the control of moisture and temperature via protective packaging is critical to maintain amorphous nature of DP during storage.

FTIR Analysis

The FTIR spectra of fresh SDs, stability samples, and the corresponding PMs are shown in Fig. 5. DP has six functional groups, including four hydroxyl (O–H groups) and two carbon-nitrogen bond (C–N groups), which can act as proton acceptors and form hydrogen bonds with the carbonyl (C=O group) present in the HPMCP (1726 cm−1), HPMCAS (1741 cm−1), and Soluplus® (1738 cm−1). However, no obvious shift in the spectra of SDs and corresponding PMs was found across these absorption bands, indicating very weak drug-polymer interactions. Drug-polymer molecular interactions between DP and HPMC have been previously reported. These interactions provide better stabilization against the precipitation and crystallization of DP (7), which could be identified from the FTIR spectra where the peak at 2820 cm−1 is assigned to the symmetrical stretch of CH2 group of DP disappeared in the SD samples. Besides, no additional functional group was detected in the stability samples, probably due to the limited sensitivity of FTIR, whereas the characteristic peaks in the FTIR spectra of DP-HPMCP SDs exposed to high humidity displayed high coincidence with that of their PMs, implying that crystallization occurred during storage. The result was consistent with the PLM analysis and also occurred in the DP-Soluplus® SDs.

HPLC and MS Analysis

The remaining contents of DP in the solid state of SDs and PMs are shown in Fig. 6a. Compared to fresh samples, the drug content remained unchanged (around 100%) in the presence of HPMC E5 and Soluplus®, suggesting good chemical stability. However, the remaining content of DP in SDs was dramatically decreased in the presence of HPMCP and HPMCAS. The DP-HPMCP SDs (DP-HPMCAS SDs) showed a reduction in drug content exceeding 80% (40%) under a high temperature and 50% (10%) under a high humidity, suggesting that drug decomposition occurred during storage. The more severe degradation in HPMCP than in HPMCAS may be caused by the higher degree of substitution (i.e., phthalic acid), with 27–35% phthalyl substitution for HPMCP versus 14–18% succinyl substitution for HPMCAS (27). The phthalate moieties present in HPMCP make HPMCP very susceptible to hydrolysis and may exert undesirable influences on the stability of formulations, resulting in initial acid decomposition and gradually decreased stability over time (28).

Irrespective of the storage environment, the remaining content of DP exceeded 96% in the corresponding PMs, and no newly generated chromatographic peak was detected by the HPLC (data not shown). The results indicated that decomposition of DP was triggered and even aggravated after incorporation into SDs with either HPMCP or HPMCAS as the carrier. It was further deduced that DP formulated in the SDs containing HPMCP or HPMCAS is more susceptible to degradation because of the increased surface area, dispersibility, mobility, and interactions with polymer.

The separation of DP and degradation products was conducted by HPLC and performed on the DP-HPMCP SDs due to the most severe drug decomposition. It is shown in the chromatograms of DP (Fig. 6b) that several new compounds, as pointed out by the arrow, were generated. In contrast to those of raw DP with stressed pretreatments, the degradation of DP was more obvious and intense.

Among the HPMC-based polymers, like HPMC E5, HPMCP, and HPMCAS, the major difference in their structure was the additional group of phthalate and acetyl succinate in HPMCAS and HPMCP, respectively. Therefore, the acidic group in the polymers may potentially interact with base DP during storage to induce the degradation of DP.

Extrapolated from the MS result (Fig. 7), one possible degradation pathway of DP-HPMCP SDs is displayed in Fig. 8. HPMCP successively decomposed into phthalic acid (PA) and phthalic anhydride (PAH). Then, PAH reacted with DP and generated the end product, compound A. It is important to note that PAH possesses potential toxicities, and its chemical incompatibility is sparsely studied in the literatures. Also, it is worth mentioning that the degradation of HPMCP was reported to occur above the temperature of 190 °C (29). Thus, it was speculated that HPMCP was more liable to degrade after formulation into SDs and can be aggravated upon exposure to a high temperature and humidity, which has not been reported elsewhere.

CONCLUSION

In this study, the SDs were destabilized upon exposure to a high temperature and humidity, resulting in the crystallization and even degradation of DP. The control of moisture and temperature is critical to maintain the stability of SDs. Besides, the selection of polymers should not be overlooked since the degradation of DP was exaggerated by acid polymers (HPMCP and HPMCAS), as confirmed by HPLC and MS. Moreover, this study provides an insight that the chemical reaction between drug and polymers could be activated and cause the drug degradation in the SD system, even though it did not occur in the PMs.

Abbreviations

- ASD:

-

Amorphous solid dispersion

- SDs:

-

Solid dispersions

- DP:

-

Dipyridamole

- PMs:

-

Physical mixtures

- HPMC E5:

-

Hydroxypropyl methyl cellulose E5

- PVP K30:

-

Poly vinyl pyrrolidne K30

- PVPVA 64:

-

Polyvinylpyrrolidone vinyl acetate

- Eudragit® L100:

-

Eudragit® L100-55

- HPMCP:

-

Hydroxypropyl methyl-cellulose phthalate NF

- HPMCAS:

-

Hydroxypropyl methylcellulose acetate succinate LF

References

Ellenberger DJ, Miller DA, Kucera SU, Williams RO. Improved vemurafenib dissolution and pharmacokinetics as an amorphous solid dispersion produced by KinetiSol® processing. AAPS PharmSciTech. 2018; https://doi.org/10.1208/s12249-018-0988-1.

Guan J, Liu Q, Zhang X, Zhang Y, Chokshi R, Wu H, et al. Alginate as a potential diphase solid dispersion carrier with enhanced drug dissolution and improved storage stability. Eur J Pharm Sci. 2018;114:346–55. https://doi.org/10.1016/j.ejps.2017.12.028.

Albadarin AB, Potter CB, Davis MT, Iqbal J, Korde S, Pagire S, et al. Development of stability-enhanced ternary solid dispersions via combinations of HPMCP and Soluplus® processed by hot melt extrusion. Int J Pharm. 2017;532(1):603–11. https://doi.org/10.1016/j.ijpharm.2017.09.035.

Xu S, Dai WG. Drug precipitation inhibitors in supersaturable formulations. Int J Pharm. 2013;453(1):36–43. https://doi.org/10.1016/j.ijpharm.2013.05.013.

Lee TWY, Boersen NA, Hui HW, Chow SF, Wan KY, Chow AHL. Delivery of poorly soluble compounds by amorphous solid dispersions. Curr Pharm Des. 2014;20(3):303–24.

Lu T, Sun Y, Ding D, Zhang Q, Fan R, He Z, et al. Study on enhanced dissolution of azilsartan-loaded solid dispersion, prepared by combining wet milling and spray-drying technologies. AAPS PharmSciTech. 2017;18(2):473–80. https://doi.org/10.1208/s12249-016-0531-1.

Chauhan H, Hui-Gu C, Atef E. Correlating the behavior of polymers in solution as precipitation inhibitor to its amorphous stabilization ability in solid dispersions. J Pharm Sci. 2013;102:1924–35. https://doi.org/10.1002/jps.23539.

Bley H, Fussnegger B, Bodmeier R. Characterization and stability of solid dispersions based on PEG/polymer blends. Int J Pharm. 2010;390(2):165–73. https://doi.org/10.1016/j.ijpharm.2010.01.039.

Li S, Pollock-Dove C, Dong LC, Chen J, Creasey AA, Dai WG. Enhanced bioavailability of a poorly water-soluble weakly basic compound using a combination approach of solubilization agents and precipitation inhibitors: a case study. Mol Pharm. 2012;9(5):1100–8. https://doi.org/10.1021/mp200352q.

Kim MS, Kim JS, Cho W, Cha KH, Park HJ, Park J, et al. Supersaturatable formulations for the enhanced oral absorption of sirolimus. Int J Pharm. 2013;445(1):108–16. https://doi.org/10.1016/j.ijpharm.2013.01.067.

Loftsson T, Brewster ME. Cyclodextrins as functional excipients: methods to enhance complexation efficiency. J Pharm Sci. 2012;101(9):3019–32. https://doi.org/10.1002/jps.23077.

Anderson BD. Predicting solubility/miscibility in amorphous dispersions: it is time to move beyond regular solution theories. J Pharm Sci. 2018;107(1):24–33. https://doi.org/10.1016/j.xphs.2017.09.030.

Lehmkemper K, Kyeremateng SO, Heinzerling O, Degenhardt M, Sadowski G. Impact of polymer type and relative humidity on the long-term physical stability of amorphous solid dispersions. Mol Pharm. 2017;14(12):4374–86. https://doi.org/10.1021/acs.molpharmaceut.7b00492.

Keratichewanun S, Yoshihashi Y, Sutanthavibul N, Terada K, Chatchawalsaisin J. An investigation of nifedipine miscibility in solid dispersions using Raman spectroscopy. Pharm Res. 2015;32(7):2458–73. https://doi.org/10.1007/s11095-015-1638-x.

Purohit HS, Ormes JD, Saboo S, Su Y, Lamm MS, Mann AKP, et al. Insights into nano- and micron-scale phase separation in amorphous solid dispersions using fluorescence-based techniques in combination with solid state nuclear magnetic resonance spectroscopy. Pharm Res. 2017;34(7):1364–77. https://doi.org/10.1007/s11095-017-2145-z.

Saboo S, Taylor LS. Water-induced phase separation of miconazole-poly (vinylpyrrolidone-co-vinyl acetate) amorphous solid dispersions: insights with confocal fluorescence microscopy. Int J Pharm. 2017;529(1):654–66. https://doi.org/10.1016/j.ijpharm.2017.07.034.

Bochmann ES, Üstüner EE, Gryczke A, Wagner KG. Predicting melt rheology for hot-melt extrusion by means of a simple Tg-measurement. Eur J Pharm Biopharm. 2017;119:47–55. https://doi.org/10.1016/j.ejpb.2017.05.010.

Sun DD, Lee PI. Probing the mechanisms of drug release from amorphous solid dispersions in medium-soluble and medium-insoluble carriers. J Control Release. 2015;211:85–93. https://doi.org/10.1016/j.jconrel.2015.06.004.

Hsieh YL, Ilevbare GA, Van Eerdenbrugh B, Box KJ, Sanchez-Felix MV, Taylor LS. pH-induced precipitation behavior of weakly basic compounds: determination of extent and duration of supersaturation using potentiometric titration and correlation to solid state properties. Pharm Res. 2012;29(10):2738–53. https://doi.org/10.1007/s11095-012-0759-8.

Truong DH, Tran TH, Ramasamy T, Choi JY, Choi HG, Yong CS, et al. Preparation and characterization of solid dispersion using a novel amphiphilic copolymer to enhance dissolution and oral bioavailability of sorafenib. Powder Technol. 2015;283:260–5. https://doi.org/10.1016/j.powtec.2015.04.044.

Patterson JE, James MB, Forster AH, Rades T. Melt extrusion and spray drying of carbamazepine and dipyridamole with polyvinylpyrrolidone/vinyl acetate copolymers. Drug Dev Ind Pharm. 2008;34(1):95–106. https://doi.org/10.1080/03639040701484627.

Miller DA, DiNunzio JC, Yang W, McGinity JW, Williams RO. Enhanced in vivo absorption of itraconazole via stabilization of supersaturation following acidic-to-neutral pH transition. Drug Dev Ind Pharm. 2008;34(8):890–902. https://doi.org/10.1080/03639040801929273.

Friesen DT, Shanker R, Crew M, Smithey DT, Curatolo WJ, Nightingale JAS. Hydroxypropyl methylcellulose acetate succinate-based spray-dried dispersions: an overview. Mol Pharm. 2008;5(6):1003–19. https://doi.org/10.1021/mp8000793.

Shah N, Iyer RM, Mair HJ, Choi DS, Tian H, Diodone R, et al. Improved human bioavailability of vemurafenib, a practically insoluble drug, using an amorphous polymer-stabilized solid dispersion prepared by a solvent-controlled coprecipitation process. J Pharm Sci. 2013;102(3):967–81. https://doi.org/10.1002/jps.23425.

Shah N, Sandhu H, Phuapradit W, Pinal R, Iyer R, Albano A, et al. Development of novel microprecipitated bulk powder (MBP) technology for manufacturing stable amorphous formulations of poorly soluble drugs. Int J Pharm. 2012;438(1):53–60. https://doi.org/10.1016/j.ijpharm.2012.08.031.

Sarode AL, Sandhu H, Shah N, Malick W, Zia H. Hot melt extrusion for amorphous solid dispersions: temperature and moisture activated drug–polymer interactions for enhanced stability. Mol Pharm. 2013;10(10):3665–75. https://doi.org/10.1021/mp400165b.

Zhang M, Li H, Lang B, O’Donnell K, Zhang H, Wang Z, et al. Formulation and delivery of improved amorphous fenofibrate solid dispersions prepared by thin film freezing. Eur J Pharm Biopharm. 2012;82(3):534–44. https://doi.org/10.1016/j.ejpb.2012.06.016.

Riedel A, Leopold CS. Degradation of omeprazole induced by enteric polymer solutions and aqueous dispersions: HPLC investigations. Drug Dev Ind Pharm. 2005;31(2):151–60. https://doi.org/10.1081/DDC-200047787.

Karandikar H, Ambardekar R, Kelly A, Gough T, Paradkar A. Systematic identification of thermal degradation products of HPMCP during hot melt extrusion process. Int J Pharm. 2015;486(1):252–8. https://doi.org/10.1016/j.ijpharm.2015.04.007.

Funding

The work was supported by the China Postdoctoral Science Foundation (Grant No. 2016M602442), the 111 project (Grant No. B16047), and the Natural Science Fund Project of Guangdong Province (Grant No. 2016A030312013).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Peng, T., She, Y., Zhu, C. et al. Influence of Polymers on the Physical and Chemical Stability of Spray-dried Amorphous Solid Dispersion: Dipyridamole Degradation Induced by Enteric Polymers. AAPS PharmSciTech 19, 2620–2628 (2018). https://doi.org/10.1208/s12249-018-1082-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1208/s12249-018-1082-4