Abstract

The natural rubber latex (NRL) film taken from medical surgical gloves was surface-modified with a dielectric barrier discharge (DBD) plasma treatment under an air environment. The results showed that surface hydrophilicity of the NRL film increased after the plasma treatment due to the presence of oxygen-containing polar groups on the plasma-treated surface. An increase in plasma treatment time increased the surface roughness of the NRL film, and eventually decreased the mechanical properties. From the obtained results, the optimum plasma treatment time of 20 s was chosen. After immersion in a chitosan solution, the amount of chitosan deposited on the plasma-treated NRL film increased with increasing chitosan concentrations. The chitosan coating smoothed the surface of the plasma-treated NRL film and also improved the mechanical properties. The highest antibacterial activities of the chitosan-coated DBD plasma-treated NRL film against both Staphylococcus aureus and Escherichia coli were achieved when a 2 %(w/v) chitosan solution was used for the coating.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Natural latex is a milky fluid containing rubber particles of cis-1,4-polyisoprene produced by the Hevea brasiliensis tree. After being processed and vulcanized, natural rubber latex (NRL) products have shown extensive uses in various fields, ranging from household to health care applications, because of its unique physical properties, such as outstanding resilience, excellent elasticity, flexibility, and acceptable mechanical strength [1–3]. Among a variety of NRL products, natural latex is the most commonly used raw material for glove manufacture, including the production of medical surgical gloves [4]. The key purpose for gloving during surgery are to protect the surgical sites from contamination caused by microorganisms on the hands of the surgeon as well as to prevent the transmission of microorganisms between the surgeon and patient, hence protecting each other from microbial infections [5, 6]. Nevertheless, it is known that one of the important drawbacks of NRL is its lack of antimicrobial activities [7]. Therefore, microorganisms can attach and grow on both the inner and outer surfaces of NRL surgical gloves, and contamination can easily occur when gloves are accidentally perforated during an operation [5, 6, 8, 9]. To decrease the microbial accumulation on glove surfaces, the development of medical surgical gloves with antimicrobial activities is of great interest.

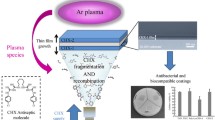

One of the simplest strategies to obtain desired properties without losing the bulk characteristics of materials is surface coating. However, a major limitation to coating NRL surfaces is that NRL possesses low surface free energy, poor wettability, and poor adhesion [3, 10]. Even after being coated properly, the coating on the NRL surface can delaminate easily [11]. Hence, various surface modification techniques have been employed in order to enhance the attachment of the coating to NRL by introducing either chemical functional groups or active species on the NRL surface for a subsequent interaction with the coating material molecules [1, 4, 12–14]. The present contribution focused on the surface modification of NRL materials with the use of dielectric barrier discharge (DBD) plasma—one of the typical plasma discharges generated at atmospheric pressure. The DBD plasma treatment has been employed for surface modification of a variety of polymers because it has several advantages, such as low energy consumption, high efficiency, rapid operation time, and minimal thermal degradation [15–21].

During the past few decades, chitosan has received a considerable attention as a promising alternative to synthetic chemical antimicrobial agents and antibiotics because of its excellent antimicrobial activities against bacteria and fungi, good biocompatibilities, and low toxicities towards mammalian cells [22–25]. Chitosan, a linear copolymer consisting of N-acetyl-d-glucosamine (GlcNAc) and d-glucosamine (GlcN), is a natural polysaccharide derived from deacetylation of chitin—a major structural component in the exoskeleton of crustaceans, including shrimps, crabs, and squids. Chitosan has shown potential use as an effective antimicrobial coating for various products, ranging from food-packaging materials to textiles [25–27]. Although a number of possible explanations have been proposed, it is widely accepted that the antimicrobial activities of chitosan rely on the interaction between the positively-charged amino groups of chitosan and the negatively-charged surface of microorganisms [23, 27, 28]. Such interaction disrupts cell permeability, thus leading to either the leakage of intracellular components or the prevention of essential substances from entering the cells and eventually causing cell death.

In the present study, the vulcanized NRL film cut from commercial medical surgical gloves was surface-modified using DBD plasma generated in a closed chamber under an air environment. The optimum plasma treatment condition was chosen based on the results of the water contact angle measurement and tensile testing in order to ensure that the plasma treatment chemically modified the surface characteristics of the NRL specimen without deteriorating its mechanical properties. The chemical composition of the NRL surface both before and after the plasma treatment was observed with the use of attenuated total reflection–Fourier transform infrared (ATR–FTIR) spectroscopy and X-ray photoelectron spectroscopy (XPS). An atomic force microscopy (AFM) was also employed to examine the effect of the plasma treatment on the surface topography of the NRL specimen. With the optimization of the plasma treatment conditions, the plasma-treated NRL specimen was further immersed in an aqueous chitosan solution at different concentrations. To investigate whether or not the DBD plasma treatment improved the interaction between the NRL and chitosan, the chitosan deposition on the plasma-treated surface was quantitatively and qualitatively determined in a comparison with that on the untreated surface. The mechanical properties of the NRL film, after chitosan coating, were then measured. The antibacterial activities of the chitosan-coated plasma-treated NRL specimen were tested against Gram-positive Staphylococcus aureus and Gram-negative Escherichia coli, compared to those of the uncoated NRL film.

Experimental

Preparation of Chitosan

Chitosan was prepared from the shells of Litopenaeus vannamei shrimp, which were provided by Surapon Foods Public Co., Ltd. (Thailand). The shrimp shells were cleaned and dried under sunlight before grinding into small pieces. The ground shrimp shells were immersed in a 1 M hydrochloric acid solution for 2 days with an occasional stirring and were washed with distilled water until neutral. The demineralized shrimp shell chips were soaked in a 4 %(w/v) sodium hydroxide solution at 80–90 °C for 4 h, followed by an excessive wash with distilled water. The deproteinized product, or chitin, was further deacetylated by heating in a 50 %(w/v) sodium hydroxide solution containing 0.5 wt% sodium borohydride in an autoclave at 110 °C for 1 h. After deacetylation, the chitosan platelets were washed with distilled water until neutral and were then dried at 60 °C. The deacetylation step was carried out four times to obtain chitosan with a high degree of deacetylation (%DD) [21]. The viscosity-averaged molecular weight of the chitosan product, calculated from the Mark–Houwink equation [29], was about 5.5 × 105 while the %DD, determined from FTIR spectroscopy following the method of Baxter et al. [30], was found to be 96.0 %. An aqueous solution of chitosan, at various concentrations, was prepared by dissolving a specific amount of chitosan platelets in a 1 %(v/v) acetic acid solution.

Experimental Set-up and Procedure

Latex medical surgical gloves (Gammex®) with a thickness of 0.15 mm and a cross-linking density of 9.0 × 10−5 mol/cm3, determined by the experimental test following the Flory–Rehner theory of swelling [31], were purchased from Ansell Limited (Malaysia). A vulcanized NRL glove specimen was cut into a square shape with the dimension of 6 cm × 6 cm before being plasma-treated using a DBD system operated at room temperature (about 25–27 °C) under an air environment at a constant pressure of 30 psig [20, 21]. The schematic of the DBD system is shown in Fig. 1. The DBD system consists of a 2-mm-thick dielectric glass plate placed between two parallel stainless steel electrodes. The input power used for the generation of uniform filamentary discharges over the whole electrode surfaces in the electrode gap is domestic alternating current (AC), 220 V and 50 Hz, which is transmitted to a high voltage current via a power supply system [32]. A function generator was used to control the output voltage and frequency. The input voltage and frequency at the low voltage side of the power supply system was measured by a power analyzer (Extech®) while the high voltage side was calculated by multiplying by a factor of 250, according to the specification of the transformer unit. The optimum operating conditions for the plasma treatment were chosen based on the work of Onsuratoom et al. [20]: an electrode gap distance of 4 mm, an applied voltage of 12.5 kV, and an input frequency of 325 Hz. After the plasma treatment, the NRL specimen was immediately immersed in a chitosan solution at six different concentrations [0.125, 0.25, 0.50, 0.75, 1.0, and 2.0 %(w/v)] with constant stirring at room temperature for 5 min [21]. The chitosan-coated NRL specimen was washed with distilled water until neutral and was then air-dried at room temperature overnight. This washing step was repeated several times in order to remove any excess chitosan that loosely adhered to the specimen surface. The plasma-treated NRL film coated with chitosan was then used for further analyses.

Analytical Methods and Measurements

A water contact angle measurement was carried out at room temperature using the sessile drop technique. The contact angle formed between the 8 μl water droplet and the specimen surface was measured by a drop shape analysis system (Krüss, DSA10 Mk2). The reported values were averaged from ten measurements.

Both ATR–FTIR spectroscopy (Thermo Nicolet Nexus, 670) and XPS analysis (Thermo Fisher Scientific, Thetaprobe) were employed to analyze the surface chemical composition of the NRL specimen. All ATR–FTIR spectra were collected using 64 scans in a wavenumber range of 4,000–650 cm−1 at a resolution of 4 cm−1. For the XPS analysis, the XPS spectra were excited by the Al Kα X-ray source (1,486.6 eV) operated at an emission voltage of 15 kV and a current of 15 mA.

The surface topography of the NRL specimen was investigated by using the AFM technique (XE-100, Park systems). The topographic profiles and the root mean squared (RMS) roughness were evaluated from the scan area of 40 μm × 40 μm. The reported RMS values were the average of eight measurements made at different scan areas.

Mechanical properties in terms of ultimate tensile strength and elongation at break were measured by using a universal testing machine (Instron, 4206). The specimen was cut into a dog-bone shape with the dimension of 60 mm × 10 mm with the gauge area of 7 mm × 3 mm. The load cell, gauge length, and displacement rate used during the testing were 5 kN, 7 mm, and 500 mm/min, respectively. Each reported datum was the mean of five measurements.

The presence of chitosan coating on the DBD plasma-treated NRL film was verified quantitatively and qualitatively, as previously reported by Sophonvachiraporn et al. [21]. To quantitatively determine the amount of the chitosan deposited on the plasma-treated NRL film, Kjeldahl nitrogen analysis was used. The specimen with a precise dimension of 6 cm × 6 cm was digested in a digestion flask containing 10 ml of a concentrated sulfuric acid with a 0.1 g of copper (II) sulfate, which acts as a catalyst for the conversion of the amine nitrogen to ammonium ions. The digestion flask was placed on a heating mantle and the specimen was completely digested within 4 h. Ten drops of 30 %(w/v) hydrogen peroxide were added to the digestion flask. The solution was continuously heated until it became transparent and colorless. Next, the digestion flask was equipped with Kjeldahl distillation equipment. An Erlenmeyer flask with 30 ml of a 0.01 M hydrochloric acid solution—an ammonia gas trapping solution—was set at the end of the condenser. A 40 %(w/v) sodium hydroxide solution was poured to the digested sample solution. The ammonium ions in the digested sample solution were then converted to ammonia, which was consequently evaporated by heating. When the ammonia gas passed through the trapping solution, it transformed to ammonium ions once again. Finally, the amount of the trapped ammonia ions was determined by back-titrating with a standard 0.01 M sodium hydroxide, and the number of nitrogen molecules was calculated to obtain the amount of chitosan deposited on the plasma-treated NRL film using the following equation:

where V1 is volume (ml) and M1 is the concentration in molarity (M) of the hydrochloric acid solution used as the trapping solution; V2 is volume (ml) and M2 is the concentration in molarity (M) of sodium hydroxide solution used in back-titration step after the chitosan-coated plasma-treated NRL film was digested; V3 is volume (ml) and M3 is the concentration in molarity (M) of the sodium hydroxide solution used in back-titration step after the uncoated NRL film was digested.

For the qualitative determination of the chitosan coating, the presence of amino groups in the chitosan on the surface of the NRL film was detected by using Amido Black 10B, an amino acid-staining diazo dye. The test specimen was immersed in a 0.01 %(w/v) Amido Black 10B solution for 12 h, followed by an excessive wash with distilled water to remove any excess dye molecules. Then, the stained specimen was imaged with a digital camera.

Antibacterial Activity Tests

Antibacterial activities of the chitosan-coated DBD plasma-treated NRL film were evaluated in a comparison with those of the plasma-treated film without chitosan coating based on the colony forming count method, as previously reported by Watthanaphanit et al. [33]. E. coli and S. aureus were selected as the representatives of Gram-negative and -positive bacteria, respectively. The bacterial suspension was prepared by transferring one colony of microorganisms to 20 ml of nutrient broth solution before being incubated at 37 °C in a shaking incubator at 150 rpm for 24 h. Next, 1 ml of bacterial suspension was added to a vial containing 9 ml of 0.85 % sterile saline solution. The obtained bacterial suspension was serially diluted until the optimum bacterial concentration was reached (10−6 colony forming units per ml (cfu/ml) for both E. coli and S. aureus). The test specimen was cut into a circle shape with a diameter of 2.5 cm and sterilized under UV light for 30 min. The sterilized specimen was added to a vial containing the bacterial suspension before being incubated at 37 °C in a shaking incubator at 150 rpm for 3 h. Then, 100 μl of bacterial suspension was withdrawn from the vial and subsequently spread on an agar plate. After incubation at 37 °C for 22 h, the bacterial reduction rate (BRR) was calculated by using the following equation:

where N1 is the number of colonies of the uncoated NRL specimen and N2 is the number of colonies of the chitosan-coated plasma-treated NRL film.

Results and Discussion

Characterization of DBD Plasma-Treated NRL

It is known that the water contact angle is very sensitive to the structure and chemical state of the outermost angstroms of a surface [34]. Hence, the water contact angle measurement was first carried out in order to study the effect of the DBD plasma treatment on the surface characteristics of the NRL film. Figure 2 displays a change in the contact angle formed between a water droplet and NRL surface as a function of the plasma treatment time. It was found that the water contact angle dramatically decreased from nearly 130° to a minimum value of about 50° as the plasma treatment time increased from 0 to 20 s, indicating an increase in surface hydrophilicity of the plasma-treated NRL film at a longer plasma treatment time. A change in surface wettability of the NRL film after the plasma treatment could be due to the surface chemical modification. Since the DBD plasma treatment was operated under an air environment in the present study, the air plasma was able to induce the formation of a large variety of active species, such as atomic oxygen, ozone, neutral and meta-stable molecules, and radicals [18, 20, 21, 35–38]. These generated active species potentially introduced oxygen-containing hydrophilic polar groups on the NRL surface, consequently resulting in increased surface hydrophilicity of the NRL film after plasma treatment. A constant water contact angle of around 50° at a treatment time longer than 20 s implies a saturation state of surface wettability. Our findings are also consistent with previous works [18, 20].

To verify the appearance of the oxygen-containing polar groups on the NRL surface after DBD plasma treatment, ATR–FTIR spectroscopy was used in combination with XPS analysis. Figure 3 shows ATR–FTIR spectrum of the untreated NRL as compared to those of plasma-treated NRL specimens at three different plasma treatment times. The ATR–FTIR spectrum of the untreated NRL exhibits the important absorption peaks at 2,960, 2,920, 2,853, 1,653, 1,443, and 1,373 cm−1, indicating the chemical structure of natural rubber—cis-1,4-polyisoprene [2, 12, 13, 39]. The strong absorption peaks at 2,960, 2,920, and 2,853 cm−1 are assigned to CH stretching while the characteristic peak observed at 1,653 cm−1 is attributed to C=C stretching. The intense absorption peaks appearing at 1,443 and 1,373 cm−1 relate to the deformation of CH2 and CH3, respectively. After the DBD plasma treatment at any given treatment time, the ATR–FTIR spectra of the plasma-treated NRL film shows new absorption bands at 3,600–3,100, 1,720, 1,620, and 1,450–1,100 cm−1. While the broad band located at 3,600–3,100 cm−1 corresponds to OH stretching, the absorption bands at 1,720, 1,620, and 1,450–1,100 cm−1 are the stretching vibrations of C=O, O–C=O, and C–O, respectively. Since the ATR–FTIR spectra of the plasma-treated NRL specimen indicates the presence of both the OH and the O–C=O bonds, it might be implied that the carboxylic functional groups (COOH) were introduced on the plasma-treated NRL surface. It is important to note that although the ATR–FTIR results suggest the inclusion of the carboxylic groups on the plasma-treated NRL surface, there are other possible oxidized products of natural rubber, including esters (O–C=O), ethers (C–O–C), ketones (C=O), and aldehydes (H–C=O), as reported by a number of studies in the past [39–41]. Several oxidation mechanisms of natural rubber have already been proposed [39–41].

The XPS analysis was consequently employed to validate the inclusion of oxygen-containing functional groups on the plasma-treated NRL surface. Figure 4 shows C1 s spectra of NRL films before and after DBD plasma treatment at 20 s. The XPS spectrum of the NRL surface before plasma treatment was deconvoluted into four main peaks at 285.0, 286.2, 287.2, and 288.8 eV and assigned to the carbons in C–C/C–H, C–O/C–N, C=O, and O–C=O groups, respectively [20, 21, 42]. The XPS spectrum shows the pristine NRL surface contains 73.9 % C–C/C–H, 16.5 % C–O/C–N, 6.6 % C=O, and 3.0 % O–C=O. Interestingly, after 20 s of plasma treatment, the XPS spectrum reveals that the percentages of oxidized components on the NRL surface increased to 26.2 and 4.4 % for the C–O and the O–C=O groups, respectively. Meanwhile, that of the C–C/C–H groups decreased from 73.9 to 69.4 %. The results imply that the active species generated by the air plasma could introduce the C–O and the O–C=O groups onto the surface of the NRL film. The results obtained from the XPS analysis were in good agreement with those of the ATR–FTIR spectroscopy.

The effect of DBD plasma treatment on the characteristics of the NRL films was further studied in terms of surface topography and mechanical properties. Figure 5 shows the AFM micrographs of the NRL surface before and after plasma treatment at three different treatment times—5, 20, and 40 s. The untreated NRL film possesses a smooth surface with an RMS of about 0.45 ± 0.05 μm, whereas the plasma-treated specimens exhibit a much rougher surface. The surface roughness of the plasma-treated NRL film gradually increases with increasing plasma treatment time, as indicated by an increase in the RMS from 0.70 ± 0.08 to 0.81 ± 0.09 and 0.85 ± 0.06 μm when the plasma treatment time increased from 5 to 20 and 40 s, respectively. This could be due to the etching effect during the DBD plasma treatment [15, 43–48]. The AFM results suggest that the active species generated by the air plasma can lead to not only chemical but also physical modification of the NRL surface.

To further investigate whether the DBD plasma treatment deteriorated the physical performance of the NRL film, tensile testing was carried out. Figure 6 shows mechanical properties of NRL film, in terms of tensile strength and elongation at break, as a function of the plasma treatment time. Obviously, no significant change in both tensile strength and elongation at break of the NRL film is observed at treatment times shorter than 100 s, suggesting that the NRL film is able to withstand DBD plasma treatment when operated under an air environment up to 100 s without losing its bulk properties. However, when exposed to plasma for longer than 100 s, the NRL film began to lose its mechanical properties, as indicated by a continuous decrease in both tensile strength and elongation at break with an increased plasma treatment time. The results might suggest that the active species generated by air plasma strongly attacked chemical bonds on the surface of the NRL specimen at a longer treatment time, consequently resulting in the breakage of longer polymeric chains to shorter chains. Severe degradation of the polymeric chains finally caused deterioration of the physical performance of the NRL film. Our findings agree well with the previous works [46–48]. Kowbel and Shan [46] observed that the mechanical properties of carbon fiber in terms of flexural strength and strain-to-failure dramatically decreased as the cold plasma treatment time increased to longer than 60 s. In another study, Cioffi et al. [47] reported that an increase in the radio frequency cold plasma treatment time to 100 s caused severe surface degradation of poly(ethylene terephthalate) (PET) fibers, thus resulting in a decrease in tensile strength.

In the present work, the plasma treatment time was found to be optimal at 20 s; this condition was able to provide the saturation state of surface wettability of the NRL film without deteriorating its physical appearance and performance. This optimum plasma treatment time was used for further experiments. The results also suggest that, under appropriate operating conditions, DBD plasma is an effective tool to chemically modify the surface of polymeric materials without detriment to the bulk properties, such as mechanical strength.

Characterization of Chitosan-Coated DBD Plasma-Treated NRL

To investigate whether DBD plasma treatment enhanced the interaction between natural rubber and chitosan, the amount of chitosan coated on the plasma-treated NRL surface was quantified compared to that of the untreated NRL with the use of Kjeldahl nitrogen analysis. All test specimens were immersed in a 2.0 %(w/v) chitosan solution at room temperature for 5 min before being repeatedly washed with distilled water to remove any excess chitosan that adhered to the NRL surface. Figure 7a shows the effect of the number of washing cycle on the amount of chitosan deposited on the surface of the plasma-treated NRL film in a comparison with that of the untreated NRL. It was observed that the chitosan deposited on the untreated NRL surface was completely removed after washing two times. Although the amount of chitosan deposited on the plasma-treated NRL film first gradually decreased with increasing the number of washing cycle, a constant amount of deposited chitosan remained after three washing cycles, implying permanent adhesion of chitosan on the plasma-treated NRL surface. Therefore, three washing cycles were chosen for further experiments.

Figure 7b shows the amount of chitosan deposited on the plasma-treated NRL film as a function of chitosan concentration after washing three times, compared to that of the untreated NRL film. At any given chitosan concentration, chitosan was not able to permanently deposit on the untreated NRL specimen, implying that there was no interaction between the original NRL surface and chitosan. The amounts of the deposited chitosan on the plasma-treated NRL film linearly increased with an increase in chitosan concentrations from 0.125 to 2.0 %(w/v). The results indicate that DBD plasma treatment plays a crucial role in the enhancement of the interaction between NRL and chitosan.

The deposition of chitosan on the surface of the plasma-treated NRL film was also qualitatively determined by colorimetric analysis of amino groups in the chitosan molecules using Amido Black 10B, an anionic diazo dye widely used in biochemical research [21, 33, 49, 50]. Due to the positively-charged nature of amino groups in the chitosan molecules, the negatively-charged Amino Black 10B was selectively adsorbed onto the coated NRL surface via the electrostatic interaction. As shown in Fig. 8a, the plasma-treated NRL film without chitosan coating was not positively stained with the dye. On the contrary, a blue color was observed for the plasma-treated NRL films with the chitosan coating, indicating a specific interaction between the deposited chitosan and the dye (Fig. 8b–g). As the chitosan concentration increased from 0.125 to 2.0 %(w/v), a darker blue color appeared on the entire surface of the plasma-treated NRL films. The results verified that the chitosan was successfully coated on the NRL and the chitosan coating was homogeneous throughout the NRL specimen. As mentioned, the DBD plasma treatment led to the incorporation of the oxygen-containing functional groups, including the carboxylic groups, onto the NRL surface. After immersion in the chitosan solution, the incorporated carboxylic groups on the DBD plasma-treated NRL surface could possibly react with the amine groups (NH2) in the chemical structure of the chitosan. Thus, the deposited chitosan could chemically bind onto the NRL surface via the amide linkages (O=C–NH) [21].

The chitosan-coated plasma-treated NRL film was also characterized with ATR–FTIR spectroscopy. Figure 9 displays the ATR–FTIR spectra of chitosan, pristine NRL film, plasma-treated NRL film, and chitosan-coated plasma-treated NRL films at six different chitosan concentrations—0.125, 0.25, 0.50, 0.75, 1.0, and 2.0 %(w/v). As shown in Fig. 9a, the ATR–FTIR spectrum of chitosan exhibits a broad band in the wavenumber range of 3,600–3,100 cm−1 represents the overlapping stretching vibrations of the OH and the NH bonds in the carbohydrate ring, while the NH2 (amide I) and the NH (amide II) peaks are respectively located at 1,655 and 1,550 cm−1 [22, 27, 33]. For the untreated NRL film, the characteristic absorption peaks of cis-1,4-polyisoprene are present at 2,960, 2,920, 2,853, 1,653, 1,443, and 1,373 cm−1. Meanwhile, the ATR–FTIR of the plasma-treated NRL specimen exhibits new adsorption bands at 3,600–3,100, 1,620, 1,720, and 1,450–1,100 cm−1, suggesting the inclusion of carboxyl groups on the NRL surface. After the plasma-treated NRL film was immersed in the chitosan solution, additional absorption peaks at 1,655 and 1,550 cm−1, which are also the characteristic peaks of chitosan, are observed in the ATR–FTIR spectra, as shown in Fig. 9d–i. Hence, the ATR–FTIR results indicate the deposition of chitosan on the NRL surface after plasma treatment.

The effect of the chitosan coating on the characteristics of the NRL film was also studied in terms of surface topography and mechanical properties. Figure 10 shows the AFM micrographs of NRL films before plasma treatment, after 20 s of plasma treatment, and after 20 s of plasma treatment with chitosan coating at the concentration of 2.0 %(w/v). The untreated NRL film and the plasma-treated NRL specimen possessed a rough surface with an RMS of 0.45 ± 0.05 and 0.81 ± 0.09 μm, respectively, while the chitosan-coated plasma-treated NRL film exhibited a much smoother surface with an RMS of 0.22 ± 0.06 μm. It might be implied that the deposited chitosan could smooth the surface of plasma-treated NRL film.

Figure 11 shows mechanical properties of the chitosan-coated plasma-treated NRL film, in terms of ultimate tensile strength and elongation at break, as a function of the chitosan concentrations used for the coating. It was found that both the tensile strength and the elongation at break of the chitosan-coated plasma-treated NRL film increased with an increase in the chitosan concentration. Since chitosan was coated only on the surface of NRL film without penetrating into the NRL matrix, the chitosan molecules did not interrupt the movement of NRL polymeric chain and did not deteriorate the mechanical properties of the NRL film. The improved tensile properties of the chitosan-coated plasma-treated NRL film could be caused by greater amounts of deposited chitosan on the plasma-treated NRL surface when a higher chitosan concentration was used. The results also indicate that the deposited chitosan molecules were able to reinforce the NRL specimen. It is known that chitosan with high molecular weight could lead to higher tensile strength and elongation at break which were attributed to an entanglement network forming during the fabrication of chitosan film [51–53]. An increase in the elongation at break of the NRL sample after the chitosan coating should also be due to the absorbed moisture in the chitosan coating layer. The absorbed moisture can act as an effective plasticizer of the chitosan, consequently increasing the elongation at break of the chitosan-based materials [54]. Another possible explanation is that the coated chitosan layer should possess less molecular alignment since no external force was applied during the coating step in order to induce the molecular alignment in this work [55]. The current finding is consistent with the work of Bangyekan et al. [55], who reported that the tensile properties of cassava starch film were improved with increasing the amounts of chitosan coating. The improved mechanical properties of the chitosan-coated NRL specimens could give more benefit to surgical gloves. A number of studies report that, the glove puncture rate caused by either sharp bone or operation instruments increases with increases in operation time [5]. Puncture holes provide a passage for microorganisms, including bacteria [5, 6] and viruses [9], from the patient to the surgeon and vice versa, possibly leading to microbial infections. Hence, strengthening surgical gloves is an attractive strategy not only to decrease the glove puncture rate but also to potentially prevent microbial penetration during surgery [6].

Antibacterial Activities of Chitosan-Coated DBD Plasma-Treated NRL

An important purpose of the use of the medical surgical gloves is to protect both the surgical site from microorganisms on the surgeon’s hands and the surgeon’s hands from the patient’s microorganisms, thus preventing the surgical team and patients from microbial infections [5, 6]. Even with the use of sterile surgical gloves, the microbial contamination can still occur during an operation. The development of medical surgical gloves with antimicrobial properties is of great interest in order to decrease the amount of microbes on the gloves—both inner and outer layers, perhaps further decreasing the possibility of microbial penetration to the surgical gloves, especially when they were accidentally perforated. Since chitosan displays outstanding antimicrobial activities against a variety of microbes [22–25], it is expected that the chitosan coating could introduce those biological properties to the NRL. The antibacterial activities of the chitosan-coated plasma-treated NRL specimens were tested against Gram-positive S. aureus and Gram-negative E. coli using the colony forming count method and then were compared to those of the uncoated NRL film.

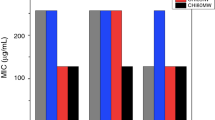

As shown in Fig. 12, after 3 h of contact with the bacterial suspension and then 24 h of incubation, the numbers of S. aureus and E. coli colonies on the uncoated plasma-treated NRL film were approximately 170 and 135, respectively. However, for specimens coated with chitosan, the numbers of colonies of both bacteria were significantly reduced with increasing chitosan concentrations. Interestingly, at the highest chitosan concentration of 2 %(w/v), no bacterial growth was observed. The results indicate that the antibacterial activities of the chitosan-coated plasma-treated NRL film originate from the deposited chitosan, not from the NRL itself.

The BRR was also calculated to represent the antibacterial activities of the chitosan-coated plasma-treated NRL films. As shown in Fig. 12, the BRRs against S. aureus and E. coli of the plasma-treated NRL films with a 0.125 %(w/v) chitosan coating are 29 and 17 %, respectively. As chitosan concentrations increase beyond 0.75 %(w/v), the BRRs against both bacteria increase to >90 %, indicating strong antibacterial activities against both the Gram-positive and -negative bacteria. A further increase in chitosan concentration to 2.0 %(w/v) finally gave 100 % BRRs against both bacteria. It was also observed that, at a chitosan concentration of lower than 2.0 %(w/v), the BRR of the chitosan-coated plasma-treated NRL film against S. aureus was greater than that against E. coli, perhaps due to a difference in the cell wall characteristics between the Gram-positive and -negative bacteria [21, 56]. Hence, it appeared that E. coli possessed a greater tolerance to the chitosan coating than S. aureus did. Based on the BRR results, the optimum chitosan concentration for the coating of 2.0 %(w/v) was chosen. The results of antibacterial activity testing also suggest that the DBD plasma treatment of the NRL surface with a subsequent chitosan coating is a promising approach to prepare NRL medical surgical gloves with appreciable antibacterial activities.

It should be noted that, although the chitosan-coated plasma-treated NRL film prepared at the optimum chitosan concentration of 2.0 %(w/v) was further washed with an aqueous acetic acid solution—a good solvent of chitosan—even at the acetic acid concentration of 4 %(v/v) for 24 h, the film still exhibited antimicrobial activities against both types of bacteria comparable to those washed with distilled water. The results also suggested that the chitosan should be firmly bound onto the NRL surface so the coated chitosan on the NRL surface was not dissolved in the acetic acid solution during the washing step.

Conclusion

Vulcanized NRL films taken from medical surgical gloves were successfully coated with chitosan with the aid of DBD plasma treatment operated under an air environment. The results showed that the plasma treatment induced the formation of oxygen-containing polar groups, including C–O and O–C=O groups, on the surface of NRL films, hence increasing surface hydrophilicity and enhancing the interaction between natural rubber and chitosan. Compared to the pristine NRL film, the chitosan-coated DBD plasma-treated NRL films possessed better mechanical properties, in terms of tensile strength and elongation at break, and much stronger antibacterial activities against both Gram-positive S. aureus and Gram-negative E. coli. Therefore, the proposed procedure—DBD plasma treatment in combination with chitosan coating—has great potential to be applied for the preparation of latex medical surgical gloves with improved mechanical properties and antibacterial activities.

References

Wang P, Tan KL, Ho CC, Khew MC, Kang ET (2000) Eur Polym J 36:1323–1331

Wang Z-F, Peng Z, Li S-D, Lin H, Zhang K-X, She X-D, Fu X (2009) Compos Sci Technol 69:1797–1803

Derouet D, Intharapat P, Tran ON, Gohier F, Nakason C (2009) Eur Polym J 45:820–836

Anancharungsuk W, Polpanich D, Jangpatarapongsa K, Tangboriboonrat P (2010) Colloid Surf B Biointerface 78:328–333

Eklund AM, Ojajärvi J, Laitinen K, Valtonen M, Werkkala KA (2002) Ann Thorac Surg 74:140–153

Harnoß J-C, Partecke L-I, Heidecke C-D, Hübner N-O, Kramer A, Assadian O (2010) Am J Infect Control 38:154–158

Berekaa MM, Linos A, Reichelt R, Keller U, Steinbüchel A (2000) FEMS Microbiol Lett 184:199–206

Lefebvre DR, Strande LF, Hewitt CW (2008) J Am Coll Surg 206:113–122

O’Connell KP, El-Masri M, Broyles JB, Korniewicz DM (2004) Clin Microbiol Infect 10:322–326

Ho CC, Khew MC (2000) Langmuir 16:1407–1414

Truscott W (2002) Methods 27:69–76

Sruanganurak A, Sanguansap K, Tangboriboonrat P (2006) Colloid Surf A Physicochem Eng Asp 289:110–117

Sruanganurak A, Tangboriboonrat P (2007) Colloid Surf A Physicochem Eng Asp 301:147–152

Jin M, Zhang X, Emeline AV, Numata T, Murakami T, Fujishima A (2008) Surf Coat Technol 202:1364–1370

Seeböck R, Esrom H, Charbonnier M, Romand M, Kogelschatz U (2001) Surf Coat Technol 142–144:455–459

Guruvenkt S, Mohan Rao G, Komath M, Raichur AM (2004) Appl Surf 236:278–284

Esena P, Riccardi C, Zanini S, Tontini M, Poletti G, Orsini F (2005) Surf Coat Technol 200:664–667

Ren C-S, Wang K, Nie Q-Y, Wang D-Z, Guo S-H (2008) Appl Surf Sci 255:3421–3425

Desmet T, Morent R, De Geyter N, Leys C, Schacht E, Dubruel P (2009) Biomacromolecules 10:2351–2378

Onsuratoom S, Rujiravanit R, Sreethawong T, Tokura S, Chavadej S (2010) Plasma Chem Plasma Process 30:191–206

Sophonvachiraporn P, Rujiravanit R, Sreethawong T, Tokura S, Chavadej S (2011) Plasma Chem Plasma Process 31:233–249

Xie Y, Liu X, Chen Q (2007) Carbohydr Polym 69:142–147

Harish Prashanth KV, Tharanathan RN (2007) Trends Food Sci Technol 18:117–131

Vishu Kumar AB, Varadaraj MC, Gowda LR, Tharanathan RN (2005) Biochem J 391:167–175

Rinaudo M (2006) Prog Polym Sci 31:603–632

Vartiainen J, Motion R, Kulonen H, Rättö M, Skytta E, Ahvenainen R (2004) J Appl Polym Sci 94:986–993

Demir A, Arık B, Ozdogan E, Seventekin N (2010) Fiber Polym 11:351–356

Chung Y-C, Chen C-Y (2008) Bioresour Technol 99:2806–2814

Wang W, Bo S, Li S, Qin W (1991) Int J Biol Macromol 13:281–285

Baxter A, Dillon M, Taylor KDA, Roberts GAF (1992) Int J Biol Macromol 14:166–169

Cizravi JC (2000) J Macromol Sci Part A Pure Appl Chem 37:1377–1389

Chavadej S, Kiattubolpaiboon W, Rangsunvigit P, Sreethawong T (2007) J Mol Catal A Chem 263:128–136

Watthanaphanit A, Supaphol P, Tamura H, Tokura S, Rujiravanit R (2010) Carbohydr Polym 79:738–746

Bain CD, Troughton EB, Tao YT, Evall J, Whitesides GM, Nuzzo RG (1989) J Am Chem Soc 111:321–335

Wilken R, Holländer A, Behnisch J (1999) Surf Coat Technol 116–119:991–995

Kuzuya M, Ito K, Kondo SI, Yamauchi Y (1999) Thin Solid Films 345:85–89

Lehocky M, Drnovski H, Lapcikova B, Timmons AMB, Trindade T, Zembala M, Lapcik L Jr (2003) Colloid Surf A Physicochem Eng Asp 222:125–131

Chung YM, Jung MJ, Han JG, Lee MW, Kim YM (2004) Thin Solid Films 447–448:354

Cibulková Z, Polovková J, Lukeš V, Klein E (2006) J Therm Anal Cal 84:709–713

Alam TM, Celina M, Assink RA, Clough RL, Gillen KT (2001) Radiat Phys Chem 60:121–127

Fan J, Zhang R (2004) Environ Chem 1:140–149

Gonzalez E II, Hicks RF (2010) Langmuir 26:3710–3719

Liu C, Cui N, Brown NMD, Meenan BJ (2004) Surf Coat Technol 185:311–320

De Geyter N, Morent R, Leys C, Gengembre L, Payen E, Van Vlierberghe S, Schacht E (2008) Surf Coat Technol 202:3000–3010

Li H, Liang H, He F, Huang Y, Wan Y (2009) Surf Coat Technol 203:1317–1321

Kowbel W, Shan CH (1995) Composites 26:791–797

Cioffi MOH, Voorwald HJC, Ambrogi V, Monetta T, Bellucci F, Nicolais L (2002) J Mater Eng Perform 11:659–666

Bozaci E, Sever K, Demir A, Seki Y, Sarikanat M, Ozdogan E (2009) Fiber Polym 10:781–786

Wilson CM (1979) Anal Biochem 96:263–278

Yonan CR, Duong PT, Chang FN (2005) Anal Biochem 338:159–161

Ziani K, Oses J, Coma V, Maté JI (2008) LWT Food Sci Technol 41:2159–2165

Chen RH, Lin JH, Yang MH (1994) Carbohydr Polym 24:41–46

Souza BWS, Cerqueira MA, Martins JT, Casariego A, Teixeira JA, Vicente AA (2010) Food Hydrocoll 24:330–335

Suyatma NE, Tighzert L, Copinet A (2005) J Agric Food Chem 53:3950–3957

Bangyekan C, Aht-Ong D, Srikulkit K (2006) Carbohydr Polym 63:61–71

Sudarshan NR, Hoover DG, Knorr D (1992) Food Biotechnol 6:257–272

Acknowledgments

The Thailand Research Fund (TRF) is acknowledged for providing a Royal Golden Jubilee (RGJ) Ph.D. scholarship (PHD/0367/2551) for the first author. The second author would like to acknowledge the Ratchadapiseksomphot Endowment Fund, Chulalongkorn University, for providing a postdoctoral fellowship. This work was financially supported by the TRF under the RDG5450059 Grant. The authors also thank Surapon Foods Public Co., Ltd. (Thailand) for supplying the shrimp shells.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yorsaeng, S., Pornsunthorntawee, O. & Rujiravanit, R. Preparation and Characterization of Chitosan-Coated DBD Plasma-Treated Natural Rubber Latex Medical Surgical Gloves with Antibacterial Activities. Plasma Chem Plasma Process 32, 1275–1292 (2012). https://doi.org/10.1007/s11090-012-9405-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11090-012-9405-9