Abstract

Effects of gas temperature on the conversion of benzene and the selectivity of CO and CO2 are analyzed and compared in dielectric barrier discharges. Gas temperature is determined by the method of the optical emission spectroscopy. The result is found that the conversion of benzene increases linearly with gas temperature. The selectivity of CO and CO2 and carbon balance are also investigated.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

It is known that non-thermal plasma (NTP) is an effective approach for controlling volatile organic compounds (VOCs) [1–4]. There is considerable research effort on improving the energy efficiency and the control of undesirable by-products generated by plasma process in the given practical application [5–7]. In most cases, the dependence of energy consumption on different parameters was investigated experimentally. However, in order to find the optimum conditions under which the energy consumption is lowest and conversion of VOCs is highest, it is desirable to understand the decomposition mechanism of VOCs in these plasmas.

In fact, many parameters may affect the conversion of VOCs: the discharge mode, the geometry of the reactor, the gas composition, the discharge power input, gas temperature, etc. There are a number of publications investigating the effect of gas temperature on the conversion of VOCs [8–12]. It is found that an increase of gas temperature is beneficial to CH4 decomposition [8]. A similar result is also obtained with toluene and propane [9]. Demidyuk and Whitehead [10] studied the effect of temperature on the conversion of gas phase toluene. Magureanu et al. [11] have studied effects of the temperature on the toluene conversion and the CO2 yield in a dielectric barrier discharge (DBD) combined with Mn-based phosphate catalysts placed downstream of the plasma reactor, it is found that in the range of 0–400°C, both the conversion and the CO2 yield increase with the temperature. Harling et al. [12] also have investigated effects of temperature on CCl2H2 (DCM) conversion under five reactive conditions: plasma hybridization TiO2, plasma hybridization Al2O3, plasma no catalyst, only TiO2 and only Al2O3 with SED 60 J/l and temperature range of 125–400°C, it is found that DCM conversion increases with temperature under all these five conditions.

In this work, the effect of temperature on the removal efficiency of benzene and the formation of by-product in a DBD is investigated. In particular, we analyze the correlation between the gas temperature, the conversion of benzene, and specific energy density (SED). The effect of temperature on the selectivity of CO and CO2 and carbon balance are also analyzed.

Experimental

Experimental Setup

The configuration of the dielectric barrier discharge (DBD) reactor is shown in Fig. 1. A quartz tube (inner diameter, 16 mm; outside diameter, 20 mm; the length, 120 mm) is used as the discharge barrier. The inner electrode is a stainless steel rod (diameter, 6 mm). The outer electrode is an aluminum mesh. The discharge length is about 40 mm. The packed material is commercial glass beads with 2–3 mm diameter.

The schematic of the experiment is shown in Fig. 2. The experimental setup consists of a benzene bubbling bath (1), a heater (2), a packed-bed plasma reactor (3), an oscilloscope (4), a high voltage AC power supply (0–15 kV, 8 kHz) (5), an optical fiber (6), a spectrometer (7), a PC (8), a gas chromatograph (9), an infrared CO gas analyzer (10), an infrared CO2 gas analyzer (11). The gas can be pre-heated by a heater and the preheating temperature is monitored by a thermocouple.

Measurement Technique

Electrical Measurement

We use V–Q Lissajous method to determine the discharge power in the plasma reactor (see Fig. 3). The charge Q is determined by measuring the voltage across the capacitor (10,300 pf), through which an aluminum mesh is connected to the ground. The applied high voltage is measured with a 1,000:1 high voltage probe (Textronix, P6015A). The signals of V and Q are recorded with a digitizing oscilloscope (Textronix, TDS2022) by averaging 64 scans. The discharge power is calculated from the area of V–Q parallelogram by multiplying the frequency.

The specific energy density (SED) is calculated by:

Here, U is the applied high voltage, u is the voltage across the capacitor, f is frequency.

Gas Analysis

The benzene concentration is monitored by a gas chromatograph (HP 6890). The initial benzene concentration is about 300 ppm, the discharge gas is air, with a flow rate of 3 l/min. The concentration of CO is measured by an infrared gas analyzer (Beijing BAIF–Maihak Analytical Instrument Co. Ltd., QGS-08C). The concentration of CO2 is measured by infrared gas analyzer (Beijing BAIF–Maihak Analytical Instrument Co. Ltd., QGS-08).

The carbon balance is given by:

The selectivity of CO and CO2 is given by, respectively:

Temperature Measurement

The optical emission of line intensity from the plasma is collected by a monochromator (Tianjin Gangdong Science & Technology Co. Ltd., WGD-8A). In Fig. 4 the measured emission line profile of the 0–0 band (337.1 nm) of the second positive system of N2 (C–B) is compared with those simulated. In this way, the N2 molecules rotational temperature can be determined. It is generally believed that the N2 rotational temperature is a reasonable estimate of gas temperature in the plasma [13, 14].

Results and Discussion

Correlation Between Temperature and the Conversion of Benzene

Figure 5 shows the relationship between the gas temperature, the conversion of benzene and SED, indicating that both the gas temperature and the conversion of benzene increase with SED with and without preheating of the input gas. This is because, when SED increases, the electron density in the plasma increases, a higher rate of collisions between the electrons and gas molecules leads to a stronger energy transfer from electrons to the gas molecules, resulting gas temperature increases with SED. It can also be seen that, there are two effects of preheating: a gas temperature increase (about 60 K) and an increase of the conversion of benzene by about 10% over the entire range of SED.

Using the same set of experimental data, the relationship between the conversion of benzene and the gas temperature is plotted in Fig. 6, which gives a linear relationship between the two quantities. This result suggests that, as long as the gas temperature takes the same value, the conversion of benzene remains the same with or without preheating. In other words, two kinds of discharge conditions can give the same conversion of benzene: a strong discharge (high SED) without the input gas preheating and a weak discharge (low SED) with the input gas preheating.

The Formation of CO and CO2

Figure 7 shows the CO concentration as a function of SED. It can be seen that preheating has little effect on the CO concentration, which is mainly determined by SED (within error bars). Experimental data shown in this figure also suggest that the CO concentration starts to level off when SED approaching at 500 J/l, after an initial increase with SED. This result is different from the one obtained by Lock et al. [15], who found that CO concentration increases monotonically with SED.

On the other hand, the result shown in Fig. 8 indicates that CO2 concentration is significantly influenced by gas temperature. It can also be seen that the data obtained in both experiments (with and without preheating) can be fitted to a single straight line. This suggests that there is a linear relationship between the concentration of CO2 and gas temperature. In other words, if the gas heating by the discharge is considered, the same CO2 concentration can be obtained with either a weak discharge with preheating or a strong discharge without preheating.

The Selectivity of CO and CO2 and Carbon Balance

Figure 9 shows the effect of SED on the selectivity of CO, which is determined by Eq. 4. In the case of no gas preheating, the selectivity of CO decreases with SED. However, when gas preheating is present, the selectivity of CO remains more or less unchanged, even though its value is lower than that obtained without preheating. In the case of no gas preheating, the conversion of benzene increases significantly with SED, as shown in Fig. 5. In the meantime, the variation in CO concentration with SED is quite limited, as shown in Fig. 7. This leads to a decrease of the CO selectivity with SED when no gas preheating is present. In the gas preheating case, however, both the conversion of benzene and the CO concentration increase with SED at more or less the same rate. This is the reason why the CO selectivity remains more or less unchanged with SED when gas preheating is present. Notice that the conversion of benzene in the preheating case is larger than that in the no preheating case (Fig. 5), while, the CO concentration is about the same in both cases. This explains why the CO selectivity is smaller in the preheating case.

Figure 10 shows the effect of SED on CO2 selectivity. It can be seen that, in both cases, the CO2 selectivity increases significantly with SED. We attribute this effect to an enhanced oxidation process by the discharge. As a result, more benzene molecules are being converted into CO2. Since, the oxidation process is also sensitive to gas temperature, at the same discharge power (SED), the CO2 selectivity in the preheating case is larger than that without preheating by about 10% over the entire range of SED.

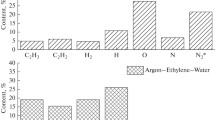

The carbon balance versus SED is plotted in Fig. 11. It can be seen that, the carbon balance does not vary much, approximately 70–75% with SED with SED in our experiment. The rest of carbon is formed into a small quantity of some organic compounds, such as, ethane and propylene, and some solid phase organic compounds, such as, phenol, nitro-phenol and quinine. However, the concentration of these organic compounds is too small to determine, so we just measure the concentration of CO and CO2.

The experimental results presented above suggest that there may be two independent reaction channels for the production of CO and CO2, respectively. Similar argument has been reported previously [16, 17]. However, a strong link between the production of CO and CO2 has also been reported in other experiments [15, 18–21]. Therefore, more detailed assessment of the experimental conditions and theoretical analysis by chemical kinetics are needed to understand this discrepancy.

Conclusion

By using the method of optical emission spectroscopy, the effect of the gas temperature and SED on the conversion of benzene in a DBD is investigated. It is found that in these discharges, the gas temperature is an important parameter for benzene conversion under our experimental condition. It is also found that the concentrations of CO and CO2 behave differently with gas temperature, suggesting the possible existence of two independent production channels.

References

Ogata A, Einaga H, Kushiyama S, Kabashima H, Kim HH (2003) Appl Catal B: Environ 46:87

Malik MA, Malik SA (1999) J Chem Eng 7(4):351

Hackam R, Akiyama H (2000) IEEE T Dielect El In 7(5):654

Urashima K, Chang JS (2000) IEEE T Dielect El In 7(5):602

Li D, Yakushiji D, Kanazawa S (2002) J Electrostat 55:311

Kim HH, Oh SM, Ogata A (2005) Appl Catal B: Environ 56:213

Oda T (2003) J Electrostat 57:293

Xia JF, Gao XX, Kong JY (2000) Plasma Chem Plasma P 20(2):225

Song YH, Kim SJ, Yamamoto T (2002) J Electrostat 55:189

Demidyuk V, Whitehead JC (2007) Plasma Chem Plasma P 27(1):85

Magureanu M, Mandache NB, Eloy P et al (2005) Appl Catal B: Environ 61:12

Harling AM, Wallis AE Christopher Whitehead J (2007) Plasma P polym 4:463

Phillips DM (1975) J phy D: Appl Phy 8:507

Porter RA, Harshbarger WR (1979) Solid-State Sci Technol 3(6):460

Lock EH, Saveliev AV, Kennedy LA (2006) Plasma Chem Plasma P 26:527

Ogata A, Mizuno K, Kushiyama S, Yamamoto T (1998) Plasma Chem Plasma P 18:363

Futamura S, Zhang A, Prieto G, Yamamoto T (1998) IEEE Trans Ind Appl 34:967

Sano T, Negishi N, Saki E, Matsuzawa S (2006) J Mol Catal A: Chem 245:235

Wong FF, Lin CM, Chang CP (2006) Plasma Chem Plasma P 26:585

Wallis AE, Whitehead JC, Zhang K (2006) Appl Catal B: Environ 72:283

Yu SJ, Moo Been C (2001) Plasma Chem Plasma P 21:311

Acknowledgment

The authors thank Drs. Wen-Xia Pan and Xian Meng of the Institute of Mechanics, Chinese Academy of Sciences, for assisting on the optical emission spectroscopy measurement.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Li, J., Bai, SP., Shi, XC. et al. Effects of Temperature on Benzene Oxidation in Dielectric Barrier Discharges. Plasma Chem Plasma Process 28, 39–48 (2008). https://doi.org/10.1007/s11090-007-9115-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11090-007-9115-x