Abstract

Intrusive igneous rock is usually found in the overlying strata above mining stopes, and its occurrence, lithology, and distribution play important roles in coal mining safety. Of the numerous coal mine disasters in China, a large number have been caused by magma intrusion. Magmatic activity is intense and widely distributed in the Haizi Coal Mine which has suffered eleven coal and gas outburst accidents and one water inrush accident under a thick-hard igneous rock with 120-m-thick. Based on theoretical analysis, laboratory testing and field observations, we found that under the effect of thermal evolution and entrapment of the igneous rock, the coal pore structure developed, the gas adsorption capacity was enhanced, and the risk of gas outburst increased. The igneous rock, as the main key stratum, will not subside or break for a long time after mining. The closing time of fractures and separations is also prolonged and provides good conditions for gas drainage. The distant penetration borehole for draining pressure relief gas is proposed which can ensure effective gas drainage and reduce the number of rock laneways. However, with the continuous mining of a large area, the igneous rock could suddenly break, instantly releasing a tremendous amount of elastic strain energy, which will easily induce the occurrence of complex dynamic disasters, such as rock bursts, water inrush, gas outbursts, and surface subsidence. Based on the cause analysis of dynamic disasters, a reasonable goaf filling height is proposed for fully eliminating mine disasters under the special geological condition.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Coals influenced by magma intrusions are relatively common and occur in many localities worldwide (Jiang et al. 2011). The magma intrusion provides a high-temperature and high-pressure environment for coal seams, which promotes the thermal evolution of the coal seam, speeds up the formation of gas and brings enormous changes in coal metamorphism, pore structure, adsorption–desorption characteristics, and coal structure (Fredericks et al. 1985; Yuan 2000; Stewart et al. 2005; Wang and Zhang 2006; Liu et al. 2007; Dai and Ren 2007; Saghafi et al. 2008; Rimmer et al. 2009; Jiang et al. 2011; Yao et al. 2011). Along with the enhanced degree of coal metamorphism caused by magma intrusions, gas content and gas diffusion rate generally would correspondingly increase, and generated gas would be stored in coal seams and trapped by the igneous rock (Gurba and Weber 2001; Saghafi et al. 2008), which often caused safety problems on gas control in coal mines (Golab 2004). Five gas outbursts associated with dikes and sills occurred in the coal mines of South Africa in the early 1990s (Anderson 1995; Saghafi et al. 2008; Jiang et al. 2011). Several CO2 outbursts were caused by the interaction of tectonics and volcanism (Beamish and Crosdale 1998; Faiz et al. 2007; Li et al. 2011). Coal and gas outbursts are a major problem for safe and efficient coal exploitation in the magmatic intruded Donets Basin (Sachsenhofer et al. 2011; Jiang et al. 2011). Of the numerous coal and gas outburst disasters in China, a large number have been caused by magma intrusion. Some typical gas outbursts were mainly in the vicinity of sill intrusions in the Huaibei coal field in China, in which eleven outbursts occurred in the Haizi Mine, two outbursts occurred in the Shitai Mine, and three outbursts occurred in the Wolonghu Mine.

The occurrence, size, distribution, and lithology of the intrusive igneous rock play important roles in coal mining safety. When a thick-hard igneous rock bed is present in overlying strata, the physical characteristics of the underlying coal seams and the laws regarding collapse and failure take on new meanings, and dynamic disasters could be easily induced, such as rock bursts, water inrush, gas outbursts, and surface subsidence. For the existence of thick-hard rocks, some experts have performed research on coal production and accident investigation to analyze the effect of extremely thick igneous rock (Zhang and Chen 2005; Li 2006; Tan et al. 2007). Other studies have dealt with failures of overlying strata and surface subsidence in coal mining under extremely thick, but weak layers mainly composed of mud and sandstone (Li et al. 2002; Song et al. 2003; Tu and Yu 2004). None of the above papers have systematically discussed the causes and comprehensive control methods of the hybrid disasters in the outburst coal seams under the thick-hard igneous rock.

The magmatic activity is more intense and more widely distributed in the Haizi Coal Mine, in which 120-m-thick igneous rock exists as a hard bedrock-like body in the overlying strata. Eleven coal and gas outburst accidents and one roof separation of water inrush accident have occurred under the thick-hard igneous rock. In this paper, we analyzed the coal seam outburst risk, overlying strata separation evolution law, and gas storage and transportation law of pressure relief gas under the thick-hard igneous rock in the Haizi Coal Mine. A new method of using distant penetration boreholes for draining pressure relief gas was proposed, and the mechanisms of dynamic disasters were discussed. The research results could provide useful references for safe and high-efficiency mining under similar geological conditions.

2 Geological setting

The Haizi Coal Mine is located in Suixi county, Anhui province, China. The mine belongs to the Huaibei coal field in the Linhaitong mining area. The Nos. 7, 8, 9, and 10 coal seams in the Haizi Coal Mine are primary mineable coal seams and are all outburst seams. In the early Yanshanian, deep crustal magma gushed along the Su-Bei Fault and intruded into the Haizi coal field along the Daliujia Fault (Han 1990; Yang and Tang 2000), as shown in Fig. 1. The magmatic rock (i.e., the extremely thick igneous rock) is distributed as a rock bed that intrudes along the No. 5 coal seam in the middle and western parts of the mine. The strike is 6.5 km long, and the length of the trend is approximately 140 km. This extremely thick igneous rock is found in a stable condition in the II102 mining area above the No. 7 coal roof and is usually more than 120 m thick. The distance in height between the Nos. 10 and 9 coal seams is 84 m on average. The No. 7 coal seam is 115 m above the No. 10 coal seam, which in turn, is 55 m above a 120-m-thick igneous rock. The coal and rock profile are shown in Fig. 2.

3 The gas outburst risk of coal seams under the thick-hard igneous rock

3.1 Mechanical parameters test results of the igneous rock

Samples of the igneous rock were collected by drilling cores from the surface well. Photographs of the cores are shown in Fig. 3. The rock is mainly diorite and diorite porphyrite and appears as light gray or green–gray with a plaque-like structure, which is clearly shown as whole block structure characteristics. The local sections of the cores were broken, and developed fissures were filled with calcite veins.

By testing the mechanical parameters of the cores, we determined that the average compression strength of the rock is 144.21 MPa, with an average tensile strength of 10.91 MPa and an average RQD (Rock Quality Designation) of more than 90 %. There are few primary structural planes in the rock, the lithology is singular, and the effect of groundwater is not obvious. The initial caving interval of the igneous rock is more than 200 m, which is clearly greater than that of general rocks (Wang 2009; Wang et al. 2011). Given these conditions, the rock’s thickness and mechanical characteristics are close to a key stratum and are considered as the main key stratum of the coal mine (Qian et al. 2003). The test results are shown in Table 1.

3.2 Physical parameters determination of outburst coal seams under the thick-hard igneous rock

The samples were collected from the No. 86 and II102 mining areas, covered by the igneous rock, and the II101 mining area without igneous covering in the Haizi Coal Mine. The physical parameters of the samples, such as coal micromacerals, vitrinite reflectance, electron microscope scanning, and porosity, were determined. The test results are shown in Table 2.

As shown in Table 2, the coal micromacerals of the Nos. 7, 8, 9, and 10 coal seams are similar. The vitrinite is above 85 %, which is the main component of coal, and exinite fades in the coal-forming process. Generally, the maximum vitrinite reflectance R omax increases with depth, whereas the R omax of the Nos. 7, 8, 9, and 10 coal seams is different and becomes smaller with increasing distance from the igneous rock, mainly due to thermal metamorphism of the coal.

The electron microscope scanning results are shown in Fig. 4. The superimposed hydrocarbon generation of coal seams occurred under the influence of the Yanshanian magmatism. The pyrolysis holes formed at the same time during the action of thermal evolution (Yang and Tang 2000). A sample of the No. 7 coal seam contains a large number of pyrolysis holes, and the maximum diameter of the holes is approximately 30 μm. The holes in the No. 9 coal seam are fewer than those in the No. 7 coal seam, and the maximum diameter is approximately 20 μm. A few holes appear in the samples of the No. 10 coal seam collected from the II102 mining area, and the maximum diameter is approximately 4 μm. However, a sample from the II101 mining area uncovered by the igneous rock is unaffected by the thermal evolution effect, and few stomas appear.

The test results of the porosity, specific surface and adsorption constant of the Nos. 7, 8, 9, and 10 coal seams are shown in Fig. 5. With nearness to the thick-hard igneous rock, the porosity and specific surface of the coal seam increase gradually, the coal seam pore structure develops, and the gas adsorption capacity is enhanced.

3.3 Determination and analysis of gas outburst indexes of the coal seams

With the existence of thick-hard igneous rocks in the Haizi Coal Mine, all the underlying coal seams’ gas adsorption capacities increase, the gas content and gas pressure increase, and the outburst risk increases significantly. There were eleven gas outburst accidents from 1984 to 2009, of which there were five in the No. 7 coal seam, four in the No. 8 coal seam, and one in the Nos. 9 and 10 coal seams. All the outburst sites are located under the thick-hard igneous rocks. The gas content and pressure variation curves with depth (Wang et al. 2012) are shown in Fig. 6, and the maximum values of each coal seam are shown in Fig. 7. Gas content and gas pressure have exceeded the critical values (gas pressure 0.74 MPa and gas content 8 m3/t) in all coal seams below a certain mining depth, and the degree of outburst risk in the Nos. 7, 8, and 9 coal seams is far greater than that in the No. 10 coal seam. According to the principle of protective seams mining, the No. 10 coal seam is selected to be the lower protective seam for the middle coal group (Nos. 7, 8, and 9 coal seams).

Coal seam adsorption constants and outburst determination indexes variations with distance from the igneous rock are shown in Fig. 8. With closeness to the rock mass, the coal volatility decreases, the degree of metamorphism increases, and the values of the outburst determination indexes Δp and f increase gradually. The critical values of the initial rate of gas emission ΔP and the coal consistency coefficient f are 10 mmHg and 0.5, respectively (Cao et al. 2001; Wang et al. 2013). All the results were caused by high-temperature baking, which made the coal seam outburst risk higher. We found that the initial gas release rate (Δp) obeyed the same variation law with the adsorption constant (a). Generally, coal seams with a large adsorption capacity always had a high initial release rate.

4 The storage and transportation characteristics and drainage method of pressure relief gas under the thick-hard igneous rock

4.1 The separation and fracture development laws under the thick-hard igneous rock

When the thick-hard igneous rock is in the bending zone, the direct roof supports the load of the overlying strata as a plate formed at the initial mining period, and the strata stress reached a balance in the roof. With the continuous mining, the form of the plate will disappear, and separations will appear after roof collapse. The upper hard rock establishes a stress arch balance after exposure as the plate forms (Su 2001; Qian et al. 2003). As the workface continues advancing, the balance arch continues to expand and move upward, separations develop within the balance arch, and the coal-rock masses keep the overall movement outside the arch. When the top of the balance arch develops to the thick-hard igneous rock, it stops developing and reaches a limit. Because of the large compressive strength and thickness, the balance arch is unable to reach the ultimate collapse distance of the igneous rock in a short time or in small mining area. The thick-hard igneous rock blocks the developing trend of separations, and the arch balance shifts to an arch slab shape. The distribution shape of the separations and fractures form a “cap,” which is shown in Fig. 9 (Wang 2009; Wang et al. 2010; Wang et al. 2011).

Based on the similar material simulation test, we studied the laws of movement and deformation in the overlying strata under the thick-hard igneous rock. Our simulation test used a plane strain model of 2.0 × 2.0 × 0.3 m laid along the strike, and we selected 1/150 as the geometric similarity constant. The model was excavated along a 1.4-m stretch with 0.3-m-coal pillars left on both sides. The ultimate form of the strata collapse after mining the No. 10 coal seam in the Haizi Coal Mine is shown in Fig. 10. From a macroscopic point of view, the igneous rock did not bend, but the separations below it were well developed. Bending and subsidence were most evident in the middle-group coal seams. A few vertical fractures and large quantities of separations were not completely closed at the roof and floor of the protected seams.

After coal seam mining, we divide the entire overlying strata into “three zones,” namely the caving, fractured, and bending zones, according to the movement of the rock bed and its damage degree (Qian and Liu 1991). These areas of bed separations are called “arc separation zones.” The caving zone is formed by destroyed and collapsed rocks of the overlying strata in the goaf. In this zone, the rocks start to form an irregular accumulation and acquire a large coefficient of looseness. The fractured zone is formed by rock bed fractures and fissures that retain their former layered distribution and by fissures consisting of parallel layers formed by bed separations and vertical cross fissures formed by rock fractures. The bending zone consists largely of parallel layered fissures and a few vertical cross fissures (Cheng et al. 2004). In the presence of thick-hard igneous rock, a new zone, namely the separation zone, is formed with large quantities of separations that will not close for a long time.

4.2 The pressure relief gas storage and transportation characteristics under the thick-hard igneous rock

After protective seam was mined, the protected coal seams expand and deform, gas pressure is released, fractures are formed among the seams, and the gas is activated. As the main key stratum of the coal mine, the thick-hard igneous rock controls the entire overlying strata movement, and it will not subside nor break for a long time after mining. The pressure relief effect is generally better than normal under the special geological conditions, the coal-rock mass permeability greatly increases, and the stroke resistance of the gas flow largely decreases. The fractures and bed separations will not close and will become good channels for gas migration. Gas then continuously flows into the separations along several vertical fissures with the driving force of the concentration difference. The separation zone in the bending zone is the region of gas enrichment, where pressure relief gas is accumulated from the protected coal seams, as shown in Fig. 11. All these data provide a theoretical basis for pressure relief gas drainage. Furthermore, after a relatively hermetic separation is formed, if there is an aquifer developed around the separation space that can continuously supply water, abscission water formation conditions are met.

4.3 Pressure relief gas drainage technology under thick-hard igneous rock

When an extremely thick key stratum exists above the roof of the protected seam, the support of the stratum and the time for subsidence of the overlying strata are prolonged, which in turn prolong the closing time of the fractures and bed separations, providing good conditions for gas drainage (Wang et al. 2008). With the existence of the gas enrichment region under the special geological conditions in the Haizi Coal Mine, a surface well for draining pressure relief gas can be established after protective seam mining (Chen et al. 2012). Besides, a new gas drainage method is proposed, namely distant penetration boreholes, which is shown in Fig. 12.

In Fig. 12, distant penetration boreholes drilled through the rock, and coal seams could be located at a high-elevation roadway or drilling fields of the air return roadway which could reduce the number of rock laneways under the protected seam for drilling boreholes to drain pressure relief gas. We drilled a few boreholes in the drilling fields directly from the floor of the No. 10 coal seam, drilling through the Nos. 7, 8, and 9 coal seams in the Haizi Coal Mine. Figure 13 shows the variation in the amount of gas drainage versus time from the No. 1 borehole drilled in the 5th drilling field of the Haizi Coal Mine. We can see that the amount of gas drainage increased during the first 47 days. The overlying strata were not stable at first, and the amount and concentration of gas drainage increased irregularly. On day 47, the amount reached 4.2 m3/min, and the concentration was 92 %. During the period from days 47–118, the amount of gas drainage was stable. The amount stayed at approximately 4.6 m3/min, and the concentration remained at 90 %. The decline period started on day 118. The amount of gas drainage slowly reduced from 4 m3/min at first. As the working-face pushed forward, the drilling field collapsed and gas drainage stopped, which resulted in a few data marked as decline in Fig. 13. However, the other boreholes took effect, which led to the total amount of gas drainage tending to increase. Records show that the drilling boreholes drained 4.86 Mm3 gas from March 2006 to March 2007. The rate of gas drainage reached 73 % in the middle coal group, where the gas drainage radius was over 100 m.

The residual gas pressure variation of the No. 7 coal seam within the pressure relief area in the II1021 workface is shown in Fig. 14, which indicates that the gas pressure of the No. 7 coal seam decreased from 1.6 to 1.0 MPa in less than 2 months of drainage. As time went on, the gas drainage radius continued expanding and the gas pressure slowly began to decline. Five months later, the gas pressure decreased to 0.4 MPa, which was less than the critical value of 0.74 MPa. At this point, the goal of eliminating the outburst risk of the middle coal group was achieved.

5 The influence of the thick-hard igneous rock on coal mine dynamic disasters

5.1 The influence of the thick-hard igneous rock on rock burst

When the igneous rock ruptures for the first time, both ends of the rock plate are supported by the coal wall and pillar, and the igneous rock is considered as a clamped beam structure. When the cycle rupture takes place later, one end of rock plate above the goaf is in a free state, and the igneous rock is considered as a cantilever structure. Based on the attenuation relationship between the energy propagation and the corresponding distance (Gao et al. 2007), Table 3 shows the amount of remaining energy in each coal seam produced after the rupture of the igneous rock. The results show that the remaining energy grade of the initial rupture propagating to the Nos. 7, 8, 9, and 10 coal seams is 104J/m3, and the remaining energy grade of the cycle rupture is 103J/m3, which shows that it has the ability to produce and induce dynamic disasters.

The rock burst tendency measured in the laboratory ranges from medium to strong in Table 4. Along with the workface in the protective seam being pushed forward, the hanging arch area increased in size. When this area reached the limit of the caving interval of the rock bed, the igneous rock became unstable, and a large amount of elastic strain energy was instantly released, resulting in a large rock burst.

5.2 The influence of the thick-hard igneous rock on water inrush

Water permeability testing of the cores showed that the average permeability coefficient is 1.15 × 10−5 cm/s (shown in Table 5), so the rock is considered as an impermeable rock bed (Yan 2006; Miao et al. 2007; Qiao et al. 2011). Along with the working-face being pushed forward, a large separation space will appear and enlarge between the igneous rock and its underlying series of coal strata. This space will often be filled with water under a certain pressure. When the strength of the igneous rock is suddenly unleashed, a large amount of elastic strain energy will instantly be released, leading to a strong impact on this stored water, forming, and exerting considerable pressure on the water. This high-pressure water will cause instant ruptures along the weak zones of the series of coal strata at the top of the working-face, forming water inrush channels, quickly resulting in water inrush, as shown in Fig. 15. A large sandstone roof water inrush accident occurred during the mining of the No. 745 workface in the Haizi Coal Mine on May 21, 2005, as recorded and described by Li (2006). The maximum instantaneous water quantity was 3,887 m3/h. This accident resulted in five deaths. The investigation concluded that the water from the separation was the most important direct cause of the water inrush.

5.3 The influence of the thick-hard igneous rock on gas disaster

The high baking temperature and pressure increased the metamorphic grade of the coal seams under the thick-hard igneous rock and generated large amounts of gas. The number of micro-pores increased, and the gas absorption of the coal seam was enhanced, which increased the capacity for gas storage. Given the extreme thickness and low permeability of the igneous rock in the Haizi Coal Mine, the igneous rock halted the gas dissipation and trapped the gas. The igneous rock became the natural barrier for gas migration and provided excellent conditions for gas storage. All the coal seams present outburst risk with high gas pressure and content. At the same time, the stress distribution at two ends of the workface goaf changed under the thick-hard igneous rock, and the stress concentration range increased, which led to an increased gas outburst risk range. On April 25, 2009, a large gas outburst disaster occurred in the No. 10 coal seam of the Haizi Coal Mine, and the coal and gas outburst volumes were as high as 656 t and 13,210 m3, respectively, resulting in one death (Wang et al. 2011), as shown in Fig. 16.

5.4 The influence of the thick-hard igneous rock on surface subsidence

With the continuous mining of the coal seam, the overlying strata were destroyed, resulting in movement and deformation. Rock movements would finally develop to the surface and cause surface subsidence. Given the high rigidity, strength, and thickness, the flexivity of the igneous rock was small, and the existence of the igneous rock weakened the influence on the overlying strata after mining of the protective seam. Based on measured surface subsidence data from the Huaibei and Huainan mining areas, the subsidence coefficient is generally 0.8–1 (Li 2006). The subsidence coefficient was usually smaller than 0.2 after mining the No. 10 coal seam, which verified that this thick-hard igneous rock controlled the surface subsidence. However, the continuous mining and its large area will cause sudden rupture of the igneous rock, resulting in sudden and large surface subsidence, threatening persons and equipments on the ground.

6 Control measures for dynamic disasters under the thick-hard igneous rock

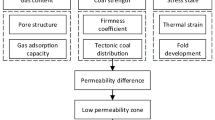

Given its high rigidity, strength and thickness, the igneous rock is considered the main key stratum, and a large number of separations would appear and not close during mining. The separations are the gas enrichment areas, and when the surface well and distant penetration boreholes are used for draining pressure relief gas, the effect is obvious (Wang et al. 2008; Wang 2009). Otherwise, the thermal evolution and the metamorphism effect of magma intrusions could change the coal pore structure and adsorption–desorption characteristics and could control the process of gas generation, storage, and entrapment, eventually leading to multi-layer outburst coal seams. At the same time, along with the continuous mining and its large area, the thick-hard igneous rock could suddenly break, instantly releasing a large amount of elastic strain energy, which easily induces the occurrence of complex dynamic disasters. Based on these aspects, basic ideas are proposed for the prevention and control of dynamic disasters under the thick-hard igneous rock, as shown in Fig. 17. If we adopt injecting grouts in the separated strata, large quantities of gas will be forced to migrate back into the outburst coal seams, which will compromise the effectiveness of the protective seam and may cause gas disasters under the high pressure of the injecting grouts. Increasing the filling height of the goaf could prevent dynamic disasters such as surface subsidence, rock burst, and water inrush. The supporting effect of the filling body could control the movement and deformation of the overlying strata, thereby affecting the pressure relief effect of the protective seam. Therefore, a reasonable filling height of the goaf is proposed for efficient coexistence of the protective seam and goaf filling under the special geological conditions to fully eliminate mine disasters.

To research the effect of the waste rock filling height after exploiting the protective seam, the concept of equivalent mining height (EMH) needs to be cited (Miao et al. 1997). The EMH is the actual mining height minus the waste rock filling height after compaction. The formula for computing the EMH is as follows:

where h is the EMH; H is the actual mining height of 2.67 m in the Hazi coal mine; h c is the waste rock filling height after compaction; k is the rock expansion coefficient; and k′ is the remnant rock expansion coefficient.

Miao et al. (1997) and Miao et al. (2010) tested the mechanical properties of waste rock taken from coal mines using a self-developed experimental device. They found the rock expansion coefficient (k) to be 1.30–1.40 and the remnant rock expansion coefficient (k′) to be 1.1–1.15. Considering the geological conditions in the Haizi Coal Mine, the rock expansion coefficient (k) is taken as 1.4, and the remnant rock expansion coefficient (k′) is 1.15.

The EMH formula of the No. 10 coal seam of the Haizi Coal Mine is as follows:

During exploitation with the filling goaf, along with the advance of the workface, the flexural deformation of the overlying strata increased gradually. If the flexivity of the thick-hard igneous rock is less than the maximum in the initial rupture when the overlying strata contacts the filling waste rock, due to the support of the filling waste rock, the extremely thick igneous rock generates little deformation and subsidence, which can help avoid dynamic disasters (Chang 2009). In other words, the waste rock filling height determines the fracture of the thick-hard igneous rock. The minimum waste rock filling height after exploiting the protective seam under the thick-hard igneous rock is as follows:

where f is the maximum initial rupture flexivity of the thick-hard igneous rock, and \( \sum h \) is the roof collapse height, which is 10 m.

When calculating the maximum initial rupture flexivity of the thick-hard igneous rock, the model can be simplified as the clamped beam model with a continuous and uniform load at the top of the strata (Qian et al. 2003, 2010; Wang 2009), where the maximum flexivity is as follows:

where q is the equivalent continuous load at the top of the strata; L is the limit caving interval; E is the elasticity modulus; and I is the moment of inertia.

After formula (4) is incorporated into in formula (3), the minimum waste rock filling height is as follows:

Here, q = 10 MPa, E = 28.6 GPa, L = 235 m and the thickness of the thick-hard igneous rock is 120 m. When these values are incorporated into formula (5), we obtain that h c = 1.33 m. In other words, if the waste rock filling height is more than 1.33 m, the thick-hard igneous rock cannot be fractured, and the EMH is 1.58 m at the moment. We can then test the effect of protective seam mining by numerical simulation.

7 Conclusions

-

1.

The Nos. 7, 8, 9, and 10 coal seams underlying the thick-hard igneous rock are all outburst coal seams in the Haizi Coal Mine. Under the effect of thermal evolution and entrapment of the igneous rock, metamorphic hydrocarbon phenomena emerged in the coal seam, which generated a large amount of gas. The number of micro-pores increased, the gas adsorption capacity was enhanced, and the risk of coal and gas outburst increased. The test results showed that with increasing distance from the igneous rock, the maximum vitrinite reflectance, porosity, and specific surface area for each seam area gradually decreased. The coal seams had more pyrolysis holes with larger diameters near the thick igneous rock, which indicated an increase in the adsorption capacity.

-

2.

The thick-hard igneous rock in the Haizi Coal Mine is a “whole block structure.” As the main key stratum of the coal mine, the igneous rock will not subside or break for a long time after mining. The igneous rock also blocks the upward development of the overlying strata. Large quantities of separations are developed as gas–water enrichment areas in the bending zone. The closing time of the fractures and bed separations is also prolonged which provides good conditions for gas drainage. The use of distant penetration boreholes for draining pressure relief gas is proposed, which can ensure the effect of gas drainage and reduce the number of rock laneways.

-

3.

We calculated the remaining energy propagating to the Nos. 7, 8, 9, and 10 coal seams after rupture of the igneous rock using the clamped beam structure model, which showed that it has the ability to produce and induce dynamic disasters. When the sudden rupture of the igneous rock occurs, rock burst and water inrush accidents will more easily occur, which could bring sudden and large surface subsidence and threaten persons and equipments on the ground.

-

4.

Based on the cause analysis of dynamic disasters in the outburst coal seams under the thick-hard igneous rock, a reasonable filling height of the goaf is proposed for the efficient coexistence of the protective seam mining and goaf filling under special geological conditions to fully eliminate mine disasters.

References

Anderson SB (1995) Outbursts of methane gas and associated mining problems experienced at Twistdraai Colliery. In: Lama, R. (Ed.), Proceedings of the international symposium cum workshop on management and control of high gas emissions and outbursts. Wollongong, pp 423–434

Beamish BB, Crosdale PJ (1998) Instantaneous outbursts in underground coal mines: an overview and association with coal type. Int J Coal Geol 35:27–55

Cao YX, He DD, David CG (2001) Coal and gas outbursts in footwalls of reverse faults. Int J Coal Geol 48(1–2):47–63

Chang QL (2009) Research on theory and practice of mining induced overlying strata deformation and surface subsidence with paste backfilling. China University of Mining and Technology, Xuzhou

Chen JH, Wang T, Zhou Y, Zhu YL, Wang XX (2012) Failure modes of the surface vent hole casing during long wall coal extraction: a case study. Int J Coal Geol 90–91:135–148

Cheng YP, Yu QX, Yuan L, Li P, Liu YQ, Tong YF (2004) Experimental research of safe and high-efficient exploitation of coal and pressure relief gas in long distance. J China Univ Min Technol 33(2):132–136

Dai SF, Ren DY (2007) Effects of magmatic intrusion on mineralogy and geochemistry of coals from the Feng feng–Handan coalfield, Hebei, China. Energy Fuels 21:1663–1673

Faiz MM, Saghafi A, Barclay SA, Stalker L, Sherwood NR, Whitford DJ (2007) Evaluating geological sequestration of CO2 in bituminous coals: the southern Sydney Basin, Australia as a natural analogue. Int J Greenhouse Gas Control 1:223–235

Fredericks PM, Warbrooke P, Wilson MA (1985) A study of the effect of igneous intrusions on the structure of an Australian high volatile bituminous coal. Org Geochem 8:329–340

Gao MS, Dou LM, Zhang N, Mou ZL, Wang K, Yang BS (2007) Experimental study on earthquake tremor for transmitting law of rock burst in geomaterials. Chin J Rock Mech Eng 26(7):1365–1371

Golab A (2004) Changes in geochemistry and mineralogy of thermally altered coal, Upper Hunter Valley, Australia. Int J Coal Geol 57:197–210

Gurba LW, Weber CR (2001) Effects of igneous intrusions on coal bed methane potential, Gunnedah Basin, Australia. Int J Coal Geol 46:113–131

Han SF (1990) Geological conditions of coal generation and its prediction in Huaibei and Huainan area. Geological Publishing House, Beijing

Jiang JY, Cheng YP, Wang L, Li W, Wang L (2011) Petrographic and geochemical effects of sill intrusions on coal and their implications for gas outbursts in the Wolonghu Mine, Huaibei Coalfield, China. Int J Coal Geol 88:55–66

Li W (2006) Cause of special water inrush accident occurred in Haizi mine and countermeasures. Coal Sci Technol 34(1):35–38

Li DH, Chen XE, Li DS (2002) Analysis of surface movement and strata parameters caused by mining under very thick loose overburden. Ground Press Strata Control 1:90–92

Li W, Cheng YP, Wang L (2011) The origin and formation of CO2 gas pools in the coal seam of the Yaojie coalfield in China. Int J Coal Geol 85:227–236

Liu FS, Xu PW, Rui LD (2007) Magmatic intrusion and its impact to coal seam and coal quality in Hanxing Coalfield. Coal Geol China 15(9):22–24

Miao XX, Mao XB, Hu GW, Ma ZG (1997) Research on expansion and compaction characteristics of broken rocks and coals. J Exp Mechan 12(3):394–400

Miao XX, Chen RH, Bai HB (2007) Fundamental concepts and mechanical analysis of water-resisting key strata in water-preserved mining. J China Coal Soc 32(6):561–564

Miao XX, Zhang JX, Guo GL (2010) Study on waste-filling method and technology in fully-mechanized coal mining. J China Coal Soc 35(1):1–6

Qian MG, Liu TC (1991) The pressure and control in coal mines. China Coal Industry Publishing House, Beijing

Qian MG, Miao XX, Xu JL (2003) The key stratum theory for control of strata movement. China University of Mining & Technology Press, Xuzhou

Qian MG, Shi PW, Xu JL (2010) Ground pressure and strata control. China University of Mining and Technology Press, Xuzhou

Qiao W, Li WP, Sun RH, Li XQ, Hu G (2011) Formation mechanism of dynamic impact failure zone of super dynamic water inrush in coal mine. Chin J Geotech Eng 33(11):1726–1733

Rimmer SM, Yoksoulian LE, Hower JC (2009) Anatomy of an intruded coal, I: effect of contact metamorphism on whole-coal geochemistry, Springfield (no. 5) (Pennsylvanian) coal, Illinois Basin. Int J Coal Geol 79:74–82

Sachsenhofer RF, Privalov VA, Panova EA (2011) Basin evolution and coal geology of the Donets Basin (Ukraine, Russia): an overview. Int J Coal Geol 89(1):26–40

Saghafi A, Pinetown K, Grobler P, Vanheerden J (2008) CO2 storage potential of South African coals and gas entrapment enhancement due to igneous intrusions. Int J Coal Geol 73:74–87

Song CS, Zhao ZM, Li HB (2003) Discussion of subsidence mechanism and strata movement model about stripe mining under thick soil layer. J Jiaozuo Inst Technol 22(3):161–164

Stewart A, Massey M, Padgett P, Rimmer S, Hower J (2005) Influence of a basic intrusion on the vitrinite reflectance and chemistry of the Springfield (no. 5) coal, Harrisburg, Illinois. Int J Coal Geol 63:58–67

Su ZJ (2001) Research of deformation mechanism of mining overburden separated strata. Liaoning Technical University, Fuxin

Tan JS, Ji HG, Yao ZX (2007) Variability analysis of overlying strata movement rule and mining field pressure under super-thick magmatic rock. Coal Technol 26(3):34–37

Tu M, Yu ZL (2004) Overburden strata movement and destroy analysis of mining under very thick loose aquifer. Ground Press Strata Control 2:1–3

Wang L (2009) Fracture evolution and seepage characteristics of distant pressure relief coal-rock masses and application in gas extraction under an extremely thick igneous rock. China University of Mining & Technology, Xuzhou

Wang WX, Zhang HC (2006) Discussion on coal metamorphism affected by magmatism. Sci Technol Inform 30:45

Wang L, Cheng YP, Li FR, Wang HF, Liu HB (2008) Fracture evolution and pressure relief gas drainage from distant protected coal seams under an extremely thick key stratum. Min Sci Technol 18(2):182–186

Wang L, Cheng YP, Jiang JY, Guo PK, Wang LG, Yang Y (2010) The coupling laws between fissure field and gas flow field under an extremely thick igneous rock. J China Coal Soc 35(8):1287–1291

Wang L, Cheng YP, Nie Z, Wang HF, Yang Y, Liu J (2011) Control effect on gas occurrence and outburst disaster of coal seam by an extremely thick igneous rock. J China Univ Min Technol 1(40):29–34

Wang L, Cheng YP, Wang L, Guo PK, Li W (2012) Safety line method for the prediction of deep coal-seam gas pressure and its application in coal mines. Saf Sci 50(3):523–529

Wang L, Cheng YP, Ge CG, Chen JX, Li W, Zhou HX, Wang HF (2013) Safety technologies for the excavation of coal and gas outburst-prone coal seams in deep shafts. Int J Rock Mech Min Sci 57:24–33

Yan HQ (2006) Hydro-geological significance of igneous intrusions in the Hanxing Coalfield. Coal Geol China 18(4):33–35

Yang Q, Tang DZ (2000) Effect of coal metamorphism on methane content and permeability of coal in North China. J China Univ Geosci 25(3):273–277

Yao YB, Liu DM, Huang WH (2011) Influences of igneous intrusions on coal rank, coal quality and adsorption capacity in Hongyang, Handan and Huaibei coalfields, North China. Int J Coal Geol 88:135–146

Yuan TX (2000) Effect of magmatic rocks on coal-seam and its characteristics of contact matemorphic zone in Wu Guiqiao, Queshan coal field. J Hebei Inst Architect Sci Technol 17(4):70–73

Zhang YS, Chen SW (2005) Practice of mining technology under nappe of mega-thickness igneous rock. Coal Min Technol 10(4):28–29

Acknowledgments

The authors are grateful to the National Science Foundation of China (No. 51004106), the first-class General Financial Grant from the China Postdoctoral Science foundation (No. 2012M510145). A Project Funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions, and the Fundamental Research Funds for the Central Universities.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, L., Cheng, Yp., Xu, C. et al. The controlling effect of thick-hard igneous rock on pressure relief gas drainage and dynamic disasters in outburst coal seams. Nat Hazards 66, 1221–1241 (2013). https://doi.org/10.1007/s11069-012-0547-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11069-012-0547-0