Abstract

The objective of this study is to select very simple and well-known laboratory scale methods able to reduce particle size of indomethacin until the nanometric scale. The effect on the crystalline form and the dissolution behavior of the different samples was deliberately evaluated in absence of any surfactants as stabilizers. Nanocrystals of indomethacin (native crystals are in the γ form) (IDM) were obtained by three laboratory scale methods: A (Batch A: crystallization by solvent evaporation in a nano-spray dryer), B (Batch B-15 and B-30: wet milling and lyophilization), and C (Batch C-20-N and C-40-N: Cryo-milling in the presence of liquid nitrogen). Nanocrystals obtained by the method A (Batch A) crystallized into a mixture of α and γ polymorphic forms. IDM obtained by the two other methods remained in the γ form and a different attitude to the crystallinity decrease were observed, with a more considerable decrease in crystalline degree for IDM milled for 40 min in the presence of liquid nitrogen. The intrinsic dissolution rate (IDR) revealed a higher dissolution rate for Batches A and C-40-N, due to the higher IDR of α form than γ form for the Batch A, and the lower crystallinity degree for both the Batches A and C-40-N. These factors, as well as the decrease in particle size, influenced the IDM dissolution rate from the particle samples. Modifications in the solid physical state that may occur using different particle size reduction treatments have to be taken into consideration during the scale up and industrial development of new solid dosage forms.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Nanocrystals, consisting of pure drugs and minimum of surface active agents required for stabilization, are carrier-free submicron colloidal drug delivery systems with a mean particle size in the nanometer range, typically between 10 and 1,000 nm (Junghanns and Müller 2008).

In recent years, particle size reduction techniques to nanometric dimensions have gained the attention of both research and pharmaceutical industry. Benefits of nanocrystallization are principally the enhanced dissolution rate and saturation solubility of drugs (Gao et al. 2008; Keck and Müller 2006) An enhancement in dissolution rate is particular important for drugs belonging to class II in the Biopharmaceutical Classification System, for which the dissolution velocity is the rate limiting step for absorption.

Several industrial technologies, originating from small scale techniques, can be applied to obtain nanocrystals. They are frequently classified as bottom-up-precipitation methods, top-down technologies, and combined technologies (Keck and Müller 2006; Junghanns and Müller 2008; Shegokar and Müller 2010; Chan and Kwok 2011; Chen et al. 2011).

Pharmaceutical industry addressed great importance in developing easily scalable techniques, by studying in dept both physical and technological-related aspects.

The investigation of the physicochemical stability of drugs under chemical or mechanical treatment remains essential under drug development (Wu et al. 2011). Actually, many of these techniques may lead to a modification of the drug physical state, such as for example, solid amorphization (Martena et al. 2012; Lindfors et al. 2007; Ali et al. 2009; Zhang et al. 2006), or polymorphic transition (Lai et al. 2009).

In addition, most studies are carried out in the presence of stabilizers such as for example, surfactants (Liu et al. 2011; Ghosh et al. 2011), with the scope of reducing particle aggregation or crystal growth (Verma et al. 2011). However, the presence of additional substances can have a profound effect on the growth of crystals, because impurities can inhibit or enhance growth, as well as exert selective effect, acting only on certain crystallographic faces and thus modifying the crystal habit and/or crystal form (Mullin 1993).

Knowledge of solid state transitions occurring in pure drugs is thus fundamental for developing stable pharmaceutical formulations. This is particularly important because changes in drug physicochemical properties (amorphization, polymorphic form transitions) induced by precipitation or milling techniques might differently affect the drug biopharmaceutical properties such as solubility and dissolution behavior, or drug technological properties such as compression and densification behavior.

The objective of this study is to select very simple and well-known laboratory scale methods able to reduce particle size of indomethacin until the nanometric scale. Several experimental conditions were tested in order to identify those able to give particles in the nanometric range. Any additive, such as for example surfactants, were deliberately avoided to reduce effects on solid state characteristics.

Thus, this study intends to gain insight into solid state stability of indomethacin under different laboratory scale nanosizing techniques, and changes on the biopharmaceutical properties during the pharmaceutical handling of the drug.

Indomethacin, a Non Steroidal Anti-inflammatory Drug (NSAID), is a poorly water soluble active substance with poor bioavailability after oral administration, for which a reduction in particle size may be beneficial.

Nanosuspensions of Indomethacin (IDM) were previously prepared through wet milling in presence of Lutrol® F-68 as stabilizer (Liu et al. 2011; Laaksonen et al. 2011).

In the present study, three different laboratory scale techniques were used to reduce the indomethacin particle size to nanometric dimensions:

-

a.

Method A: Crystallization by solvent evaporation in a nano-spray dryer

-

b.

Method B: Wet milling and lyophilization

-

c.

Method C: Cryo-milling

Experimental procedure

Materials

IDM (Native Crystals: NCs) (γ form) was kindly supplied by Fabbrica Italiana Sintetici (F.I.S., Vicenza, Italy) as white crystalline powder. Native crystals are indicated as NCs in the text. Ultrapure water was produced by Gradient Milli-Q® (Millipore, Molsheim, France). Chemicals, all of analytical purity, were supplied by Sigma-Aldrich (Steinheim, Germany). NCs were stored in a desiccator in presence of P2O5 as desiccant during the experiment time interval.

Preparation of indomethacin α and amorphous forms

The α form of IDM was prepared by a modification of the method of Borka (Borka 1974; Kaneniwa et al. 1985). 10 g of IDM bulk powder was dissolved in 10 ml of ethanol at 80 °C, the undissolved drug was filtered off, and 20 ml of distilled water at room temperature was added to the IDM-saturated ethanol solution at 80 °C. The precipitated crystals were removed by filtration using a glass funnel and then dried overnight in a P2O5 desiccator under vacuum at room temperature. The crystallinity of this material was assumed to be 100 %. The X-ray powder diffraction (XRPD) patterns of this sample were compared to those described in literature (Kaneniwa et al. 1985) to confirm the obtainment of a pure α form.

Amorphous IDM (Otsuka and Kaneniwa 1988) was obtained by cooling in liquid nitrogen after melting the bulk powder at 165 °C for 5 min. The crystallinity of this material, assessed by XRPD, was assumed to be 0 %.

IDM α and amorphous forms were stored in a desiccator in presence of P2O5 as desiccant during the experiment time interval.

Preparation of IDM different batches

Nanocrystals were prepared by three different methods:

-

a.

Method A: Crystallization by solvent evaporation in a nano-spray dryer

Indomethacin was dissolved in a mixture of ethanol:ultrapure water 1:3 at the concentration of 6.0 g/l. The solution was then spray-dried by a Nano Spray Dryer B-90 (Büchi, Flawil, Switzerland) using a membrane with pores of 7 μm, at an inlet temperature of 50 °C and a feeding rate of 90 l/min. The yield was approximately 90 %.

Nanocrystals obtained by this procedure are indicated as Batch A.

-

b.

Method B: Wet milling and lyophilization

A suspension of IDM in water (2 g in 250 ml of water) was prepared and particles were homogenized by an Ultraturrax T25 (IKA®-Werke Gmbh, Staufen, Germany) at 24.000,00 rounds min−1 (Borka 1974) for 15 or 30 min. The two wet milling times were selected in order to identify conditions able to produce particles in the nanometric range. The particle suspension was dried upon lyophilization for 24 h at −30 °C (Vir Tis Benchtop Tray Lyophilizer, SP Scientific, Warminster, PA, USA). Two batches were obtained by milling for 15 and 30 min and named Batch B-15 and Batch B-30, respectively.

-

c.

Method C: Cryo-milling

1 g of IDM powder was ground for 20 or 40 min in a mortar of 500 ml of volume with or without liquid nitrogen. Four different batches were obtained:

-

i.

Batch C-20: dry milled for 20 min without liquid nitrogen.

-

ii.

Batch C-20-N: dry milled for 20 min in the presence of liquid nitrogen.

-

iii.

Batch C-40: dry milled for 40 min without liquid nitrogen.

-

iv.

Batch C-40-N: dry milled for 40 min in the presence of liquid nitrogen.

-

i.

During preliminary steps, in order to assess the batch-to-batch variability, every technique was repeated three times. Everyone resulted highly reproducible, consequently only results of one batch per technique are given.

These different experimental conditions were selected in order to identify those able to produce particles in the nanometric range. All the IDM batches were stored in a desiccator in presence of P2O5 as desiccant during the experiment time interval.

Evaluation of the chemical stability during processing

The evaluation of the chemical stability of IDM during processing was evaluated in accordance to the method described by Nováková et al. (2005). Briefly, an HPLC analysis was performed by a HPLC 1090 Hewlett Packard Series I (Ramsey, MN, USA), equipped with a Hewlett Packard HP1100 MSD Chemstation Rev. A.08.03. The columns were a Zorbax SB-Phenyl (75 mm × 4.6 mm, 3.5 μm) (Agilent Technologies, Agilent, Santa Clara, CA, USA) (column temperature 25 °C). Detection of individual compounds was done with built-in UV–VIS detector. The stock solution of internal standard was prepared by dissolving 50 mg of ketoprofen working standard in 100 ml of methanol. Reference standard solution for indomethacin was prepared in 100 ml volumetric flask by dissolving of 25.0 mg of IDM in methanol. 0.5 g of indomethacin was accurately weighed and was transferred into 50.0 ml centrifuge tube. Twenty milliliters of internal standard working solution in methanol (1 mg/100 ml of ketoprofen in methanol) were added. This mixture was sonicated for 10 min and then centrifuged for 15 min at 1,300×g (Scilogex D3024R, Berlin CT, USA). The supernatant was filtered through the 0.45 μm filters.

The mobile phase consisted of acetic acid:acetonitrile 40:60 (V/V). The experimental pH of the mobile phase was 3.72. pH was checked by a pH meter (Jenway 3510, Essex, England), equipped with a pH electrode (Jenway, Essex, England) calibrated with appropriate standard solutions. The volume of injection was 10 μl and the flow rate 1 ml/min. The mass spectrometer, performed with an electrospray ionization source (ESI), and analysis were carried out in positive single ion monitoring, SIM, ion:340.2, Frag 75 V, ion source 13.0 l/min drying gas flow, nebulizer pressure 60 Psi, drying gas temperature 350 °C, capillary voltage 4,000 V. The chemical stability of IDM was assessed by considering the retention time of chromatogram peaks and their eight. Under the used conditions, typical IDM peak have a retention time of 5.38 min.

Thermogravimetric analysis

Thermogravimetric analysis was carried out by the simultaneous thermal analysis (STA) which enables to simultaneously analyze a sample for change in weight (thermogravimetric analysis, TGA) and change in enthalpy flow (differential scanning calorimetry, DSC). In this text, the thermogravimetric analysis is referred to as STA–TGA. The analysis was performed using a Simultaneous Thermal Analyser (STA 6000, Perkin Elmer, Inc., Waltham, MA, USA), under nitrogen atmosphere (20 ml/min) in 0.07 ml open aluminium oxide pans. Samples were heated from room temperature to 445 K at a heating rate of 10 K/min. STA was calibrated for temperature and heat flow with three standard metals (tin, indium, and zinc), taking into account their expected melting temperatures (505.08, 429.75, 692.68 K, respectively), and for weight with an external Perkin Elmer standard (Calibration Reference Weight P/N N520-0042, Material lot 91101 GB, Weight 55.98 mg, 01/23/08 VT). Calibration was repeatedly checked to assure deviation ≤±0.3 K.

Differential scanning calorimetry analysis

DSC analysis was performed on a Pyris 1 (Perkin Elmer, Co. Norwalk, USA) equipped with a cooling device (Intracooler 2P, Cooling Accessory, Perkin Elmer, Co. Norwalk, USA). A dry purge of nitrogen gas (20 ml/min) was used for all runs. DSC was calibrated for temperature and heat flow using a pure sample of indium and zinc standards. Sample mass was about 4–5 mg and aluminium perforated pans of 50 μl were used. Samples were heated from room temperature to 445 K at a heating rate of 10 K/min.

DSC was also used for the evaluation of the crystalline degree of the samples prepared, taking into account the melting enthalpy value of pure 100 % crystalline forms and the relative enthalpy value of samples under investigation.

X-ray powder diffractometry

X-ray powder diffractometry (XRPD) was carried out on a Philips PW 1730 (Philips Electronic Instruments Corp., Mahwah, NJ, USA) as X-ray generator for Cu Kα radiation (λ α1 = 1.54056 Å, λ α2 = 1.54430 Å) was used. The experimental X-ray powder patterns were recorded on a Philips PH 8203. The goniometer supply was a Philips PW 1373 and the channel control was a Philips PW 1390. Data were collected in the discontinuous scan mode using a step size of 0.01° 2α. The scanned range was 2θ to 40° (2θ).

The crystallinity degree of powders was evaluated by XRPD and calculated according to a previously described method (Gashi et al. 2009). Briefly, a calibration curve was determined from physical mixtures of pure IDM (α or γ form), considered as completely crystalline (100 % crystalline), and IDM completely amorphous (100 % amorphous). The calibration curve was determined, in presence of an internal standard, by calculating the total area (A tot) of the diffraction patterns (crystalline + amorphous) and the area (A Cr) of the crystalline part (the area over the peak baseline). The powder crystallinity degree was expressed according to the following equation (1):

Crystallinity degree represents the average value of three different measurements. The statistical significance was evaluated by a one-way ANOVA test for α = 0.05.

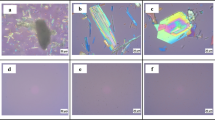

Scanning electron microscopy

Particle morphology was determined using a scanning electron microscope (SEM) (Stereoscan 360, Cambridge Instruments, Cambridge, UK). Samples were mounted on a metal stub with double-sided adhesive tape and then sputtered under vacuum with a gold layer of about 200 Å thickness using a metallizator (Balzer MED 010, Linchestein). The particle size of coarsest crystals was determined by measuring the Ferret’s diameter of 500 particles.

Dynamic light scattering analysis

The nanoparticle size was determined by dynamic light scattering (DLS) (Zetasizer Nano S90, Malvern Instruments, Worcestershire, UK), by dispersing nanocrystals in water under mixing by a vortex. During the analyses, the attenuation and the polydispersity index were checked to verify the appropriateness of the measurements.

Long-term stability study

Long-term stability study (12 months) was carried out according to the ICH (stability testing of new drug substances and products, Q1A(R2), 2003) by storing samples in tightly closed glass containers at 25 °C ± 2 °C/60 % RH ± 5 % RH. The stability was evaluated by DSC and XRPD in order to assess changes in the physical solid form of the IDM samples.

Intrinsic dissolution rate (IDR) study

Dissolution studies were carried out by the rotating disk method (Banakar 1992). Thirteen millimeter diameter tablets were obtained by compressing 300 mg of powder in a Perkin-Elmer hydraulic press for IR spectroscopy KBr disks, at a force of 15 kN for 10 min. This process yielded tablets with a surface area of 132.73 mm2 that would not disintegrate during the test. Tablets were inserted into a stainless steel holder, so that only one face was exposed to the dissolution medium. The holder was then connected to the stirring motor of a dissolution apparatus (Erweka DT6, Gloucestershire, England), centrally immersed in a 1,000-ml beaker containing 900 ml of phosphate buffer (pH 7.2) (buffer solution, USP Pharmacopoeia) at 37 °C and rotated at 50 rpm. Suitable aliquots were withdrawn with a regenerated cellulose filter syringe (0.45 μm; Filalbet, Rosello, Spain) at specified times and assayed for drug content spectrophotometrically at a wavelength of 318 nm. A correction was calculated for cumulative dilution caused by replacement of the sample with an equal volume of fresh medium. Each test was repeated six times. Low standard deviations were obtained, indicating the good reproducibility of this technique. The IDRs were calculated from the slope of the straight line of cumulative drug release.

Dissolution from the particle samples

Dissolution from the particle samples was carried out in sink conditions in a 200-ml beaker containing 100 ml of phosphate buffer (pH 7.2) at 37 °C and rotated at 50 rpm. Suitable aliquots were withdrawn with a regenerated cellulose filter syringe at specified times and assayed for drug content spectrophotometrically at a wavelength of 318 nm. A correction was calculated for cumulative dilution caused by replacement of the sample with an equal volume of original medium. Each test was repeated six times. Low standard deviations were obtained, indicating the good reproducibility of this technique. Results are expressed as percentage of total drug release.

Statistical analysis

Data were analyzed by one-way analysis of variance (ANOVA), using a Bonferoni test. The statistical analysis was conducted using an Origin® software (version 8.5) (Northampton, MA, USA). Results are shown as mean ± SD (standard deviation), and considered significantly different when P < 0.05.

Results and discussion

Preparation of IDM different batches

For the Method A, a new spray dryer, the Nano Spray Dryer B-90 (Büchi Instruments), was used for the generation of particles of nano-dimensions. In this new apparatus, the droplet generation is based on a piezoelectric driven actuator, vibrating a thin, perforated, stainless steel membrane in a small spray cap. The drying gas enters in laminar flow from the top into the drying chamber and is heated up to the set inlet temperature. The piezo-driven spray head generates ultra-fine droplets, which are gently dried into solid particles. The dried solid particles are electrostatically charged and collected at the collecting electrode. The drying gas exits the spray dryer, the outlet temperature is measured and the gas is filtered. The principle of nanospray drying is similar to that of the common spray drying, but it makes use of a stainless steel membrane and a piezoelectric driven actuator for the generation of very small droplets. This makes it possible to obtain very small particles in the nanometer range with a very small particle size dispersion. Another important advantage with the respect to the classical spray drying technique (laboratory scale) is the higher yield and batch to batch reproducibility. The nanospray drying technique has been previously applied by the same authors to nicergoline (Martena et al. 2012). Interestingly, this technique favored the recovery of nicergoline nanoparticles in the amorphous state showing significant improvement of solubility and dissolution rate. This result encouraged the authors to apply this interesting technique to indomethacin. Several essays were preliminary performed to assess the formation of indomethacin nanoparticles by means of the new nanospray drying technique. Several parameters were modified such as the solvent, the inlet temperature, and the feeding rate. Selected conditions, described in the paragraph “Preparation of nanoparticles”, were used to produce several batches all showing a good reproducibility of the powder characteristics, in terms of mean particle size, particle size dispersion, and physical state. For the sake of simplicity, only the results of a batch identified as Batch A are shown.

The formation of nanocrystals by the nanospray drying was firstly confirmed by SEM (Fig. 1). IDM native crystals (NCs) were rather irregular in shape and size, and characterized by the presence of round edges. Batch A nanocrystals (Fig. 1d) were also irregular in shape, but edges were more rounded. No spherical particles were observed. In addition, several needle-shape crystals were present. In a previous work (Kaneniwa et al. 1985), it was described that particles of polymorphic γ form were irregular, while particles of polymorphic α form were needle-shaped. The reported finding allowed hypothesizing a change in the crystalline form of Batch A upon spray-drying, as compared to native crystals. A discussion concerning this aspect will be provided in the subsequent paragraphs. A representation of the particle size distribution determined by DLS for the Batch A and compared to that of NCs determined by SEM analysis is given in Table 1 and Fig. 2. The aqueous nanosuspension of Batch A had a mean particle diameter of 0.59 ± 1.28 μm (polydispersity index: 0.42), while the mean particle diameter of NCs was 9.24 ± 5.30 μm. In addition, if for NCs no particles under 1,000 nm were identified, for Batch A 94 % of particles are under 1,000 nm.

Comparison of particle size distribution of indomethacin batches. Native crystals (NCs) and Batch A obtained by the method A: crystallization by solvent evaporation in a nano-spray dryer (a); native crystals (NCs) and Batches B-15 and B-30 obtained by the method B: wet milling and lyophilization (b); native crystals and Batches C-20, C-20-N, C-40, and C-40-N obtained by method C: cryo-milling

Concerning the evaluation of the crystalline form of Batch A, the coexistence of particles of different shape, rounded and needle-like would lead to conclude that Batch A consisted of a mixture of two different polymorphic forms. It has been previously reported that three different polymorphic forms of IDM were isolated (form β, also named III, has been never isolated) (Borka 1974; Yamamoto 1968; Allen and Kwan 1969; Monkhouse and Lach 1972; Legendre and Feutelais 2004), characterized by three different extrapolated onset melting temperature (T m): γ (also named form I) (T m: 157.9 °C), α (also named form II) (T m: 151.4 °C), and δ (also named form IV) (T m: 130.6 °C) (Crowley and Zografi 2002). In our study, it was shown that the crystallization of IDM under spray drying of native crystals (form γ) induced the formation of crystals prevalently composed by the α form, in presence of a certain amount of γ form. Based on DSC analysis, it is possible to observe only one peak corresponding to the melting of the α form (Table 2). The absence of any transition peaks or additional melting peaks regardless of the heating rate (from 1 to 40 °C min−1) might demonstrate the crystallographic purity of Batch A. However, the XRPD analysis showed that the patterns of the spray-dried particles corresponded to a mixture of α and γ form (Fig. 3), as also confirmed by comparing the diffractogram to that of a pure α form prepared in our laboratory as reference material.

Comparison of indomethacin X-ray powder diffraction patterns. Native crystals (NCs) are compared to nanoparticles obtained by the other three methods. a Batch A produced by the method A: crystallization by solvent evaporation in a nano-spray dryer is also compared to the α and amorphous forms. b Batch B-30 produced by the method B: Wet milling and lyophilization. c Batches C-40 and C-40-N produced by the method C: Cryo-milling

The formation of the metastable α form (lower melting temperature as compared to the γ form) by a spray drying process is due to the fact that the two polymorphs α and γ have a monotropic relationship and thus in a bottom up technique such as the spray drying the generation of the metastable α polymorph is expected. Actually, the very fast evaporation of the solvent from the solution, typical of the spray drying process, favors the nucleation and growth of the metastable form α, which is the form of higher energy content (free Gibbs energy) and higher disorder degree (entropy) (Grant 1999).

In addition, in Fig. 3a, it is possible to observe a clear decrease in the peak intensity and a certain curvature of the baseline. This behavior suggests a loss in crystallinity degree that was confirmed by evaluating the percentage of the crystalline part as compared to the amorphous one through XRPD. Calculations demonstrated a crystallinity degree of 45.0 ± 5.0 % for the Batch A. The lower crystallinity degree of Batch A may also be highlighted by the lower enthalpy variation with the respect to the native α form and from DSC measurement the percentage of crystalline part resulted near to the 78 %. It must be noted a noticeable difference between the crystallinity degree calculated from XRPD and DSC methods. Authors believe the XRPD method less accurate than the DSC one. Actually, the first one is based on the measurement of the areas corresponding to the crystalline and amorphous parts directly on the diffractograms by using the Origin® Pro 7SR2 program (OriginLab Corporation, Northampton, MA, USA). On the contrary, the enthalpy measurement through the DSC analysis may be considered more accurate.

Concerning the evaluation of IDM chemical stability, the only peak detected in the chromatograms of samples under investigation is that typical of pure IDM (5.38 min). The integration of peak area may range from 98.50 to 99.98 % for any sample. These results confirm the chemical stability of IDM under different treatments. Values remain the same also under long-term stability study.

The Method B consisted in reducing the particle size by using a simple laboratory scale equipment, that is an homogenizer. The process time was determined by measuring the time necessary to obtain particles of constant size, so that further increase in milling time did not translate into decrease in particle size. After several preliminary essays, the maximum milling time was fixed at 30 min and for comparison a process time consisting in the half max time was also considered (15 min). By this way, two different batches were obtained, the Batches B-15 and B-30. From native crystals to Batches B-15 and B-30, the particles size reduction was clearly evident. It is significant that while a time milling of 15 min was unable to reduce particle size under 1,000 nm, increasing milling time to 30 min favored the recovery of nanoparticles (Table 1; Fig. 2b). At the end of this process, about 62.0 % of particles possessed a particle size smaller than 1,000 nm (mean particle size 0.85 ± 3.75 μm; polydispersity index: 0.63). Particle shapes of Batches B-15 and B-30 appeared very similar to native crystals (Fig. 1e, f). It was further shown that milling did not affect IDM crystallographic form, as shown by DSC (Table 2) and XRPD (Fig. 3b) analyses: IDM of Batches B-15 and B-30 remained in their γ form, and no significant changes in crystallinity were observed (Table 2; Fig. 3). Actually, the evaluation of the crystalline degree based on DSC analysis revealed values nearly 96 and 95 %, respectively, for Batches B-15 and B-30. The crystallinity degree evaluated by XRPD was in this case very close to those values (97.8 and 97.5 %, respectively for Batches B-15 and B-30.

The Method 3, the cryo-milling, was applied in order to evaluate the effect of very low temperatures on the particle size reduction of IDM. The limit of classical mechanical milling techniques is that particle size reduction is limited to 2–3 μm and no nanoparticles are obtained (Jimbo 1986). The cryo-milling is an attractive technique because solids usually become brittle under super cold conditions. In this study, cryo-milling was applied by simply milling IDM in a mortar with the pestle upon the addition of liquid nitrogen directly on the powder. Liquid nitrogen is an inert liquid possessing several interesting properties, such as a very low temperature (−196 °C), low viscosity and surface tension, spontaneous volatility, wide availability, low cost. Consequently, many advantages may arise from the application of the cryo-milling in the presence of liquid nitrogen. One particular interesting aspect of the cryo-milling is the spontaneous removal of the liquid at room temperature without any adsorption effect that makes this technique advantageous as compared to other wet milling techniques (such as for example, the one used in Method B, which request to remove solvent by any technique, in our case lyophilization). Despite all the advantages, this technique has been applied to a limited extend up to now, and some encouraging results have been only recently described for the preparation of nanocrystals of phenytoin (Niwa et al. 2010). To our knowledge, milling in cryogenic media has not been reported up to now for the development of pharmaceutical dosage forms.

SEM microphotographs (Fig. 1g, h, i, l) clearly showed a progressive reduction in particle size by increasing the milling time (from 20 to 40 min) and in the presence of liquid nitrogen (from Batch C-20 to Batch C-20-N; from Batch C-40 to Batch C-40-N). Particles appeared irregular and a certain tendency to particle agglomeration must be highlighted particularly for Batches C-20-N, C-40, and C-40-N. The particle size reduction is clearly shown in Fig. 2c and Table 1, where the progressive size reduction from native crystals, Batches C-20, C-20-N, C-40, to C-40-N is highlighted. The cryo-milling for 40 min turned out to be very efficacious to obtain IDM nanoparticles. Actually, grounding for 40 min allowed downsizing the particles up to nanometric size, with nearly 73.0 % of the sample below 1,000 nm.

In this study, under cryo-milling no polymorphic transitions must be highlighted (Table 2; Fig. 3). On the contrary, a decrease in crystallinity degree was observed for Batch C-40-N: while 86.7 % of Batch C-40 was crystalline, 77.4 of Batch C-40-N was crystalline as determined from DSC determination. Close values were obtained from XRPD measurements: while 95.0 ± 3.5 % of Batch C-40 was crystalline, 67.0 ± 6.7 % of Batch C-40-N was crystalline.

In a previous study, Crowley and Zografi (2002), described the obtainment of a completely amorphous IDM under cryogenic grinding, performed for 60 min using a cryogenic impact mill. The results of the two studies appear not comparable because the two grinding procedures are rather different in terms of equipment, process time, and energy involved. The impact mill undoubtedly impacts the process with a higher energy, thus being responsible for the complete destruction of the IDM lattice. Because the study of Crowley and Zografi (2002) was above all devoted to the identification of the conditions able to recover a completely amorphous form, less attention was paid to the particle size decrease, particularly in term of the possibility to obtain particles of nano-dimensions. On the contrary, in our study we were able to demonstrate that milder conditions may lead to the obtainment of crystals of nanoparticles dimensions avoiding the complete destruction of the crystal lattice; consequently, during the scale up it will be necessary to foresee conditions able to reduce the particle size with a minimum effect on the crystallinity degree in order to minimize all the negative effects on the product shelf life.

Finally, the powder weight loss, determined by STA-TGA between 20 and 140 °C, revealed very low values for any samples, which may lead to predict a very poor effect of residual solvent on physicochemical and biopharmaceutical properties.

Long-term stability of the samples

The absence of any stabilizer for the batch production has the major consequence of a considerable agglomeration tendency. Once produced particles are in the solid physical state. They were dispersed in water by a vortex for 30 s in order to proceed with the DLS analysis and the evaluation of particle size. Samples of particle size higher than 3 μm could not be analyzed by this technique and thus were evaluated by SEM analysis. By this technique the agglomeration tendency was already pointed out. Only samples of particle size lower than 3 μm were thus measured by DLS. After 1 week from the production, the possibility to disperse the particles by the vortex was reduced for any sample, thus confirming a noticeable tendency to particle agglomeration. An evaluation of the particle size during long-term stability was impossible due to the inability to redisperse the powder in individual particles. For the same reason, dissolution studies were not repeated for long-term stability evaluation. In further studies, it will be necessary to introduce an appropriate stabilizer to avoid particle aggregation under storage, but as previously stated this was not in the aim of the present study.

The long-term stability study was thus only carried out to verify a change in the solid physical state of sample under investigation. As shown in Table 2, a slight tendency to crystallization was observed for any sample.

Intrinsic dissolution rate and dissolution from the particle samples

The IDR of IDM samples was determined in phosphate buffer (pH 7.2) (Table 3). The IDR of IDM native crystals was found similar to that of crystals obtained by method B and C, and differences were not statistically different, with the exception of Batch C-40-N. This result is in agreement with the results previously reported with respect to the fact that methods B and C did not involve a modification in the physical state, with the exception of a certain loss in the crystallinity degree for the Batch C-40-N. Actually, it is well known that IDR is not influenced by the powder particles size or agglomeration tendency, but rather by the solid physical state, i.e., crystallinity degree, and/or polymorphic form. Thus, the observation that the Batch C-40-N showed higher IDR is due to its lower crystallinity degree. For comparison, the IDR of amorphous particles was also determined revealing in this case the highest IDR.

The IDR of Batch A was significantly higher than that of NCs. The explanation can be found in the different crystalline form of the two powders, as previously stated. Batch A is a mixture of α form, γ form, and amorphous solid. The α form and the amorphous solid showed higher IDR as compared to native crystals, confirming the influence of their higher solubility on this parameter (Borka 1974). The analysis of variance revealed that cumulative drug releases of native crystals (γ form), Batch A and IDM α form were significantly different (significance level P < 0.05).

The dissolution of IDM from the particle samples reflected differences in particle size and in IDR, which means solid physical state. Results of particle dissolution rates of IDM samples are given in Fig. 4. The cumulative drug release of Batch A (Fig. 4a) was significantly higher than that of NCs (γ form) and differences are statistically relevant (significance level P < 0.05). Its cumulative drug release was also compared to those of a reference α form and an amorphous form previously described: the cumulative drug release of the Batch A is intermediate between that of the amorphous form (which is the highest one) and that of the pure polymorph α form. This evidence clearly demonstrates that the dissolution from particles of Batch A is influenced by its physical form (as demonstrated before it is a mixture of α and γ form with a certain % of amorphous part). Undoubtedly differences in particles size may play a significant role according to the Noyes–Whitney’s equation (Noyes and Whitney 1897), which states the lower the particle size, the higher the surface area exposed to the dissolution medium, and consequently the higher the dissolution rate.

Cumulative drug release % of NIC samples in phosphate buffer pH 7.2. In each graph, particle dissolution is compared to that of native crystals (NCs). a Batch A produced by the method A: crystallization by solvent evaporation in a nano-spray dryer. b Batches B-15 and B-30 produced by the method B: Wet milling and lyophilization. c Batches C-40 and C-40-N produced by the method C: Cryo-milling

Concerning the method B, the Batch B-30 showed a particle dissolution rate higher than that of Batch B-15, and higher of the NCs. Particularly interesting is the faster dissolution of the Batches B-15 and B-30 during the first minutes of the process, that may be explained by the higher particle surface exposed to the dissolution medium, due to the milling procedure, and lyophilization, this last increasing the affinity of the powder for the solvent.

The cumulative drug release of samples obtained by method C was always higher than that of reference IDM. In particular, the particle dissolution of Batches C-40 and C-40-N was higher than that of NCs. Obviously, this result was influenced by the particle size reduction, but also by the reduction in crystallinity degree (higher IDR) for the Batch C-40-N.

As indicated in “Introduction”, the use of surfactants was deliberately avoided in order to limit their possible effect on the IDM physical state. Anyway, during the product scale up the particle stabilization by surfactants is unavoidable (Wu et al. 2011), since they are utmost important for the colloidal stability of particles. In this case, it may be also foresee an influence of the surfactant on the dissolution from the particles.

Conclusions

The three laboratory scale methods described in this work, the crystallization by solvent evaporation in a nano-spray dryer, the wet milling and lyophilization, and the cryo-milling proved effective in reducing the indomethacin particle size to nanometric dimensions. During these treatments, IDM was subjected to modifications of the physicochemical state (polymorphic state modification, and/or decrease in crystallinity degree), which resulted in the altered dissolution behavior of IDM. The investigation of the physicochemical stability of drugs under chemical or mechanical treatments remains essential in drug development and knowledge of solid state transitions occurring in pure drugs is fundamental for developing stable pharmaceutical formulations.

According to the results obtained from this study, the method A permitted to obtain the particles of lower size, characterized by an interesting increase in drug dissolution. This technique promote the crystallization of the IDM in a mixture composed in part by an amorphous solid and in part by a mixture of two polymorphs, the stable γ form and the metastable α form. As proven by the long-term stability studies, these particles tend to increase the crystallinity degree with a possible loss/modification of the dissolution properties during its shelf life.

The method B permitted to obtain the best product first of all because the dissolution from particle sample was the fastest one (even if the particle size reduction to micrometric scale was inferior to that obtained through the other methods), and also because of the physical stability under the treatment: no change in polymorphic form, no decrease in crystalline degree were observed, with an important impact on the shelf life of the product.

The method C showed an interesting increase in particle dissolution, even if a certain tendency to decrease of crystalline degree must be highlighted, with a certain tendency to crystallization that is expected to induce a modification in the particle dissolution during the product shelf life.

Starting from the preliminary results obtained during the laboratory scale phase, the scale up may be oriented to point out possible criticisms during the industrialization of a new drug product, such as the modification of the physical state and the physicochemical stability. In addition, in next studies, appropriate stabilizers will be added to IDM to evaluate their influence on the crystalline solid form, particle size decrease, and stabilization under long-term conditions.

References

Ali HSM, York P, Blagden N (2009) Preparation of hydrocortisone nanosuspension through a bottom-up nanoprecipitation technique using microfluidic reactors. Int J Pharm 375:107–113

Allen DJ, Kwan KC (1969) Determination of degree of crystallinity in solid–solid equilibria. J Pharm Sci 58:1190–1193

Banakar UV (1992) Pharmaceutical dissolution testing. In: Swarbrick J (ed) Pharmaceutical dissolution testing. Marcel Dekker, New York, pp 55–105

Borka L (1974) The polymorphism of indomethacin. Acta Pharm Suec 11:295–303

Chan H-K, Kwok PCL (2011) Production methods for nanodrug particles using bottom-up approach. Adv Drug Del Rev 63:406–416

Chen H, Khemtong C, Yang X, Chang X, Gao J (2011) Nanonization strategies for poorly water-soluble drugs. Drug Discov Today 16:354–360

Crowley KJ, Zografi G (2002) Cryogenic grinding of indomethacin polymorphs and solvates: assessment of amorphous phase formation and amorphous phase physical stability. J Pharm Sci 91:492–507

Gao L, Zhang D, Chen M (2008) Drug nanocrystals for the formulation of poorly soluble drugs and its application as a potential drug delivery system. J Nanopart Res 10:845–862

Gashi Z, Censi R, Malaj L, Gobetto R, Mozzicafreddo M, Angeletti M, Masic A, Di Martino P (2009) Differences in the interactions between different aryl propionic acid derivatives and poly(vinylpyrrolidone) K30:a multi-methodological approach. J Pharm Sci 98:4216–4228

Ghosh I, Bose S, Vippagunta R, Harmon F (2011) Nanosuspension for improving the bioavailability of a poorly soluble drug and screening of stabilizing agents to inhibit crystal growth. Int J Pharm 409:260–268

Grant DJW (1999) Theory and origin of polymorphism. In: Brittain HG (ed) Polymorphism in pharmaceutical solids. Marcel Dekker, New York, pp 227–278

Jimbo G (1986) Recent formulation technologies and their application 3. Iyaku, Journal Inc, Tokyo, pp 168–172

Junghanns JHAH, Müller RH (2008) Nanocrystal technology, drug delivery and clinical applications. Int J Nanomed 3:295–309

Kaneniwa N, Otzuka M, Hayashi T (1985) Physicochemical characterization of indomethacin polymorphs and the transformation kinetics in ethanol. Chem Pharm Bull 33:3447–3455

Keck MC, Müller RH (2006) Drug nanocrystals of poorly soluble drugs produced by high pressure homogenization. Eur J Pharm Biopharm 62:3–16

Laaksonen T, Liu P, Rahikkala A, Peltonen L, Kauppinen EI, Hirvonen J, Järvinen K, Raula J (2011) Intact nanoparticulate indomethacin in fast-dissolving carrier particles by combined wet milling and aerosol flow reactor methods. Pharm Res 28:2403–2411

Lai F, Sinico C, Ennas G, Marongiu F, Marongiu G, Fadd AM (2009) Diclofenac nanosuspensions influence of preparation procedure and crystal form on drug dissolution behavior. Int J Pharm 373:124–132

Legendre B, Feutelais Y (2004) Polymorphic and thermodynamic study of indomethacin. J Therm Anal Calorim 76:255–264

Lindfors L, Skantze P, Skantze U, Westergren J, Olsson U (2007) Amorphous drug nanosuspensions. Particle dissolution and crystal growth. Langmuir 23:9866–9874

Liu P, Rong X, Laru J, Van Veen B, Kiesvaara J, Hirvonen J, Laaksonen T, Peltonen L (2011) Nanosuspensions of poorly soluble drugs: preparation and development by wet milling. Int J Pharm 411:215–222

Martena V, Censi R, Hoti E, Malaj L, Di Martino P (2012) A new nano spray drying method for the preparation of nicergoline pure nanoparticles. J Nanopart Res 14:934

Monkhouse DC, Lach JL (1972) Use of adsorbents in enhancement of drug dissolution. J Pharm Sci 61:1435–1441

Mullin JW (1993) Crystallization, 3rd edn. Butterworth-Heinemann, Oxford

Niwa T, Nakanishi Y, Danjo K (2010) One-step preparation of pharmaceutical nanocrystals using ultra cryo-milling technique in liquid nitrogen. Eur J Pharm Sci 41:78–85

Nováková L, Matysová L, Havlíková L, Solich P (2005) Development and validation of HPLC method for determination of indomethacin and its two degradation products in topical gel. J Pharm Biomed Anal 37:899–905

Noyes A, Whitney WR (1897) The rate of solution of solid substances in their own solutions. J Am Chem Soc 19:930–934

Otsuka M, Kaneniwa N (1988) A kinetic study of the crystallization process of noncrystalline indomethacin under isothermal conditions. Chem Pharm Bull 36:4026–4032

Shegokar R, Müller RH (2010) Nanocrystals: industrially feasible multifunctional formulation technology for poorly soluble actives. Int J Pharm 399:129–139

Verma S, Kumar S, Gokhale R, Burgess DJ (2011) Physical stability of nanosuspensions: investigation of the role of stabilizers on Ostwald ripening. Int J Pharm 406:145–152

Wu L, Zhang J, Watanabe W (2011) Physical and chemical stability of drug nanoparticles. Adv Drug Del Rev 63:456–469

Yamamoto H (1968) 1-Acyl-indoles. II. A new syntheses of 1-(ion-chlorobenzoyl)-5-methoxy-3-indolacetic acid and its polymorphism. Chem Pharm Bull 16:17–19

Zhang X, Xia Q, Gu N (2006) Preparation of all-trans retinoic acid nanosuspensions using a modified precipitation method. Drug Dev Ind Pharm 32:857–863

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Martena, V., Censi, R., Hoti, E. et al. Indomethacin nanocrystals prepared by different laboratory scale methods: effect on crystalline form and dissolution behavior. J Nanopart Res 14, 1275 (2012). https://doi.org/10.1007/s11051-012-1275-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-012-1275-9