Abstract

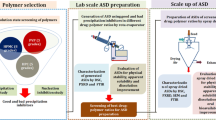

The objective of this study was to develop and examine innovative and very simple and easily scalable techniques able to improve solubility and/or dissolution rate and thus oral bioavailability of nimesulide. Three different nimesulide batches were obtained by three different laboratory-scale methods: Method A (Batch A) used crystallization by solvent evaporation in a nanospray dryer, Method B (Batches G and GLN) involved cryo-milling, and Method C (Batch Neu) dispersed nimesulide in Neusilin® UFL2. All the nimesulide batches were fully characterized for chemical stability, thermal behaviour, physicochemical and micromeritics properties, and intrinsic dissolution and particle dissolution rates. Batch A not only showed a good reduction in particle size but also exhibited a reduced degree of crystallinity by both differential scanning calorimetry and X-ray powder diffractometry, which could explain the increase in intrinsic dissolution rate (IDR) and particle dissolution. Batch GLN showed an acceptable increase in IDR, probably caused by a slight decrease in the degree of crystallinity, and good improvement in dissolution rate due to a certain decrease in particle size. Batches G and native crystals exhibited very close IDRs, while G showed somewhat higher particle dissolution, probably attributed to the particle size reduction. The dispersion of nimesulide in Neusilin UFL2 in a 1:6 drug–polymer ratio made it possible to recover anamorphous powder, as proven by thermal analysis and X-ray powder diffractometry, characterized by pronounced particle size reduction to nanometric dimensions. Both amorphous character and nanometric dimensions could account for the fastest particle dissolution during the first 10 min of the experiment. The stability study conducted according to the International Conference on Harmonization (ICH) confirmed the good chemical and physicochemical stability of all the batches.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The objective of this study was to develop and examine potential use on the several innovative and very simple industrial-level laboratory-scale methods for increasing the particle dissolution rate and thus drug bioavailability of nimesulide. A full physicochemical and stability evaluation was done through several techniques such as scanning electron microscopy, thermal analyses, X-ray powder diffractometry, HPLC.

Nimesulide is a typical non-steroidal anti-inflammatory drug (NSAID) widely used in solid oral formulations. It has analgesic, anti-inflammatory, and anti-pyretic properties, being an inhibitor of prostaglandin synthetase and of platelet aggregation [1, 2]. Nimesulide is a preferential selective COX-2 inhibitor and thus suppresses prostaglandin synthesis from arachidonic acid by hindering the COX pathway. It is 5- to 16-fold more selective for COX-2 than for COX-1 [3].

Because nimesulide has very poor water solubility (0.01 mg mL−1) and thus oral bioavailability, the pharmaceutical industry has been seeking methods to improve its bioavailability that are economical and easily applicable to the industrial level.

Some of the more frequent approaches for improving drug bioavailability are the reduction in particle size [4], including micronization [5] and more recently nanonization [6–12], salt formation [13], use of cosolvents [14], crystallization engineering [15–17], inclusion complexation [18], cogriding [19], and solid dispersion [20–23]. Several technological approaches have afforded increased nimesulide solubility and/or dissolution rate and thus bioavailability [24–29].

However, many of the approaches generally applied to improve drug bioavailability may induce solid-state transitions of drug, and thus close evaluation is required in order to choose those able to yield stable pharmaceutical formulations [12, 22, 30, 31].

In the present study, three different laboratory-scale techniques were used to reduce nimesulide particle size and/or modify its solid state:

-

a.

Method A: Crystallization by solvent evaporation in a nanospray dryer,

-

b.

Method B: Cryo-milling, and

-

c.

Method C: Nimesulide dispersion in Neusilin® UFL2.

Experimental

Materials

Nimesulide (NIM) (native crystals—NCs) was kindly supplied by Procos S.p.A. (Novara, Italy) as yellow crystalline powder. NCs were stored in a desiccator in the presence of P2O5 as desiccant during the experiment time interval. Ultrapure water was produced by Gradient Milli-Q® (Millipore, Molsheim, France). Chemicals, all of analytical purity, were supplied by Sigma-Aldrich (Steinheim, Germany). Neusilin® UFL2 was kindly supplied by Seppic (Paris, France).

Preparation of nimesulide different batches

Samples were prepared by three different methods:

-

a.

Method A: Crystallization by solvent evaporation in a nanospray dryer

Nimesulide was dissolved in ammonia at the diluted concentration of 6.0 g L−1. The solution was then spray-dried by a Nano Spray Dryer B-90 (Büchi, Flawil, Switzerland) using a membrane with pores of 7 μm, at an inlet temperature of 90 °C and a feeding rate of 85 L min−1. The yield was approximately 90 %. Nanocrystals obtained by this procedure were indicated as Batch A.

-

b.

Method B: Cryo-milling

Twenty grams of NIM powder was ground for 40 min in a mortar with or without liquid nitrogen, thus obtaining two different batches:

-

i.

Batch G: dry milled for 40 min without liquid nitrogen.

-

ii.

Batch GLN-20-N: dry milled for 40 min in the presence of liquid nitrogen.

-

i.

-

c.

Method C: Nimesulide dispersion in Neusilin® UFL2

An appropriate amount of nimesulide and Neusilin® UFL2 and 15 % of polysorbate 80 (Tween® 80) were dispersed in acetone. The suspension was stirred under heating at 35 °C for 10 min. The solvent was then evaporated at 35 °C under reduced pressure (Rotavapor® R-210, Buchi, Flawil, Switzerland; vacuum pump, V-710, Buchi, vacuum level 680 mmHg). This product was identified as Batch Neu. In order to find the best ratio NIM–Neusilin appropriate to obtain a completely drug dispersion, several batches were produced and analysed:

-

Batch Neu 1:2: NIM 100 mg + NEU 200 mg (theoretical NIM content 33.3 %);

-

Batch Neu 1:4: NIM 100 mg + NEU 400 mg (theoretical NIM content 20.0 %);

-

Batch Neu 1:6: NIM 100 mg + NEU 600 mg (theoretical NIM content 14.3 %).

-

During preliminary steps, in order to assess the batch-to-batch variability, each technique was repeated three times. As each one proved to be highly reproducible, for the sake of simplicity it was decided to report the results of only one batch per technique.

Evaluation of the chemical stability during processing

The chemical stability of NIM during processing was evaluated through HPLC analysis, performed using an HPLC 1090 Hewlett Packard Series I (Ramsey, MN, USA) equipped with a Hewlett Packard HP1100 MSD Chemstation Rev. A.08.03. An Inertsil column was (C18, 5 m, 150 mm × 4.6 mm) (GL Science, Eindhoven, The Netherlands) used at 25 °C. Twenty-five milligrams of NIM was dissolved in methanol and passed through 0.45 filters (Millipore, Molsheim, France). The mobile phase consisted in acetonitrile–methanol–water (40:40:20) (diluted orthophosphoric acid). The experimental pH of the mobile phase was 4.5, measured by a pH meter (Jenway 3510, Essex, England) equipped with a pH electrode (Jenway, Essex, England) calibrated with appropriate standard solutions. The volume of injection was 20 μL, and the flow rate was 1 mL min−1. Detection was done at 276 nm. The chemical stability of IDM was assessed by considering the retention time of chromatogram peaks and their area. Under the conditions used, typical NIM peak had a retention time of 4.67 min.

Simultaneous thermal analysis

The water content of the samples was determined by simultaneous thermal analysis (STA), which can simultaneously analyse a sample for change in mass (thermogravimetric analysis, TG) and change in enthalpy flow (differential scanning calorimetry, DSC). The analysis was performed with a Simultaneous Thermal Analyser (STA 6000, Perkin Elmer, Inc, Waltham, MA, USA) under nitrogen atmosphere (20 mL min−1) in 0.07-mL open aluminium oxide pans. STA was calibrated for temperature and heat flow with two standard metals (indium and tin), taking into account their expected melting temperatures (156.45 and 231.78 °C, respectively), and for mass with an external Perkin Elmer standard (Calibration Reference Mass P/N N520-0042, Material lot 91,101 GB, Mass 55.98 mg, 01/23/08 VT). Calibration was repeatedly checked to assure deviation ≤±0.3 °C. The scanning analysis was performed on samples (approximately 10 mg) tested in quadruplicate by heating them from 20 to 180 °C at a heating rate of 10 C min−1.

Differential scanning calorimetry analysis (conventional DSC)

Differential scanning calorimetry (DSC) analysis was performed on a Pyris 1 machine (Perkin Elmer, Co, Norwalk, USA) equipped with a cooling device (Intracooler 2P, Cooling Accessory, Perkin Elmer, Co, Norwalk, USA). To be distinguished from DSC carried out through the STA technique, this DSC analysis is identified as conventional DSC. A dry purge of nitrogen gas (20 mL min−1) was used for all runs. DSC was calibrated for temperature and heat flow using a pure sample of indium and zinc standards. Sample mass was about 4–5 mg, and aluminium perforated pans of 50 µl were used. Samples were heated from room temperature to 180 °C at a heating rate of 10 °C min−1.

DSC was also used to evaluate the crystalline degree of the samples prepared, taking into account the melting enthalpy value of starting NCs to that a 100 % value of crystalline forms was attributed arbitrarily. The crystallinity degree of the other samples was thus determined with respect to the enthalpy value of the reference sample.

X-ray powder diffractometry

X-ray powder diffractometry (XRPD) was carried out on a Philips PW 1730 (Philips Electronic Instruments Corp, Mahwah, NJ, USA) as X-ray generator for Cu Kα radiation (λ α1 = 1.54056 Å, λ α2 = 1.54430 Å). The experimental X-ray powder patterns were recorded on a Philips PH 8203 recorder. A Philips PW 1373 goniometer supply and a Philips PW 1390 channel control were used. Data were collected in the discontinuous scan mode using a step size of 0.01° 2α. The scanned range was 2 θ to 40° (2 θ).

Scanning electron microscopy

Nanocrystal morphology was determined using a scanning electron microscope (SEM) (Stereoscan 360, Cambridge Instruments, Cambridge, UK). Samples were mounted on a metal stub with double-sided adhesive tape and then sputtered under vacuum with an approximately 200 Å thick layer of gold using a metallizator (Balzer MED 010, Linchestein). The particle size of the coarsest crystals was determined by measuring the Ferret’s diameter of 500 particles.

Dynamic light-scattering analysis

The nanocrystal size was determined by dynamic light scattering (DLS) (Zetasizer Nano S90, Malvern Instruments, Worcestershire, UK) by dispersing nanocrystals in water in a vortex mixer. During the analyses, the attenuation and the polydispersity index were checked to verify the appropriateness of the measurements.

Intrinsic dissolution rate (IDR) study

Dissolution studies were carried out by the rotating disc method [32]. Thirteen-millimetre-diameter tablets were obtained by compressing 300 mg of powder in a Perkin Elmer hydraulic press for IR spectroscopy KBr discs, at a force of 15 kN for 10 min. This process yielded tablets with a surface area of 132.73 mm2 that would not disintegrate during the test. Tablets were inserted into a stainless steel holder, so that only one face was exposed to the dissolution medium. The holder was then connected to the stirring motor of a dissolution apparatus (Erweka DT6, Gloucestershire, England), centrally immersed in a 1000-mL beaker containing 900 mL of phosphate buffer (pH 7.2) (buffer solution, USP Pharmacopoeia) at 37 °C and rotated at 100 rpm. Suitable aliquots were withdrawn with a regenerated cellulose filter syringe (0.45 μm; Filalbet, Rosello, Spain) at specified times and assayed for drug content spectrophotometrically at a wavelength of 397 nm for 20 min. A correction was calculated for cumulative dilution caused by replacement of the sample with an equal volume of fresh medium. Each test was repeated six times. Low standard deviations were obtained, indicating the good reproducibility of this technique. The intrinsic dissolution rates (IDRs) were calculated from the slope of the straight line of cumulative drug release.

Dissolution from the particle samples

Dissolution from the particle samples was carried out in sink conditions in a 500-mL beaker containing 100 mL of phosphate buffer (pH 7.2) at 37 °C and rotated at 100 rpm (Erweka DT6, Gloucestershire, England). Suitable aliquots were withdrawn with a regenerated cellulose filter syringe at specified times and assayed for drug content spectrophotometrically at a wavelength of 397 nm. A correction was calculated for cumulative dilution caused by replacement of the sample with an equal volume of original medium. Each test was repeated six times. Low standard deviations were obtained, indicating the good reproducibility of this technique. Results are expressed as percentage of total drug release.

Long-term stability study

The long-term stability study (12 months) was carried out according to the ICH [stability testing of new drug substances and products, Q1A(R2), 2003] by storing samples in tightly closed glass containers at 25 ± 2 °C/60 % RH ± 5 % RH. The stability was evaluated by HPLC to confirm chemical stability under technological treatments, by DSC and XRPD to assess changes in the physical solid form of the IDM samples and by particle dissolution to look for changes in dissolution behaviour.

Statistical analysis

Data were analysed by one-way analysis of variance (ANOVA), using a Bonferroni test. The statistical analysis was conducted using an Origin® software (version 8.5) (Northampton, MA, USA). Results are shown as mean ± SD (standard deviation) and considered significantly different when P < 0.05.

Results and discussion

Evaluation of chemical and physicochemical properties

Before characterizing batches of NIM at the solid state produced by the different methods, it was necessary to evaluate their chemical stability to assure that the results observed were not influenced by chemical effects. For all the batches, only the peak typical of pure NIM in the chromatograms was detected, its typical retention time being 4.67 min. The integration of the peak area of different batches may range from 99.50 to 99.98 % for any sample. These results confirmed the chemical stability of NIM under different treatments and the absence of impurities in both starting and processed materials. The chemical stability of different batches was again evaluated after one year of storage, and no changes in the chromatograms in the integration peak areas were noted, confirming the good chemical stability of nimesulide under our three treatments.

The Nano Spray Dryer B-90 is a recent and innovative technique and emerged as very interesting technique to reduce particle size of active pharmaceutical ingredients and to prepare nanoparticles. It has been more frequently suggested preparing polymeric nanoparticles, but also to encapsulate proteins, or for the preparation of inhalable NSAID powders [33–35].

In our laboratory, this technique has been proposed to reduce particle size of active pharmaceutical ingredients (APIs) and thus increase their bioavailability [9, 12]. In particular, spherical nicergoline nanoparticles in the amorphous state with significantly improved solubility and dissolution rate were recovered using this technique [12], while, in the case of indomethacin, the particles were not spherical, but rather a mixture of irregular and needle-shaped crystals; X-ray diffractometry studies indicated that the metastable higher-soluble polymorphic α-form of indomethacin coexisted with a certain quantity of crystals of polymorphic γ-form [9].

In the case of nimesulide, several preliminary assays were performed to validate the crystallization method in the new nanospray dryer, and the parameters of solution concentration, inlet temperature, and feeding rate were modified. Selected conditions, described in the paragraph “Preparation of nanoparticles”, were used to produce several batches, all of which showed good reproducibility of the powder characteristics in terms of mean particle size, particle size dispersion, and physical state. For the sake of simplicity, only the results of a batch identified as Batch A are shown.

For completeness, all the batches produced were compared to the native crystals. Under SEM observation, NIM native crystals (NCs) appeared as rounded edged particles (Fig. 1a). A slight reduction in particle size was observed after the nanospray drying, and particles of Batch A appeared as irregular or round-shaped particles with a certain tendency to agglomeration. Particles appeared isodimensional, and some spherical agglomerates could be distinguished (Fig. 1b). The geometrical mean particle size changed from 2.88 ± 1.24 in NCs to 1.37 ± 1.15 μm in Batch A particles (Table 1). Figure 2 shows that the particle size distribution of Batch A is displaced to lower sizes with the respect to NCs, but that only 10 % of particles are lower than 1.0 μm. Unlike the previous studies [9, 12], no reduction to nanoscale dimensions was observed for Batch A, which actually showed a more modest reduction in size than expected with this technique.

SEM microphotographs of different samples of nimesulide (×5000). a Native crystals (NCs); b Batch A obtained using a nanospray drier; c Batch N obtained by grinding without liquid nitrogen; d Batch GLN obtained by grinding in the presence of liquid nitrogen; e Batch Neu 1:6 obtained by coprecipitation in the presence of Neusilin® UFL2

Comparison of particle size distribution of nimesulide batches: native crystals (NCs), Batch A obtained by solvent evaporation in a nanospray dryer, Batch N and Batch GLN obtained by grinding in the absence and in the presence of liquid nitrogen, respectively, and Batch Neu 1:6 obtained by coprecipitation in the presence of Neusilin® UFL2

A slight decrease in the degree of crystallinity was observed by XRPD (Fig. 3a). The interreticular distances of NCs and Batch A were superimposable, but it was possible to observe a reduction in peak intensity and a curvature of baseline, indicating that Batch A had a loss in crystallinity. A tendency to amorphization is quite common with techniques that favour rapid crystallization such as the evaporative technique of spray drying.

DSC analysis of reference NIM permitted the evaluation of the melting by calculating the extrapolated onset temperature (152.24 ± 1.02 °C) and an enthalpy content (113.94 ± 2.47 J g−1) of the melting peak (Table 2; Fig. 4a). The water content (0.89 ± 0.23 %) is consistent with an anhydrous solid (Table 2). The melting endotherm of Batch A shows slightly decreased extrapolated onset temperature (149.76 ± 1.23 °C) and a decreased enthalpy content (75.71 ± 2.27 J g−1), which may suggest a decrease in crystallinity degree by considering the XRPD results and the exclusion of impurities that was possible by HPLC analysis. The water content (0.57 ± 0.14 %) is consistent with an anhydrous solid. The decrease in the degree of crystallinity of Batch A highlighted by XRPD was thus confirmed by DSC, and the percentage of the crystalline part of Batch A was proved by DSC to be close to 66.4 % in comparison with the NCs that were considered as 100 % crystalline (Table 2).

Method B consisted of reducing particle size by a simple laboratory-scale technique, namely grinding in the absence or presence of liquid nitrogen. Grinding in the presence of liquid nitrogen, called cryo-milling [36], exploits the capacity of liquid nitrogen to increase the brittleness of solids, thus improving particle comminution [10]. In spite of a very simple technique, only more recently it emerged as very interesting technique to control the particle size of APIs.

In our study, the process time was determined by measuring the time necessary to obtain particles of constant size, such that further grinding time did not afford a continued decrease in particle size. After several preliminary assays, the maximum grinding time was determined to be 40 min. Using Method B in the absence or in the presence of liquid nitrogen, Batches G and GLN were obtained, respectively. Grinding in the absence of liquid nitrogen (Batch G) failed to produce a significant reduction in particle size: particle size changed from 2.88 ± 1.24 to 2.54 ± 1.28 μm for NCs and Batch G, respectively (Table 1), and particle size distribution of Batch N is only moderately displaced to lower sizes with respect to NCs. Also shape change was modest if compared to the starting material (Fig. 1c). On the contrary, grinding in the presence of liquid nitrogen (Batch GLN) significantly reduced particle size, confirming its capacity to improve the grinding potential of solids; numerous irregular and small particles were formed that appeared to be grouped in large aggregates (Fig. 1d). The geometric mean particle diameter was 1.16 ± 1.16 μm (Table 1). The particle size distribution is displaced to lower particle sizes, and more than 55 % of particles are lower than 1.0 μm (Fig. 2). Under grinding, no modification in crystalline solid state was revealed by XRPD for both grinding products: the interreticular distances, peak intensity, and baseline curvature did not differ from those of NCs (Fig. 3b), and thus, it can be supposed that there was no reduction in the degree of crystallinity. DSC Curves of Batches NCs, G, and GLN showed the drug melting endotherm, the extrapolated onset temperature and the enthalpy content of which are reported in Table 2. While the Batch G showed values close to NCs, DSC revealed a non-negligible decrease in enthalpy content for the GLN Batch (crystallinity degree 86.7 %), which could indicate a decrease in the degree of crystallinity under grinding in nitrogen liquid (Table 2). The water content of Batch G is consistent with an anhydrous solid (0.93 ± 1.05 %), while a slight increase in water content is observed for Batch GLN (1.24 ± 1.10 %), because a lower particle size creates higher particle surface responsible for water absorption.

Method C consisted of dispersing NIM in an amorphous polymer, Neusilin® UFL2. Neusilin® UFL2 is an amorphous, synthetic form of magnesium aluminometasilicate widely used for pharmaceutical applications as a carrier and filler for improving the quality of tablets, powders, granules, and capsules. Only more recently its use has been proposed in solid dispersions thanks to its ability to favour the amorphization of drugs under cogrinding [19, 37–39] and hot-melt granulation [40–42].

The objective in the present study was to completely disperse the crystalline drug into the amorphous matrix in order to promote the complete amorphization of the mixture. Preliminary assays were conducted to establish the appropriate ratio able to promote the amorphization of the mixture, and the following were tested 1:2, 1:4 or 1:6, leading to the respective three batches (Batch Neu 1:2, Batch Neu 1:4, and Batch Neu 1:6). XRPD (Fig. 3c) still showed small peaks of crystalline nimesulide in Batches Neu 1:2 and Neu 1:4. In the Batch Neu 1:6, the more relevant diffraction peaks of drug are still present, but in the pattern the amorphous nature of the sample is predominant and proportional to the amorphous polymer that dilutes the drug.

The DSC curves of NCs, pure Neusilin® UFL2, Batch Neu 1:2, and Batch 1:6 are compared in Fig. 4c. The DSC curve of pure Neusilin® UFL2 is characterized by a broad endotherm between 60 and 140 °C due to the loss of hydration water from the amorphous material. The loss of water from NEU was 4.48 ± 1.48 % (Table 2), value that is in agreement with the technical document that is <7 % depending on the environmental conditions.

DSC curves of the Batches Neu 1:2 and Neu 1:4 (this last in not reported because very close to the previous one) showed very small melting peaks (enthalpy content 8.80 ± 3.56 and 1.76 ± 3.28 J g−1) leading to suppose that mixtures were still slightly crystalline. A completely amorphous mixture was only formed at a NIM–NEU ratio of 1:6 (Batch Neu 1:6), in the curve of which no melting peak was observed. Since the DSC is a dynamic technique, the amorphization recorded in the curve of Batch Neu 1:6 is probably a consequence of an interaction between drug and polymer induced by heating. Thus, XRPD is the only technique able to confirm the amorphous or crystalline nature of the sample, and thus, the presence of the more relevant diffraction peaks of the drug confirms that a low crystallinity degree still characterizes the sample.

Slight baseline curvature for all the three NIM–NEU batches could be observed corresponding to the water loss associated with the drug–polymer mixture and due to amorphous portion. The water content increased proportionally from Batches Neu 1:2, 1:4, 1:6 and is proportional to the increasing amount of the amorphous polymer fraction in the sample.

The drug dispersion into the polymer not only afforded an amorphization tendency but also markedly reduced particle size, obtaining particles with a geometric mean of 0.78 ± 0.33 μm for the Batch Neu 1:2, 0.80 ± 0.25 μm for the Batch Neu 1:4, and 0.72 ± 0.20 μm for the Batch Neu 1:6 (Table 1). The particle size distribution of Batch Neu 1:6 appeared the lowest among all the samples: nearly 85 % of the particles are lower than 1.0 μm and 30 % are lower than 0.5 μm (Fig. 2). The SEM analysis of Batch Neu 1:6 showed a strong tendency to particle agglomeration, fact that can probably be attributed to the analytical technique, which entailed deposition of solid material onto the stub. Actually, particle size identification by dynamic light-scattering analysis clearly showed the strong reduction in particle size and no agglomeration.

The batches stored for 1 year under the ICH conditions were analysed by DSC to check variations in crystallinity degree (Table 2). The crystallinity degree increased with time for Batches A, G, and GLN. Batch Neu 1:6 remained completely amorphous because the polymer was able to prevent drug crystallization during the year. These observations confirmed a widely described tendency, which is the ability of polymers to prevent drug crystallization with time [43, 44]. Batches 1:2 and 1:4 showed a tendency to crystallization, because the presence of a certain amount of crystalline nimesulide favours the nimesulide crystallization.

Because of the amorphous properties and stability, only Batch Neu 1:6 was selected for the dissolution study.

Intrinsic dissolution rate and dissolution from the particle samples

The intrinsic dissolution rate (IDR) of NIM samples was determined in phosphate buffer (pH 7.2) (Table 3). Dissolution profiles are shown in Fig. 5. The intrinsic dissolution rates (IDRs) were calculated from the slope of the straight line of cumulative drug release (Table 3). The lowest dissolution profile, and consequently the lowest IDR, was exhibited by the NCs. Batch G exhibited very similar behaviour, and thus, it can be concluded that the two batches exhibit non-significant differences (significance level P < 0.05). Batch GLN showed a slightly higher intrinsic dissolution profile and thus IDR. Since IDR is not affected by particle size, but rather by solubility and/or wettability, the slightly higher IDR of Batch GLN could be attributed to its tendency to become less crystalline, as observed by the DSC analyses, which may account for an increase in dissolution rate. Higher IDR was exhibited by Batches A and Neu 1:6, the latter exhibiting the highest dissolution profile and IDR. In both cases, this result can be ascribed to the decrease in crystallinity degree noted for Batch A and the almost complete amorphization observed for Batch Neu. In addition, in the case of Batch Neu, the presence of polysorbate 80 as surfactant may have increased the solid wettability and thus increased dissolution rate.

The dissolution of NIM from the particle samples reflected differences in both particle size and IDR results: Fig. 5 shows the results of the particle dissolution rates of NIM samples. The lowest dissolution from particles was exhibited by NCs, followed by that of Batch G, as expected according to the IDR results. More marked differences than expected from IDR results were observed for Batch GLN with NCs and Batch G, because in the particle dissolution the particle size contributed to improving the dissolution rate. The dissolution rate of Batch Neu 1:6 was very fast in the first 10 min, but it was exceeded by the dissolution rate of Batch A after the first 20 min, and only Batch A reached 100 % particle release at the end of dissolution experiment. The initial faster dissolution rate of Batch Neu 1:6 compared to that of Batch A could be explained by the higher wettability conferred by polysorbate 80, a surfactant that acts as a wetting agent. In addition, drug molecules are molecularly dispersed in the amorphous matrix (Fig. 6).

After 1 year of storage according to ICH conditions, the particle dissolution was analysed again, and no statistically relevant differences were observed (significance level P < 0.05) for the Batch Neu, while a slight decrease in particle dissolution was exhibited for Batch A and GLN result that probably can be ascribed to the variation in crystallinity degree.

Conclusions

The three laboratory-scale methods described in this work, namely crystallization by solvent evaporation in a nanospray dryer, cryo-milling, and dispersion in Neusilin UFL2, showed their potential for increasing the dissolution rate of nimesulide, and results demonstrated are affected by the reduction in particle size and in crystallinity degree. The innovation, simplicity, and scalability of all the three techniques make them promising candidates for use on an industrial scale, while dispersion in Neusilin® UFL2 and nanospray drying, which gave the best results, are especially promising. In particular, due to the greatest physical stability exhibited by the Batch Neu 1:6, this preparation method can be selected as the best one for industrial application.

References

Moore GGI, Harrington JK. Belgian patent 801, 812; US Patent 3, 840, 597 (1974).

Swingle KF, Moore GGI. Preclinical pharmacological studies with nimesulide. Drugs Exp Clin Res. 1984;10:587–97.

Kulkarni SK. On the safety of nimesulide, a preferential COX-2 inhibitor. Curr Sci. 2002;83:1442–3.

Liversidge GG, Cundy KC. Particle size reduction for improvement of oral bioavailability of hydrophobic drugs: I. Absolute oral bioavailability of nanocrystalline danazol in beagle dogs. Int J Pharm. 1995;125:91–7.

Chaumeil JC. Micronization: a method of improving the bioavailability of poorly soluble drugs. Methods Find Exp Clin Pharmacol. 1998;20:211–5.

Gao L, Zhang D, Chen M. Drug nanocrystals for the formulation of poorly soluble drugs and its application as a potential drug delivery system. J Nanopart Res. 2008;10:845–62.

Keck MC, Müller RH. Drug nanocrystals of poorly soluble drugs produced by high pressure homogenization. Eur J Pharm Biopharm. 2006;62:3–16.

Merisko-Liversidge E, Liversidge GG, Cooper ER. Nanosizing: a formulation approach for poorly-water-soluble compounds. Eur J Pharm Sci. 2003;18:113–20.

Martena V, Censi R, Hoti E, Malaj L, Di Martino P. Indomethacin nanocrystals prepared by different laboratory scale methods: effect on crystalline form and dissolution behavior. J Nanopart Res. 2012;14:1275–89.

Martena V, Censi R, Hoti E, Malaj L, Di Martino P. Preparation of glibenclamide nanocrystals by a simple laboratory scale ultra cryo-milling. J Nanopart Res. 2013;15:1712–22.

Martena V, Shegokar R, Di Martino P, Müller RH. Effect of four different size reduction methods on the particle size, solubility enhancement and physical stability of nicergoline nanocrystals. Drug Dev Ind Pharm. 2014;40:1199–205.

Martena V, Censi R, Hoti E, Malaj L, Di Martino P. A new nanospray drying method for the preparation of nicergoline pure nanoparticles. J Nanopart Res. 2012;14:934–48.

Serajuddin ATM. Salt formation to improve drug solubility. Adv Drug Del Rev. 2007;59:603–16.

Gomez-Orellana I. Stretegies to improve oral drug bioavailability. Exp Opin Drug Deliv. 2005;2:419–33.

Blagden N, de Matas M, Gavan PT, York P. Crystal engineering of active pharmaceutical ingredients to improve solubility and dissolution rates. Adv Drug Deliv Rev. 2007;59:617–30.

Dubbini A, Censi R, Martena V, Hoti E, Ricciutelli M, Malaj L, Di Martino P. Influence of pH and method of crystallization on the solid physical form of indomethacin. Int J Pharm. 2014;473:536–44.

Malaj L, Censi R, Capsoni D, Pellegrino L, Bini M, Ferrari S, Gobetto R, Massarotti V, Di Martino P. Characterization of nicergoline polymorphs crystallized in several organic solvents. J Pharm Sci. 2011;100:2610–22.

Shanmuga PA, Sivakamavalli J, Vaseeharan B, Stalin T. Improvement on dissolution rate of inclusion complex of rifabutin drug with β-cyclodextrin. Int J Biol Macromol. 2013;62:472–80.

Bahl D, Bogner RH. Amorphization of indomethacin by co-grinding with Neusilin US2: amorphization kinetics, physical stability and mechanism. Pharm Res. 2006;23:2317–25.

Dhirendra K, Lewis S, Udupa N, Atin K. Solid dispersions: a review. Pak J Pharm Sci. 2009;22:234–46.

Vasconcelos T, Sarmento B, Costa P. Solid dispersions as strategy to improve oral bioavailability of poor water soluble drugs. Drug Discov Today. 2007;12:1068–75.

Censi R, Martena V, Hoti E, Malaj L, Di Martino P. Preformulation study of nicergoline solid dispersions. J Therm Anal Calorim. 2014;115:2439–46.

Malaj L, Censi R, Mozzicafreddo M, Pellegrino L, Angeletti M, Gobetto R, Di Martino P. Influence of relative humidity on the interaction between different aryl proprionic acid derivatives and poly(vinylpyrrolidone) K30. Evaluation of the effect on drug bioavailability. Int J Pharm. 2010;398:61–72.

Piel G, Pirotte B, Delneuville I, Neven B, Labres G, Delarge J, Delattre L. Study of the influence of both cyclodextrins and l-lysine on the aqueous solubility of nimesulide; isolation and characterization of nimesulide l-lysine–cyclodextrin complexes. J Pharm Sci. 1997;86:475–80.

Buchi Nalluri N, Chowdary KPR, Murthy KVR, Becket G, Peter Crooks A. Tablet formulation studies on nimesulide and meloxicam—cyclodextrin binary systems. AAPS Pharm Sci Tech 2007;8:E71–7.

Buchi Nalluri N, Chowdary KPR, Murthy KVR, Becket G, Hayman AR. Physicochemical characteristics and dissolution properties of nimesulide–cyclodextrin binary systems. AAPS Pharm Sci Technol. 2003;4:6–17.

Shoukri RA, Ahmed IS, Shamma RN. In vitro and in vivo evaluation of nimesulide lyophilized orally disintegrating tablets. Eur J Pharm Biopharm. 2009;73:162–71.

Gohel MC, Patel LD. Processing of nimesulide-PEG 400-PG-PVP solid dispersions: preparation, characterization, and in vitro dissolution. Drug Dev Ind Pharm. 2003;29:299–310.

Gohel MC, Patel LD. Improvement of nimesulide dissolution by a co-grinding method using surfactants. Pharm Pharmacol Comm. 2000;6:433–40.

Crowley KJ, Zografi G. Cryogenic grinding of indomethacin polymorphs and solvates: assessment of amorphous phase formation and amorphous phase physical stability. J Pharm Sci. 2002;91:492–507.

Ghosh I, Bose S, Vippagunta R, Harmon F. Nanosuspension for improving the bioavailability of a poorly soluble drug and screening of stabilizing agents to inhibit crystal growth. Int J Pharm. 2011;409:260–8.

Banakar, UV. Pharmaceutical dissolution testing. In: Swarbrick J, editor. New York: Marcel Dekker; 1992. pp. 55–105.

Li X, Anton N, Arpagaus C, Belleteix F, Vandamme TF. Nanoparticles by spray drying using innovative new technology: the Büchi Nano Spray Dryer B-90. J Controll Rel. 2010;104:304–10.

Lee SH, Heng D, Kiong Ng W, Chan HK, Tan RBH. Nano spray drying: a novel method for preparing protein nanoparticles for protein therapy. Int J Pharm. 2011;403:192–200.

Aquino RP, Stigliani M, Del Gaudio P, Mencherini T, Sansone F, Russo P. Nanospray drying as a novel technique for the manufacturing of inhalable NSAID powders. Sci World J 2014; Article ID 838410. doi:10.1155/2014/838410.

Niwa T, Danjo K. One-step preparation of pharmaceutical nanocrystals using ultra-cryomilling technique in liquid nitrogen. Eur J Pharm Sci. 2010;41:78–85.

Gupta MK, Vanwert A, Bogner RH. Formation of physically stable amorphous drugs by milling with Neusilin. J Pharm Sci. 2003;92:536–51.

Vadher AH, Parikh JR, Parikh RH, Solanki AB. Preparation and characterization of co-grinded mixtures of aceclofenac and Neusilin US2 for dissolution enhancement of aceclofenac. AAPS PharmSciTech. 2009;10:606–14.

Lou H, Liu M, Wang L, Mishra SR, Qu W, Brunson E, Almoazen H, Johnson J. Development of a mini-tablet of co-grinded prednisone-neusilin complex for pediatric use. AAPS PharmSciTech. 2013;14:950–8.

Gupta MK, Goldman D, Bogner RH, Tseng YC. Enhanced drug dissolution and bulk properties of solid dispersions granulated with a surface adsorbent. Pharm Dev Tech. 2001;6:563–72.

Gupta MK, Bogner RH, Goldman D, Tsend YC. Mechanism for further enhancement in drug dissolution from solid-dispersion granules upon storage. Pharm Dev Tech. 2002;7:103–12.

Gupta MK, Tseng YC, Goldman D, Bogner RH. Hydrogen bonding with adsorbent during storage governs drug dissolution from solid-dispersion granules. Pharm Res. 2002;11:1663–72.

Khougaz K, Clas SD. Crystallization inhibition in solid dispersions of MK-0591 and poly(vinylpyrrolidone) polymers. J Pharm Sci. 2000;89:1325–34.

Yoshioka M, Hancock BC, Zografi GJ. Inhibition of indomethacin crystallization in poly(vinylpyrrolidone) coprecipitates. J Pharm Sci. 1995;1995(84):983–6.

Acknowledgements

The authors would like to thank Mr Simone Verdolini for his kind contribution to the experimental work. They would also like to thank Sheila Beatty for editing the English usage of the manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rascioni, R., Censi, R., Malaj, L. et al. Effect of particle size reduction and crystalline form on dissolution behaviour of nimesulide. J Therm Anal Calorim 123, 2213–2223 (2016). https://doi.org/10.1007/s10973-015-4874-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-015-4874-8