Abstract

In this work, the synthesis of two fruit flavor esters, namely methyl and ethyl butyrate, by lipase from Rhizomucor miehei immobilized onto chitosan in the presence of the surfactant sodium dodecyl sulfate SDS was investigated. In the optimized conditions, maximum esterification yield for ethyl butyrate and methyl butyrate was (92 ± 1%) and (89 ± 1%), respectively. Esterification yields for both reactions were comparable or even superior to the ones achieved when the synthesis was catalyzed by a commercial enzyme, Lipozyme®, at the same reaction conditions. For ethyl butyrate, the developed biocatalyst was used for seven consecutive cycles of reaction with retention of its catalytic activity. For methyl butyrate synthesis the biocatalyst was used for four consecutive cycles without loss of its catalytic activity. The results show that chitosan may be employed in obtaining biocatalysts with high catalytic efficiency and can successfully replace the currently commercial available biocatalysts.

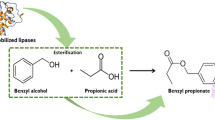

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

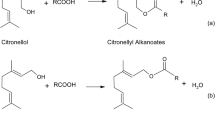

Short chain aliphatic esters are the major components of some natural flavors and fragrances widely used in the food, beverages, cosmetics and pharmaceutical industries [1]. Currently, most of these compounds are extracted from natural sources or produced by chemical routes [2]. Extractions from natural sources are too expensive due to their low concentrations in the natural products and very low extraction yields [3]. Chemical synthesis is considered economical but makes use of strong acids such as sulfuric acid, p-toluene sulfonic or phosphoric acid as catalyst and sometimes high temperature and pressure conditions, requiring additional steps for the separation and purification of the obtained products, being considered environmentally unsafe [4].

“Clean technologies” based on enzymatic processes mediated by lipases mainly in its immobilized form are emerging and promising techniques that may successfully replace the methods traditionally used in the ester synthesis [5,6,7].

Compared to conventional chemical route, the enzymatic approach allows the ester synthesis at mild conditions with better product purity, elimination of side reactions with low energy requirements [8]. Moreover, products obtained by enzymatic processes are labeled as “natural” having high market value [9,10,11,12,13].

The most popular enzymes in biocatalysis are lipases (triacylglycerol ester hydrolases, EC 3.1.1.3) because they couple a broad specificity to a high regio- and enantioselectivity; therefore, they may be used in many different reactions [14,15,16,17,18]. Lipases, from different sources, immobilized onto various kinds of supports have been used in some non-conventional media (e.g., ionic liquids, supercritical fluids) but mainly on organic solvents aiming to the production of different flavoring esters [7, 19].

Chitosan (linear β-1, 4-linked polysaccharide), a natural biopolymer obtained by the partial deacetylation of chitin has shown suitable properties for enzyme immobilization such as low cost of acquiring, variety of forms, high affinity for proteins, nontoxicity, physiological inertness, hydrophilicity, among others [20]. Lipases may be immobilized on chitosan supports by physical adsorption or through covalent attachment after modification of its hydroxyl (–OH) and primary amino (–NH2) groups with specific reagents like epichlorohydrin, glycidol or glutaraldehyde [21,22,23].

In ester synthesis, the development of biocatalysts that fulfill some requirements such as high catalytic activity, thermal stability and good operational stability and a better understanding of the several parameters affecting the esterification reactions are key factors for possible large-scale production of such compounds using lipases [24, 25].

Furthermore, the availability of less expensive immobilized preparations with high activity may contribute to a reduction in the overall cost of the processes where these enzymes are used [26].

In the present work, enzymatic synthesis of two short chain flavor esters (methyl and ethyl butyrate) have been attempted using Rhizomucor miehei lipase (RML) immobilized on chitosan in the presence of the surfactant sodium dodecyl sulfate (SDS). Immobilization in the presence of detergents at low concentration levels has proved to be a valuable method for improving the enzymatic activity of some lipases [27].

Lipases have different performance in the presence of non-ionic, anionic or cationic [28] surfactants [29]. These effects may be due to the type of interactions between the enzyme and the surfactants [30, 31], since the non-ionic surfactants interact via hydrophobic interactions while the ionic surfactants bind the lipases through electrostatic and hydrophobic interactions [18, 32]. Thus, the different interactions may result in modifications in the three-dimensional structure of lipases, which may lead to an increase or decrease of enzymatic activity [18, 33]. For the more, the performance of lipases in the presence of surfactants depends on some factors, such as ionic strength, pH and composition of the detergent, washing temperature, among others [13, 34]. SDS increase the enzymatic activity and leads a weak interaction allowing the enzyme to be more flexible and accommodate more substrate molecules.

A detailed study of process parameters that affect the reaction rates was evaluated. At the optimized reaction conditions, the operational stability of the developed biocatalyst was compared to a commercial enzyme Lipozyme®.

Materials and methods

Materials

Powdered chitosan, 85.2% deacetylation degree, was purchased from Polymer Ind. Ltda. (Ceará, Brazil). Soluble RML (128 U mL−1 or 4.2 mg mL−1 according to Bradford [35]), Lipozyme® (all the terms Lipozyme® used in the text it is referent to immobilized lipase from Mucor miehei, > 30 U g−1 against tristearin at pH 8.0 and 70 °C) and glutaraldehyde 25% (v v−1) were acquired from Sigma-Aldrich Chemical Co. (St. Louis, MO). All other reagents and solvents used were of analytical grade.

Methods

Support preparation

Powdered chitosan was dissolved in an acetic acid 5% v v−1 solution. The obtained solution of 2.5% (mV−1) was dropped into a gently stirred NaOH 100 mmol L−1 solution at room temperature (ratio chitosan/NaOH = 1:10) [27]. After 24 h, chitosan was washed exhaustively with distilled water until neutrality and then dried by vacuum filtration.

Immobilization procedure

Rhizomucor miehei lipase (RML) was firstly adsorbed onto chitosan in the presence of SDS (0.23% mV−1) in phosphate buffer 100 mmol L−1 at pH 7.0 and 220 rpm, for 1 h and 4 °C. Then, the composite RML-chitosan-detergent was cross-linked with glutaraldehyde 0.6% v v−1 in phosphate buffer 100 mmol L−1 at pH 7.0, under low stirring at 25 °C for 1 h [27]. After that, the support was washed several times with distilled water to remove excess of surfactant and glutaraldehyde, dried under vacuum and stored at 4 °C.

The immobilization parameters immobilization yield (IY), theoretical activity (Att) and recovery activity (Atr) were calculated according to Santos et al. [7]. For doing that, the initial (Ati) and the remaining (Atf) enzyme activity were determined and used to calculate the IY, according to Eq. (1).

The theoretical activity (Att) of immobilized lipase was determined by Eq. 2. Atoff is the enzyme activity per g of the gel at the beginning of the essay.

After determining the biocatalyst activity (Atd), the recovery activity (Atr) was determined according to Eq. 3:

Enzymatic synthesis of esters

The esterification reactions were carried out in 125 mL glass-stoppered flasks using n-heptane as a solvent. The reaction mixture (20 mL) containing substrates and biocatalyst was incubated on an orbital shaker (Tecnal TE-420, Piracicaba, Brazil) under different conditions [temperature (25–60 °C), acid and alcohol concentrations (0.1–1 mol L−1), enzyme load (0.52–3.22 mgprotein g−1support), stirring speed (50–250 rpm), mass of biocatalyst used in reaction system, molar ratio of the substrates, amount of water (0.5–2% wt) and reaction time (1–8 h)]. Before and after the reaction, aliquots of the reaction mixture were withdrawn and titrated against standard potassium hydroxide using phenolphthalein as an indicator to determine the residual acid concentration [36]. Ethanol was used as a quenching agent [37]. Control experiments were also conducted without lipase under similar conditions. The percentage of esterification was calculated from the acid consumed in the reaction system according to Eq. 4.

where C0 is acid concentration measured before the start of reaction and C is the residual acid concentration after reaction time.

FTIR analysis

Qualitative analysis of esters standards and the reaction mixture in n-heptane were made by Fourier Transform Infrared Spectra (FTIR) from an FTLA 2000-102, ABB-BOMEM, with 15 scans at a resolution of 4 cm−1. A frequency range of 4000–400 cm−1 was used.

Biocatalyst reuse

The reuse of the biocatalyst produced in this work was evaluated performing successive reaction cycles for both esters under the optimum reactions conditions.

At the end of the reaction, the biocatalyst was washed with n-heptane, to remove adsorbed reagents and reaction products, dried under vacuum at room temperature and introduced in a new reaction medium with fresh reactants.

Results and discussion

Parameters of immobilization

In this study, the biocatalysts were prepared by the immobilization of soluble enzymes obtaining IY, theoretical activity (Att) and recovery activity (Atr) around 97.0 ± 1.0 (%), 10.0 ± 1.0 (UpNPB/g) and 69 ± 1 (%), respectively. The immobilization parameters were achieved using an enzymatic loading of 16 Uenzyme g−1 (g of wet support).

The yield of immobilization was 97.0 ± 1.0%, showing that a large part of the enzyme was immobilized on the support successfully. This result can be explained by the performance of glutaraldehyde in the immobilization process. Ion exchange, interfacial activation and covalent multipoint bonding are the possible routes of immobilization when glutaraldehyde is used [38]. Furthermore, some properties of glutaraldehyde may justify the immobilization rate attained. The high reactivity of the glutaraldehyde molecules can modify the catalytic properties of the enzymes due to their interaction with amino groups of the proteins [7]. The surface of the enzymes (i.e., their hydrophobicity) can be changed because the glutaraldehyde molecules are quite hydrophobic. Crosslinking of glutaraldehyde with amino groups and other glutaraldehyde free molecules cannot be ignored [7]. Distortion of the structure of the enzymes during the immobilization process may contribute to a decrease in the catalytic activity of the immobilized enzymes [10]. From the results obtained, the immobilization process was effective with biocatalyst activity of 10.0 ± 1.0 (UpNPB/g) and recovery activity of 69 ± 1 (%). It cannot be ignored that some protein molecules are not covalently bound to glutaraldehyde, suffering desorption during carrier washing.

Effect of the temperature

In lipase-catalyzed systems, temperature markedly influences the reaction rates and the stability of the enzyme altering some properties of the substrates and reaction products, such as solubility and ionization state [39]. While the binding equilibrium of substrates and products with enzyme decrease with the increase in temperature, acid dissociation and solubility rise with temperature, all resulting in unfavorable esterification conditions [40]. In most cases, an increase in temperature reaction improves the conversions rates, but the stability of enzymes declines [41]. Based on this contradictory information, a study of the influence of temperature in the esterification reactions was performed in the range of 25–60 °C for ethyl butyrate and 25–50 °C for methyl butyrate, due to the low boiling point of methanol (65 °C). The results of this set of experiments are displayed in Fig. 1a.

a Effect of temperature on the synthesis of methyl butyrate (closed circle) and ethyl butyrate (open circle) conditions: solvent: n-heptane; Vreaction = 20 mL; protein load (mgprotein g−1support) = 1.61; biocatalyst amount (mg) = 100 (methyl butyrate) and 200 (ethyl butyrate); [alcohol]/[acid] molar ratio = 1:1; substrates concentration: 0.2 mol L−1; stirring speed = 150 rpm, reaction time (t): 8 h. b Effect of substrates concentration on esterification yields of methyl butyrate (open circle) and ethyl butyrate (closed square). Conditions: solvent: n-heptane; Vreaction = 20 mL; protein load (mgprotein g−1support) = 1.61; biocatalyst amount (mg): 100 (methyl butyrate) and 200 (ethyl butyrate); [alcohol]/[acid] molar ratio = 1:1; stirring speed = 150 rpm, reaction time (t): 8 h; temperature (T): 25 °C

Figure 1a shows that the maximum conversion yield was observed at 25 °C for both esters. For ethyl butyrate, a temperature increase from 25 to 37 °C did not promote a considerable decrease in conversion rates. However, temperatures higher than 37 °C drastically reduced the esterification yields. Further increase in the temperature leads to a drastic reduction in conversion ratios, probably due to heat inactivation of the enzyme [42]. For methyl butyrate, the conversion rates were drastically reduced in the temperature range of 37–50 °C. Some works have pointed out that the decrease of catalytic activities of immobilized enzymes at a higher temperature may be brought to some restrictions on the enzyme movements due to the covalent bonds established between the enzyme and the support or a low restriction for the diffusion of substrates [43].

Considering the results obtained in these experiments 25 °C was adopted as the optimal reaction temperature.

Effect of substrate concentration

The effect of the variation of acid and alcohol concentrations, added in equimolar proportions, in the reaction medium in the range of 0.1–1 mol L−1 was investigated. Results are shown in Fig. 1b.

For ethyl butyrate, maximum esterification yielding of 85% was observed at 0.02 mol L−1 of each substrate. An increase in substrate concentrations above 0.02 mol L−1 promoted a sharp decrease of esterification yield. At 1 mol L−1, the esterification yield was only 5%. On the methyl butyrate synthesis, the best result of conversion (80%) was achieved when the concentration was 0.1 mol L−1 for both substrates. According to Fig. 2, above this concentration, the esterification reactions have experienced a pronounced decrease in their yields.

Effect of alcohol/acid molar ratio on esterification yields of methyl butyrate (b) and ethyl butyrate synthesis (a): alcohol concentration fixed at 0.1 mol L−1 (closed circle) and acid concentration fixed at 0.2 mol L−1 (open circle). c Effect of protein load on esterification yields of methyl butyrate (open circle) and ethyl butyrate synthesis (closed circle). Conditions: solvent: n-heptane; Vreaction = 20 mL; [alcohol]/[acid] molar ratio: methyl butyrate 1,5:1 and ethyl butyrate 1:1; biocatalyst amount (mg): 100 (methyl butyrate) and 200 (ethyl butyrate); stirring speed = 150 rpm; reaction time (t): 8 h; temperature (T): 25 °C. d Effect of biocatalyst load on esterification yields of methyl butyrate (σ) and ethyl butyrate synthesis (closed triangle). Conditions: solvent: n-heptane; Vreaction = 20 mL; protein load (mgprotein g−1support) = 1.61; [alcohol]/[acid] molar ratio: methyl butyrate 1,5:1 and ethyl butyrate 1:1; stirring speed = 150 rpm, reaction time (t): 8 h; temperature (T): 25°C

A possible explanation for the observed results is that in the presence of high concentrations of substrates (acid or alcohol), the polarity of the medium is altered making the organic phase more hydrophilic. Consequently, the partition coefficients become less favorable to esters formed (more hydrophobic) shifting the equilibrium of the reaction in the opposite direction of the formation of these compounds [44]. Furthermore, possible inhibitory effects of one or by the two substrates used in the reactions should also be considered [45].

Effect of alcohol to the acid molar ratio

The molar ratio of the substrates is one of the parameters that influence the yield of esterification reactions catalyzed by lipases. Since the reaction is reversible, the increased concentration of one of the reagents may shift the equilibrium towards products formation resulting in high conversions. On the other hand, inhibitory effects occasioned by both substrates or by the products of the reaction can drastically reduce the esterification yields [46].

For ethyl butyrate the effect of alcohol to acid molar ratio on esterification yields was studied by fixing the alcohol concentration at 0.2 mol L−1 varying acid concentration in the interval of 0.2–0.8 mol L−1 and vice versa. The experiments were performed with 200 mg of the biocatalyst (protein loaded = 1.61 mgprotein g−1support). For methyl butyrate, the alcohol concentration was fixed at 0.1 mol L−1 varying acid concentration in the interval of 0.1–0.8 mol L−1 and vice versa. For this series of experiments 100 mg of the biocatalyst was utilized (protein loaded = 1.61 mgprotein g−1support). In both reaction systems, the reaction medium was incubated for 8 h at 25 °C and 150 rpm. The results for the synthesis of the two esters are shown in Fig. 2.

For ethyl butyrate (Fig. 2a) the maximum ester conversion (85%) was obtained when the alcohol/acid molar ratio was 1:1 (0.2 mol L−1 each). Figure 2a also shows that by fixing the ethanol concentration at 0.2 mol L−1 and increasing the acid concentration above this value, substantial inhibition of the enzyme activity can be observed. When the initial concentration of acid was 0.8 mol L−1 (alcohol/acid molar ratio = 1:4) the reaction yield was about 5%. According to the literature [42], high acid concentrations may result in a potent inhibition on the enzyme activity probably due to the acid dissociation, which in leads to a decrease in the pH of the microaqueous environment of the enzyme. Furthermore, some short-chain acids such as acetic, propionic and butyric acid can bind to the serine residue (Ser) in the catalytic site of lipases leading to inhibition of its activities, decreasing the yield of the reactions [47].

In the second set of experiments, when the concentration of butyric acid was fixed at 0.2 mol L−1, and the concentration of ethyl alcohol was increased, it was observed that concentrations higher than 0.2 mol L−1 of this substrate also promoted a significant decrease on the esterification yields, see Fig. 2a. A major increment at ethanol concentration may promote the binding of molecules of this substrate with the lipase during the first step of the reaction competing with the acid molecules and thus result in a decrease in the amount of butyric acid on the enzyme. In this situation, a reduction in the reaction rate will occur, since the reaction is limited by the amount of acid in the vicinity of the enzyme [48].

In addition to these factors, low molecular weight alcohols such as methanol or ethanol can be accumulated in the aqueous microenvironment of the enzyme reaching a sufficiently high concentration to induce protein denaturation blocking the nucleophilic portion of its active site [49]. Another possible mechanism of inactivation is that these substrates, due to their high polarity, may remove the layer of water necessary for maintaining the structural integrity of the enzyme, distorting its three-dimensional structure [50].

The results of the study of the effect of alcohol/acid molar ratio on the synthesis of methyl butyrate are shown in Fig. 2b. The results show that at a fixed concentration of alcohol, increasing acid concentrations above 0.1 mol L−1 (80% conversion), promoted a reduction in esterification yields. For an alcohol/acid molar ratio of 1:4, the yield of esterification was 13%. These results show the significant inhibition of enzyme activity caused by the acid substrate, as in the previous case.

In an alcohol/acid molar ratio of 1.5:1, Fig. 2b, the maximum yield for this reaction was achieved (89%). Molar ratios above 1.5:1 promoted a fairly sharp decline in yields of reaction. For an alcohol/acid molar ratio of 4:1, the reaction yield was only 9%. The same considerations described previously can be used to explain the results observed for the methyl butyrate synthesis.

Based on the obtained results, the optimal alcohol/acid molar ratio for ethyl butyrate was 1:1 (0.2 mol L−1 each) and the methyl butyrate was 1.5:1. These optimal conditions were used in subsequent experiments.

Effect of protein load on esterification reactions

From the standpoint of practical and economical, it is desirable that high yields of reaction should be achieved using a small amount of enzyme in short reaction time. Therefore, to investigated the effect of enzyme load, the esterification reactions were carried out at 25 °C and 150 rpm in n-heptane using different amounts of immobilized lipase (0.52–3.22 mgprotein g−1support). For ethyl butyrate, the reactions were performed by using an equimolar mixture of butyric acid and ethanol (0.2 mol L−1). For methyl butyrate, alcohol/acid molar ratio of 1.5:1 (0.15/0.1 mol L−1) was used in these experiments. The results for both esters are shown in Fig. 2c.

As described in Fig. 2c, the conversion percentage for both esters is increased as more lipase was present in the reaction medium but until a certain limit. The maximal conversion of ethyl and methyl butyrate was achieved at a protein load of 1.61 mgprotein g−1support. For the two esters, the conversions remained almost constant when amounts of protein greater than the value mentioned above were added on the reaction. This probably occurred due to diffusional limitations of substrates to the active site of enzymes located inside the biocatalyst [51]. In this case, the active sites of the enzyme molecules, that are inside the biocatalyst, are not exposed to the substrates and thus do not contribute significantly to the reaction [52]. According to the results obtained, the protein load used in further experiments was 1.61 mgprotein g−1support.

Effect of biocatalyst load

In a reaction catalyzed by immobilized enzymes, the increase in the amount of enzyme can, within a certain limit, positively affect the reaction rates. Therefore, the effect of increasing the mass of biocatalyst used in reaction systems was evaluated, and results are displayed in Fig. 2d. For both esters, growing amounts of biocatalyst mass promoted an increase in conversion rates, but up to a certain limit. For methyl butyrate, the maximum rate of conversion (89%) was obtained when 100 mg of the biocatalyst was added to the reaction system. Amounts of biocatalyst above 100 mg did not produce significant differences in reaction rates. For ethyl butyrate, the maximum conversion (85%) was observed when 200 mg of the biocatalyst was added to the reaction. Amounts of biocatalyst above this value produced a slight decrease in the yield of this reaction.

According to the literature [53], a large increase in the amount of biocatalyst used in the reactions may lead to a decrease in synthesis activity due to the random distribution of the enzyme on the support resulting in less contact between enzyme and substrate.

From the results obtained in these experiments, the mass of biocatalyst used in the following experiments was 100 and 200 mg for methyl and ethyl butyrate, respectively.

Effect of stirring speed

To evaluate the possible effects of mass external transference limitations experiments were carried out by varying the stirring speeds from 50 to 250 rpm. Figure 3 shows the effect of stirring speed on the esterification reactions.

Effect of stirring speed on esterification yields of methyl butyrate (open circle) and ethyl butyrate (closed circle). Conditions: solvent: n-heptane; Vreaction = 20 mL; protein load (mgprotein g−1support) = 1.61; biocatalyst amount (mg): 100 (methyl butyrate) and 200 (ethyl butyrate); [alcohol]/[acid] molar ratio: methyl butyrate 1,5:1 and ethyl butyrate 1:1; reaction time (t): 8 h; temperature (T): 25 °C

As can be seen in Fig. 3, the rate of esterification for both esters increased by increasing the stirring rate reaching a maximum at 150 rpm. No significant difference in the reaction rates was observed between 150 and 250 rpm, indicating that the external resistance transfer is negligible at stirring speeds higher than 150 rpm. Therefore, the rotational speed of 150 rpm was chosen for all further studies.

Effect of initial amount of water

The amount of water present on the surface of some enzymes, such as lipases, contributes to the maintenance of its structural integrity, limits the solubility of hydrophobic substrates in the vicinity of the enzyme and affects the reaction equilibrium [54]. Most lipases require only a small amount of water to maintain its active conformation and to promote esterification reactions in organic systems with high efficiency [55]. Indeed, a large amount of water may inhibit the esterification reactions shifting the equilibrium toward hydrolysis or may induce enzyme inactivation. The investigate the influence of the amount of water in the enzymatic activity of RML immobilized onto chitosan, water was added to the reaction mixture from 0.5 to 2% (wt), concerning total mass of reagents. The results are displayed in Fig. 4a.

a Effect of initial amount of water on the synthesis of methyl butyrate (open circle) and ethyl butyrate (closed square). Conditions: solvent: n-heptane; Vreaction = 20 mL; protein load (mgprotein g−1support) = 1.61; biocatalyst amount (mg): 100 (methyl butyrate) and 200 (ethyl butyrate); [alcohol]/[acid] molar ratio: methyl butyrate 1,5:1 and ethyl butyrate 1:1; reaction time (t): 8 h; temperature (T): 25 °C. b Effect of time on the esterification reactions for ethyl butyrate (open circle) and methyl butyrate (closed square). Conditions: solvent: n-heptane; Vreaction = 20 mL; protein load (mgprotein g−1support) = 1.61; biocatalyst amount (mg): 100 (methyl butyrate) and 200 (ethyl butyrate); [alcohol]/[acid] molar ratio: methyl butyrate 1,5:1 and ethyl butyrate 1:1; temperature (T): 25 °C. FTIR spectra for methyl butyrate (c) and ethyl butyrate (d) after 6 h reaction

As can be seen in Fig. 4a, for both esters, conversion rates decreased with the increased amount of water added to the reaction medium. Highest yields were observed in the absence of water (89% for methyl butyrate and 85% for ethyl butyrate). Other authors reported similar results on the enzymatic synthesis of butyl oleate [56].

Thus, it can be concluded that the amount of water initially adsorbed on the support chitosan can be considered sufficient for the enzyme showing its maximum activity for the synthesis of these two esters in particularly. Additional amounts of water may have markedly increased the degree of hydration of support increasing the thickness of the film around the enzyme. This phenomenon may have resulted in problems of diffusion of substrates to the active site of the enzyme disadvantaging esterification reactions.

Effect of time on the esterification reactions

Generally, a biocatalytic process to be used on a large scale should combine high conversion rates in relatively short times of reaction, using the least amount of enzyme possible [57]. Thus, the reaction time can be considered an important indicator of economic performance and effectiveness of the process. In this sense, the time courses of both reactions were determined. The reactions were assayed at various reaction time intervals, and the esterification percentage was determined. Results are presented in Fig. 4b.

Figure 4b shows that the conversions for the studied esters were increased with increasing reaction times up to 6 h of reaction. At this point, the conversion percentage for both esters started to decrease probably due to a large amount of water produced during reactions. According to the results obtained in these assays, the optimal conditions for the synthesis of methyl butyrate and ethyl butyrate are summarized in Table 1.

Identification of reaction products

After the reactions are completed, the synthesized esters were analyzed using Fourier transform infrared (FTIR) spectroscopy. Figure 4c, d shows the spectra obtained for the synthesized esters.

According to Fig. 4c, d, a strong peak indicating the presence of ester carbonyl group (C=O) about 1740 cm−1 for both esters was evidenced. These results are in agreement with some results reported in the literature.

Comparative study with the commercial enzyme Lipozyme®

Within the optimized conditions to obtain the esters studied, a comparative study of esterification yields between the biocatalyst produced in this work, the commercial enzyme Lipozyme®, the soluble enzyme and the biocatalyst produced in the absence of the SDS was performed. The results for both syntheses are shown in Fig. 5a, b.

Comparative study of esterification yields in the synthesis of esters ethyl butyrate (a) and methyl butyrate (b) with biocatalysts: (I) soluble enzyme; (II) biocatalyst produced in the absence of the surfactant; (III) biocatalyst produced in the presence of the surfactant and (IV) commercial enzyme Lipozyme®. Operation stability for the synthesis of methyl butyrate (c) and ethyl butyrate (d)

For ethyl butyrate (Fig. 5a), the conversion yield for the biocatalyst III (92 ± 1%) was comparable to the commercial enzyme Lipozyme® (86 ± 1%) and soluble enzyme (89 ± 1%). Making a comparison between yields obtained with the biocatalysts produced in the presence and absence of SDS (II and III, respectively) the results show the increase in enzymatic activity promoted by the addition of this tensoactive used during the immobilization procedure. The esterification yield for biocatalyst III was 2.3 greater than biocatalyst II (37 ± 2%).

For methyl butyrate (Fig. 5b), the conversion rate of the biocatalyst III (89 ± 1%) was 4.5 times higher than the rate of conversion of the ester derivative obtained when using the biocatalyst II (immobilization in the absence of surfactant SDS), which allowed conversion of 20%.

Furthermore, slightly higher rates of reaction were achieved when the biocatalyst prepared in the presence of SDS was used, compared to the results obtained when commercial enzyme Lipozyme® (86 ± 1%) and soluble enzyme (87 ± 2%) was used under the same reaction conditions.

The presented results show that the biocatalyst produced in this work, under optimized conditions, showed high catalytic efficiency in the synthesis of esters, comparable to the commercial enzyme Lipozyme®, which is widely used in the synthesis of flavor esters.

Operational stability of immobilized lipase

The reusability of immobilized lipase is one of the major advantages to make an enzymatic process cost-effective. Therefore, a set of consecutive batches of synthesis of methyl butyrate and ethyl butyrate were conducted, using a protein load of 27 mgprotein g−1support. A comparison between our preparations and the commercial enzyme Lipozyme® was made. Figure 5c, d show the results for both esters.

As can be seen, the biocatalyst used for the synthesis of methyl butyrate (Fig. 5c) retained its high activity only until the fourth cycle. Until this cycle, the developed biocatalyst showed esterification conversions higher than the commercial enzyme Lipozyme® used in the same conditions. From the fourth reaction cycle, the esterification yields experienced an almost linear decrease and after eight consecutive cycles, the conversion percentage was only 13%. The reduction on the esterification yields may have been a consequence of loss of mass of the biocatalyst due to the successive steps of handling of the derivative after each reaction cycle [41].

For ethyl butyrate synthesis, the biocatalyst was used for seven consecutive cycles without the loss (retained activity close to 100% of initial activity) of its catalytic activity (Fig. 5d). The conversion yields during these cycles were higher than the conversions obtained by using the commercial enzyme Lipozyme®. After ten cycles the esterification yield remained at 50%. As mention before, possible loss of mass of the biocatalyst during the successive cycles of reaction may have contributed to the reduction of yields after seven cycles. Besides that, the reductions on the esterification percentages for the two esters can also be attributed to enzyme denaturation caused by one or both substrates used in the reactions [45].

Conclusions

In this work, RML was immobilized onto chitosan in the presence of surfactant SDS 0.23% (w v−1) to obtain low-cost biocatalysts for the synthesis of two flavor esters (methyl butyrate and ethyl butyrate). In the optimized conditions, the biocatalysts produced showed high catalytic efficiency in obtaining the mentioned esters providing esterification yields comparable and even superior to commercial enzyme Lipozyme® used under the same reaction conditions. For ethyl butyrate, the biocatalyst was used for seven consecutive cycles of reaction with retention of its catalytic activity and for methyl butyrate synthesis the biocatalyst was used for four consecutive cycles without loss of its catalytic activity. The results show that chitosan, a low-cost natural biopolymer, may be employed in obtaining biocatalysts with high catalytic efficiency and that can successfully replace the currently commercial available biocatalysts.

References

Singh M, Singh S, Singh RS, Chisti Y, Banerjee UC (2008) Transesterification of primary and secondary alcohols using Pseudomonas aeruginosa lipase. Bioresour Technol 99(7):2116–2120

Alvarez-Macarie E, Baratti J (2000) Short chain flavour ester synthesis by a new esterase from Bacillus licheniformis. J Mol Catal B 10(4):377–383

de Barros DPC, Fonseca LP, Fernandes P, Cabral JMS, Mojovic L (2009) Biosynthesis of ethyl caproate and other short ethyl esters catalyzed by cutinase in organic solvent. J Mol Catal B 60(3–4):178–185

Kiss MA, Sefanovits-Bányai É, Tóth Á, Boross L (2004) Extractive synthesis of ethyl-oleate using alginate gel co-entrapped yeast cells and lipase enzyme. Eng Life Sci 4(5):460–464

Hasan F, Shah AA, Hameed A (2006) Industrial applications of microbial lipases. Enzym Microb Technol 39(2):235–251

Rueda N, dos Santos CS, Rodriguez MD, Albuquerque TL, Barbosa O, Torres R, Ortiz C, Fernandez-Lafuente R (2016) Reversible immobilization of lipases on octyl-glutamic agarose beads: a mixed adsorption that reinforces enzyme immobilization. J Mol Catal B 128:10–18

dos Santos JCS, Bonazza HL, de Matos LJBL, Carneiro EA, Barbosa O, Fernandez-Lafuente R, Gonçalves LRB, de Sant’ Ana HB, Santiago-Aguiar RS (2017) Immobilization of CALB on activated chitosan: application to enzymatic synthesis in supercritical and near-critical carbon dioxide. Biotechnol Reports 14:16–26

Orrego CE, Valencia JS, Zapata C (2009) Candida rugosa lipase supported on high crystallinity chitosan as biocatalyst for the synthesis of 1-butyl oleate. Catal Lett 129(3–4):312–322

Berger RG (2009) Biotechnology of flavours—the next generation. Biotechnol Lett 31(11):1651–1659

Galvão WS, Pinheiro BB, Golçalves LRB et al (2018) Novel nanohybrid biocatalyst: application in the kinetic resolution of secondary alcohols. J Mater Sci. https://doi.org/10.1007/s10853-018-2641-5

Lima GV, da Silva MR, de Sousa Fonseca T et al (2017) Chemoenzymatic synthesis of (S)-pindolol using lipases. Appl Catal A 546:7–14

Melo A, Silva F, dos Santos J, Fernández-Lafuente R, Lemos T, Dias Filho F (2017) Synthesis of benzyl acetate catalyzed by lipase immobilized in nontoxic chitosan-polyphosphate beads. Molecules 22(12):2165

Pinheiro MP, Rios NS, Fonseca T, de S, Bezerra, de A F, Rodríguez-Castellón E, Fernandez-Lafuente R, Carlos de Mattos M, dos Santos JCS, Gonçalves LRB (2018) Kinetic resolution of drug intermediates catalyzed by lipase B from Candida antarctica immobilized on immobead-350. Biotechnol Prog 34(4):878–889

Bornscheuer UT, Kazlauskas RJ (2006) Hydrolases in organic synthesis: regio- and stereoselective biotransformations, 2nd edn. Wiley, Weinheim. https://doi.org/10.1002/3527607544

Fernandez-Lorente G, Godoy CA, Mendes AA, Lopez-Gallego F, Grazu V, de Las Rivas B, Palomo JM, Hermoso J, Fernandez-Lafuente R, Guisan JM (2008) Solid-phase chemical amination of a lipase from Bacillus thermocatenulatus to improve its stabilization via covalent immobilization on highly activated glyoxyl-agarose. Biomacromolecules 9(9):2553–2561

Koeller KM, Wong C-H (2001) Enzymes for chemical synthesis. Nature 409(6817):232–240

Palomo JM, Muñoz G, Fernández-Lorente G, Mateo C, Fuentes M, Guisan JM, Fernández-Lafuente R (2003) Modulation of Mucor miehei lipase properties via directed immobilization on different hetero-functional epoxy resins: hydrolytic resolution of (R,S)-2-butyroyl-2-phenylacetic acid. J Mol Catal B 21(4–6):201–210

Rios NS, Pinheiro BB, Pinheiro MP, Bezerra RM, dos Santos JCS, Barros Gonçalves LR (2018) Biotechnological potential of lipases from Pseudomonas: sources, properties and applications. Process Biochem. https://doi.org/10.1016/j.procbio.2018.09.003

Raghavendra T, Sayania D, Madamwar D (2010) Synthesis of the ‘green apple ester’ ethyl valerate in organic solvents by Candida rugosa lipase immobilized in MBGs in organic solvents: effects of immobilization and reaction parameters. J Mol Catal B 63(1–2):31–38

Krajewska B (2004) Application of chitin- and chitosan-based materials for enzyme immobilizations: a review. Enzyme Microb Technol 35(2–3):126–139

Bonazza HL, Manzo RM, Santos JCS, Mammarella EJ (2017) Operational and thermal stability analysis of thermomyces lanuginosus lipase covalently immobilized onto modified chitosan supports. Appl Biochem Biotechnol. https://doi.org/10.1007/s12010-017-2546-9

Rodrigues DS, Mendes AA, Adriano WS, Gonçalves LRB, Giordano RLC (2008) Multipoint covalent immobilization of microbial lipase on chitosan and agarose activated by different methods. J Mol Catal B 51(3–4):100–109

Silva JA, Macedo GP, Rodrigues DS, Giordano RLC, Gonçalves LRB (2012) Immobilization of Candida antarctica lipase B by covalent attachment on chitosan-based hydrogels using different support activation strategies. Biochem Eng J 60:16–24

Tufvesson P, Törnvall U, Carvalho J, Karlsson AJ, Hatti-Kaul R (2011) Towards a cost-effective immobilized lipase for the synthesis of specialty chemicals. J Mol Catal B 68(2):200–205

Villalba M, Verdasco-Martín CM, dos Santos JCS, Fernandez-Lafuente R, Otero C (2016) Operational stabilities of different chemical derivatives of Novozym 435 in an alcoholysis reaction. Enzyme Microb Technol 90:35–44

dos Santos JCS, Garcia-Galan C, Rodrigues RC, de Sant’Ana HB, Gonçalves LRB, Fernandez-Lafuente R (2014) Stabilizing hyperactivated lecitase structures through physical treatment with ionic polymers. Process Biochem 49(9):1511–1515

de Oliveira UMF, Lima de Matos LJB, de Souza MCM, Pinheiro BB, dos Santos JCS, Gonçalves LRB (2018) Effect of the presence of surfactants and immobilization conditions on catalysts’ properties of Rhizomucor miehei lipase onto chitosan. Appl Biochem Biotechnol 184(4):1263–1285

Rodrigues RC, Godoy CA, Volpato G, Ayub MAZ, Fernandez-Lafuente R, Guisan JM (2009) Immobilization-stabilization of the lipase from Thermomyces lanuginosus: critical role of chemical amination. Process Biochem 44:963–968

Li X-L, Zhang W-H, Wang Y-D, Dai Y-J, Zhang H-T, Wang Y, Wang H-K, Lu F-P (2014) A high-detergent-performance, cold-adapted lipase from Pseudomonas stutzeri PS59 suitable for detergent formulation. J Mol Catal B 102:16–24

Helistö P, Korpela T (1998) Effects of detergents on activity of microbial lipases as measured by the nitrophenyl alkanoate esters method. Enzyme Microb Technol 23(1–2):113–117

Holmberg K (2018) Interactions between surfactants and hydrolytic enzymes. Colloids Surf B 168:169–177

Fernández-Lorente G, Palomo JM, Fuentes M, Mateo C, Guisán JM, Fernández-Lafuente R (2003) Self-assembly of Pseudomonas fluorescens lipase into bimolecular aggregates dramatically affects functional properties. Biotechnol Bioeng 82(2):232–237

Mogensen JE, Sehgal P, Otzen DE (2005) Activation, inhibition, and destabilization of Thermomyces lanuginosus lipase by detergents †. Biochemistry 44(5):1719–1730

Jutila A, Zhu K, Patkar SA, Vind J, Svendsen A, Kinnunen PK (2000) Detergent-induced conformational changes of Humicola lanuginosa lipase studied by fluorescence spectroscopy. Biophys J 78(3):1634–1642

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254

Aragão VC, Rita M, Porto A, André C, Burkert V, Kalil SJ, Fernandes J, Burkert DM (2011) Response surface methodology approach for the synthesis of ethyl butyrate. Food Technol Biotechnol 49(1):103–110

Romero MD, Calvo L, Alba C, Daneshfar A (2007) A kinetic study of isoamyl acetate synthesis by immobilized lipase-catalyzed acetylation in n-hexane. J Biotechnol 127(2):269–277

Barbosa O, Ortiz C, Berenguer-Murcia Á, Torres R, Rodrigues RC, Fernandez-Lafuente R (2014) Glutaraldehyde in bio-catalysts design: a useful crosslinker and a versatile tool in enzyme immobilization. RSC Adv 4(4):1583

Ozyilmaz G, Gezer E (2010) Production of aroma esters by immobilized Candida rugosa and porcine pancreatic lipase into calcium alginate gel. J Mol Catal B 64(3–4):140–145

Krishna SH, Manohar B, Divakar S, Karanth NG (1999) Lipase-catalyzed synthesis of isoamyl butyrate: optimization by response surface methodology. J Am Oil Chem Soc 76(12):1483–1488

Foresti ML, Ferreira ML (2007) Chitosan-immobilized lipases for the catalysis of fatty acid esterifications. Enzyme Microb Technol 40(4):769–777

Romero MD, Calvo L, Alba C, Daneshfar A, Ghaziaskar HS (2005) Enzymatic synthesis of isoamyl acetate with immobilized Candida antarctica lipase in n-hexane. Enzyme Microb Technol 37:42–48

Dave R, Madamwar D (2008) Candida rugosa lipase immobilized in Triton-X100 microemulsion based organogels (MBGs) for ester synthesis. Process Biochem 43(1):70–75

Marty A, Chulalaksananukul W, Willemot RM, Condoret JS (1992) Kinetics of lipase-catalyzed esterification in supercritical CO2. Biotechnol Bioeng 39(3):273–280

Ceni G, Lerin LA, de Conto JF et al (2010) Optimization of 1-glyceryl benzoate production by enzymatic transesterification in organic solvents. Enzyme Microb Technol 46(2):107–112

Belafi-Bako K, Badr AK, Nemestothy N, Ehrenstein U, Gubicza L (2003) Kinetics of ethyl acetate formation by lipase in organic solvent and solvent-free system. Chem Pap 57(4):278–281

Langrand G, Rondot N, Triantaphylides C, Baratti J (1990) Short chain flavour esters synthesis by microbial lipases. Biotechnol Lett 12(8):581–586

Pires-Cabral P, da Fonseca MMR, Ferreira-Dias S (2009) Synthesis of ethyl butyrate in organic media catalyzed by Candida rugosa lipase immobilized in polyurethane foams: a kinetic study. Biochem Eng J 43(3):327–332

Zaidi A, Gainer J, Carta G, Mrani A, Kadiri T, Belarbi Y, Mir A (2002) Esterification of fatty acids using nylon-immobilized lipase in n-hexane: kinetic parameters and chain-length effects. J Biotechnol 93(3):209–216

Paiva AL, Balcão VM, Malcata FX (2000) Kinetics and mechanisms of reactions catalyzed by immobilized lipases. Enzyme Microb Technol 27(3–5):187–204

Gonçalves LRB, Ferreira ALO, Fernandez-Lafuente R, Guisan JM, Giordano RC, Giordano RLC (2008) Influence of mass transfer limitations on the enzymatic synthesis of β-lactam antibiotics catalyzed by penicillin G acylase immobilized on glioxil-agarose. Bioprocess Biosyst Eng 31(5):411–418

Gandhi NN, Sawant SB, Joshi JB (1995) Studies on the lipozyme-catalyzed synthesis of butyl laurate. Biotechnol Bioeng 46(1):1–12

Shu C, Cai J, Huang L, Zhu X, Xu Z (2011) Biocatalytic production of ethyl butyrate from butyric acid with immobilized Candida rugosa lipase on cotton cloth. J Mol Catal B 72(3–4):139–144

Klibanov AM (2001) Improving enzymes by using them in organic solvents. Nature 409(6817):241–246

Dordick JS (1989) Enzymatic catalysis in monophasic organic solvents. Enzyme Microb Technol 11(4):194–211

Ghamgui H, Karra-Chaâbouni M, Gargouri Y (2004) 1-Butyl oleate synthesis by immobilized lipase from Rhizopus oryzae: a comparative study between n-hexane and solvent-free system. Enzyme Microb Technol 35(4):355–363

Martins AB, Graebin NG, Lorenzoni ASG, Fernandez-Lafuente R, Ayub MAZ, Rodrigues RC (2011) Rapid and high yields of synthesis of butyl acetate catalyzed by Novozym 435: reaction optimization by response surface methodology. Process Biochem 46(12):2311–2316

Acknowledgements

The authors would like to thank the Brazilian research-funding agencies FUNCAP (BP3-0139-00005.01.00/18), CNPq and CAPES. The data used in this article originated from the Ph.D. Thesis of Ulisses Marcondes Freire de Oliveira (ORCID ID: orcid.org/0000-0002-5479-4905), available in: (http://repositorio.ufc.br/bitstream/riufc/17222/1/2012_tese_%20umfoliveira.pdf?). This Doctoral thesis has been submitted (2012) to the Postgraduate Program in Biotechnology of the Northeast Biotechnology at Federal University of Ceará—UFC as part of the requirements for obtaining title Ph.D. in Industrial Biotechnology. Thesis Advisor: Prof. Dr. Luciana Rocha Barros Gonçalves.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors whose names are listed immediately below certify that they have no affiliations with or involvement in any organization or entity with any financial interest (such as honoraria; educational grants; participation in speakers’ bureaus; membership, employment, consultancies, stock ownership, or other equity interest; and expert testimony or patent-licensing arrangements), or non-financial interest (such as personal or professional relationships, affiliations, knowledge or beliefs) in the subject matter or materials discussed in this manuscript.

Rights and permissions

About this article

Cite this article

de Oliveira, U.M.F., Lima de Matos, L.J.B., de Souza, M.C.M. et al. Efficient biotechnological synthesis of flavor esters using a low-cost biocatalyst with immobilized Rhizomucor miehei lipase. Mol Biol Rep 46, 597–608 (2019). https://doi.org/10.1007/s11033-018-4514-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11033-018-4514-z