Abstract

Lipase from Rhizomucor miehei (RML) was immobilized onto chitosan support in the presence of some surfactants added at low levels using two different strategies. In the first approach, the enzyme was immobilized in the presence of surfactants on chitosan supports previously functionalized with glutaraldehyde. In the second one, after prior enzyme adsorption on chitosan beads in the presence of surfactants, the complex chitosan beads-enzyme was then cross-linked with glutaraldehyde. The effects of surfactant concentrations on the activities of free and immobilized RML were evaluated. Hexadecyltrimethylammonium bromide (CTAB) promoted an inhibition of enzyme activity while the nonionic surfactant Triton X-100 caused a slight increase in the catalytic activity of the free enzyme and the derivatives produced in both methods of immobilization. The best derivatives were achieved when the lipase was firstly adsorbed on chitosan beads at 4 °C for 1 h, 220 rpm followed by cross-link the complex chitosan beads-enzyme with glutaraldehyde 0.6% v.v−1 at pH 7. The derivatives obtained under these conditions showed high catalytic activity and excellent thermal stability at 60° and 37 °C. The best derivative was also evaluated in the synthesis of two flavor esters namely methyl and ethyl butyrate. At non-optimized conditions, the maximum conversion yield for methyl butyrate was 89%, and for ethyl butyrate, the esterification yield was 92%. The results for both esterifications were similar to those obtained when the commercial enzyme Lipozyme® and free enzyme were used in the same reaction conditions and higher than the one achieved in the absence of the selected surfactant.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Lipases (glycerol ester hydrolases E.C. 3.1.1.3) are an important group of enzymes whose biological function is to catalyze the hydrolysis of oils and fats. Apart from hydrolysis, under micro-aqueous environment, they can catalyze reactions such as esterification [1,2,3], transesterification [4], alcoholysis [5], acidolysis [6], epoxidations [7], etc.

The great versatility of lipases makes them suitable for various applications in food and flavor making, pharmaceutical, fine chemical and cosmetic industries, among others [8].

Despite the advantages of these biocatalysts, problems arise when these enzymes are utilized in its free form. They are unstable at moderately high temperatures and solvents and hard to be recovered from the reaction medium [9]. Therefore, immobilization is often requested for most of the industrial applications involving these enzymes. Immobilization of lipases on an insoluble support can overcome the mentioned limitations, avoiding product contamination, diminishing thermal deactivation of the enzyme, and allowing easy biocatalyst recovery, reuse, and continuous operation, minimizing downstream process costs as well as environmental impact [10]. Lipases have been immobilized using several types of carriers and by numerous methods like physical adsorption [11], covalent attachment to a solid matrix [12], entrapment or encapsulation in an insoluble carrier. Various inorganic and organic supports have been used for the immobilization of lipases. However, the high cost of some materials like silica-based carriers, acrylic resins, synthetic polymers, and exchange resins, as well as the techniques commonly used for immobilization of these enzymes, significantly increases the costs of biocatalysts. Among several supports employed for the immobilization of lipases, chitosan has shown suitable properties for this purpose [13,14,15].

Chitosan is a low-cost linear β-1, a 4-linked polysaccharide that is obtained by the partial deacetylation of chitin. Chitin is an abundant raw material found in cell walls of some fungi and especially in the shells of some shellfish (mainly shrimp, lobster, krill, and crabs), wastes of the seafood industry [16]. Chitosan has found broad application in the immobilization of enzymes to present desirable properties such as hydrophilicity, biocompatibility, biodegradability, nontoxicity, physiological inertness also possessing high affinity for proteins [14].

Due to its amine groups, chitosan is a cationic polyelectrolyte (pKa = 6.5) being insoluble in neutral aqueous solutions, but it is soluble in acidic solutions below pH 6.5.

This biopolymer has hydroxyl and reactive amine groups in its structure amenable to modification with bifunctional reagents such as glycidol and glutaraldehyde [17].

Glutaraldehyde is a versatile reagent that under specific conditions reacts with themselves and with different groups (e.g., thiols, phenols, and imidazoles) but mainly with primary amino groups of proteins [17].

At least three distinct reaction types of glutaraldehyde are known: (i) the free glutaraldehyde, (ii) the glutaraldehyde-amino, and (iii) the amino-glutaraldehyde-glutaraldehyde moiety. These active forms can react with themselves or with structures closely related depending on the medium pH [18]. At extreme pH conditions (pH values above 8) or higher concentrations (e.g., 1 mol .L−1), uncontrolled polymerization of glutaraldehyde in solution is observed [18].

This reagent has been widely used as a cross-linker to immobilize enzyme molecules onto various supports, but in most cases, this bifunctional compound is commonly used to immobilize enzymes on supports having primary amino groups [15].

When glutaraldehyde is used as a cross-linker, two general immobilization strategies can be employed. In the first one, the enzyme is primarily adsorbed by ionic exchange onto the laminated support, and then the enzyme-support compound is treated with glutaraldehyde under mild conditions [18]. In such strategy, all the primary amino groups of the enzyme and the support are modified with just one molecule of the glutaraldehyde and an intense multipoint covalent enzyme-support attachment may be achieved [19].

The second possibility is to immobilize the enzyme in a glutaraldehyde-activated support. In this procedure, conditions under which modification of the amine group occurred specifically with one or two glutaraldehyde molecules [19]. The resulting structure would react with the primary amino groups of the enzyme (pK 7–8) usually at neutral pH value. At this pH, the reactivity of ɛ-amino groups of lysine (Lys) is quite small (pK over 10) and, as a result, the intensity of the multipoint covalent attachment may not be so high as in the first case [19].

While the second approach limits the chemical modification of the enzyme to only the groups of the protein involved in the immobilization, the entire surface of the enzyme may be modified with glutaraldehyde when the first immobilization protocol is used [18]. Thus, the selection of one of the immobilization methods aforementioned will produce biocatalysts with different properties regarding activity and stability.

Esters of short chain carboxylic acids and alcohols are the major components of some natural flavors widely used as additives or precursors in food, beverages, cosmetics, agrochemical, and pharmaceutical preparations [20]. Nowadays, most flavor and fragrances are obtained from a plant extract or by chemical synthesis. Esters from plant materials are very scarce, and the high costs of extraction and isolating of such compounds due to their low concentrations and meager extraction yields makes this process prohibitive [21]. By the other hand, chemical synthesis of these esters is considered economical but makes use of strong acids or alkalis as a catalyst and high temperature and pressure conditions being considered environmentally unsafe, requiring too additional post-treatment steps [22].

Lipase-catalyzed ester synthesis has been pointed out as a promising alternative to the traditional methods. The enzymatic approach allows mild operation conditions, elimination of side reactions, low energy-cost, a higher degree of purity of the products which may lead to lower the overall operating costs [23]. Besides, the products are labeled as “natural” by some food regulatory agencies [24].

Lipases from different sources immobilized onto various kinds of supports have been used in some non-conventional media (e.g., ionic liquids, supercritical fluids) but especially on organic solvents aiming at the production of various flavoring esters [25]. Thus, the development of biocatalysts that fulfill some requirements such as high catalytic activity, thermal stability, excellent operational stability, and low cost must be taken into account for a possible application of these biocatalysts in various industrial processes including the large-scale production of such esters using immobilized lipases [26].

Rhizomucor miehei lipase (RML) is an extracellular enzyme whose structure was well resolved at 1.9 Å resolution [27]. The molecular size of RML is 31,600 Da, and its isoelectric point is 3.8 [28]. Its active site is composed of the catalytic triad Ser144, His257, and Asp203 with an active serine buried under a short helical fragment of an extended surface loop (lid).This enzyme is a single polypeptide chain of 269 residues [27].

R. miehei lipase in homogeneous aqueous solutions exhibit two different conformations in equilibrium: a closed form (inactive) where the catalytic site of the enzyme is secluded from the reaction medium by means of a helicoidal polypeptide chain (flat or lid) and the second form (open form) active, where this lid is entirely displaced in the presence of hydrophobic surfaces exposing the catalytic site of the enzyme to the reaction medium [11]. On a homogeneous aqueous medium, some lipases including RML tends to form bimolecular aggregates (dimmers) with reduced activity [29]. The aggregate formed will have an active center open but partially blocked leading to certain implications in some of its biochemical properties like activity, stability, and enantioselectivity.

Thus, a suitable method to obtain biocatalysts with high catalytical activity should try to immobilize these enzymes in a given support in their most active form (open form). In this sense, some strategies such as the immobilization of lipases on porous hydrophobic supports or in the presence of additives like surfactants have been proposed [30]. Several studies have shown that the presence of some surfactants stabilizes the open form of lipases which can be fixed to a support via chemical or physical immobilization leading to the formation of hyperactivated biocatalysts [15]. To obtain biocatalysts with high catalytic efficiency, R. miehei lipase (RML) was immobilized onto chitosan support in the presence of some surfactants added at low concentrations. The lipases’ activities can be improved in the presence of surfactants, and this effect has been attributed mainly to the breakdown of lipase aggregates (dimmers) and/or the shift in the open-closed equilibrium of the individual enzyme molecules towards the open form more active [31]. It is believed that lipase-surfactant interactions are primarily hydrophobic, but the nature of the hydrophilic group on the surfactant also contributes to the contact, and the intensity of such interactions may be responsible for the breakdown of these self-assembled structures.

Two immobilization strategies were adopted. In the first, lipases were immobilized in the presence of surfactants on chitosan supports previously activated with glutaraldehyde. In the second protocol, chitosan was reticulated with glutaraldehyde after prior adsorption of the enzymes. This study evaluated the influence of surfactants added at various concentration levels on the enzymatic activity of free and immobilized enzymes. Although some studies on the use of surfactants for the stabilization of lipases have been reported, to our knowledge, this is the first report on the use of surfactants to improve catalytical properties of immobilized R. miehei lipase onto chitosan supports.

To evaluate its potential as a useful biocatalyst, the best derivative was used in the synthesis of two flavor esters of commercial interest, namely methyl butyrate and butyl butyrate. The experimental results were compared concerning commercial enzyme Lipozyme®, free enzyme, and the biocatalyst produced in the absence of the selected surfactant in the best conditions of immobilization in the synthesis of such esters in the same reaction conditions.

Materials and Methods

Materials

Powdered chitosan, 85.2% deacetylation degree, was purchased from Polymar Ind Ltda (Ceará, Brazil). R. miehei lipase (128 ± 3 UpNPB/mL), Lipozyme® (immobilized lipase from Mucor miehei, > 30 units.g−1 against tristearin at pH 8.0 and 70 °C), p-nitrophenyl butyrate (pNPB), and glutaraldehyde 25% (v.v−1) were acquired from Sigma-Aldrich Chemical Co. (St. Louis, MO). All other reagents and solvents used were of analytical grade.

Methods

All experiments were performed in triplicate, and the results are reported as the mean of this value and the standard deviation (under 10%).

Preparation of Chitosan Beads

Powdered chitosan was dissolved in an acetic acid 5%v.v−1 solution. The obtained solution of 2.5% (m.v−1) was dropped into a gently stirred NaOH 100 mM solution at 25 °C (ratio chitosan/NaOH = 1:10). After 24 h, chitosan beads were washed exhaustively with distilled water until neutrality and then dried by vacuum filtration.

Activation with Glutaraldehyde

Chitosan beads were activated in sodium phosphate buffer solution 100 mM pH 7.0 containing 0.6% (v.v−1) glutaraldehyde (ratio V gel/V total 1:10) for 60 min at 25 °C under slow stirring. After that, chitosan support was washed thoroughly with distilled water to remove glutaraldehyde excess and then dried under vacuum.

Immobilization Strategies

In this work, two immobilization strategies were performed, named: Immobilization strategy I and Immobilization strategy II (Fig. 1).

Immobilization Strategy I

In the first step, chitosan beads were activated with glutaraldehyde according to item 2.2.2. After that, the support and the enzymes were incubated in the presence of surfactants under slow stirring for 5 h at 25 °C. Afterwards; the immobilized enzyme was washed several times with distilled water to remove excess of surfactant and glutaraldehyde and stored at 4 °C.

Immobilization Strategy II

R. miehei lipase (RML) was firstly adsorbed at the support in the presence of surfactants in phosphate buffer 100 mM pH 7.0 under moderate agitation for 5 h at 25 °C. The composite RML-chitosan was reticulated with glutaraldehyde under the same conditions described (at 2.2.2. item), and then the detergent was added. The obtained derivative was then washed several times with distilled water and stored at 4 °C.

In all strategies, to evaluate enzyme deactivation during immobilization (control assay), a solution of RML was placed in a reactor under the same conditions of immobilization, but in the absence of support.

Assay of Hydrolytic Activity: Hydrolysis of pNPB

The hydrolysis of p-nitrophenyl butyrate (pNPB) was used to follow the free and immobilized enzyme hydrolytic activities. Assays were performed by measuring the increase in the absorbance at 400 nm produced by the release of p-nitrophenol in the hydrolysis of 0.5 mM pNPB in 25 mM sodium phosphate buffer at pH 7.0 and 25 °C, according to the methodology described in the literature, with some modifications [32]. The reaction time was 12 min. One unit of pNPB activity (U pNPB) was defined as the amount of enzyme that is necessary to hydrolyze 1 μmol of pNPB per minute under the conditions described.

Protein concentration was measured according to Bradford [33] using bovine serum albumin (BSA) as a standard.

Assay of Thermal Stabilities of Free and Immobilized RMLs

Free and immobilized enzymes were incubated in a sodium phosphate buffer 25 mM and pH 7 at 60 °C. Periodically, samples were withdrawn, and their residual hydrolytic activities were assayed. The single step on the first-order model, proposed by Sadana and Henley [34], was fitted to the experimental data. This model considers that a single step inactivation leads to a final state that exhibits a residual activity, which is very stable. The activity-time expression is expressed in Eq. 1:

where A R is the residual activity (dimensionless), the ratio between the specific activity of the final state, A tf, and one of the initial state, Ato; and k d is the first-order deactivation rate constant (time−1). With the exponential nonlinear decay model and its parameters, it was possible to determine the inactivation constant (k d) and the half-lives (t 1/2) of the immobilized and free enzyme. Stabilization factor (S F) was given as the ratio between the half-life of the immobilized enzyme and the half-life (t 1/2) of the free enzyme at the same conditions.

Enzymatic Synthesis of Methyl and Butyl Butyrate

The esterification reactions were carried out in 125 mL glass-stoppered flasks using n-heptane as a solvent. The reactional medium containing substrates and biocatalysts was 20 mL. To initiate the reaction, 150 mg of the biocatalyst for methyl butyrate and 200 mg for ethyl butyrate was added to the freshly prepared reaction medium that was kept on an orbital shaker (Tecnal TE-420, Piracicaba, Brazil) at 25 °C and 150 rpm. For methyl butyrate synthesis, the molar ratio [alcohol]/[acid] was 1.5:1 with a fixed acid concentration of 0.1 mol L−1. For ethyl butyrate, both substrates were added at equimolar concentrations (0.2 mol L−1 each, molar ratio [alcohol]/[acid] 1:1). In all experiments, the offer enzyme loaded was 50 units.g−1 support (1.63 mg.g−1 support). Before and after 6 h reaction, aliquots of the reaction mixture were withdrawn and titrated against standard potassium hydroxide using phenolphthalein as an indicator to determine the residual acid concentration [25]. Ethanol was used as quenching agent [35]. The percentage of esterification was calculated from the acid consumed in the reaction mixture according to Eq. 2:

where C 0 is the true concentration of acid measured before the start of reaction and C is the residual acid concentration after 6 h reaction time. Control experiments were also conducted without lipase under similar reaction conditions.

Scanning Electron Microscopy

The scanning electron microscopy analyses were performed in a TESCAN electron microscope scanning electron microscopy (SEM) (Model VEGA/Xmu, Brno, Czech Republic) using accelerating voltage of 30 kV. The samples were sputter-coated with gold before analysis.

Immobilization Parameters

The immobilization parameters, immobilization yield (IY), theoretical activity (Att) of immobilized lipase, and recovery activity (Atr), were calculated according to Santos et al. 2017 [32]. For doing that, the initial (Ato) and the final (Atf) enzyme activities in the supernatant and the blank assay were determined. The remaining enzyme activity in the supernatant (Ato − Atf) was used to calculate the immobilization yield (IY), according to Eq. 3.

The theoretical activity (Att) of immobilized lipase was determined by Eq. 4, being Atoff the enzyme activity per gram of the gel at the beginning of the essay:

After determining the apparent immobilized activity (Atder), the recovery activity (Atr) was determined according to Eq. 5:

Results and Discussion

Effect of Surfactants on the Activity of RML

The effect of increasing concentrations of different surfactants on the activity of free RML was evaluated, and the results are shown in Fig. 2. The measurements of the activities were performed after a few minutes of exposure of the lipase to the surfactants, and convenient dilutions of samples were made to avoid surfactant interferences. The presence of different surfactants, added at various levels to the reaction medium, promoted different effects on the hydrolytic activity of free RML.

As can be seen in Fig. 2, free RML exhibited a moderate increase in its activity (1.5-fold) in the presence of Triton X-100, using 0.015% m. v−1 of surfactant, around the critical micellar concentration of this surfactant [36]. At concentrations above this level, the biocatalyst activity decreased markedly.

Soluble RML showed a nearly linear behavior in its hydrolytic activity after consecutive increments of SDS added reaching a maximum when the concentration of surfactant was 0.23% m.v−1, near its critical micellar concentration (CMC). At this concentration, the activity of free RML was approximately three times higher than the activity of the free enzyme in the absence of surfactant. Above CMC, the enzyme activity declined, but it was still higher when compared with enzyme activity in the absence of surfactant. The same behavior was observed on the activity of the free Thermomyces lanuginosus lipase against pNPB in the presence of that surfactant [37].

The different effects caused by the addition of surfactants on the activity of free lipases can be attributed to two factors. First, the detergents can act breaking the lipase-lipase aggregates rendering individual enzyme molecules that can be stabilized in their most active conformation (open form) with improved activities. By the other hand, additional detergent molecules (above CMC, in our case) may bind to the active site region, blocking the substrate access, inducing inhibition [38].

It can also be seen in Fig. 2 that the surfactant SDS especially around its CMC has promoted more positive effects on the hydrolytic activity of free RML against pNPB as compared to Triton X-100.

Two possible considerations to explain this phenomenon has been done: (i) SDS shows a specific interaction with the active site region increasing the enzymatic activity and (ii) in addition, SDS binds unspecifically to the protein surface, and its charge leads to a weakening of the interactions in the native state, making it more flexible (partially destabilized) allowing the accommodation of more substrate molecules leading to a higher catalytic turnover, and thus, enhancing enzymatic activity [37]. On the contrary, Triton X-100, a nonionic surfactant regarded as a mild detergent interacts with the protein surface but without promoting changes in the enzyme activity against pNPB.

The presence of hexadecyltrimethylammonium bromide (CTAB) in the reaction medium exerted a negative effect on the hydrolytic activity of the free RML. After a slight increase in enzyme activity when the surfactant was added at a low concentration (0.00015% m.v−1), increasing amounts of surfactant resulted in a decrease in the hydrolytic activity of the free enzyme. At concentrations above 0.1% m.v−1, the surfactant led to complete inhibition of the enzyme. Positive charged surfactants tends to form complexes with RML over a broad pH range, even below its isoelectric point due to a combination of electrostatic or hydrophobic interactions or the presence of carboxylic groups in the enzyme with very low pKa values located adjacent to hydrophobic amino acid residues leading to activity reduction or enzyme inactivation [39].

Taking into account these preliminary results, the immobilizations were performed only in the presence of the surfactants Triton X-100 and SDS.

Effect of the Presence of Surfactants on the Activity of the Immobilized Enzyme

Effect of Triton X-100

In these experiments, Triton X-100 was added with the same range of concentrations used in earlier experiments to free RML. The results of the two immobilization strategies adopted in this study are displayed in Fig. 3. In both strategies, the immobilization yields (IY) were quite similar varying in the interval of 80–99%. These results are in agreement with some publications reported at literature [40, 41]. However, in terms of relative activity, the two immobilization strategies exhibited very significant differences.

Effect of Triton X-100 on the activity against pNPB of Chitosan (CHIT) immobilized RML preparations. Experiments were performed as described in Material and Methods. Relative activity considers 100% the lipase activity in the absence of surfactant. X-axis plotted in log scale. (■) strategy I; (●) strategy II

The results displayed in Fig. 3 show that the first immobilization strategy did not yield the desirable effects on the catalytic activities of the immobilized enzyme. A small increase in the activity of the immobilized enzyme was evidenced only when the surfactant concentration in the immobilization medium was 0.015% m.v−1. Above this concentration value, the activities of the immobilized enzyme were sharply reduced to values lower than those obtained when the immobilization was carried out in the absence of surfactant.

In contrast, Fig. 3 indicates that cross-linking with glutaraldehyde of lipases previously adsorbed on chitosan support in the presence of Triton X-100 seems to be an appropriate alternative to obtain derivatives with relative good catalytical properties using this surfactant to immobilize RML onto chitosan support. Some differences between the two immobilization protocols when some levels of this surfactants were added must be due to some experimental errors.

Chitosan is a support which has hydrophilic characteristics while RML has a large number of non-polar amino acid in its structure. The RML adsorption onto chitosan support may be attributed to a combination of two interaction mechanism: (i) ionic, through charged amino acids (e.g., Asp and Glu) of the protein with NH3 + groups of chitosan on pH values near to its pKa where the fraction NH2/NH3 + approaches to 0.5 and (ii) through hydrophobic interactions (e.g., van der Waals interactions) and hydrogen bonding involving NH2/OH groups of the support [42]. But, for the first immobilization strategy used in this work, in the presence of surfactants, an ionic exchange may be the first immobilization process [40].

Surfactant concentration greater than 0.00015% and up to 0.015% m.v−1 resulted in immobilized enzyme derivatives with improved catalytic activities as compared to the derivatives obtained when the first immobilization strategy was employed. As well as in the first strategy, maximum activity was observed when the concentration of surfactant added was 0.015% m.v−1. Above this level, the derivative activity was appreciably diminished but to a lesser extent in comparison with activities of those derivatives produced in the first strategy or when the immobilizations were performed in the absence of surfactant.

Lipases from different sources have been immobilized in the presence of Triton X-100 onto various supports [43]. The results obtained in these works are somewhat different in comparison with the results presented in the current work.

However, the degree of activation or hyperactivation of lipases do not obey a general rule being markedly influenced by the kind of enzyme used, the characteristics and the concentration of the surfactant added to the immobilization medium, the characteristics of the support, the immobilization conditions as well as the substrate used in the reactions [43].These considerations may in part explain the slight differences observed.

Effect of SDS

Figure 4 shows that unlike what was observed to immobilizations carried out in the presence of Triton X-100, the presence of SDS in the concentration range of 0.00015 to 0.23% m.v−1, regardless of the immobilization strategy, was always accompanied by an almost linear increase in the activities of the immobilized enzyme derivatives. In both approaches, the maximum activity was achieved when the SDS concentration reached its CMC, around 0.23% m.v−1. At this concentration, the activities of the derivatives were increased by a 2.9-fold and 3.4-fold factor, respectively, for the first and the second immobilization strategy. The results were very similar to the results obtained with the free RML. Above the CMC value, the derivative activities declined, but yet these activities were higher than the activities measured for derivatives produced in the absence of surfactant.

Effect of SDS on the activity against pNPB of Chitosan (CHIT) immobilized RML preparations. Experiments were performed as described in the “Material and Methods” section. Relative activity considers 100% the lipase activity in the absence of surfactant. X-axis plotted in log scale. (▲) strategy I; (□) strategy II

In a recent work [44], RML was immobilized onto a support with different characteristics using three immobilization protocols in the presence of anionic detergent sucrose laurate. When the enzyme was physically adsorbed on Q-Sepharose support, a strong anionic exchanger at pH 7.0 and 25 °C after prior purification and hyperactivation with 0.5% sucrose laurate, the enzyme immobilized derivatives preserved more than 90% of its hyperactivation after removal of the detergent. On CNBr-activated Sepharose (one-point immobilization), the hyperactivation was completely removed after removal of the detergent. In multipoint covalent attachment at pH 10 on activated glyoxyl-Sepharose, the enzyme lost 50% of its hyperactivation during immobilization, and after removal of the detergent, the entire value was lost. The best results obtained with the anionic exchanger was attributed to a possible change in the region with the highest density of negative charge involved in the adsorption when the closed form of the lipase is transformed into hyperactivated open form. Besides, the presence of the detergent induces a complex change in the enzyme’s active center promoting too a structural rearrangement in the other regions of the enzyme.

These considerations can explain the results achieved in the actual work. Chitosan support at pH 7.0 is a polycationic electrolyte acting as an ion exchanger like Q-Sepharose. Thus, the presence of the anionic surfactant SDS in the immobilization medium may cause the same structural change in the enzyme molecule, leading to a stabilization of RML open form even after removal of the detergent.

The data presented in Fig. 2 and Fig. 4 show that no differences were observed in the relative activities of the free enzyme and the derivatives obtained when the second immobilization strategy was used. The results reported so far showed that SDS was more effective to obtain derivatives with higher catalytic activities as compared to the same derivatives achieved when Triton X-100 was used to RML immobilization on chitosan support. Therefore, further assays were performed in the presence of this surfactant at a concentration level of 0.23% m.v−1 by using the second immobilization strategy.

In order to check possible inactivation effects of long-term incubation of free RML on the presence of SDS, which was added to the immobilization medium in its critical micellar concentration, the hyperactivation kinetics of free RML was accompanied for 5 h in the same conditions adopted by the two immobilization methods in the preliminary studies of RML immobilization on chitosan support. The results are shown in Fig. 5.

Time courses of the hyperactivation of free RML incubated in the presence of 0.23% m.v−1 SDS. Experiments were carried out as described in the “Materials and Methods” section. Relative activity considers 100% the lipase activity in the absence of surfactant

The results presented in Fig. 5 show that RML undergoes a marked inhibition of their activities after prolonged exposure to SDS at the concentration added. The results presented in Fig. 5 show a decrease in RML activity in the presence of SDS along time. After 120 min of exposure to this surfactant, a decrease of 80% compared to activity measured initially was evidenced. However, Fig. 5 also reveals, even with greatly diminished activity, the free enzyme exhibited a higher activity when compared to the free enzyme incubated in the absence of surfactant after 24 h.

Taking into account the results of this assay and to minimize the effects of extended exposure to the enzymes to SDS under the conditions previously established, new experiments were performed varying the immobilization conditions. Some factors such as temperature and agitation speed were studied. The immobilization time in all experiments was 1 h, and the support activation conditions were the same as used in previous experiments. Table 1 shows the effects of these parameters on the properties of the obtained biocatalysts.

The results stated in Table 1 shows that the immobilization yields did not vary significantly. However, Table 1 reveals that the immobilized enzyme activities were markedly influenced by the immobilization conditions. Enzyme immobilization carried out for 1 h at mild temperature and at high agitation speed yielded biocatalysts with increased catalytic activities. By using the second immobilization method in the presence of 0.23% m.v−1 of SDS, the best immobilized enzyme derivatives were achieved when the immobilization temperature was kept at 4 °C and the agitation speed was 220 rpm for 1 h followed by the cross-link of the complex enzyme-chitosan-surfactant with glutaraldehyde 0.6% v.v−1 for 1 h at 25 °C at low agitation. Thus, these optimized conditions were used for further studies.

Effect of pH Value on the Activity of the Different RML Preparations

The effect of pH is one of the main parameters in the design of enzymatic biocatalysts. Variations in pH values provide ionic modifications at the protein surface. And consequently how they will interact with the carrier during the immobilization process. In general, the soluble enzyme RML presented an excellent profile of catalytic activity, when the pH was alkaline, approximately pH 8. A similar result was reached by Adamczak [45].

For the immobilized enzyme, a lower capacity of enzymatic activity was observed in the acid pH range (4–5). On the other hand, an increase in activity at alkaline pH was observed (8–9). At pH 10, a strong decrease in the catalytic activity of the biocatalyst was observed, with loss of up to 80% of initial activity. This fact can be related to the lower stability of the glutaraldehyde molecules in this pH range [17], which is not adequate, besides being a pH range not suitable for RML [46], thus compromising the stability of the biocatalyst.

The Final Structure of the Biocatalysts

Finally, the difference of the final structure of the catalysts using two different strategies can be explained by different possibilities. However, it is important to consider some factors that contribute to the design of more efficient biocatalysts. In the first, the RML is activated by some detergents, even in organic media. Second, to emphasize that RML tends to form bimolecular aggregates with reduced activity and to consider that detergents can break these dimers. Third, RML has a lid that recovers its active site; the balance between open form and closed form is broken by the presence of detergent molecules, as demonstrated in the present study. And lastly, the effect of glutaraldehyde on the molecular covalent bond formation. In the first strategy (I), the support was previously activated with glutaraldehyde, and then the enzyme was immobilized in the presence of detergent.

According to the details already mentioned above, it is possible that most of the immobilized enzymes are in their final, closed, and therefore less active structural form, since the possibility of immobilization of protein clusters may have occurred. Also, after the washing step of the detergent, the enzyme is returned to its closed structural form. Meanwhile, in the second immobilization strategy (II), initially the enzyme was adsorbed onto the support, glutaraldehyde was added, and finally the detergent, thus ensuring that a greater amount of enzyme in the open form was attached to the support. In this strategy, positive conformational deformation is considered. Thus, after washing the detergent, the enzyme remains immobilized in its open structural form and produces a more active biocatalyst.

Scanning Electron Microscopy

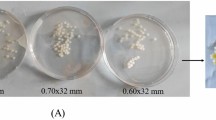

Chitosan support may undergo considerable changes in its morphology after treatment with glutaraldehyde. The morphological changes on chitosan surface before and after activation with glutaraldehyde was examined. Figure 6 shows three scanning electron microphotographs of (a) chitosan powder (CHIT), (b) CHIT/GLU 0.6% (v.v−1), and (c) CHIT/GLU 0.6% (v.v−1) after the immobilization of RML.

It can be observed that there is an accentuated difference between the chitosan powder (Fig. 5a) and the chitosan after treatment with glutaraldehyde. After cross-linking with glutaraldehyde, an improvement on the superficial chitosan area is observed which provides a large contact area for enzyme immobilization (Fig. 5b). The rounded structures (Fig. 5c) may be attributed to protein aggregates after RML immobilization [47].

These structural changes on chitosan with an improvement of its superficial area after cross-link with glutaraldehyde may explain the high yields of RML immobilization on this support.

Thermal Stability of the Immobilized Enzyme

The derivatives produced from strategy II in optimized conditions were subjected to thermal stability assay at 60 °C. The obtained results were compared with the thermal stability of the free RML and a commercial derivative (Lipozyme®) at the same temperature. For each thermal stability assay, the half-life (t 1/2) and the stabilization factor (S F) were determined.

In these assays, the effect of the concentration of the cross-linking agent on the activities and thermal stabilities of the immobilized enzyme was also evaluated. Some studies have pointed out that different concentrations of glutaraldehyde used on support activation can lead to significant alterations in the biocatalysts properties [48]. The results of these experiments are presented in Table 2 and Fig. 7.

Thermal inactivation profile of free RML and chitosan-glutaraldehyde derivatives. Immobilization at pH 7.0, 4 °C, 1 h., offered enzyme load of 16 UpNPB/ggel. Free enzyme and derivatives were incubated in a sodium phosphate buffer 25 mM, pH 7.0 at 60 °C: (■)soluble RML; (□) Lipozyme®; (●) CHI-GLU 0.6%; (∆) CHI-GLU 1.5%;(○) CHI-GLU 2.5%; (▲) CHI-GLU 5%.The lines represent the trend of the Sadana and Henley model

The results presented in Table 2 shows that immobilization yields in all experiments did not vary significantly with increasing concentrations of glutaraldehyde. In fact, these results indicate that RML immobilization with 0.6% v.v−1 glutaraldehyde concentration at pH 7 for 1 h is enough to modify all the primary amino groups on the RML surface which is consistent with some reports in the literature [49].

However, increased glutaraldehyde concentrations on the support activation yielded biocatalysts with lower recovery activity than those obtained when glutaraldehyde concentration on support activation was 0.6% and 1.5% v.v−1. The lower immobilized enzyme activities of CHIT-GLU 2.5% and CHIT-GLU 5% v.v−1 may be due to some distortion in enzyme tertiary structure caused by strong interaction between the enzyme and the support used or by the linkage of glutaraldehyde with different groups on the enzyme surface other than lysine (Lys) residues causing reduction in its activity [50]. The immobilized enzyme derivative that showed the higher S F was CHIT-GLU 0.6% v.v−1, being approximately 65 times more stable than the free enzyme and 13 times more stable than the commercial immobilized Lipozyme®. The moderate S F for the best derivative (CHIT-GLU 0.6% v.v−1) may be due the presence of the anionic detergent SDS during the immobilization process which produces a more flexible protein structure as mentioned earlier, increasing its activity, but this increase in activity might have been accompanied by a considerable reduction in the thermal stability of the protein making it easier the lipase denaturation under extreme temperature conditions. Besides, at low glutaraldehyde concentrations (0.6% v.v−1 in the actual work) and in the mild immobilization conditions used, only the monomeric form of the cross-linking agent is present, and the adsorbed enzyme is cross-linked to the chitosan with just one molecule of this reagent per molecule of amino in the support and the protein [14, 32]. So it is expected that the derivatives obtained on these conditions may be less stable than the derivatives immobilized on the presence of the dimeric form of this reagent. Another important consideration to be made is that according to some studies the unimolecular form of the enzyme is less thermally stable than the bimolecular structure showing too considerable alterations in optimal temperatures for both forms (Fig.8).

Nonetheless, the results presented in the actual work shows that a relatively strong interaction enzyme-support may be achieved using a simple and fast immobilization method under mild immobilization conditions as has been demonstrated in some studies [13, 14, 32]. The derivative CHIT-GLU 1.5% (v v−1) was 30 times more stable than the free enzyme and approximately six times more stable than the commercial immobilized Lipozyme®.

The thermal stability of the best derivative was also evaluated at 37 °C. After 120 h incubation time at 37 °C, the derivative retained 89% of its initial activity (data not shown), indicating that the biocatalyst can be used for the synthesis of compounds that require long reaction times at this temperature without significant loss of its biocatalytic activity. This result can be explained as a consequence of the effect of glutaraldehyde has not always a positive effect on enzyme stability. Thus, the effects on the enzyme stability depend on the immobilization strategy employed, and it is not possible to give any general rule. Even glutaraldehyde cross-linking has not always a positive effect on enzyme stability [51].

Influence of External and Internal Mass Transfer Limitations on the Hydrolysis of pNPB

To observe the effect of external mass transfer limitations, experiments were carried out by varying the agitation speeds from 200 to 800 rpm, maintaining all other conditions constant. The offered enzyme load in these experiments was 8 units.g−1 support to ensure that the hydrolysis reaction under study occurred without internal diffusion effects.

Figure 7 shows the results of this set of experiments.

As can be observed in Fig. 7, the activity derivative increased progressively, reaching a maximum at 600 rpm, exhibiting slight decreased above this value, indicating that the external resistance transfer can be neglected at agitation speeds higher than the value above. The gradual increase in the agitation speed reduces the film thickness around the biocatalyst particles, leading to a decrease in the effects of external mass transfer resistance.

In this study, further experiments were carried out to evaluate the adsorption capacity of chitosan beads and the hydrolytic activity of the derivatives obtained after addition of increasing amounts of the enzyme. RML was added in the range of 8–100 units.g−1 support (0.3–3.2 mg.g−1 support). The results of these experiments are displayed in Fig. 9.

As can be seen in Fig. 9, the hydrolytic activity of the immobilized enzyme increased as more lipase was loaded onto the support. However, in amounts above 32 units.g−1 support (1.04 mg.g−1 support), the activity per gram of support is not significantly altered, becoming nearly constant since it has more protein immobilized, but with the same activity.

When the results are stated regarding efficiency (activity/loading), higher activities were obtained only when lower amounts of enzyme were added. The results suggest that for loadings over 32 units.g−1 support.

At higher loads, the enzyme molecules can be immobilized with different orientations or excessive agglomeration of these molecules within the chitosan pores may become an effective barrier to substrates and product diffusion. Besides, steric hindrance effects of the enzyme molecules at high loading densities must also explain the obtained experimental results.

Synthesis of Methyl and Butyl Butyrate

The biocatalyst selected was used in the synthesis of some esters of commercial interest. The reaction yields obtained under the experimental conditions described previously were compared with the results observed for reactions carried out with the commercial enzyme Lipozyme®, the free enzyme and with the derivatives immobilized in the absence of the detergent SDS. The results for methyl and ethyl butyrate synthesis are shown in Fig. 10a, b, respectively.

Comparative study of esterification yields in the synthesis of esters ethyl butyrate (a) and methyl butyrate (b) with biocatalysts: (I) free enzyme; (II) biocatalyst produced in the absence of a surfactant; (III) biocatalyst produced in the presence of a surfactant, and (IV) commercial enzyme Lipozyme®. Conditions are detailed in the “Materials and Methods” section

For ethyl butyrate, the results displayed in Fig. 10a shows that the biocatalyst III (immobilization in the presence of SDS) was very efficient in the synthesis of the ester investigated featuring reaction yields (92 ± 1%) comparable to the yields obtained when the free enzyme (89 ± 1%) was used showing too a maximum conversion yield enzyme slightly higher than the commercial enzyme Lipozyme® (86 ± 1%) in the same experimental conditions.

In the synthesis of methyl butyrate (Fig. 10b), when the selected derivative (biocatalyst III) was used, a maximum yield of (89 ± 1%) was observed while the commercial enzyme Lipozyme ® and the free enzyme showed a conversion yield of (86 ± 1%) and (87 ± 2%) respectively under the reaction conditions established.

In this work, a comparison between the conversion yields obtained for the biocatalysts produced in the presence and absence of SDS (II and III, respectively) was made. For ethyl butyrate (Fig. 10a), the esterification yield for biocatalyst III was 2.3 greater than biocatalyst II (37 ± 2%), produced in the absence of SDS and for methyl butyrate synthesis the maximum conversion yield for the biocatalyst obtained in the absence of the detergent (biocatalyst II) was 20% while the biocatalyst III produced in the presence of SDS showed a conversion 4.5 times higher (89 ± 1%).

The results presented in this work demonstrate that the presence of the surfactant SDS in the selected immobilization protocol promoted an increase not only in the hydrolytic activities of the derivatives obtained but also a high ester conversions in the studied reaction conditions.

It is worth mentioning that the reaction conditions for obtaining these esters were not optimized. Further studies will be carried out to establish the optimum conditions for the synthesis of these compounds.

This result is in agreement with other reports from the literature using lipases from different sources [23, 25, 35].

Conclusions

The results presented in this study show that the use of low concentrations of some surfactants may be considered as a simple and efficient way to achieve biocatalysts with high catalytic activity. The maximum increase in RML activity not only on the free enzyme but also on the immobilized enzyme derivatives obtained was observed when the surfactants Triton X-100 and sodium dodecyl sulfate (SDS) were added near their critical micelle concentrations (CMC). However, as observed for CTAB in our experiments, the surfactants may also exert some negative effects on the enzymatic activity, behaving as an inhibitor or deactivating the enzyme even when added at low levels. Thus, it can be concluded that the surfactants favor the shifting of the closed-open form of RML towards the open forms, although it depends on the particular type of enzyme, the characteristics of support used in immobilization, and the properties of the surfactant. Last but not least, the use of selected biocatalyst in the synthesis of some esters of commercial interest was also evaluated. At non-optimized conditions, the esterification yields for the two esters used as models were similar to those obtained when the free enzyme and the commercial enzyme Lipozyme® were used in the same reaction conditions, indicating that the latter may be replaced by low-cost biocatalysts with high esterification efficiency for the synthesis of these two flavor esters. Thus, the results reported in this study show that the immobilization of RML lipase onto chitosan support in the presence of surfactants like SDS seems to be a good choice for getting biocatalysts with improved activity and which can be used with success to obtain products of industrial interest.

Further studies will be conducted for the biocatalyst developed in this work to optimize the reaction conditions for the synthesis of these and another flavor esters like optimal temperature, biocatalyst amount, offer enzyme loaded, agitation speed, and reusability among others parameters that affects the esterification reactions as well as to evaluate the utilization of this new biocatalyst in a solvent-free system.

References

Zhang, Y., Dai, Y., Hou, M., Li, T., Ge, J., & Liu, Z. (2013). Chemo-enzymatic synthesis of valrubicin using Pluronic conjugated lipase with temperature responsiveness in organic media. RSC Advances, 3(45), 22963. https://doi.org/10.1039/c3ra44879g.

Hou, M., Wang, R., Wu, X., Zhang, Y., Ge, J., & Liu, Z. (2015). Synthesis of lutein esters by using a reusable lipase-Pluronic conjugate as the catalyst. Catalysis Letters, 145(10), 1825–1829. https://doi.org/10.1007/s10562-015-1597-1.

Li, Z., Zhang, Y., Lin, M., Ouyang, P., Ge, J., & Liu, Z. (2013). Lipase-catalyzed one-step and regioselective synthesis of clindamycin Palmitate. Organic Process Research & Development, 17(9), 1179–1182. https://doi.org/10.1021/op400135y.

Gharat, N., & Rathod, V. K. (2013). Enzyme catalyzed transesterification of waste cooking oil with dimethyl carbonate. Journal of Molecular Catalysis B: Enzymatic, 88, 36–40. https://doi.org/10.1016/j.molcatb.2012.11.007.

Villalba, M., Verdasco-Martín, C. M., dos Santos, J. C. S., Fernandez-Lafuente, R., & Otero, C. (2016). Operational stabilities of different chemical derivatives of Novozym 435 in an alcoholysis reaction. Enzyme and Microbial Technology, 90, 35–44. https://doi.org/10.1016/j.enzmictec.2016.04.007.

Palla, C. A., Pacheco, C., & Carrín, M. E. (2012). Production of structured lipids by acidolysis with immobilized Rhizomucor miehei lipases: selection of suitable reaction conditions. Journal of Molecular Catalysis B: Enzymatic, 76, 106–115. https://doi.org/10.1016/j.molcatb.2011.11.022.

Tornvall, U., Orellana-Coca, C., Hatti-Kaul, R., & Adlercreutz, D. (2007). Stability of immobilized Candida Antarctica lipase B during chemo-enzymatic epoxidation of fatty acids. Enzyme and Microbial Technology, 40(3), 447–451. https://doi.org/10.1016/j.enzmictec.2006.07.019.

Hasan, F., Shah, A. A., & Hameed, A. (2006). Industrial applications of microbial lipases. Enzyme and Microbial Technology, 39(2), 235–251. https://doi.org/10.1016/j.enzmictec.2005.10.016.

Gutierrez-Ayesta, C., Carelli, A. A., & Ferreira, M. L. (2007). Relation between lipase structures and their catalytic ability to hydrolyze triglycerides and phospholipids. Enzyme and Microbial Technology, 41(1–2), 35–43. https://doi.org/10.1016/j.enzmictec.2006.11.018.

Bezerra, R. M., Neto, D. M. A., Galvão, W. S., Rios, N. S., de Carvalho, A. C. L. M., Correa, M. A., et al. (2017). Design of a lipase-nano particle biocatalysts and its use in the kinetic resolution of medicament precursors. Biochemical Engineering Journal, 125, 104–115. https://doi.org/10.1016/j.bej.2017.05.024.

Manoel, E. A., dos Santos, J. C. S., Freire, D. M. G., Rueda, N., & Fernandez-Lafuente, R. (2015). Immobilization of lipases on hydrophobic supports involves the open form of the enzyme. Enzyme and Microbial Technology, 71, 53–57. https://doi.org/10.1016/j.enzmictec.2015.02.001.

dos Santos, J. C. S., Rueda, N., Barbosa, O., Fernández-Sánchez, J. F., Medina-Castillo, A. L., Ramón-Márquez, T., et al. (2015). Characterization of supports activated with divinyl sulfone as a tool to immobilize and stabilize enzymes via multipoint covalent attachment. Application to chymotrypsin. RSC Advances, 5(27), 20639–20649. https://doi.org/10.1039/C4RA16926C.

Rodrigues, D. S., Mendes, A. A., Adriano, W. S., Gonçalves, L. R. B., & Giordano, R. L. C. (2008). Multipoint covalent immobilization of microbial lipase on chitosan and agarose activated by different methods. Journal of Molecular Catalysis B: Enzymatic, 51(3–4), 100–109. https://doi.org/10.1016/j.molcatb.2007.11.016.

Silva, J. A., Macedo, G. P., Rodrigues, D. S., Giordano, R. L. C., & Gonçalves, L. R. B. (2012). Immobilization of Candida Antarctica lipase B by covalent attachment on chitosan-based hydrogels using different support activation strategies. Biochemical Engineering Journal, 60, 16–24. https://doi.org/10.1016/j.bej.2011.09.011.

dos Santos, J. C. S., Barbosa, O., Ortiz, C., Berenguer-Murcia, A., Rodrigues, R. C., & Fernandez-Lafuente, R. (2015). Importance of the support properties for immobilization or purification of enzymes. ChemCatChem, 7(16), 2413–2432. https://doi.org/10.1002/cctc.201500310.

Krajewska, B. (2004). Application of chitin- and chitosan-based materials for enzyme immobilizations: a review. Enzyme and Microbial Technology, 35(2), 126–139. https://doi.org/10.1016/j.enzmictec.2003.12.013.

Barbosa, O., Ortiz, C., Berenguer-Murcia, Á., Torres, R., Rodrigues, R. C., & Fernandez-Lafuente, R. (2014). Glutaraldehyde in bio-catalysts design: a useful crosslinker and a versatile tool in enzyme immobilization. RSC Advances, 4(207890), 1583. https://doi.org/10.1039/c3ra45991h.

Migneault, I., Dartiguenave, C., Bertrand, M. J., & Waldron, K. C. (2004). Glutaraldehyde: Behavior in aqueous solution, reaction with proteins, and application to enzyme crosslinking. BioTechniques, 37, 790–802.

Fernandez-Lafuente, R., Rosell, C. M., Rodriguez, V., & Guisan, J. M. (1995). Strategies for enzyme stabilization by intramolecular crosslinking with bifunctional reagents. Enzyme and Microbial Technology, 17(6), 517–523. https://doi.org/10.1016/0141-0229(94)00090-E.

Alvarez-Macarie, E., & Baratti, J. (2000). Short chain flavour ester synthesis by a new esterase from Bacillus licheniformis. Journal of Molecular Catalysis - B Enzymatic, 10(4), 377–383. https://doi.org/10.1016/S1381-1177(99)00109-5.

Salihu, A., Alam, M. Z., AbdulKarim, M. I., & Salleh, H. M. (2014). Esterification for butyl butyrate formation using Candida cylindracea lipase produced from palm oil mill effluent supplemented medium. Arabian Journal of Chemistry, 7(6), 1159–1165. https://doi.org/10.1016/j.arabjc.2013.08.012.

Hills, G. (2003). Industrial use of lipases to produce fatty acid esters. European Journal of Lipid Science and Technology, 105(10), 601–607. https://doi.org/10.1002/ejlt.200300853.

Escandell, J., Wurm, D. J. J., Belleville, M. P. P., Sanchez, J., Harasek, M., & Paolucci-Jeanjean, D. (2015). Enzymatic synthesis of butyl acetate in a packed bed reactor under liquid and supercritical conditions. Catalysis Today, 255, 3–9. https://doi.org/10.1016/j.cattod.2015.01.048.

Dubal, S. A., Tilkari, Y. P., Momin, S. A., & Borkar, I. V. (2008). Biotechnological routes in flavour industries. Review Literature And Arts Of The Americas, 14(March), 15.

Matte, C. R., Bordinhão, C., Poppe, J. K., Rodrigues, R. C., Hertz, P. F., & Ayub, M. A. Z. (2016). Synthesis of butyl butyrate in batch and continuous enzymatic reactors using Thermomyces lanuginosus lipase immobilized in Immobead 150. Journal of Molecular Catalysis B: Enzymatic, 127, 67–75. https://doi.org/10.1016/j.molcatb.2016.02.016.

Tufvesson, P., Törnvall, U., Carvalho, J., Karlsson, A. J., & Hatti-Kaul, R. (2011). Towards a cost-effective immobilized lipase for the synthesis of specialty chemicals. Journal of Molecular Catalysis B: Enzymatic, 68(2), 200–205. https://doi.org/10.1016/j.molcatb.2010.11.004.

Derewenda, Z. S., Derewenda, U., & Dodson, G. G. (1992). The crystal and molecular structure of the Rhizomucor miehei triacylglyceride lipase at 1.9 Å resolution. Journal of Molecular Biology, 227(3), 818–839. https://doi.org/10.1016/0022-2836(92)90225-9.

Derewenda, Z. S., & Derewenda, U. (1991). Relationships among serine hydrolases: evidence for a common structural motif in triacylglyceride lipases and esterases. Biochemistry and Cell Biology, 69(12), 842–851. https://doi.org/10.1139/o91-125.

Rodrigues, R. C., & Fernandez-Lafuente, R. (2010). Lipase from Rhizomucor miehei as an industrial biocatalyst in chemical process. Journal of Molecular Catalysis B: Enzymatic, 64(1–2), 1–22. https://doi.org/10.1016/j.molcatb.2010.02.003.

Sheldon, R. A., Schoevaart, R., & Van Langen, L. M. (2006). Cross-linked enzyme aggregates. Methods in Biotechnology: Immobilization of Enzymes and Cells, 4, 31–45. https://doi.org/10.4061/2011/851272.

Fernández-Lorente, G., Palomo, J. M., Mateo, C., Munilla, R., Ortiz, C., Cabrera, Z., Guisán, J. M., & Fernandez-Lafuente, R. (2006). Glutaraldehyde cross-linking of lipases adsorbed on aminated supports in the presence of detergents leads to improved performance. Biomacromolecules, 7(9), 2610–2615. https://doi.org/10.1021/bm060408+.

Dos Santos, J. C. S., Bonazza, H. L., de Matos, L. J. B. L., Carneiro, E. A., Barbosa, O., Fernandez-Lafuente, R., Gonçalves, L. R. B., De Sant'Ana, H. B., & Santiago-Aguiar, R. S. (2017). Immobilization of CALB on activated chitosan: application to enzymatic synthesis in supercritical and near-critical carbon dioxide. Biotechnology Reports, 14, 16–26. https://doi.org/10.1016/j.btre.2017.02.003.

Bradford, M. M. (1976). A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Analytical Biochemistry, 72, 248–254. https://doi.org/10.1016/0003-2697(76)90527-3.

Sadana, A., & Henley, J. P. (1987). Analysis of enzyme deactivations by a series-type mechanism: influence of modification on the activity and stability of enzymes. Annals of the New York Academy of Sciences, 501, 73–79.

Romero, M. D., Calvo, L., Alba, C., & Daneshfar, A. (2007). A kinetic study of isoamyl acetate synthesis by immobilized lipase-catalyzed acetylation in n-hexane. Journal of Biotechnology, 127(2), 269–277. https://doi.org/10.1016/j.jbiotec.2006.07.009.

Helistö, P., & Korpela, T. (1998). Effects of detergents on activity of microbial lipases as measured by the nitrophenyl alkanoate esters method. Enzyme and Microbial Technology, 23(1–2), 113–117. https://doi.org/10.1016/S0141-0229(98)00024-6.

Mogensen, J. E., Sehgal, P., & Otzen, D. E. (2005). Activation, inhibition, and destabilization of Thermomyces lanuginosus lipase by detergents. Biochemistry, 44(5), 1719–1730. https://doi.org/10.1021/bi0479757.

Bañó, M. C., González-Navarro, H., & Abad, C. (2003). Long-chain fatty acyl-CoA esters induce lipase activation in the absence of a water-lipid interface. Biochimica et Biophysica Acta - Molecular and Cell Biology of Lipids, 1632(1–3), 55–61. https://doi.org/10.1016/S1388-1981(03)00061-1.

Skagerlind, P., Jansson, M., Bergenståhl, B., & Hult, K. (1995). Binding of Rhizomucor miehei lipase to emulsion interfaces and its interference with surfactants. Colloids and Surfaces B: Biointerfaces, 4(3), 129–135. https://doi.org/10.1016/0927-7765(94)01167-4.

Fernandez-Lafuente, R., Armisén, P., Sabuquillo, P., Fernández-Lorente, G., Guisán, M., & J. (1998). Immobilization of lipases by selective adsorption on hydrophobic supports. Chemistry and Physics of Lipids, 93(1–2), 185–197. https://doi.org/10.1016/S0009-3084(98)00042-5.

Sánchez-Otero, M. G., Valerio-Alfaro, G., García-Galindo, H. S., & Oliart-Ros, R. M. (2008). Immobilization in the presence of Triton X-100: modifications in activity and thermostability of Geobacillus thermoleovorans CCR11 lipase. Journal of Industrial Microbiology and Biotechnology, 35(12), 1687–1693. https://doi.org/10.1007/s10295-008-0433-7.

Collins, S. E., Lassalle, V., & Ferreira, M. L. (2011). FTIR-ATR characterization of free Rhizomucor meihei lipase (RML), Lipozyme RM im and chitosan-immobilized RML. Journal of Molecular Catalysis B: Enzymatic, 72(3–4), 220–228. https://doi.org/10.1016/j.molcatb.2011.06.009.

Fernandez-Lorente, G., Palomo, J. M., Cabrera, Z., Fernandez-Lafuente, R., & Guisán, J. M. (2007). Improved catalytic properties of immobilized lipases by the presence of very low concentrations of detergents in the reaction medium. Biotechnology and Bioengineering, 97(2), 242–250. https://doi.org/10.1002/bit.21230.

Filice, M., Marciello, M., Betancor, L., Carrascosa, A. V, Guisan, J. M., & Fernandez-Lorente, G. (2011). Hydrolysis of fish oil by hyperactivated Rhizomucor miehei lipase immobilized by multipoint anion exchange. Biotechnology Progress, 27(4), 961–968. https://doi.org/10.1002/btpr.635.

Adamczak, M., & Bednarski, W. (2004). Enhanced activity of intracellular lipases from Rhizomucor miehei and Yarrowia lipolytica by immobilization on biomass support particles. Process Biochemistry, 39(11), 1347–1361. https://doi.org/10.1016/S0032-9592(03)00266-8.

Rodrigues, R. C., & Fernandez-Lafuente, R. (2010). Lipase from Rhizomucor miehei as a biocatalyst in fats and oils modification. Journal of Molecular Catalysis B: Enzymatic. https://doi.org/10.1016/j.molcatb.2010.03.008.

Romdhane, I., Ben, B., Romdhane, Z. B., Gargouri, A., & Belghith, H. (2011). Esterification activity and stability of Talaromyces thermophilus lipase immobilized onto chitosan. Journal of Molecular Catalysis B: Enzymatic, 68(3–4), 230–239. https://doi.org/10.1016/j.molcatb.2010.11.010.

Adriano, W. S., Mendonça, D. B., Rodrigues, D. S., Mammarella, E. J., & Giordano, R. L. C. (2008). Improving the properties of chitosan as support for the covalent multipoint immobilization of chymotrypsin. Biomacromolecules, 9(8), 2170–2179. https://doi.org/10.1021/bm8002754.

Barbosa, O., Torres, R., Ortiz, C., & Fernandez-Lafuente, R. (2012). The slow-down of the CALB immobilization rate permits to control the inter and intra molecular modification produced by glutaraldehyde. Process Biochemistry, 47(5), 766–774. https://doi.org/10.1016/j.procbio.2012.02.009.

Tardioli, P. W., Pedroche, J., Giordano, R. L. C., Fernández-Lafuente, R., & Guisán, J. M. (2003). Hydrolysis of proteins by immobilized-stabilized Alcalase-glyoxyl agarose. Biotechnology Progress, 19(2), 352–360. https://doi.org/10.1021/bp025588n.

Garcia-Galan, C., Dos Santos, J. C. S., Barbosa, O., Torres, R., Pereira, E. B., Corberan, V. C., GONÇALVES, L. R. B., & Fernandez-Lafuente, R. (2014). Tuning of Lecitase features via solid-phase chemical modification: Effect of the immobilization protocol. Process Biochemistry, 49(4), 604–616. https://doi.org/10.1016/j.procbio.2014.01.028.

Acknowledgements

The authors would like to thank the Brazilian research-funding agencies FUNCAP, CNPq, and CAPES.

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

ESM 1

(PPTX 99 kb)

Rights and permissions

About this article

Cite this article

de Oliveira, U.M.F., Lima de Matos, L.J.B., de Souza, M.C.M. et al. Effect of the Presence of Surfactants and Immobilization Conditions on Catalysts’ Properties of Rhizomucor miehei Lipase onto Chitosan. Appl Biochem Biotechnol 184, 1263–1285 (2018). https://doi.org/10.1007/s12010-017-2622-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-017-2622-1