Abstract

This paper compared the potential application of gas chromatograph (GC) and differential scanning calorimetry (DSC) to verify adulteration of camellia oil (CMO) with sesame oil (SSO), sunflower oil (SFO), peanut oil (PNO), corn oil (CO) and canola oil (CNO) which are cheaper oils mixed as adulterants with CMO. DSC offers unique thermal profiling for each oil. A combination of analysis of FAs and fingerprint were applied for GC to detect the adulteration. According to a similarity calculation (with a standard below 0.9989) of included angle, the detection limit of sesame oil, sunflower oil and corn oil was 10 %, peanut oil 20 %, and rapeseed oil 30 %; for DSC, similarly CMOs had the unique fingerprint according to their DSC peak shape and thermodynamic parameters, and an adulteration contents of 5 % could be detected qualitatively. Satisfactory results were achieved from stepwise multiple linear regression analysis (SMLR) for the data of T on , T off , T peak, △H and peak height (H) of DSC to quantitatively predict the other five oils adulteration in CMO with R 2 to 0.999. The average error obtained from the error analysis corresponding to SMLR was 1.2620 %. The preliminary results presented in this study suggest that DSC analysis is an attractive tool in detecting SSO, SFO, PNO, CO and CNO adulteration in CMO.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Camellia oil is also known as oil-tea camellia seed oil, tea tree oil or tea seed oil. It is a kind of edible vegetable oil squeezed or extracted from the seed of camellia (Camellia oleifera Abel). Its main producing areas are located in Hunan, Jiangxi, Guangxi, Zhejiang and other southern provinces of China [1]. Camellia oil is one of the four major woody oil plants in the world. As its many similarities with olive oil in physical and chemical constants, it is generally referred as “eastern olive oil” and “the king of cooking oil.” Meanwhile, because of the high nutritional value (rich in vitamins A, B, E and other essential fatty acids, especially oleic acid which is 74–87 % of its fatty acid compositions [2]), the consumption of camellia oil has been associated with health benefits, such as a reduced risk of high blood pressure, coronary heart disease, atherosclerosis and also other diseases [3]. A special example is extending lifespan in a longevity village of Bama in Hechi city, Guangxi province, China, where camellia oil locally represents the main source of dietary fats. Therefore, camellia oil is usually called as the “longevity oil” (confirmed by National medical center of America) and “beauty oil” [4].

Food adulteration is a longtime problem in food trade and industry. Almost all foodstuffs that have high intrinsic commercial values face the quality problems. The price of camellia oil is generally 3–5 times more expensive than canola oil in edible oil market in China, but in Japan, it is higher than olive oil. Therefore, based on the high economic benefit of camellia oil, some unscrupulous traders have been mixing the cheap vegetable oils or non-edible oils with the camellia oil to seek high profits, which violate the rights and interests of consumers. Nowadays, Chinese government has taken many measurements to vindicate consumer rights. With regard to authentication of pure camellia oil, GB/T5539-2008 [5] and GB 11765-2003 [6] are specifically chosen as the qualitative and quantitative methods, respectively. However, the researches on adulteration methods of camellia oil are very few. The method of GC/GC-MS was adopted by Yan et al. [7] and Chen et al. [8], respectively, to differentiate camellia oil through testing fatty acid compositions and contents. Li et al. [9] and Zhang et al. [10] combined near-infrared spectroscopy (NIR) with pattern recognition techniques and PLS separately to discriminate camellia oil with good results. The basic physical and chemical testing methods unavoidably have artificial errors and may involve some highly toxic and corrosive chemical reagents. For GC methods, sample pretreatment is time consuming and tedious, and professional experiments are required to operate. NIR is a rapid online method which needs a combination with chemometrics. When studying oils, the feature information of them is not easy to extract by the NIR detector due to their complexities; in chemometrics analysis, selection of variables is difficult.

In the world of inspecting edible oils adulteration, many new methods have been introduced. These examples would be Raman spectroscopy [11–15], near-infrared spectroscopy (NIR) [16, 17], nuclear magnetic resonance (NMR) [18–21], electronic nose technique [22–24] and differential scanning calorimetry (DSC) method [25, 26].

DSC is a thermo-analytical technique which promises to offer a sensitive, rapid and reproducible fingerprint method for the identification of edible oils and fats [27]. Recently, DSC has been widely employed for its several advantages, no chemical treatment and hazardous manipulation practices required. As different edible oils show different contents and ratios of the chemical compositions (FA and TAG), the thermal properties of cooling and heating curves in DSC are closely associated with them. Many reported researches indicated the applicability of DSC for discriminating the authenticity of edible oils, especially for olive oil [28–35]. These publications presented that DSC method is a valuable tool with a broad prospect.

Nowadays, a combination of GC and fingerprint is widely used in many fields with satisfactory results. However, DSC application on camellia oil has not been reported in the literature. The objective of this preliminary work was through the comparison of GC combined with fingerprint with DSC combined with stepwise multiple linear regression analysis (SMLR) methods to evaluate the compromising use of DSC to detect adulteration of camellia oil with selected vegetables qualitatively and quantitatively.

Materials and methods

Sampling

Camellia oil (CMO) was mainly gathered from Hechi, Guangxi, produced by semi-refining. Sesame oil (SSO), sunflower oil (SFO), peanut oil (PNO), corn oil (CO) and canola oil (CNO) were purchased from a local supermarket. One sample of each oil was analyzed.

Preparation of blends

Camellia oil was separately mixed with SSO, SFO, PNO, CO and CNO in the following ratios (mass of CMO to adulterant: 95:5, 90:10, 80:20, 70:30 and 60:40, w/w). Each blend was prepared in triplicate. Samples were stored in dark bottles without headspace at room temperature before analysis.

Reagents, solvents and standards

All solvents used were of analytical or high-performance liquid chromatography (HPLC) grade. The standard mixture of FA methyl esters (GLC 463) was supplied by Supelco (America).

Acid value and peroxide value

Acid value and peroxide value were determined only on pure oils, according to the GBT5009.37-2003 [36] and GB/5538-2005 [37] (Official methods, China), respectively. Three replicates were analyzed per sample.

Fatty acid compositional analysis

Fatty acid methyl esters were prepared according to the method of GBT17376-2008 [38] by dissolving oil sample (60 mg) with isooctane (4.0 mL) and potassium hydroxide methanol solution (2 mol L−1 0.2 mL) followed by subsequent analysis using a gas chromatograph (Agilent 7890A, America) fitted with a flame ionization detector. A polar capillary column Qmegawax250 (30 m × 0.25 mm × 0.25 μm) was used. The initial column temperature was 80 °C (kept for 2 min), then increased to 220 °C at a rate of 10 °C min−1 and kept for 14 min at 220 °C. The temperature of the injector and detector was maintained, respectively, at 250 and 260. Standard fatty acid methyl esters were used as authentic samples, and peak identification was done by comparing relative retention times.

Thermal analysis by DSC

DSC-200PC (from Germany NETZSCH company) equipped with thermal analysis data station was used to perform DSC analysis. Nitrogen (99.99 % purity) was used as the purge gas at a flow rate of 50 mL min−1. Indium (melting temperature 156.6 °C, ΔH f = 28.45 J g−1) and n-dodecane (melting temperature −9.65 °C, ΔH f = 216.73 J g−1) were used to calibrate the instrument. Samples of oil (8–10 mg) were weighed into aluminum pans and then hermetically sealed. An empty covered pan was used as a reference. The reference used was an empty covered aluminum pan of the same size as used in the samples. The following temperature program was used to obtain the cooling and melting profiles: 30 °C isotherm for 3 min, cooled at 2 °C min−1 to −80 °C and held for 3 min. The same sample was then heated from −80 to 30 °C at the same rate. The scanning rate was programmed at 2 °C min−1 to reduce the lag in output response from the DSC instrument as well as to preserve the minor peaks and to reduce the peak smoothing tendencies, which can occur at a high scanning rate. The software (Version 3.9A, TA Instruments) was used. 3 replicates were analyzed per sample.

Statistical analysis

Means and standard deviations (SD) were calculated with SPSS (version 19.0, SPSS) statistical software. SPSS was used to perform one-way analysis of variance and Tukey’s honest significant difference test at a 95 % confidence level (p < 0.05) to identify differences among groups. DSC data were also further evaluated by the stepwise multiple linear regression model using SPSS.

Results and discussion

Chemical indices

Acid value is a sign of free fatty acid content and the index of rancidity in fat, whose value is based on the raw material, processing technology, shipping method and the suitable conditions and so on. Peroxide value is also used to judge the quality and degree of metamorphism in oils. All the samples were tested according to GBT5009.37-2003 and GB/5538-2005. Meanwhile, their results were all within the standard limits which suggest the oils keep a good quality albeit the peroxide value of corn oil (CO) was a little higher.

FAs composition

Different oil or fat has different characteristic FA profiles which can be used as the method to determine the purity of oils, albeit some similarities of FAs in different oils. The results of FAs compositions would not be discussed in this report as many literatures have illustrated them. Through research and analysis, fingerprinting technology is adopted and the level of oleic acid can be regarded as an index of fraud mixing of the other five oil samples in CMO which has higher levels of oleic acid.

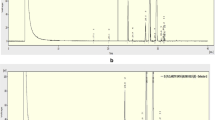

Fingerprinting technology is a sensitive and accurate detection method as the supplement for the food traceability system to keep products from adulteration, it refers to the spectrum or image with specificity and representative characteristic generated by certain analytic tools; GC has relatively higher separation efficiency than most high-performance liquid chromatography (HPLC) detectors. The GC fingerprint of the same vegetable oil under certain experimental conditions is basically stable, and therefore, it has a good repeatability, when measured a kind of oil mixing with other oils, the fingerprints of the oil would change owning to the differences of the fatty acid composition and content. According to that, GC fingerprint can be a method to detect oil counterfeit. In this study, with the method to verify the effectiveness of determining the adulteration quantity in camellia oil samples, we observed that a fingerprint similarity greater than 0.9989 of the 15 kinds of camellia oil is presented in Fig. 1a. Based on that, a parameter lower than 0.9989 can estimate the adulteration in contrast to the 15 kinds of camellia oil. Figure 1b shows the six common peaks as a comparison in these camellia oils. Through comparison, the GC fingerprint of camellia oil mixed with the other vegetable oils, respectively (mass of CMO to adulterant: 95:5, 90:10, 80:20, 70:30 and 60:40, w/w), changed regularly as the addition increased as shown in Fig. 2. According to the similarity calculation (with a standard below 0.9989) of included angle, the detection limit of sesame oil, sunflower oil and corn oil was 10 %, peanut oil 20 %, and rapeseed oil 30 % (Table 1). It must be mentioned that the analysis of FAs combining GC fingerprint in our study produced relatively satisfactory results with regard to the levels of adulteration, whereas the method might be inadequate to detect the lower adulteration percentage.

Thermal analysis of camellia oil by DSC(DSC analysis of cooling and melting curves)

DSC is characterized by representing the crystallization and melting phase transition. This is an especially suitable technique for detecting vegetable oils. As shown in Fig. 3, all the 14 camellia oil samples (CMO) exhibited their single defined events onsetting at −35.0 °C in the cooling and −14.6 °C in the heating curve. Whereas the endothermic event carried with a small shoulder peak which was at around −4 °C. All of them presented similar peak shape and thermodynamic parameters whose RSD % were in a range of 10 and 5 % respectively, especially the onset temperature of peaks, RSD % were −1.52 % and −2.13 % respectively. Based on that, we can speculate that the similar cooling and heating curves may be used as “fingerprint” of CMO and their peaks as the “fingerprint peak.” Considering the differences in growing condition, cultivar type, maturity and origin of CMO, and also unsteady condition of different DSC instruments, the subtle shifts of peak can happen. However, this would be in a limited range and we might as well conclude the unchangeable similarity of different CMO in a certain condition. The “fingerprint” of CMO can be studied further.

Thermal analysis of mixed oil by DSC

Cooling curve

Crystallization is commonly used to characterize the thermal behavior of oil samples as a physical event which requires the release of thermal enthalpy. DSC cooling curves obtained for CMO, SSO, SFO, PNO, CO, CNO and their mixtures (5–40 % SSO, SFO, PNO, CO, and CNO in CMO, respectively) are presented in Fig. 4. The other vegetable oils addition to CMO altered the overall lineshape of the exothermic peak which showed significant differences in comparison with pure CMO, and its peak height of crystallization event decreased upon addition of the other five vegetable oils. The inevitable co-crystallization happened in only one exothermic peak among all the six vegetable oil samples because of the wide variety of TAG that are mostly unsaturated cooling in their uniquely exothermic region.

Different contents of saturated or unsaturated TAG and FA lead to different endothermic and exothermic peaks. In contrast, the taller and sharper crystallization peak which developed over a narrower temperature range resulted from a more compactly associated TAG chains which attributed to a highly cooperative phase transition in CMO. This was possibly associated with the much higher TUTAG and MUFA contents (e.g., OOO and oleic acid) in CMO. The thermal behavior of oils correlates well with their FA composition (reported above by this paper) according to Fasina et al. [39]. As for SSO, SFO, PNO, CO and CNO, a much lower Ton of about −62.05, −64.05, −59.10, −66.95, −58.80 °C, respectively, and also the shorter, broader peaks might be related with their higher contents of PUFA (especially linoleic acid and linolenic acid).

The other vegetable oils addition to CMO changed its chemical composition, allowing TAG crystallization during cooling. It is assumed that ΔH (the enthalpy taken from the measurement of the area under the peaks), H (peak height), T onset and T peak lessoned, the range of the transition increased with the ever-growing adulteration in CMO as a whole. Table 2 lists their respective T onset (Temperature of curves start), T offs (Temperature of curves end), T peak (Temperature of curves at the peak) H and ΔH (J g−1) through data processing, and we can conclude that a significant difference existed in T onset and T peak when their addition to 5 % except CNO which increased to 10 %. Otherwise, ΔH (enthalpy) rises in the adulteration of 5 % of SSO, CO, CNO and 10 % of SFO, PNO. This can be explained by the possibility that some of the unsaturated TAG joined the saturated TAG to increase their cooling enthalpy.

Heating curve

DSC heating curves obtained for CMO, SSO, SFO, PNO, CO, CNO and their admixtures (5–40 %) are shown in Fig. 5. CMO displayed a well-defined endothermic event peaking at −6.65 °C, with a less distinct shoulder peak embedded at a higher temperature (−2 °C). The major endothermic peak may be ascribed to the melting of the most unsaturated fraction of TAG (e.g., OOO) and the minor shoulder peak to less unsaturated TAG in CMO. Polymorphism phenomenon which could be associated with the solid-to-solid transformation happened in all the other five oil samples before the melting onset. Besides these peaks mentioned above, SSO and PNO showed two overlapping peaks which were assumed to be the melting peaks of all the TAG in this wide endotherm region. The peaks at the lower temperature may be related with the highly unsaturated TAG, especially LLL, LLO and LLO, LOO, respectively. And the first distinguishably peak in PNO might be connected to LOO. Similarly, for SFO and CNO, each of them shows a well-defined endothermic event peaking at −13.8, −23.1 °C, with a minor shoulder peak at −8, −8.1 °C, respectively. The prominent and shoulder peaks correspond to the highly and less unsaturated TAGs. The endothermic events in CO were smaller, flatter and less distinct than in other oils that might result from higher values of POV, PAV and free acidity, whose molecules adsorbed in the crystal lattice of the TAG might form mixed crystal, leading to the lower phase transition enthalpy. All the other oil samples presented the completely different lineshape from CMO.

Tan et al. [40, 41] reported that the inseparable shoulder peak which may melt over the same temperature range arrives from the complex mature of TAG, and the smaller or shoulder peak corresponds to differing type of TAG. It is hypothesized that the shoulder peak of CMO is due to the complex mature of TAG because of its higher contents of OOO. The other oils might be on account of the different types of TAG. Along with adulteration, the shoulder peak belonging to CMO disappeared, the total heating event significantly shifted toward lower temperature, and the heating enthalpy decreased, which is owing to increased highly unsaturated TAGs. According to Table 3, when SSO, SFO, PNO and CO is adulterated to 5 % and CNO to 10 %, T onset, T peak and ΔH changed significantly. The more compactly associated TAG chains formed a more ordered crystal structure which needs higher energy to melt, leading to the increasing heating enthalpy.

Different melting profiles may be observed because of different experimental conditions and/or DSC instrumentation and/or nature of the samples. In a controlled condition, the misbranding of CMO by other five vegetable oils can be detected from DSC melting data. The limit of detection (LOD) for all these five oils adulteration with CMO was 5 % by the synthesis in characterizing DSC curves and overall thermal properties.

Quantitative analysis by SMLR

Through the quantitative analysis of their DSC thermal properties in the cooling events, the accurate adulteration percentage of SSO, SFO, PNO, CO and CNO in CMO can be estimated. Adopting the method of stepwise multiple linear regression analysis (SMLR), the data of Tonset, Toffs, Tpeak, ΔH and peak height (H) were collected as independent predictors to analyze the relevance among them. We obtained the regression models as given in Table 4. The coefficient of determination (R 2) was calculated to be 0.999 that was a very good correlation.

In order to test the feasibility of these polynomials, we adopted the error analysis method for validation. Ten kinds of CMO samples adulterated with the other five oils were chosen to test their accuracy. As a result from Table 5, the range of error is between −3.4265 and 2.6517 % and the average error 1.2620 % which was relatively small to be accepted. Therefore, the quantitative prediction models established by SMLR combining DSC profiles could be acted as the method to determine the specific adulteration contents in CMO.

Conclusions

This work showed the comparison of GC and DSC to detect the adulteration of CMO with selected vegetable soils (SSO, SFO, PNO, CO and CNO). DSC had a more satisfactory result, and the cooling and heating curves of DSC combining the use of stepwise multiple linear regression (SMLR) analysis could be an effective method to detect CMO adulterated with selected vegetable soils qualitatively and quantitatively with the lower limit of detection to 5 % and higher coefficient of determination (R 2) to 0.999. Meanwhile, the average error that arrived from the error analysis corresponding to SMLR was 1.2620 %. The result from FA analysis which was operated by GC and fingerprint was lower than the method of DSC in the qualitative and quantitative analysis and are restricted by the complicated pretreatment and instrument operation procedures. DSC offers a simple, sensitive and rapid method for quality control of oils by this passage.

Although the precision and feasibility of the results obtained above were proven by more samples in this study, they should be confirmed further by a larger number of samples considering the variation of chemical composition of oils from different cultivars, geographical origins, agronomical practices, processing technologies and harvesting periods. Moreover, a further evaluation should be made using X-ray diffraction or other techniques that could gather the structural information to help determine the specific DSC peak which are contributed by specific TAG or FA, thus gaining more accurate detection information about oils.

References

Zhong XM, Zhang BG, Zhu J. The comprehensive utilization of camellia oil in China. Oils Foods. 2007;15:3.

Bai YN, Song DH, et al. The comparison of nutritional value between camellia oil and olive oil. China Oils Fats. 2008;33:39–41.

Shen JF, Jiang TJ. Nutritional value and health care function of camellia seed oil. Cereal Food Ind. 2006;6:6–8.

Xie J, Zhou X, Luo CY. The major quality research of camellia oil in Guangxi. Light ind Sci Technol. 2013;7:15–6.

General administration of quality supervision, inspection and quarantine of the People’s Republic of China. National standards of the People’s Republic of China. Inspection of grain and oils: qualitative test of oils; 2008. GB/T 5539–2008.

General administration of quality supervision, inspection and quarantine of the People’s Republic of China. National standards of the People’s Republic of China. Oil-tea camellia oil; 2003. GB-11765–2003.

Yan XL, Xu X. A qualitative & quantitative study of distinguishing adulteration in camellia oil by gas chromatography. Food Eng. 2011;2:47–9.

Chen YJ, Chen HG, Bai WD, Ouyang CJ. The detection of authentication in camellia oil. Food Ferment Ind. 2012;4:180–3.

Li SF, Zhu XR, Zhang JH, Li GY, Su DL, Shan Y. Authentication of pure camellia oil by using near infrared spectroscopy and pattern recognition techniques. Food Sci. 2012;4:374–80.

Zhang JH, Zhu XR, Shang XB, Shuai M. Quantification analysis of camellia oils adulteration with rapeseed oil and soybean oil by combining near infrared spectroscopy and partial least squares. Food Sci Technol. 2012;3:334–6.

Lopez-Diez EC, Bianchi G, Goodacre R. Rapid quantitative assessment of the adulteration of virgin olive oils with hazelnut oils using Raman spectroscopy and chemometrics. J Agric Food Chem. 2003;51:6145–50.

Yang H, Irudayaraj J. Comparison of near-infrared. Fourier transform-infrared, and Fourier transform-Raman methods for determining olive pomace oil adulteration in extra virgin olive oil. J Am Oil Chem Soc. 2001;78(9):889–95.

Baeten V, Dardenne P, Aparicio R. Interpretation of fourier transform Raman spectra of the unsaponifiable matter in a selection of edible oils. J Agric Food Chem. 2001;49:5098–107.

El-Abassy R, Donfack P, Materny A. Assessment of microwave versus conventional heating induced degradation of olive oil by VIS Raman spectroscopy and classical methods. J Am Oil Chem Soc. 2009;86:507–11.

Farid S, Farhard U, Abedin KM. Determination of ratio of unsaturated to total fatty acids in edible oils by laser Raman spectroscopy. Appl Sci. 2009;9:1538–43.

Christy AA, Kasemsumran S, Du Y, Ozaki Y. The detection and quantification of adulteration in olive oil by near-infrared spectroscopy and chemometrics. Anal Chem Soc. 2004;20:935–40.

Zhuang XL, Xiang YH, Qiang H. Near infrared spectroscopy and chemometrics methods for quality analysis and adulteration detection in olive oil. Spectrosc Spectr Anal. 2010;30:933–6.

Mannina L, Patumi M, Proietti N. PDO (protected designation of origin): geographical characterization of Tuscan extra virgin olive oils using high-field H-1 NMR spectroscopy. Ital Food Sci. 2001;13:53–63.

Brescia MA, Alviti G, Liuzzi V. Chemometric classification of olive cultivars based on compositional data of oils. Am Oil Chem Soc. 2003;80:945–50.

Mannina L, et al. Study of the cultivar-composition relationship in Sicilian olive oils by GC, NMR, and statistical methods. J Agric Food Chem. 2003;51:120–7.

Vigli G, Philippidis A, Spyros A. Classification of edible oils by employing 31P and 1H NMR spectroscopy in combination with multivariate statistical analysis. A proposal for the detection of seed oil adulteration in virgin olive oils. J Agric Food Chem. 2003;51:5715–22.

Guadarrama A, Rodriguez-Mendez ML, Sanz C. Electronic nose based on conducting polymers for the quality control of the olive oil aroma discrimination of quality, variety of olive and geographic origin. Anal Chim Acta. 2001;432:283–92.

Martin YG, Oliveros MCC, Pavon JLP. Electronic nose based on metal oxide semiconductor sensors and pattern recognition techniques characterisation of vegetable oils. Anal Chim Acta. 2001;449:69–80.

James D, Scott SM, O’hare WT. Classification of fresh edible oils using a coated piezoelectric sensor array-based electronic nose with soft computing approach for pattern recognition. Trans Inst Meas Control. 2004;26:3–18.

Marikkara JMN, Ghazali HM, Man YBC, Lai OM. The use of cooling and heating thermograms for monitoring of tallow, lard and chicken fat adulterations in canola oil. Food Res Int. 2002;35:1007–14.

Marina AM, Man YBC, Nazimah SAH, Amin I. Monitoring the adulteration of virgin coconut oil by selected vegetable oils using differential scanning calorimetry. J Food Lipids. 2009;16:50–61.

Maggio RM, Barnaba C, Cerretani L, Paciulli M, Chiavaro E. Study of the influence of triacylglycerol composition on DSC cooling curves of extra virgin olive oil by chemometric data processing. J Therm Anal Calorim. 2014;115:2037–44.

Chiavaro E. Differential scanning calorimetry: a potential tool for discrimination of olive oil commercial categories. Anal Chim Acta. 2008;625:215–26.

Angiuli M, Ferrari C, Lepori L. On testing quality and traceability of virgin olive oil by calorimetry. J Thermal Anal Calorim. 2006;84:105–12.

Mansor TST, Man YBC, Shuhaimi M. Employment of differential scanning calorimetry in detecting lard adulteration in virgin coconut oil. J Am Oil Chem Soc. 2012;89:485–96.

Maggio RM, Cerretani L, Barnaba C, Chiavaro E. Application of differential scanning calorimetry-chemometric coupled procedure to the evaluation of thermo-oxidation on extra virgin olive oil. Food Biophys. 2012;7:114–23.

Chiavaro E, Vittadini E, Rodriguez-Estrada MT. Differential scanning calorimeter application to the detection of refined hazelnut oil in extra virgin olive oil. Food Chem. 2008;110:248–56.

Chiavaro E, Vittadini E, Cerretani L. Differential scanning calorimetry detection of high oleic sunflower oil as an adulterant in extra-virgin olive oil. J Food Lipids. 2009;16:227–44.

Barba L, Arrighetti G, Calligaris S. Crystallization and melting properties of extra virgin olive oil studied by synchrotron XRD and DSC. Eur J Lipid Sci Technol. 2013;115:322–9.

Jiménez A, Márquez G, Beltrán M. Application of differential scanning calorimetry (DSC) at the characterization of the virgin olive oil. J Grasas Y Aceites. 2003;54(4):403–9.

General administration of quality supervision, inspection and quarantine of the People’s Republic of China. National standards of the People’s Republic of China. Method of analysis of hygienic standard of edible oils; 2003. GBT5009.37-2003.

General administration of quality supervision, inspection and quarantine of the People’s Republic of China. National standards of the People’s Republic of China. Animal and vegetable fats and oils-Determination of peroxide value; 2005. GB/5538-2005.

General administration of quality supervision, inspection and quarantine of the People’s Republic of China. National standards of the People’s Republic of China. Animal and vegetable fats and oils: analysis by gas chromatography of methyl esters of fatty acids; 2008. GB/T17377–2008.

Fasina OO, Craig-Schmidt M, Colley Z, Hallman H. Predicting melting characteristics of vegetable oils from fatty acid composition. LWT Food Sci Technol. 2008;41:1501–5.

Tan CP, Man YBC. Differential scanning calorimetric analysis of edible oils: comparison of thermal properties and chemical composition. J Am Oil Chem Soc. 2000;77:142–55.

Tan CP, Man YBC, Selamat J, Yusoff MSA. Application of Arrhenius kinetics to evaluate oxidative stability in vegetable oils by differential scanning calorimetry. J Am Oil Chem Soc. 2001;78:1133–8.

Acknowledgements

The authors gratefully acknowledge Guangxi University for their technical assistance in performing part of the experiments. This work was funded by the research projects of Guangxi scientific and technological (12118011-2A) and also project of college students’ experimental skills and science and technology innovation, Guangxi University (SYJN20131404). Furthermore, it was supported by the BaGui scholars team in “Food biotechnology,” the key laboratory “Intensive processing and Security Control of Guangxi Characteristic agricultural products” for Guangxi colleges and universities and the talent highland of food and drug safety evaluation in Guangxi.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, R., Huang, J., Huang, L. et al. Comparison of GC and DSC monitoring the adulteration of camellia oil with selected vegetable oils. J Therm Anal Calorim 126, 1735–1746 (2016). https://doi.org/10.1007/s10973-016-5606-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-016-5606-4