Abstract

A static headspace gas chromatography coupled with flame ionisation detector (SHS-GC-FID) has been used to develop a method for the identification and quantification of hexanal in various fresh and stored edible oils to assess their oxidative rancidity. The optimization has been done for three parameters, i.e. time, temperature and amount of sample. The method has been validated for linearity, limit of detection and quantification, accuracy, precision and recovery. The SHS-GC method has been successfully applied to six types of edible oils, i.e. soybean, sunflower, coconut, mustard, rice bran and palm oil. Simultaneously, oxidative rancidity parameters have been determined, and Pearson’s correlation analysis has been done between these parameters and hexanal concentration. The results clearly demonstrated positive correlation between the main oxidative rancidity indicating parameters and hexanal concentration. Also, the effect of storage at two different temperatures (25 °C and 45 °C) on the hexanal concentration in edible oils has been monitored for 3 months.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

India is the world’s fourth largest economy in terms of vegetable oils. The most commonly used edible oils for cooking or frying in India are groundnut oil, sunflower oil, mustard oil, soybean oil, rice bran oil, palm oil, coconut oil, sesame oil, etc. Edible oils during deep frying act as the heat transfer medium and create unequalled flavours, good appearance, delicious and crispy taste. Deep fat frying involves various chemical reactions, i.e. hydrolysis, oxidation and polymerization, which result in generation of a large number of oxidised toxic chemicals and volatile organic compounds (VOCs) into it (Chang et al. 2019; D.-C. Zhang et al. 2019). The correct selection of edible oil become very essential, i.e. it should have high shelf life, high oxidative stability and low concentration of potentially toxic compounds (Katragadda et al. 2010).

The hydroperoxides formed in oxidized edible oil are estimated by peroxide value (PV). Other parameters such as acid value (AV), iodine value (IV), total polar content (TPC), thiobarbituric value (TBA), saponification value (SV), viscosity, density and p-anisidine value (p-AnV) are also important to assess the quality and stability of the edible oils. These parameters are measured by using wet chemistry experimental methods which have many drawbacks such as stability of the reagents used, laborious procedure and ambiguous results due to variability in prescribed methods (Meng et al. 2017; Yu et al. 2015) and interference from various organic flavouring agents (De Boer et al. 2018). Therefore, in past few years, GC-FID (Azarbad and Jeleń 2015; Xu et al. 2018), FTIR (Yu et al. 2015), NMR (Merkx et al. 2018), ESR (Chen et al. 2018), RAMAN (Chen et al. 2018), UV–vis spectroscopy (Conceição et al. 2019) and many other techniques (Barriuso et al. 2013) have been reported for monitoring the oxidative degradation of edible oils (Xia et al. 2019). Among all the oxidation products, aldehydes are the most prominent secondary oxidation products formed in edible oils (Xiao et al. 2020; Katragadda et al. 2010). Aldehydes are responsible for the aroma characteristics of oils, however, these are harmful if ingested, exposed or presented as components of the environment and also if represented a potential health risk and toxicity. The presence of aldehyde in organisms by any means is linked to different types of cancer and neurodegenerative diseases such as Alzheimer’s and Parkinson’s (Grünblatt and Riederer 2016; D.-C. Zhang et al. 2019). The types of aldehydes that are generated in the different edible oils are intimately allied with the fatty acid composition of that particular oil (Cao et al. 2014a). In the current study hexanal, an apparently ubiquitous component of fresh and stored edible oils (Snyder et al. 1988; Azarbad and Jeleń 2015) is the focal point. By far, hexanal is the most well-known volatile aldehyde in vegetable oils rich in linoleic acid (LA, 18:2) and is formed by 13-hydroperoxides degradation. The amount of hexanal in oil could be a marker for oxidative rancidity of edible oil or food matrix containing oil.

There are many procedures of the sample preparation for the quantification of aldehydes in the edible oils, including solid-phase microextraction (Javidipour et al. 2017) (SPME) and headspace solid-phase microextraction (Xu et al. 2018) (HS-SPME), solid-phase extraction (Song et al. 2022) (SPE) and high performance liquid chromatography (HPLC) (Cao et al. 2014b). However, in addition to being monotonous, prolonged and large volumes dependent, SPE may cause environmental pollution because it involves use of a large volume of organic solvent and its discard could be hazardous. Although SPME can be a solvent less technique, it is quite expensive, sensitive and involves obdurate desorption. Thus, there exists a challenge for a chemist to provide a fast, simple, effective and convinced method to extract and quantify the hexanal from edible oil matrix. During the last decade, few reports related to SHS-GC-FID (static headspace coupled with gas chromatography-flame ionization detector) for the detection of hexanal were reported which involved tedious extraction process, sample preparation by using organic solvent (Vičkačkaitė et al. 2020) and longer retention time (Azarbad and Jeleń 2015), and moreover, the studies were limited to trivial number of edible oil samples.

In the current study, a SHS-GC-FID method has been developed and validated for the quantification of hexanal in different edible oils. The headspace extraction parameters have been optimized. The developed method has been applied to six types of commonly used edible oils in India, viz. soybean oil, sunflower oil, coconut oil, mustard oil, rice bran oil and palm oil; two sets of ten soybean oil samples were kept at two different temperatures (25 °C ± 2 and 45 °C ± 2) and eight samples of used cotton seed oil and palm oil. Simultaneously, analytical tests PV, AV, p-AnV, TPC and TOTOX have been monitored for these oils. Pearson’s correlation analysis with the hexanal concentration has been done with various parameters. Also, the effect of temperature on the hexanal formation in the edible oil has been monitored for 3 months.

Materials

Hexanal (98% purity) was purchased from the Sigma-Aldrich Inc., St. Louis, MO, USA. Glacial acetic acid (99.9%), potassium iodide (99.8%) and iso-octane (2,2,4-trimethylpentane, 99.5%) extra pure AR were purchased from the Sisco Research Laboratories Pvt. Ltd., New Mumbai, India. Hexane (99.5%) was purchased from the Spectrochem Pvt. Ltd., Mumbai, India. p-Anisidine (98%), sodium thiosulphate, iodine monochloride solution, sulphuric acid, potassium dichromate and potassium hydroxide extra pure AR were purchased from the Loba Chemie Pvt. Ltd., Mumbai, India.

Edible Oils Used for the Study

Commonly available indigenous edible oils, namely, sunflower, soybean, mustard, coconut, rice bran, cottonseed and palm oils of different brands were grouped in to four sets for the study.

a) Set 1

The following six types of edible oils (48 samples) were collected from Chandigarh local market and used to study the correlation of hexanal concentration with the various quality parameters that are responsible for their oxidative stability and rancidity.

-

1.

Sunflower oil (nine samples of three brands in triplicates, SuG-1, 2 and 3; SuFP-1, 2 and 3, SuC-1, 2 and 3)

-

2.

Soybean oil (nine samples of three brands in triplicates, SoF-1, 2 and 3; SoFP-1, 2 and 3; SoD-1, 2 and 3)

-

3.

Mustard oil (nine samples of three brands in triplicates, MOT-1, 2 and 3; MNF-1, 2 and 3; MR-1, 2 and 3)

-

4.

Coconut oil (nine samples of three brands in triplicates, COI-1, 2 and3; CTO-1, 2 and 3; CP-1, 2 and 3)

-

5.

Rice bran oil (nine samples of three brands in triplicates, RR-1, 2 and 3; RF-1, 2 and 3; RK-1, 2 and 3)

-

6.

Palm Oil (three samples of same batch, PRG-1, 2 and 3)

b) Set 2

Soybean oil samples (10 samples of different brands collected from Chandigarh local market) were used to study the correlation with the amount of hexanal generated when the same samples were kept at two different temperatures (25 °C ± 2 and 45 °C ± 2).

c) Set 3

It consists of eight samples (used oil samples from local restaurants collected by Food and Drug Administration (FDA), Chandigarh) comprising mainly of cottonseed and palmolein oils.

All the above edible oil samples from all the sets were analysed for PV, AV and p-AnV and TPC and TOTOX value to determine their oxidative degradation.

d) Set 4

It consists of 13 samples of different edible oils covering a range of 0–33 ppm hexanal.

-

1.

Sunflower oil—SuFP_1 and SuFP_2

-

2.

Soybean oil—SoF_1 and SoFP_1

-

3.

Mustard oil—MOT_3 and MNF_ 1

-

4.

Coconut oil—CoI_1, CTO_1 and CP_1

-

5.

Rice bran oil—RR_2 and RK_2

-

6.

Palmolein oil—used and PRG_1-unused

-

7.

Cottonseed oil—used

Experimental Methods

Estimation of Hexanal by Static Headspace (SHS) GC-FID

Standards Preparation

Hexanal stock solution (1.22µL in 1 mL) was prepared in fresh soya bean oil and diluted with the same oil for calibration. The spiked samples were prepared in 20-mL vials capped with the silicon-polytetrafluoroethylene and mixed using a vortex shaker. Seven hexanal concentrations were prepared in the range of 0.5–32 ppm for the calibration purpose.

Optimization of the Extraction Method

The weight of the oil sample, temperature of extraction in headspace and time of extraction were optimized for developing an extraction method for hexanal from the edible oils.

GC-FID Analysis

Samples were analysed on the GC (DANI master) coupled to the headspace sampler (HSS 86.50). The headspace vials of 20 mL were used for the analysis. Samples were injected in a 1:30 split ratio at 250 °C. The carrier gas used was nitrogen at a constant flow rate of 25 mL/min. The column oven temperature program involved an initial temperature of 55 °C for 1 min, increased to 100 °C at the rate of 5 °C/min, held for 2 min and then increased to 200 °C at the rate of 20 °C/min. GC was equipped with a flame ionization detector (FID), and a DN WAX MS column (25 m × 0.25 mm i.d.) was used for gas chromatographic separation (detector temperature 250 °C; H2 flow, 35 mL/min; air flow, 250 mL/min; auxiliary gas N2).

Headspace Conditions

Different parameters such as incubation time and temperature were set for oil samples. The oven, manifold and transfer tube temperature were kept 120 °C, 130 °C and 140 °C, respectively, and incubation/equilibrium time was 20 min.

Validation Methods

Linearity

The linearity was validated by a sequence of injections of standard solutions including hexanal in the concentration range 0.5–32.0 ppm. A plot between concentrations versus peak area response gives the calibration curve. The regression coefficient and the intercept were obtained from the plot.

Accuracy

In this study, spike and recovery method were used to determine the accuracy of the device. The solution was prepared by spiking 5.0 ppm in soybean oil, and then the analysis was performed. The amount of hexanal was determined as the percentage of the given compound present in the matrix. The same procedure was repeated five times. The estimation of the accuracy was done by comparing the amount observed versus the amount added to the oil. The accuracy percentage was expressed as the average of the five observed values ± standard deviation among the values.

Precision

Precision in retention time and area was determined in the current study. It was assessed on the basis of intra-day precision in retention time and area. Study was conducted by using 8.0 ppm solution of oil spiked with hexanal for the precision in retention time and area. The precision was expressed in terms of average of value of three injections ± standard deviation among the values.

Recovery

The recovery experiment was performed by taking six spiked samples of hexanal in soybean oil (triplicate). The range of the acceptable mean recovery depends upon the amount of the analyte. The percentage recovery for each concentration was expressed as an average of three value ± standard deviation among them.

LOD and LOQ

The limit of quantization (LOQ) and the limit of detection (LOD) are used to assess the sensitivity of the method. The limit of detection (LOD) is defined as the lowest concentration of an analyte that can be determined with accuracy and precision in a sample. LOQ is ten times of the standard deviation (SD) in response.

In the meantime, the limit of detection (LOD) is defined as the lowest analyte concentration that can be identified in a sample, but not necessarily quantified, under the stated experimental conditions.

LOD and LOQ was obtained by injecting blank samples five times.

Analytical Methods for the Determination of Oxidative Degradation of Edible Oils

Determination of Acid Value (AV)

The acid value is defined as the number of milligrams of potassium hydroxide required to neutralize the free fatty acids present in 1 g of oil/fat. The acid value is determined by titrating the oil/fat in an alcoholic medium against standard potassium hydroxide/sodium hydroxide solution (AOCS Cd 3d-63). A known amount of oil sample was taken in a 250-mL conical flask to which freshly neutralized hot ethyl alcohol (50–100 mL) and phenolphthalein indicator solution (0.5–1 mL) were added. The mixture was boiled for about 5 min and titrated, while hot against standard alkali solution was shaking vigorously during the titration.

where

- V :

-

volume in mL of standard potassium hydroxide or sodium hydroxide used

- N :

-

normality of the potassium hydroxide solution or sodium hydroxide solution

- W :

-

weight of the sample in grams

Determination of Iodine Value (IV)

The iodine value of an oil/fat is the number of grams of iodine absorbed by 100 g of the oil/fat, when determined by using Wijs solution. The oil/fat sample taken in carbon tetrachloride is treated with a known excess of iodine monochloride solution in glacial acetic (Wijs solution). The excess of iodine monochloride is treated with potassium iodide, and the liberated iodine was estimated by titration with sodium thiosulfate solution (AOCS Cd 1–25).

A known amount of the oil/fat was taken into a 500-mL glass stoppered conical flask and carbon tetrachloride (25 ml); Wijs solution (25 mL) was added and stirred well. The glass stopper was replaced after wetting with potassium iodide solution, swirled for proper mixing and kept the flasks in dark for 30–60 min. After standing, potassium iodide solution (15 mL) was added followed by 100 mL of water (rinsed the stopper also with water). The liberated iodine was titrated against standardized sodium thiosulphate solution, using starch as indicator until the blue colour formed disappeared after thorough shaking with the stopper on. The blank titration was carried out simultaneously in the same manner as test sample but without oil/fat.

where

- B :

-

volume in mL of standard sodium thiosulphate solution required for the blank

- S :

-

volume in mL of standard sodium thiosulphate solution required for the sample

- N :

-

normality of the standard sodium thiosulphate solution

- W :

-

weight of the sample in grams

Determination of Peroxide Value (PV)

This is an indication of the extent of oxidation suffered by oil and is determined according to the procedure mentioned in AOCS Cd 8b-90. Oil sample (5.0 g) was weighed in a 250-mL stoppered conical flask followed by the addition of 30 mL of acetic acid: chloroform (3:2, v/v) solvent mixture and swirled to dissolve. Saturated potassium iodide solution (0.5 mL) was added and allowed to stand in dark for 1 min with occasional shaking, and then about 30 mL of water was added. The liberated iodine was titrated against sodium thiosulphate solution (0.1 N) with vigorous shaking until yellow colour was almost disappeared. Then, starch solution (0.5 mL) was added as an indicator and continued titration along with shaking vigorously to release all I2 from chloroform layer until blue colour disappeared. The blank titration was carried out simultaneously in the same manner as test sample but without oil/fat.

Peroxide value expressed as milliequivalent of peroxide oxygen per kg sample (m.eq/kg).

where

- Titre value:

-

mL of sodium thiosulphate used (blank corrected)

- N :

-

normality of sodium thiosulphate solution

- W :

-

weight of the sample in grams

Determination of p-Anisidine Value (p-AnV) and TOTOX Value

Aldehydes, derived from the secondary oxidation of oil/fat, reacts with the p-anisidine determining a variation in the absorbance, measured at 366 nm. P-Anisidine value is expressed as p-AnV (AOCS Cd 18–90). Known amount of oil/fat (~ 1 g) was dissolved in 25 mL of isooctane (test solution (a)). Then, 5 mL of test solution (a) was mixed with 1 mL p-anisidine (0.25% in glacial acetic acid, test solution (b)). The reference solution was prepared mixing p-anisidine (1.0 mL of 2.5 g/L in glacial acetic acid) and isooctane (5.0 mL). Absorbance of both test solutions and reference solution were measured at 350 nm and calculated the p-anisidine value as:

where

- A1:

-

absorbance of test solution (b) at 350 nm

- A2:

-

absorbance of test solution (a) at 350 nm

- W :

-

weight of the sample in grams

TOTOX value was calculated as the sum of the p-anisidine value plus twice the peroxide value.

Determination of Total Polar Compounds (TPC)

The estimation of total polar compounds (TPC) is a widely accepted parameter to decide whether the oil is safe for further use or not. TPC was measured using a digital cooking oil tester (Testo 270) procured from M/S Testo India Ltd.

FAME Analysis

The FAME analysis of selected edible oil (set 4) samples covering a range of 0–33 ppm hexanal has been done by performing fat extraction followed by esterification. The separation of the fatty acid methyl esters was done by liquid–liquid partitioning with distilled water and petroleum ether (Ranganna 2000). The analysis of the edible oil sample was done by GC-FID of Thermo Scientific, Trace GC Ultra equipped with column HP-88 (100 m × 0.25 mm × 0.20µ). The volume used for one injection was 1 µL in split mode with a ratio of (1:100) with the run time of 41.87 min. The oven temperature ranges from 60 to 140 °C, and injector temperature was 250 °C.

Statistical Analysis

Pearson correlation analysis of the GC-based hexanal concentration in edible oils dataset and various rancidity indicating parameters and also for palmitic acid, stearic acid, oleic acid, linoleic acid, linolenic acid and hexanal in edible oil samples was performed using statistical analysis software, The Unscrambler™ (CAMO, Norway).

Results and Discussion

GC Method Development

Optimization of Conditions for the Extraction of Hexanal by HS Method

Choice of Extraction Solvent

The extraction solvent should be non-volatile/less volatile for static headspace extraction to avoid or eliminate the interference of impurities in the GC analysis. Also, it should be highly stable so that optimization and validation could be done precisely. Commonly, water, methanol, dichloromethane, dimethylformamide, edible oil, etc. have been reported for the extraction of hexanal depending upon the matrix to be analysed (Ramezani et al. 2015; Azarbad and Jeleń 2015). In the present study, soybean oil (fresh) has been used for all the optimizations, calibration and validation purposes to keep the matrix same as of the real samples, viz. edible oils. Use of edible oil as a solvent has added advantages of stability and non-volatility.

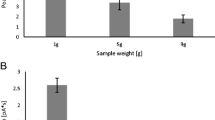

Effect of Sample Size

Increasing sample size is one of the ways of increasing the concentration of analytes in the headspace. In this work, 20.0 mL headspace vials were used. Different sample sizes were chosen to determine the effect of sample size on headspace volume. The sample of the same concentration (10.0 ppm) was taken in three different vials of 20 mL, i.e., 1.0 g, 5.0 g and 10.0 g. The effect was observed in terms of change in the peak area response in GC chromatogram. Maximum area response was observed for 10 g sample size as shown in Fig. 1a, and hence, 10 g sample size was used in further studies.

Effect of Time on Extraction

Time of extraction is an important extraction optimization parameter. Equilibrium should be established between the headspace and the sample so as to facilitate the maximum response of the analyte, but at the same time, we have to avoid the decomposition of the sample due to prolonged heating. Different incubation time ranging from 5 to 30 min at 120 °C was used for extraction optimisation. When the time of extraction was increased from 5 to 30 min, the rise in area response was observed. Further, increase in time of extraction was not useful as clearly shown in Fig. 1b. Also, the hexanal peak area obtained in 20 min of equilibration time was 92.322%, and further of equilibration time to 30 min did not show any significant change in the peak area. Therefore, 20-min extraction time was used for further experiments.

Effect of Temperature on Extraction

Temperature is a critical factor for the extraction of any analyte from the sample. The increased temperature influences the partition of compounds of high K values into the headspace. Generally, the oils and fats required higher temperature for the extraction (H. Zhang et al. 2015). Also, higher temperature increases the probability of the volatiles to spend more time in the vapour phase. The samples were extracted at three different temperatures 60, 90 and 120 °C, and the hexanal peak area response data is given in Fig. 1c. The most suitable temperature for the extraction was found to be 120 °C as the maximum area response was observed at this temperature.

HS-GC Method

The optimized extraction temperature for HS analysis was found to be 120 °C. The manifold and tube temperature were set at 130 °C and 140 °C, respectively so as to avoid the condensation of the volatiles. GC column temperature affects retention time, selectivity and peak shapes. Combination of isothermal and temperature gradient was used to analyse the hexanal using GC. It has been reported earlier that initial higher GC column temperature leads to co-elution or poor resolution. So, the initial GC column temperature was set near the mid of boiling point of solvent to avoid undesirable band broadening and co-elution. Then, temperature gradient was used (55 to 100 °C @ 5 °C/min) to elute low boiling volatiles from the column. Continual rise in column temperature leads to improved peak resolution and peak shapes.

Linearity

Figure 2 shows good linearity in the range of 0.5–32 ppm. The calibration curve obtained with correlation coefficient R2 = 0.999 ± 0.000 and regression equation for the calibration was 0.428 ± 0.003 (Table 1).

Accuracy

The accuracy of the method and device was determined by five repeated injections of 5 ppm hexanal, and 100.908 ± 0.861 accuracy was observed (Table 1).

Precision

The precision in retention time was observed to be 4.211 ± 0.001, and precision in area was found 11.888 ± 0.117 (Table 1).

Recovery

The acceptable range of percentage recovery decreases as the amount of analyte increases and vice-versa. The standard deviation in the recovery of the spiked samples was found to be within the acceptable limit as per given by Standard Method Performance Requirements (SMPR) Guidelines. The recovery percentage for six spiked samples is given in Table 2.

LOD and LOQ

The minimum amount that can be detected by the method and device was found to be 0.252 ± 0.004 ppm, and the minimum amount that can be quantified was 0.841 ± 0.016 ppm (Table 1).

Application of the Method for the Determination of Oxidative Rancidity in Oils

The developed HS-GC-FID method for the determination of hexanal was applied to 48 samples of six types of edible oils and 10 soybean oil samples, and the data is given in Table 3. At the same time, the edible oil quality parameters, i.e. p-AnV, IV, AV, FFA and PV were also determined for these oil samples. The amount of hexanal in edible oil was analysed, and co-relation between various parameters was observed.

Iodine value is given as the amount of iodine in grams reacts with 100 g of oil. The IV gives the degree of unsaturation and reactivity of the edible oils. The IV range for a particular kind of edible oil is different depending upon the number of C = C bonds present in them. As the auto-oxidation takes place, there may be a decrease in the number of double bonds so in the iodine value as well. Iodine value for edible oil samples given in Table 3 was within the given range as prescribed by the Food Safety and Standards Authority of India (FSSAI). It was observed that the stored edible oil does not show a significant decrease in the IV. It is better to consider IV as an indicator of oil composition rather than a measure of quality.

The AV is an important parameter for the oxidative quality determination of edible oil. It is defined as the weight of KOH (in mg) needed to neutralize the organic acids present in 1 g of oil and is expressed as mg KOH/g. It is a measure of the free fatty acids (FFA) present in the oil. The rise in the amount of FFA in a sample indicates the hydrolysis of triglycerides or oxidative degradation of the sample. The increment in the FFA content in a particular oil sample indicates the inadequate processing or storage conditions, i.e. high temperature and relative humidity and exposure to light. Table 3 shows that 27.08% of the oil samples have exceeded the permissible level of AV. The AV for all the refined edible oils should be ≤ 0.5 mg KOH/g (Tesfaye and Abebaw 2016).

The estimation of total polar compounds (TPC) is an extensively accepted parameter in terms of oil safety. The TPC value will decide whether particular oil can be further used or not. The TPC value is believed to be a better indicator since it refers to all degraded products, i.e. dimeric fatty acids, hydroperoxides, polymerized triglycerides, aldehydic triglycerides and cyclic fatty acid monomers (Mlcek et al. 2015). Generally, the percentage (%) of TPC in the cooking oil has been considered to be almost identical to the one present in the oil absorbed by the food. TPC (%) was measured by Testo which calculates the TPC (%) based on the dielectric constant of the oil. The FSSAI fixed the TPC for fresh/unused vegetable oils/fats at 15%. The TPC (%) data measured for the studied oils shows that 27.083% of edible oil samples (Table 3) and 75% of used edible oil samples (Table 4) are required to be replenished.

Measurement of the oxidation of edible oils involves an analysis of the primary and secondary breakdown products. PV of any oil can be related to the degree of incipient oxidative rancidity. The amount of peroxide in oil is useful for the assessment of the extent to which spoilage has advanced. It has been observed that the rice bran oil has the highest and coconut oil has the lowest peroxide concentration. As per FSSAI guidelines, the vegetable oil having PV less than 10 is acceptable for edible purpose and considered to be safe. From the PV data generated for the edible oils (Table 3), it was observed that 60.41% of oil samples have exceeded the acceptable limit. Although this parameter is the most widely used for the detection of oxidation, but as the rancidity proceeds, oils can have a reduced PV due to the formation of secondary metabolites. The primary oxidation product, i.e. hydroperoxides, decomposes to form carbonyls compounds, i.e. aldehydes and ketones and other compounds. These secondary products are detected by the colorimetric technique, i.e. p-AnV. The p-AnV is given by the spectrometric analysis of the compound formed by the reaction of p-anisidine (in glacial acetic acid) with the aldehyde at 350 nm. This gives the extent of secondary oxidation of the edible oil. The p-AnV test is a well-accepted way to determine the secondary oxidation products, and it should be used along with PV. The p-AnV data illustrates that only 2.08% of the samples have crossed the limit value and the rest of the oil samples have a low concentration of secondary oxidation product. TOTOX value is the combination of PV with p-AnV, and it indicates the overall oxidation state of oil. The recommended TOTOX value is less than or equal to 19.5 m.eq/kg (Esfarjani et al. 2019). The TOTOX data (Table 3) also indicates that 64.58% of the studied edible oil samples have oxidized.

None of these analytical parameters can be used alone; rather all of these collectively define the degree of the oxidation of edible oil in a superlative way. The coconut oil consists of approximately 82.0% saturated fatty acids, 5.0% monounsaturated and 1.5% polyunsaturated fatty acid; it thus contains the lowest amount of unsaturated fatty acid among the six edible oils (Table 3). Therefore, the hexanal concentration in coconut oil (≥ 1.0 ppm) is much lower than those in other edible oils (0.5–12.30 ppm) used in this study. The other analytical test results observed also supports the above observation. However, rice bran oil and palm oil exceptionally show the higher concentration of the hexanal as well as higher values for all other parameters. This could be explained by the short shelf life of these oils and may be due to improper storage conditions prior to sample collection. Pearson’s correlation analysis with the different parameters has been observed which shows a positive correlation of the amount of hexanal generated with the p-AnV, AV and PV (Table 5). Hexanal shows negative moderate correlation with the palmitic acid, oleic acid and linoleic acid (Table 6). As hexanal in edible oil is generated due to oxidative degradation of the linoleic acid, the highest negative correlation between them is thus justified. A moderate correlation was observed between the amount of hexanal generated and the amount of linoleic acid declined by the Pearson’s correlation analysis.

This substantiates that hexanal can be considered as a key marker for oxidative rancidity detection.

The method was also applied to the oil samples collected from the FDA, Chandigarh. These eight oil samples (three cottonseed oil and five palmolein oil samples) (Table 4) were analysed in a similar manner, and it was observed that all eight oil samples except refined palmolein shows a high concentration of the hexanal. This was also justified with the higher values of the AV, p-AnV, PV and FFA content which indicate the oxidation level of these oil samples.

Further, the method was applied to the soybean oil samples (being rich in PUFA) to observe the effect of temperature and period of storage on the amount of hexanal generated. The soybean oil samples were studied in two sets for 3 months. One set of ten samples was kept at 25 ± 2 °C and another set was kept at 45 ± 2 °C and monitored for the amount of hexanal generated after every 30 days. The results in Fig. 3a and b clearly shows that below 1.0 ppm of hexanal was detected in all the oil samples at month zero, whereas, in the successive months, there is a considerable rise in the concentration of hexanal implicating increase in oxidative rancidity at a higher temperature.

Conclusion

A SHS coupled with GC-FID method was successfully developed and applied to determine the amount of hexanal produced in edible oil samples, samples stored at two different temperatures and used edible oil samples. Moreover, the developed method does not require any pre-treatment like sample preparation using any solvent. Positive Pearson’s correlation for the amount of hexanal formed with the various other rancidity indicating parameters was observed. The present method corroborates the scope of hexanal to be used as an oxidative stability marker for all the edible oils having polyunsaturated fatty acids which are prone to oxidative degradation.

Data Availability

All data generated or analysed during this study are included in the published article.

References

Azarbad MH, Jeleń H (2015) Determination of hexanal—an indicator of lipid oxidation by static headspace gas chromatography (SHS-GC) in fat-rich food matrices. Food Anal Methods 8(7):1727–1733. https://doi.org/10.1007/s12161-014-0043-0

Barriuso B, Astiasarán I, Ansorena D (2013) A review of analytical methods measuring lipid oxidation status in foods: a challenging task. Eur Food Res Technol 236(1):1–15. https://doi.org/10.1007/s00217-012-1866-9

Boer AA, De AI, Marshall K, Bannenberg G, Yan KL, Rowe WJ (2018) Examination of marine and vegetable oil oxidation data from a multi-year, third-party database. Food Chem 254:249–255. https://doi.org/10.1016/j.foodchem.2018.01.180

Cao J, Zou X-G, Deng L, Fan Y-W, Li H, Li J, Deng Z-Y (2014a) Analysis of nonpolar lipophilic aldehydes/ketones in oxidized edible oils using HPLC-QqQ-MS for the evaluation of their parent fatty acids. Food Res Int 64:901–7. https://doi.org/10.1016/j.foodres.2014.08.042

Cao J, Zou XG, Deng L, Fan YW, Li H, Li J, Deng ZY (2014b) Analysis of nonpolar lipophilic aldehydes/ketones in oxidized edible oils using HPLC-QqQ-MS for the evaluation of their parent fatty acids. Food Res Int 64:901–907. https://doi.org/10.1016/j.foodres.2014.08.042

Chang C, Wu G, Zhang H, Jin Q, Wang X (2020) Deep-fried flavor: characteristics, formation mechanisms, and influencing factors. Crit Rev Food Sci Nutr 60:9, 1496–1514. https://doi.org/10.1080/10408398.2019.1575792

Chen Q, Xie Y, Xi J, Guo Y, Qian He, Cheng Y, Chen Yi, Yao W (2018) Characterization of lipid oxidation process of beef during repeated freeze-thaw by electron spin resonance technology and Raman spectroscopy. Food Chem 243:58–64. https://doi.org/10.1016/j.foodchem.2017.09.115

Conceição JN, Marangoni BS, Michels FS, Oliveira IP, Passos WE, Trindade MAG, Oliveira SL, Caires ARL (2019) Evaluation of molecular spectroscopy for predicting oxidative degradation of biodiesel and vegetable oil: correlation analysis between acid value and UV–Vis absorbance and fluorescence. Fuel Process Technol 183(August 2018):1–7. https://doi.org/10.1016/j.fuproc.2018.10.022

Esfarjani F, Khoshtinat K, Zargaraan A, Mohammadi-Nasrabadi F, Salmani Y, Saghafi Z, Hosseini H, Bahmaei M (2019) Evaluating the rancidity and quality of discarded oils in fast food restaurants. Food Sci Nutr 7(7):2302–2311. https://doi.org/10.1002/fsn3.1072

Grünblatt E, Riederer P (2016) Aldehyde dehydrogenase (ALDH) in Alzheimer’s and Parkinson’s disease. J Neural Transm (Vienna, Austria: 1996) 123(2):83–90. https://doi.org/10.1007/s00702-014-1320-1

Javidipour I, Erinç H, Baştürk A, Tekin A (2017) Oxidative changes in hazelnut, olive, soybean, and sunflower oils during microwave heating. Int J Food Prop 20(7):1582–1592. https://doi.org/10.1080/10942912.2016.1214963

Katragadda HR, Fullana A, Sidhu S, Carbonell-Barrachina ÁA (2010) Emissions of volatile aldehydes from heated cooking oils. Food Chem 120(1):59–65. https://doi.org/10.1016/j.foodchem.2009.09.070

Meng X, Ye Q, Nie X, Jiang L (2017) Iodine value determination of edible oils using ATR-FTIR and chemometric methods. Eur J Lipid Sci Technol 119(9):1–7. https://doi.org/10.1002/ejlt.201600323

Merkx DWH, Sophie Hong GT, Ermacora A, Van Duynhoven JPM (2018) Rapid quantitative profiling of lipid oxidation products in a food emulsion by 1H NMR. Anal Chem 90(7):4863–4870. https://doi.org/10.1021/acs.analchem.8b00380

Mlcek J, Druzbikova H, Lasek P, Sochor J, Jurikova T, Borkovcová M, Baron M, Balla S (2015) Assessment of total polar materials in frying fats from Czech restaurants. Ital J Food Sci 27(June):32–37. https://doi.org/10.14674/1120-1770/ijfs.v182

Ramezani Z, Mirzajani R, Kardani F (2015) A novel ultrasound-assisted back extraction reverse micelles method coupled with gas chromatography-flame ionization detection for determination of aldehydes in heated edibles oils. Food Chem 188:30–36. https://doi.org/10.1016/j.foodchem.2015.04.112

Ranganna S (2000) Handbook of analysis and quality control for fruit and vegetable products. Tata McGraw-Hill. https://books.google.co.in/books?id=Lzw3tQEACAAJ. Accessed 25 Jan 2022

Snyder JM, Frankel EN, Selke E, Warner K (1988) Comparison of gas chromatographic methods for volatile lipid oxidation compounds in soybean oil. J Am Oil Chem Soc 65(10):1617–1620. https://doi.org/10.1007/BF02912565

Song S, Zheng F, Tian X, Feng T, Yao L, Sun M, Shi L (2022) Evolution analysis of free fatty acids and aroma-active compounds during tallow oxidation. Molecules. https://doi.org/10.3390/molecules27020352

Tesfaye B, Abebaw A (2016) Physico-chemical characteristics and level of some selected metal in edible oils. Edited by Maria Roca. Adv Chem 2016:3480329. https://doi.org/10.1155/2016/3480329

Vičkačkaitė V, Pipiraitė G, Poškus V, Jurkutė I, Bugelytė B (2020) Static headspace gas chromatographic determination of hexanal as a marker of lipid oxidation in fat-rich food. Chemija 31(2):95–100. https://doi.org/10.6001/chemija.v31i2.4221

Xia L, Yuanqi Du, Xiao X, Li G (2019) One-step membrane protected micro-solid-phase extraction and derivatization coupling to high-performance liquid chromatography for selective determination of aliphatic aldehydes in cosmetics and food. Talanta 202(May):580–590. https://doi.org/10.1016/j.talanta.2019.05.035

Xiao L, Li C, Chai D, Chen Y, Wang Z, Xianbing Xu, Wang Yi, Geng Y, Dong L (2020) Volatile compound profiling from soybean oil in the heating process. Food Sci Nutr 8(2):1139–1149. https://doi.org/10.1002/fsn3.1401

Xu L, Xiuzhu Yu, Li M, Chen J, Wang X (2018) Monitoring oxidative stability and changes in key volatile compounds in edible oils during ambient storage through HS-SPME/GC–MS. Int J Food Prop 20(January):S2926–S2938. https://doi.org/10.1080/10942912.2017.1382510

Yu X, Li Q, Sun D, Dong X, Wang T (2015) Determination of the peroxide value of edible oils by FTIR spectroscopy using polyethylene films. Anal Methods 7(5):1727–1731. https://doi.org/10.1039/c4ay02718c

Zhang D-C, Liu J-J, Jia L-Z, Wang P, Han X (2019) Speciation of VOCs in the cooking fumes from five edible oils and their corresponding health risk assessments. Atmos Environ 211:6–17. https://doi.org/10.1016/j.atmosenv.2019.04.043

Zhang H, Wang Z, Liu O (2015) Development and validation of a GC-FID method for quantitative analysis of oleic acid and related fatty acids. J Pharm Anal 5(4):223–230. https://doi.org/10.1016/j.jpha.2015.01.005

Acknowledgements

Authors are highly thankful to the Director, CSIR-Central Scientific Instruments Organization, Chandigarh, and Director, CSIR-Institute of Chemical Technology, Hyderabad, for permitting us to carry out this research work in the laboratory and the Food and Drug Administration, Chandigarh, for helping us in the collection of edible oil samples.

Funding

This work was carried out with the financial grant provided by Council of Scientific and Industrial Research (CSIR), Govt. of India under the FOCUS mission project (HCP-0016).

Author information

Authors and Affiliations

Contributions

AS and BD supervised the work; AS and AB wrote the manuscript; BD and TR edited the manuscript; AB, GK, SP and TR carried out the experiments; MS and MS collected the samples and provided technical support; SB and RK statistically analysed the data; APB conceived the idea and designed the experiments.

Corresponding authors

Ethics declarations

Ethics Approval

This article does not contain any studies with human or animals.

Informed Consent

Informed consent is not applicable.

Conflict of Interest

Anupma Sharma declares that he has no conflict of interest. Ambika Bhardwaj declares that he has no conflict of interest. Ghata Khanduja declares that he has no conflict of interest. Saurav Kumar declares that he has no conflict of interest. Sudeshna Bagchi declares that she has no conflict of interest. Rishemjit Kaur declares that she has no conflict of interest. Manu Sharma declares that he has no conflict of interest. Monika Singla declares that she has no conflict of interest. T. Ravinder declares that he has no conflict of interest. Amol P Bhondekar declares that he has no conflict of interest. B. L. A. Prabhavathi Devi declares that she has no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sharma, A., Bhardwaj, A., Khanduja, G. et al. Determination of Hexanal Using Static Headspace GC-FID Method and Its Correlation with Oxidative Rancidity in Edible Oils. Food Anal. Methods 15, 2652–2663 (2022). https://doi.org/10.1007/s12161-022-02320-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-022-02320-4