Abstract

Coconut (CO) and virgin coconut oil (VCO) are popular functional oils owing to their health benefits. The fraudsters intentionally blend cheap and poor-quality vegetable oils with CO and VCO for economic benefits. Adulteration causes safety and health issues for consumers. In this context, there is a need for rapid, accurate, and precise analytical techniques to detect adulteration in CO and VCO. Conventional analytical methods are arduous and lengthy processes using toxic chemicals and involve tedious sample preparation. Thus, food researchers are in search of precise, rapid, and green analytical techniques to detect and quantify the adulteration of CO and VCO. The present review focuses on summarizing all the analytical techniques along with chemometric tools developed in recent times. Various techniques, such as chromatographic, spectroscopic, and thermal techniques coupled with chemometrics, have been successfully applied in this field. The NIR-based spectroscopic technique is a very optimisable and practical method for adulteration detection in CO and VCO. The official methods currently used must be upgraded as they are comparatively less sensitive than the latest methods.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

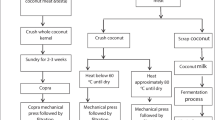

Coconut (Cocos nucifera) is a prevalent plantation crop cultivated in more than 80 countries. Coconut oil (CO) is immensely used for food purposes (Rohman et al. 2021). CO is extracted by either dry or wet processing. Dry processing involves pressing ground and steamed copra to extract oil, which then undergoes the processes of refining, bleaching, and deodorizing (RBD). Since dry processing involves heat, CO extracted from cream obtained from coconut milk is called wet processing. Cold-pressed oil processing, the oilseeds are pressed at room temperature, so the temperature of the oil and acid value are very low, whereas in hot-pressed oil extraction, the oil seeds are subjected to roasting and then pressed through a screw press under high pressure and temperature. The resulting coconut oil is called virgin coconut oil (VCO) (Marina et al. 2009a, b; Manikantan et al. 2018). This process has become more popular as it does not involve any chemical treatment.

Coconut oil is rich in medium-chain fatty acids, including caproic, caprylic, and capric acids, and shows good digestibility. Also, it exhibits antifungal, antiviral, hepatoprotective, cardioprotective, hypolipidemic, and antidiabetic characteristics which are highly beneficial to human health (Salian and Shetty 2018). This contributes to the extremely good quality and high commercial value of the oil. This makes the oil highly susceptible to intentional adulteration with low-cost, low-quality vegetable oils such as palm oil, sunflower oil, corn oil, canola oil, and soybean oil (Neves and Poppi 2020; Pizzo et al. 2019a; Pandiselvam et al. 2015) and other oils (Amit et al. 2020b; Pandiselvam et al. 2015) for economic reasons. In India, there are14 brands of coconut oil banned by the Food Safety and Standards Authority of India (FSSAI) due to adulteration (Neo 2019). This adulteration not only causes consumer disappointment, but also safety and health issues (Bansal et al. 2017). Oil millers are getting badly affected due to the trading of adulterated coconut oil. In a report, it was noted that 90% of the oil that is traded as coconut oil is palm kernel oil (Keshavaram 2015). In China, low-cost animal fats produced from waste tissues and valueless skin from animal or poultry slaughterhouses were used as adulterants in VCO and peanut oil (Xu et al. 2015).

The European Union Commission and Food and Agricultural Organization have established regulations and quality control methods for oil. However, certain established official methods for the quality control of oil are complicated, laborious, use toxic and expensive chemicals, and require tedious sample preparation procedures (Valli et al. 2016; Rifna et al. 2022). There are two common methods to detect and quantify adulterants in CO and VCO that have been reported, viz, spectroscopic techniques (Amit et al. 2020c; Pizzo et al. 2019a; Popa et al. 2020) and chromatographic techniques (Komaram et al. 2021; Xu et al. 2015) coupled with chemometric tools such as principal component analysis, partial least square regression, discriminant analysis, and clustering analysis (Naveen et al. 2022). Therefore, authentication and adulteration control are critical in the VCO industry.

To the best of our knowledge, there is no review paper on the aspect of advanced analytical techniques application to VCO adulteration detection. This review highlighted the methods of determining adulteration and quantification of VCO along with the statistical analysis (Fig. 1). Different analytical techniques such as spectroscopic techniques (FTIR spectroscopy, NIR spectroscopy, Raman spectroscopy, ultraviolet–visible spectroscopy, mass spectroscopy, nuclear magnetic spectroscopy), chromatographic techniques (gas chromatography and high-performance liquid chromatography), thermal techniques (differential scanning calorimetry), and other techniques (electronic nose) have been applied for the identification and quantification of VCO adulteration to date. The application of the E-nose technique for the detection of adulteration is mainly focused. All of these techniques are employed for authentication. Adulteration detection in oil is discussed in the succeeding sections.

Vibrational Spectroscopy for the Determination of Adulteration in CO and VCO

Vibrational spectroscopy assesses the interaction between electromagnetic radiation and the vibrational states of the atomic nuclei within their corresponding molecules. Vibrational spectroscopic techniques have various advantages over other analytical techniques, such as non-destructive, rapid analysis, no tedious sample preparation, and low running costs (Meenu and Xu 2019; Pandiselvam et al. 2021, 2022; Mahanti et al. 2022). Vibrational spectroscopy encompasses Raman and infrared (near, mid, or far) spectroscopy. Vibrational spectroscopy, in association with chemometrics, has been comprehensively utilised in the food industry (Pandiselvam et al. 2015;Galvin-King et al. 2021; Taylan et al. 2021; Kaavya et al. 2020; Mahanti et al. 2022). Several works have conveyed the application of Raman and infrared spectroscopic techniques for determining and quantifying the adulterants present in coconut oil, which are discussed in the following sections.

Determination of Adulteration by FTIR Spectroscopy

In FTIR spectroscopy (Fig. 2), multiple frequencies can be measured simultaneously by interferometric modulation of radiation in the range of 4000 to 400 cm−1 wavenumber to identify and quantify food constituents (Valand et al. 2020; Rifna et al. 2022). Manaf et al. (2007) conjugated FTIR with attenuated total reflectance (ATR) and chemometrics (partial least square regression — PLS) to detect the adulterant (palm kernel olein) in virgin coconut oil (VCO). Fourteen sets of pure VCO and eighteen sets of adulterated VCO with palm kernel oil up to 50% by volume were used for data collection using FTIR. The PLS calibration model developed with the actual adulteration concentration versus the predicted adulteration concentration resulted in a high coefficient of determination (R2) value of 0.9973 and the cross-validation yielded a 0.9875 R2 value and 1.70 RMSECV value. The discriminant analysis (DA) using 10 principal components (PC) factors was carried out to classify the pure and adulterated samples which resulted in 100% classification with not even a single sample being mistakenly classified. In a similar study conducted by Rohman and Man (2009), FTIR combined with ATR and PLS was employed to detect and quantify adulterated palm oil in VCO. Twenty-five sets of VCO samples adulterated using a palm oil combination of about 1–50% by weight in the presence of chloroform were used for developing the PLS calibration model. Forty independent samples were used for the calibration of the model. APLS calibration model was established using the spectral regions to determine the level of adulteration that showed a linear relationship. The variations between the actual and FTIR-predicted values were described using the R2 value (0.999) and the SEC value (0.533). The cross-validation resulted in R2 and standard error of prediction (SEP) values of 0.996 and 0.993, respectively. They were also able to successfully classify pure and adulterated coconut oil with 100% accuracy by employing discriminant analysis using 7 principal component factors, which showed that the developed model can predict the adulteration of up to a 1% lower control limit.

Abdul Rohman and Man (2011) attempted to quantify VCO in the ternary mixture with olive oil and palm oil utilizing FTIR-ATR combined with PLS and principal component regression (PCR). In the spectrum obtained from the ternary oil mixture, there were bands observed for olive oil and palm oil, but no bands were found for VCO at the frequencies of 3005 and 1654 cm−1. Such differences have been exploited to determine the VCO content in complex oil mixtures. The FTIR spectral data was pre-processed by the mean centering method, then PCR and PLS models were built based on the original and derivative (first or second) spectra at 1200–1000 cm−1 frequency regions for VCO quantification. The PLS model constructed using the second derivative spectra reveals the highest R2 (0.9999) value and the lowest RMSEC (0.200) value. In an identical study, FTIR-ATR with multivariate calibration methods (PLS and PCR) has been applied to find VCO content in binary oil mixtures (VCO and olive oil; VCO and palm oil) (Rohman et al. 2010). The distinction between the VCO and olive oil spectrum was found at 1111 cm−1 and 962 cm−1 frequency regions, whereas the distinction between the VCO and palm oil spectrum was found at 1120–1105 cm−1 and 965–960 cm−1 frequency regions. The PLS calibration models constructed at these spectral frequency regions were reported to be the best in terms of the highest R2 (0.9992) and lowest RMSEC (0.756) for the binary mixture of VCO and olive oil. Meanwhile, the R2 and RMSEC values of the binary mixture of VCO and palm oil were found to be 0.996 and 0.494 respectively, proving FTIR along with PLS to be one of the efficient techniques to quantify VCO in oil mixtures.

The virgin coconut oil adulterated with sunflower oil and corn oil was determined using FT-MIR spectroscopy in conjugation with chemometrics (PLS and DA) (Rohman and Che Man 2011). DA using 10 PCs was able to classify pure and adulterated oil samples with 100% accuracy. The adulterants which were successfully quantified using the PLS regression model resulted in the highest R2 (0.999) value and low RMSEP values for both adulterants. In the same way, lard adulteration in VCO has been detected and quantified by employing FTIR spectroscopy coupled with chemometrics (Tengku Salwani, Tengku Mansor et al. 2011). The frequency regions selected for PLS and DA analysis were 3020–3000 cm−1 and 1120–1000 cm−1. The established PLS model was able to effectively predict lard content in VCO with a high R2 (0.9970) value and RMSEC of 1.54%. Also, the classification of pure VCO and lard adulterated samples were conducted by DA using 6 PC factors and none of the samples was misclassified. The VCO adulterated with mustard and palm oil was detected by FTIR with the assistance of hierarchical cluster analysis (HCA), principal component analysis (PCA), and DA (Mk et al. 2017). Similarly, ATR-FTIR has been reported to analyse the adulteration of VCO with mustard oil with the help of chemometric tools (Amit et al. 2020a). The LDA revealed 100% exact classification between pure and adulterated samples, and the selected spectral frequency regions for PCA analysis ranged from 3010 to 2800 cm−1 and from1800 to 720 cm−1. The PLS-R and PCR models were constructed based on the original and derivative spectra in the same frequency region. The PLS-R model showed excellent prediction with the highest R2 of 0.999 and the lowest limit of detection of mustard oil in VCO being 1% v/v.

Paraffin oil is one of the major adulterants of VCO, which was identified by the ATR-FTIR technique associated with some chemometric tools. PCA and linear discriminant analysis (LDA) efficiently (100%) distinguished adulterated samples from pure VCO. The PLS-R model yielded the highest coefficient of determination (R2 = 0.999, RMSEC = 0.142, and RMSEP 0.162) with the lowest limit of detection of paraffin oil in VCO being 1% v/v (Amit et al., 2020b). VCO is not only adulterated with cheap vegetable oils but also adulterated with fried coconut oil and this adulteration can be determined by ATR-FTIR spectroscopy (Amit et al. 2020c). The spectral frequency regions selected for PCA were 3000 to 2800 cm−1 and 1800 to 500 cm−1 and the PCA 3D plot excellently separated the pure and adulterated samples into different clusters. The LDA exhibited 100% exact classification between pure and adulterated samples and the lowest detectable limit of fried coconut oil in pure coconut oil was found to be 0.5% v/v. The PCR and PLS-R models were built using original and derived spectra in which the PLS model for the first derivative at the frequency regions 1800 to 500 cm−1was reported to have predicted the best with high accuracy.

The ATR-FTIR spectroscopy, in tandem with DD-SIMCA (data-driven-soft independent modelling of class analogy) has been utilised to assess the authenticity and adulteration of VCO which is adulterated with corn oil, canola oil, sunflower oil, and soybean oil (Neves and Poppi 2020). The PCA was applied to all the spectra of pure and adulterated coconut oil, and a clear separation was found between them, showing that the proposed methodology was able to verify the authenticity of coconut oil. The developed DD-SIMCA models to identify vegetable oil adulterants showed acceptable results, with high sensitivity (88.23–100%) and specificity (95.74–100%) in the prediction step. FTIR can be used to detect and quantify adulteration. However, the Fourier transform (FT-NIR) spectroscopy records the interferogram based on time-domain measurements.

Determination of Adulteration by NIR Spectroscopy

Near infrared (NIR) spectroscopy (Fig. 2) utilises the NIR region (800 to 2200 nm) of the electromagnetic spectrum to measure the molecular overtones and combination bands of a few fundamental vibrations (Ozaki et al. 2021; Kaavya et al. 2020; Pandiselvam et al. 2022). The adulteration of palm olein in VCO was detected and quantified by FT-NIR using a PLS model (Jayatunga et al. 2020). For the analysis, 20 VCO samples with adulteration ranging from 1 to 70% v/v of palm olein in CCO were prepared by vortex at 1500 rpm for 2 min. A PLS model was developed and validated for the prediction of adulteration with the regression coefficient (R2) of 0. 0.9997 and 0.9993. There is a high correlation between PLS calculated and actual values of adulteration. NIR spectroscopy has been applied to determine adulteration in edible oils, for instance, coconut oil which is adulterated with paraffin oil has been detected in a study (Raj et al. 2018). The samples are prepared with 0, 1, 2, 3, 4, 5, 10, and 100% of paraffin oil which are labelled as P0, P1, P2, P3, P4, P5, P10, and P100, respectively. The peaks appearing in the NIR spectrum (1200–1800 nm) of pure paraffin oil indicate the vibration of an alkyl group whereas the coconut oil spectrum shows additional peaks at 1904, 1928, and 2132 nm corresponding to the vibration of the carbonyl group. At 2132 nm, the intensity of the peak decreased with a decrease in paraffin oil content, and thereby the adulterant content was quantified with the highest R2 value of 0.986.NIR spectroscopy works in the spectrum of 750- to 2600-nm electromagnetic region. C-H, O–H, and N–H bonds molecules in the samples absorb NIR waves at specific wavelengths. These absorbances are and the difference in the absorbance is used to predict adulteration.

Determination of Adulteration by Raman Spectroscopy

Raman spectroscopic technique provides distinctive fundamental vibrations that can be used to elucidate the sample’s molecular structure (Bhunia et al. 2014). Raman spectroscopy, in conjugation with multivariate curve resolution-alternating least squares (MCR-ALS) was utilised for the detection of adulteration of coconut oil contaminated with other relatively cheap oils such as palm kernel, castor bean, peanut, soybean, sunflower, canola, sesame, mineral, babassu, and Vaseline oils. The acquisition of spectra was in the range of 3200 to 200 cm−1 and at 2 cm−1 resolution. The control charts were built using the score values from MCR-ALS analysis, and they were reported to successfully differentiate adulterated samples (adulteration level — above 2%) from the pure ones. The adulterant content was quantified using regression models constructed using the MCR-ALS algorithm, and it showed excellent prediction results (De Géa Neves and Poppi 2018). The list of the utilisation of vibrational spectroscopic techniques for the detection and quantification of adulteration in virgin coconut oil is summarised and presented in Table 1.

Other Spectroscopic Techniques for the Determination of Adulteration in CO and VCO

Determination of Adulteration by Ultraviolet–Visible Spectroscopy

The cold-pressed coconut oil adulterated with its refined versions was reported to be detected rapidly using UV–Vis spectroscopy (Popa et al. 2020). They have also employed FTIR spectroscopy to analyse its ability to establish adulteration of cold-pressed coconut oil with refined coconut oil and observed some notable differences in the spectra between cold-pressed (pure) and adulterated ones, but it is not enough to quantitatively determine the saturated and unsaturated fatty acid content, whereas the colour analysis by the UV–Vis spectroscopy technique was found to be a promising method for distinguishing the pure cold-pressed coconut oil from its adulterated refined version. The results of colour analysis show that there is a difference in the absorption spectra and the CIE (International Illuminating Committee) L*, a*, and b* values between cold-pressed oil and the refined one. The parameter a* and b* values were found to be three and six times higher, respectively, for refined coconut oil than for cold pressed coconut oil. The parameters a* and b* were reported to be linearly dependent with the highest correlation coefficient (R2 = 0.99) and from which the cold-pressed coconut oil content in a given sample can be determined. Thus, the only UV–Vis spectroscopic study by Popa et al. (2020) proved to be an excellent method to detect virgin coconut oil adulteration. A similar kind of work has been done for the detection of adulteration in virgin olive oil using UV–VIS. The EVOO and mixed olive oil were subjected to UV analysis at 232 to 400 nm by a spectrophotometer (Jen Way 6105 UV–VIS, Esses, England). The samples were heated for 45 and 90 min to assess the thermal degradation. The samples were prepared by diluting 250 mg of the oil samples in isooctane solution and diluted to a 0.8 mg/mL concentration. The adulterated EVOO with mixed oils highly absorbed the UV–VIS light between the 240- and 300-nm band and the study revealed that the UV–VIS spectrometer is the most suitable and reliable technique to detect and quantify high levels (over 10%) of adulteration in the EVO (Gholami Khesht et al. 2020).

Determination of Adulteration by Nuclear Magnetic Resonance Spectroscopy

The 13C INEPT NMR spectroscopy, along with chemometrics, with an untargeted finger printing approach, has been employed for the authentication of numerous commercial food products by using a spectral database built with 294 spectra of raw plant and animal fats and oils (Guyader et al. 2018). The plant oil (including coconut oil) belonging to one origin was spiked with another and the limit of detection was found to be around 5%. Also, when animal oil was spiked with plant oil, the limit of detection was 2%. These limits cannot be achieved by a fatty acid profile. Even though spectroscopic methods like FTIR can reach these limits, this method was proved to cover a vast range of oils of plant and animal origins. The PCA analysis was able to discriminate between plant and animal oils and among 30 origins of plant oils.13C NMR was also employed to distinguish between VCO, degraded VCO, adulterated VCO, and RBD coconut oil with the help of untargeted multivariate analysis (Lagurin et al. 2020). The PCA analysis was able to differentiate among all the coconut oil samples. The PLS-DA was used as a binary classifier, and the optimised model resulted in improved performance in differentiating all the coconut oil samples.

Determination of Adulteration by Mass Spectroscopy

The MALDI-MS, matrix-assisted laser desorption/ionisation mass spectrometry, was used to create a complete spectral database which includes more than 30 edible oil species (including coconut oil), for the quick cataloguing of edible oil samples by comparing them with the reference MALDI-MS spectra in the database (Ng et al. 2018). Many research have shown that the triacylglyceride (TAG) region in the MALDI-MS spectra of different edible oils was specific which can be useful for the description and cataloguing of edible oils (Ng et al. 2015). The TAG region of coconut oil was dominated by peaks less than m/z 850, with abundant peaks in the lower mass region (m/z 689.6) corresponding to TAGs with C14:0. This specific TAG was only found in coconut oil, which made it cluster separately from the rest of the oils in the PCA plot, and the established PLS-DA models accurately classified 97.2% of all the edible oils.

Coconut oil adulterated with some cheaper quality soybean oil has been detected using direct infusion electrospray ionisation mass spectrometry (ESI–MS) (Pizzo et al. 2019b). The lipid profile spectra were obtained and the [TAG + NH4]+ of the region 870.9 m/z was selected as the lipid marker of soybean oil, which is absent in coconut oil. A calibration curve was built using [LLnP + NH4] + intensity versus soybean oil percentage to effectively quantify adulterant content with the highest R2 of 0.994 and the lowest limit of detection is 2%. In a similar study, direct infusion ESI–MS combined with chemometrics was applied to detect coconut oil adulterated with palm kernel oil (Pizzo et al. 2019b). The lipid profile spectra of coconut oil and palm kernel oil were obtained in the region of 100–1200 m/z by direct infusion (ESI–MS). The principal component analysis of ESI–MS data shows that it separated adulterated samples from pure ones, indicating that mass spectrometry can effectively detect adulteration in coconut oil.

Chromatographic Techniques for the Determination of Adulteration in CO and VCO

The chromatographic techniques (Fig. 3) used for the detection of coconut oil adulteration are based on specific marker compound quantification. The tocopherols, triglycerides, tocotrienols, phenolic compounds, polar fraction, and pyropheophytins are the marker compounds that can be determined by HPLC, whereas the fatty acid methyl esters (FAME), sterols (stigmasterol and campesterol), sigmastadiene, triacylglycerol, and volatile compounds are the marker compounds that can be determined by gas chromatography.

Determination of Adulteration by High-Performance Liquid Chromatography

The coconut oil adulterated with palm olein and palm kernel oil has been determined using a reverse phase (RP)-HPLC-based method using triglyceride as a marker (Komaram et al. 2021). The three major triacylglyceride molecular species of coconut oil are trilaurin (C36), dilaurin-monocaprin/myristin-caprylin-laurin (C34), and dilaurin-monomyristin (C38) from which trilaurin was selected as a detection index for quantification of the level of palm kernel oil. Whereas to quantify palm olien adulterant in coconut oil, the ratio of peak area of dipalmitoyl-monoolein and trilaurin was chosen as detection index. The developed RP-HPLC based method proves to be satisfactory with 2–4% lowest limit of detection and detection accuracy being 78–98%, varying with the type of oil and level of adulteration. Information about the HPLC method for authentication of CO and VCO was acute, so the use of the HPLC method for detecting adulteration in other oils was discussed. By estimating the phenols and tocopherols in virgin olive oil, HPLC was used to differentiate the oil quality. Simultaneous extraction of virgin olive oil was carried out using methanol and isopropanol-methanol mixture and the extract was separated by HPLC using a reversed phase C18 column with acetic acid/water–methanol-acetonitrile-isopropanol mixture under gradient elution methods (Tasioula-Margari and Okogeri 2001). Similarly, in another study, triglycerides of extra/virgin olive oil tainted with 5% soybean oil were determined by HPLC for adulteration detection (Jabeur et al. 2014). The extra-virgin olive oil was adulterated with the soybean, sunflower, and corn oils at the levels of 1, 2, 3, 4, 5, and 10% w/w which were separated using an ion trap mass spectrometer interfaced to the HPLC system through an atmospheric pressure chemical ionisation (APCI) (Fasciotti and Netto 2010). The study reported that the TAGs were separated at isocratic elution with a 60:40 acetone/acetonitrile mixture; 137 column temperature, 30 °C; flow rate, 1.5 mL/min; and injection volume of 20 μL of the sample and identified by their mass and equivalent carbon number (ECN). The absolute difference between theoretical and experimental ECN42 content (ΔECN42) in all seed oils was higher than in extra-virgin olive oil. The ΔECN42 value must not exceed 0.20 in the case of edible virgin olive oil, 0.30 in the case of lampante olive oil, 0.50 in the case of olive pomace oil, and 0.60 in the case of crude olive pomace.

Extra virgin olive oil (EVOO) and a commercial oil blend labelled as 15% (w/w) of olive oil in soybean oil were analysed by HPLC using a reverse-phase LiChrospher octadecyl (ODS) column (250 mm × 3 mm; 5 m) and a guard column of similar characteristics (Vydac ODS, 201TP54, 2.1 mm; 10 mm). The analysis conditions were a constant flow rate of 0.7 mLmin−1, the column temperature of 35 °C, and the injected volume of 5L.

Determination of Adulteration by Gas Chromatography

Gas chromatography mass spectrometry (GC–MS) and NMR fingerprinting techniques in conjugation with chemometrics were employed for the classification of different types of oil, including coconut oil (Fang et al. 2013). The PCA models of both techniques were able to cluster 14 different types of oils. The PLS-DA and orthogonal projections tolatent structures — discriminant analysis (OPLS-DA) models built using GC–MS data resulted in better classification specificity and sensitivity in comparison with models built using NMR data. However, data from either of the two techniques can be efficiently applied to establish an oil and fat database for the identification of unknown samples.

A new method was developed to identify the presence of animal fats in VCO, with cholesterol as a marker, employing two-dimensional gas chromatography (GC × GC) conjugated with time-of-flight massspectrometry (TOF–MS). The better baseline separation of trimethylsilyl ether (sterol derived from cholestanol and cholesterol) was obtained from GC × GC systems compared to one-dimensional GC so that the adulterant content could be precisely determined. This method can identify the presence of chicken fat, beef tallow, mutton tallow, lard, or their blends in VCO, with a detection limit as low as 0.25% (Xu et al. 2015). GC system can be used to detect and quantity of adulteration in VCO by developing and validating an appropriate method.

Thermal Analysis Technique for the Determination of Adulteration in CO and VCO

1Determination of Adulteration by Differential Scanning Calorimetry

Differential scanning calorimetry (DSC) is a thermo-analytical technique that elucidates the temperature and heat flow related to the transition of materials as a function of temperature and time (Farah et al. 2018; Mahanti et al., 2021). The heating and cooling thermograms of DSC were used to determine adulteration in VCO with soybean oil (SBO) and palm kernel oil (PKO) (Marina, et al. 2009a, b). The melting and crystallisation enthalpy of VCO adulterated with SBO and PKO were studied. The SBO-adulterated sample’s heating curve revealed that the adulterant peak occurs at the low-temperature region at an adulteration level of 10%. While the PKO-adulterated samples did not show any adulterant peak, a gradual decrease in peak height was observed in the major exothermic peak, the stepwise multiple linear regression was applied to quantify adulterant content with a high R2 value of 0.9490.

The thermal profiling of coconut oil employing DSC can be useful for the detection of lard adulteration in it. In the heating thermogram of the adulterated sample, with increasing lard content, one major endothermic peak and a minor peak, which is progressively smoothening out to become a major peak, were observed. Whereas one minor peak and two major exothermic peaks were observed in the cooling thermogram, one peak increased and the other decreased with lard content. The SMLR analysis shows that two independent variables were able to quantify lard content with R2 of 0.9582 (Mansor et al. 2012). In another study, they detected adulterated palm olein in VCO by DSC. There was a significant difference between the heating and cooling curves of VCO and palm olein. The changes in the thermal transitions were due to the varying ratios of saturated to unsaturated triacylglyceride molecules. The detected adulterant peaks were correlated with the degree of adulteration using SMLR and resulted in a high correlation coefficient and very low standard error values (Marikkar 2019). Studies indicate that adulteration is altering the glass transition temperature (Tg) by changing the heat capacity and viscosity of oil based on the oxidation of oils and other chemical reactions happening in the VCO.

Recent Techniques for the Determination of Adulteration in CO and VCO

Determination of Adulteration by Electronic Nose

The E-nose can reproduce human senses to artificially perceive volatiles and distinguish them using an array of sensors and pattern recognition systems. Lately, electronic nose systems along with chemometrics are being evolved as a rapid and reliable technique for the detection of adulteration of edible oils (Roy and Yadav 2021). Fast gas chromatography-surface acoustic wave sensors (GC-SAW E-nose) were employed to detect coconut oil adulteration with palm olein as an adulterant. From the chromatographic profile, the adulterant peak was provisionally identified as methyl dodecanoate and its intensity was correlated (using PLS analysis) with the level of adulterant added (R2 = 0.91). The Pearson’s correlation coefficient obtained between the adulterant peak and the chemical analysis, viz., iodine value, and peroxide value were 0.92 and 0.89, respectively. Also, the PCA resulted in excellent discrimination between pure and adulterated coconut oil samples (Marina et al. 2010). In a similar study, the GC-SAW E-nose system was employed to identify lard adulteration in VCO. The chromatographic profiles identified ten different adulterant peaks, out of which one peak had the best relationship with lard content in VCO having the highest R2 value of 0.934 (Tengku Salwani Tengku Mansor et al. 2011) proving E-nose to be an efficient method for the identification of coconut oil adulteration (Table 2) .

Chemometrics

Chemometrics, a chemical discipline, uses mathematical statistics, information technology, and probability theory to analyse multidimensional chemical data. The overview of commonly used chemometric tools is summarised in Table 3. Traditional statistical methods are often times not sufficient for precise interpretation of results and can only analyse single variables, whereas chemometrics enables us to obtain valuable information from a broad range of intricate datasets and allows us to detect the relationships between the variables (Esteki et al. 2018). The key advantages of chemometric methods are that they lower the number of measurements and analyses required, reduce costs, and save time. Therefore, chemometric tools, especially multivariate analysis, find numerous applications in food quality control, food safety, and qualitative and quantitative determination of chemical parameters to evaluate food authenticity and adulteration (Gómez-Caravaca et al. 2016; Kaavya et al. 2020; Pandiselvam et al. 2022; Rifna et al. 2022).

Chemometric techniques of pattern recognition are divided into unsupervised pattern recognition and supervised pattern recognition. Unsupervised pattern recognition can determine the structure of a dataset based on its measurements. It displays clusters with respect to the type and number of classes. The results are revealed as two- or three-dimensional graphs or dendograms. The most popular unsupervised pattern recognition techniques are CA, HCA, and PCA. In supervised pattern recognition, object membership in the classes and the number of classes are known beforehand. The unknown samples can be projected into known classes based on experimental results. Supervised pattern recognition may include QDA, LDA, RDA, SIMCA, K-NN, PLS-R, ANN, and SVM methods (Efenberger-Szmechtyk et al. 2018). As previously reported, several research studies have adapted the chemometric tools in association with analytical techniques like chromatography and spectroscopy to identify food scandals, adulteration, and the authenticity of virgin coconut oil.

Limitations of Advanced Analytical Method

Chromatography techniques are physical separation methods to determine and identify the various compounds based on their density by making the mobile phase move on the surface of the stationary phase. Some errors occur during chromatography, such as improper sample loading, incubation temperature and flow rate of the samples, and sample preparation methods. Solvent and standard requirements are one of the major limitations of chromatography techniques. They are very costly and very difficult to obtain for each sample. All the chromatography techniques require trained manpower to operate. The chromatography instruments are so expensive and handling is very difficult. The operating costs and power requirements are also the major disadvantages of chromatography techniques. Troubleshooting procedure and validation errors, measurement errors that result in inaccurate readings due to parallax errors, transcription errors, and conversion and calculation errors are all barriers to using analytical methods.

The limitations of the chromatography techniques can be overcome by the spectroscopic techniques, since the spectroscopic techniques are non-destructive and allow the use of the sample matrix as such without any destruction. The samples used in spectroscopic techniques can be used for further analysis. So, sample error will be reduced. Spectroscopic measurements are easy and quick. Handling the instruments is also easy and requires less trained personnel. However, the selection of wavelength and light scattering through samples cause serious errors. Any obstacles in the samples would prevent the accurate wavelength measurement. Alignment or positing of the samples is very important. Misalignment causes the wrong spectrograph. In particular, IR spectroscopy provides only the relative positions of a molecule’s functional groups and will not determine the molecular weight of the samples.

Data analysis and management are one of the limitations. Collecting, managing, and deriving results from the data are very crucial for efficient chromatographic and spectroscopic techniques for determining the adulteration. Predictive analytics to mine the data and build robust models are still inaccessible for laboratory data analysis. The unavailability of a systematic and structured collection of data and ontologies limits the data aggregation process.

Conclusion and Future Research Directions

During the last decade, substantial interest has been paid to virgin coconut oil quality and production methods owing to the recent crises and frauds in the food industry. This has seriously undermined the confidence of consumers. The official methods for detecting fraud are laborious and use harmful chemicals. The demand for rapid determination of authenticity and adulteration of CO and VCO using advanced analytical techniques is greater than ever; therefore, various spectroscopic, chromatographic, and other methods have been developed. Most of these techniques are non-destructive and give abundant information on both physical states and molecular structure, as well as a complete fingerprint of the product. Along with these techniques, chemometric tools have been applied for the targeted and untargeted analysis of the data to identify food fraud, and adulteration, or to trace its biological and geographical origins (authenticity). Among several chemometric tools, PCA was the most commonly used technique to discriminate against pure adulterated samples; PLS was widely used to quantify adulterant levels.

The conventional chromatographic techniques, which detect the marker compounds such as fatty acid methyl esters and triacylglycerols, for the identification of virgin coconut oil adulteration, are laborious, time consuming, and use harmful chemicals. Hence, rapid, precise, and environment-friendly vibrational spectroscopic techniques were developed. However, they generate a large amount of data that can only be managed by chemometrics, which is a tedious job. DSC was successfully employed to detect VCO adulteration, but it suffers from the disadvantage that it is not efficient in quantifying adulterants. Unfortunately, detecting the minute concentration of all possible adulterants using an ideal analytical technique is not feasible in reality. However, in the future, for rapid and effective screening of adulterated VCO at commercial and consumer levels, hand-held devices based upon digital imaging, vibrational spectroscopic techniques, and electronic tongue should be developed and applied.

The development of explicit, unique-purposed sensors and open-source software-based data collection and analysis systems will enable more sophisticated and tailor-made adulteration detection methods and devices. The combination of deep learning models and machine algorithms with artificial intelligence and cloud-based database management will reduce the burden of data analysis and derive the results. Image processing analysis of the oil samples and products prepared from the oil will be a quick adulteration detection and grading technique. Furthermore, the combination of electronic nose, E-tongue, and E-colour measurement with an electromyogram-based sensory system will help to detect and quantify adulteration in virgin coconut oils.

Abbreviations

- VCO:

-

Virgin coconut oil

- CO:

-

Coconut oil

- RBD:

-

Refined, bleached, and deodorised

- ATR:

-

Attenuated total reflectance

- FTIR:

-

Fourier transform infrared spectroscopy

- FT-MIR:

-

Fourier transform mid-infrared spectroscopy

- NIR:

-

Near infrared spectroscopy

- PLS:

-

Partial least square

- PLS-R:

-

Partial least square-regression

- PLS-DA:

-

Partial least square-discriminant analysis

- RMSECV:

-

Root mean square error of cross-validation

- RMSEP:

-

Root mean square error of prediction

- DA:

-

Discriminant analysis

- PC:

-

Principal components

- SEC:

-

Standard error of calibration

- SEP:

-

Standard error of prediction

- PCR:

-

Principal component regression

- HCA:

-

Hierarchical cluster analysis

- LDA:

-

Linear discriminant analysis

- DD-SIMCA:

-

Data-driven-soft independent modelling of class analogy

- NMR:

-

Nuclear magnetic resonance spectroscopy

- PL:

-

Photoluminescence

- MCR-ALS:

-

Multivariate curve resolution-alternating least squares

- UV-VIS:

-

Ultraviolet-visible spectroscopy

- CIE:

-

International Illuminating Committee

- INEPT:

-

Insensitive nuclei enhanced by polarisation transfer

- MS:

-

Mass spectrometry

- MALDI:

-

Matrix-assisted laser desorption/ionisation

- TAG:

-

Triacylglycerol

- ESI-MS:

-

Electrospray ionisation mass spectrometry

- HPLC:

-

High-performance liquid chromatography

- FAME:

-

Fatty acid methyl esters

- RP-HPLC:

-

Reverse phase high-performance liquid chromatography

- GC:

-

Gas chromatography

- OPLSDA:

-

Orthogonal projections to latent structures-discriminant analysis

- TOF-MS:

-

Time-of-flight mass spectrometry

- DSC:

-

Differential scanning calorimetry

- SBO:

-

Soybean oil

- PKO:

-

Palm kernel oil

- SMLR:

-

Stepwise multiple linear regression

- E-NOSE:

-

Electronic nose

- GC-SAW:

-

Gas chromatography-surface acoustic wave sensor

- QDA:

-

Quadratic discriminant analysis

- RDA:

-

Redundancy analysis

- K-NN:

-

K-Nearest neighbours algorithm

- ANN:

-

Artificial neural networks

- SVMS:

-

Support vector machine

References

Amit, Jamwal R, Kumari S, Dhaulaniya AS, Balan B, Kelly S, Cannavan A, Singh DK (2020a) Utilizing ATR-FTIR spectroscopy combined with multivariate chemometric modelling for the swift detection of mustard oil adulteration in virgin coconut oil. Vib Spectrosc 109(April):103066. https://doi.org/10.1016/j.vibspec.2020.103066

Amit, Jamwal R, Kumari S, Dhaulaniya AS, Balan B, Singh DK (2020b) Application of ATR-FTIR spectroscopy along with regression modelling for the detection of adulteration of virgin coconut oil with paraffin oil. Lwt 118:108754. https://doi.org/10.1016/j.lwt.2019.108754

Amit, Jamwal R, Kumari S, Kelly S, Cannavan A, Singh DK (2020c) Rapid detection of pure coconut oil adulteration with fried coconut oil using ATR-FTIR spectroscopy coupled with multivariate regression modelling. Lwt 125(2019):109250. https://doi.org/10.1016/j.lwt.2020.109250

Bansal S, Singh A, Mangal M, Mangal AK, Kumar S (2017) Food adulteration: sources, health risks, and detection methods. Crit Rev Food Sci Nutr 57(6):1174–1189. https://doi.org/10.1080/10408398.2014.967834

Bhunia AK, Kim MS, Taitt CR (2014) High throughput screening for food safety assessment: biosensor technologies, hyperspectral imaging and practical applications. In High Throughput Screening for Food Safety Assessment: Biosensor Technologies, Hyperspectral Imaging and Practical Applications. https://doi.org/10.1016/C2013-0-16367-2

De Géa Neves M, Poppi RJ (2018) Monitoring of adulteration and purity in coconut oil using Raman spectroscopy and multivariate curve resolution. Food Anal Methods 11(7):1897–1905. https://doi.org/10.1007/s12161-017-1093-x

Efenberger-Szmechtyk M, Nowak A, Kregiel D (2018) Implementation of chemometrics in quality evaluation of food and beverages. Crit Rev Food Sci Nutr 58(10):1747–1766. https://doi.org/10.1080/10408398.2016.1276883

Esteki M, Simal-Gandara J, Shahsavari Z, Zandbaaf S, Dashtaki E, Vander Heyden Y (2018) A review on the application of chromatographic methods, coupled to chemometrics, for food authentication. Food Control 93:165–182. https://doi.org/10.1016/j.foodcont.2018.06.015

Fang G, Goh JY, Tay M, Lau HF, Li SFY (2013) Characterization of oils and fats by 1H NMR and GC/MS fingerprinting: classification, prediction and detection of adulteration. Food Chem 138(2–3):1461–1469. https://doi.org/10.1016/j.foodchem.2012.09.136

Farah JS, Silva MC, Cruz AG, Calado V (2018) Differential calorimetry scanning: current background and application in authenticity of dairy products. Curr Opin Food Sci 22:88–94. https://doi.org/10.1016/j.cofs.2018.02.006

Fasciotti M, Netto ADP (2010) Optimization and application of methods of triacylglycerol evaluation for characterization of olive oil adulteration by soybean oil with HPLC–APCI-MS–MS. Talanta 81(3):1116–1125

Galvin-King P, Haughey SA, Elliott CT (2021) Garlic adulteration detection using NIR and FTIR spectroscopy and chemometrics. J Food Compos Anal 96:103757. https://doi.org/10.1016/j.jfca.2020.103757

Gholami Khesht S, Kavusi E, Mousavi M, Sharaj Sharifi Y (2020) Efficient detection of extra virgin olive oil adulteration via UV and FTIR spectra in combination with heat-mediated oxidation method. Tabari Biomed Stud Res J 2(4):0

Gómez-Caravaca AM, Maggio RM, Cerretani L (2016) Chemometric applications to assess quality and critical parameters of virgin and extra-virgin olive oil. A review. Analytica Chimica Acta 913:1–21. https://doi.org/10.1016/j.aca.2016.01.025

Guyader S, Thomas F, Portaluri V, Jamin E, Akoka S, Silvestre V, Remaud G (2018) Authentication of edible fats and oils by non-targeted 13C INEPT NMR spectroscopy. Food Control. https://doi.org/10.1016/j.foodcont.2018.03.046

Jabeur H, Zribi A, Makni J, Rebai A, Abdelhedi R, Bouaziz M (2014) Detection of Chemlali extra-virgin olive oil adulteration mixed with soybean oil, corn oil, and sunflower oil by using GC and HPLC. J Agric Food Chem 62(21):4893–4904

Jayatunga H, Somasiri H, Mahanama KR (2020) Rapid determination of adulteration in virgin and copra coconut oil using Fourier transform near infrared spectroscopy. Int J Food Sci Nutri 5(3):38–43

Kaavya R, Pandiselvam R, Mohammed M, Dakshayani R, Kothakota A, Ramesh SV, Ashokkumar C (2020) Application of infrared spectroscopy techniques for the assessment of quality and safety in spices: a review. Appl Spectrosc Rev 55(7):593–611

Keshavaram (2015) Adulteration in coconut oil. https://cocoguru.com/adulteration-in-coconut-oil/. Accessed 20 Jan 2022

Komaram AC, Anjaneyulu E, Goswami K, Nayak RR, Kanjilal S (2021) Detection and quantification of palmolein and palm kernel oil added as adulterant in coconut oil based on triacylglycerol profile. J Food Sci Technol 58(11):4420–4428. https://doi.org/10.1007/s13197-020-04927-z

Lagurin, L. G., Garrovillas, M. J. M., & Dayrit, F. M. (2020). The application of 13C NMR and untargeted multivariate analysis for classifying virgin coconut oil. Proceedings 70(1): 54. https://doi.org/10.3390/foods_2020-07718

Mahanti NK, Pandiselvam R, Kothakota A, Ishwarya P, Chakraborty SK, Kumar M, Cozzolino D (2022) Emerging non-destructive imaging techniques for fruit damage detection: image processing and analysis. Trends Food Sci Technol 120:418–438

Manaf MA, Man YBC, Hamid NSA, Ismail A, Abidin SZ (2007) Analysis of adulteration of virgin coconut oil by palm kernel olein using Fourier transform infrared spectroscopy. J Food Lipids 14(2):111–121. https://doi.org/10.1111/j.1745-4522.2007.00066.x

Mansor TST, Man YBC, Rohman A (2011) Application of fast gas chromatography and Fourier transform infrared spectroscopy for analysis of lard adulteration in virgin coconut oil. Food Anal Methods 4(3):365–372. https://doi.org/10.1007/s12161-010-9176-y

Mansor TST, Man YBC, Shuhaimi M (2012) Employment of differential scanning calorimetry in detecting lard adulteration in virgin coconut oil. JAOCS, Journal of the American Oil Chemists’ Society 89(3):485–496. https://doi.org/10.1007/s11746-011-1936-3

Marina AM, Che Man YB, Amin I (2009a) Virgin coconut oil: emerging functional food oil. Trends Food Sci Technol 20(10):481–487. https://doi.org/10.1016/j.tifs.2009.06.003

Marina AM, Che Man YB, Nazimah SAH, Amin I (2009b) Monitoring the adulteration of virgin coconut oil by selected vegetable oils using differential scanning calorimetry. J Food Lipids 16(1):50–61. https://doi.org/10.1111/j.1745-4522.2009.01131.x

Marina AM, Man YBC, Amin I (2010) Use of the SAW sensor electronic nose for detecting the adulteration of virgin coconut oil with RBD palm kernel olein. JAOCS, Journal of the American Oil Chemists’ Society 87(3):263–270. https://doi.org/10.1007/s11746-009-1492-2

Marikkar JMN (2019) Differential scanning calorimetric analysis of virgin coconut oil, palm olein, and their adulterated blends. Cord 35(01):9. https://doi.org/10.37833/cord.v35i01.10

Meenu M, Xu B (2019) Application of vibrational spectroscopy for classification, authentication and quality analysis of mushroom: a concise review. Food Chem 289(September 2018):545–557. https://doi.org/10.1016/j.foodchem.2019.03.091

Mk P, Murugesan S, Shettu N (2017) Detection of adulteration of coconut oil using Fourier transform infrared spectroscopy and chemometrics. International Journal of Statics and Applied Mathematics 2(6):46–51

Neo P (2019) News & analysis on food & beverage development & technology – Asia Pacific. https://www.foodnavigator-asia.com/Article/2019/05/07/Coconut-oil-adulteration-FSSAI-bans-14-brands-in-India-as-new-detection-method-gains-traction?utm_source=copyright&utm_medium=OnSite&utm_campaign=copyright. Accessed 04 March 2022

Neves MDG, Poppi RJ (2020) Authentication and identification of adulterants in virgin coconut oil using ATR/FTIR in tandem with DD-SIMCA one class modeling. Talanta, 219(July). https://doi.org/10.1016/j.talanta.2020.121338

Ng TT, So PK, Zheng B, Yao ZP (2015) Rapid screening of mixed edible oils and gutter oils by matrix-assisted laser desorption/ionization mass spectrometry. Anal Chim Acta 884:70–76. https://doi.org/10.1016/j.aca.2015.05.013

Ng TT, Li S, Ng CCA, So PK, Wong TF, Li ZY, Chan ST, Yao ZP (2018) Establishment of a spectral database for classification of edible oils using matrix-assisted laser desorption/ionization mass spectrometry. Food Chem 252(September 2017):335–342. https://doi.org/10.1016/j.foodchem.2018.01.125

Ozaki Y, Huck C, Satoru T, Søren BE (2021) Near-infrared spectroscopy_ theory, spectral analysis, instrumentation, and applications (2021, Springer Singapore_Springer) - libgen.li.pdf

Pandiselvam R, Thirupathi V, Mohan S, Uma D (2015) Development of PLS model for rapid estimation of protein content of rice using fourier transform near infrared spectroscopy. Agric Eng 4:27–34

Pandiselvam R, Sruthi NU, Kumar A, Kothakota A, Thirumdas R, Ramesh SV, Cozzolino D (2021) Recent applications of vibrational spectroscopic techniques in the grain industry. Food Rev Int 1–31. https://doi.org/10.1080/87559129.2021.1904253

Pandiselvam R, Mahanti NK, Manikantan MR, Kothakota A, Chakraborty SK, Ramesh SV, Beegum PS (2022) Rapid detection of adulteration in desiccated coconut powder: vis-NIR spectroscopy and chemometric approach. Food Control 133:108588. https://doi.org/10.1016/j.foodcont.2021.108588

Pizzo JS, Galuch MB, Santos PDS, Manin LP, Zappielo, Silva Filho OJ, Visentainer JV (2019a) Determination of coconut oil adulteration with soybean oil by direct infusion electrospray ionization mass spectrometry 30(7):1468–1474

Pizzo JS, Galuch MB, Manin LP, Daniele P, Santos S, Zappielo CD, Junior OS, Visentainer JV, Santos PDS, Zappielo CD, Santos Junior O, Visentainer JV (2019b) Direct infusion electrospray ionisation mass spectrometry applied in the detection of adulteration of coconut oil with palm kernel oil. Food Addit Contam Part A 36(11):1597–1604. https://doi.org/10.1080/19440049.2019.1669834

Popa S, Milea MS, Boran S, Nițu SV, Moșoarcă GE, Vancea C, Lazău RI (2020) Rapid adulteration detection of cold pressed oils with their refined versions by UV–Vis spectroscopy. Sci Rep 10(1):1–9. https://doi.org/10.1038/s41598-020-72558-7

Raj V, Swapna MS, Sankararaman S (2018) Nondestructive radiative evaluation of adulteration in coconut oil. Eur Phys J Plus 133(12). https://doi.org/10.1140/epjp/i2018-12357-6

Rifna EJ, Pandiselvam R, Kothakota A, Rao KS, Dwivedi M, Kumar M, Ramesh SV (2022) Advanced process analytical tools for identification of adulterants in edible oils–a review. Food Chem 369:130898

Rohman A, Che Man YB (2011) The use of Fourier transform mid infrared (FT-MIR) spectroscopy for detection and quantification of adulteration in virgin coconut oil. Food Chem 129(2):583–588. https://doi.org/10.1016/j.foodchem.2011.04.070

Rohman A, Che Man YB, Ismail A, Hashim P (2010) Application of FTIR spectroscopy for the determination of virgin coconut oil in binary mixtures with olive oil and palm oil. JAOCS, Journal of the American Oil Chemists’ Society 87(6):601–606. https://doi.org/10.1007/s11746-009-1536-7

Rohman A, Man YBC (2009) Monitoring of virgin coconut oil (VCO) adulteration with palm oil using Fourier transform infrared spectroscopy. J Food Lipids 16(4):618–628. https://doi.org/10.1111/j.1745-4522.2009.01170.x

Rohman A, Man YBC (2011) Potential use of FTIR-ATR spectroscopic method for determination of virgin coconut oil and extra virgin olive oil in ternary mixture systems. Food Anal Methods 4(2):155–162. https://doi.org/10.1007/s12161-010-9156-2

Rohman A, Irnawati, Erwanto Y, Lukitaningsih E, Rafi M, Fadzilah NA, Windarsih A, Sulaiman A, Zakaria Z (2021) Virgin coconut oil: extraction, physicochemical properties, biological activities and its authentication analysis. Food Rev Intl 37(1):46–66

Roy M, Yadav BK (2021) Electronic nose for detection of food adulteration: a review. J Food Sci Technol. https://doi.org/10.1007/s13197-021-05057-w

Salian V, Shetty P (2018) Coconut oil and virgin coconut oil: an insight into its oral and overall health benefits. J Clin Diagn Res 12(1):ZE01–ZE03. https://doi.org/10.7860/JCDR/2018/31409.11051

Tasioula-Margari M, Okogeri O (2001) Simultaneous determination of phenolic compounds and tocopherols in virgin olive oil using HPLC and UV detection. Food Chem 74(3):377–383

Taylan O, Cebi N, Yilmaz MT, Sagdic O, Ozdemir D, Balubaid M (2021) Rapid detection of green-pea adulteration in pistachio nuts using Raman spectroscopy and chemometrics. J Sci Food Agric 101(4):1699–1708. https://doi.org/10.1002/jsfa.10845

Valand R, Tanna S, Lawson G, Bengtström L (2020) A review of Fourier transform infrared (FTIR) spectroscopy used in food adulteration and authenticity investigations. Food Additives and Contaminants - Part A Chemistry, Analysis, Control, Exposure and Risk Assessment 37(1):19–38. https://doi.org/10.1080/19440049.2019.1675909

Valli E, Bendini A, Berardinelli A, Ragni L, Riccò B, Grossi M, GallinaToschi T (2016) Rapid and innovative instrumental approaches for quality and authenticity of olive oils. Eur J Lipid Sci Technol 118(11):1601–1619. https://doi.org/10.1002/ejlt.201600065

Xu B, Li P, Ma F, Wang X, Matthäus B, Chen R, Yang Q, Zhang W, Zhang Q (2015) Detection of virgin coconut oil adulteration with animal fats using quantitative cholesterol by GC × GC-TOF/MS analysis. Food Chem 178:128–135. https://doi.org/10.1016/j.foodchem.2015.01.035

Acknowledgements

The authors acknowledge the NIFTEM-T, Thanjavur, and ICAR-CPCRI, Kasaragod.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Ethical Approval

Not applicable.

Informed Consent

Not applicable

Conflict of Interest

Banu Priya declares no competing interests. Rashmitha declares no competing interests. Sai Preetham declares no competing interests. Chandrasekar declares no competing interests. Jagan Mohan declares no competing interests. Sinija declares no competing interests. Pandiselvam declares no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Coconut oil (CO) and virgin coconut oil (VCO) are commonly adulterated with cheaper vegetable oils.

• Authentication and adulteration control are critical in coconut oil industry.

• The prevailing official methods for quality control must be upgraded.

• Spectroscopic techniques for oil adulteration detection are discussed.

• Chromatographic and other techniques for VCO adulteration detection are discussed.

Rights and permissions

About this article

Cite this article

Priya, R.B., Rashmitha, R., Preetham, G.S. et al. Detection of Adulteration in Coconut Oil and Virgin Coconut Oil Using Advanced Analytical Techniques: A Review. Food Anal. Methods 15, 2917–2930 (2022). https://doi.org/10.1007/s12161-022-02342-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-022-02342-y