Abstract

For the development of dispersible tablets of itraconazole (ITR), techniques of thermal, Raman spectroscopy, and isothermal stress testing (IST) were used to assess the compatibility of ITR with selected excipients. Initially, differential scanning calorimeter (DSC) was used to evaluate the compatibility. Raman spectrum of drug–excipient mixture was also compared with that of pure drug and excipient. Compatibility of excipients defined in the prototype formula was tested using IST. Based on the DSC results alone, PEG-4000 was found to exhibit interaction with ITR. However, the results of Raman and IST studies showed that all the excipients used in the formula were compatible with ITR. Overall, compatibility of excipients with ITR was successfully evaluated using the combination of DSC, Raman spectroscopy, and IST techniques.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Itraconazole (ITR) is an orally active triazole antifungal agent to inhibit most human fungal pathogens. This function is dependent upon blocking synthesis of ergosterol of the fungi. The chemical structure of ITR that corresponds to (±)-1-[(RS)-sec-butyl]-4-[p-[4-[p-[[(2R,4S)-2-(2,4-dichlorophenyl)-2-(1H-1,2,4-triazol-1-ylmethyl)-1,3-dioxolan-4-yl]methoxy]phenyl]-1-piperazinyl]phenyl]-Δ2-1,2,4-triazolin-5-one is given in Fig. 1 [1]. ITR capsules have been widely used in clinical treatment of fungal infections. However, there is still need of improvement about the oral bioavailability [2]. Compared to ordinary solid preparation, dispersible tablets have the advantages of convenient oral, collapsing quickly, fast absorption, and high bioavailability. Therefore, the development of ITR dispersible tablets is significant.

Incompatibility between drugs and excipients can alter stability and bioavailability of drugs, thereby, affecting its safety and efficacy. Excipients may interact with drug that gives rise to changes in the chemical nature, solubility, absorption, and therapeutic response of drugs. Therefore, the stable and effective solid dosage form depends on the selection of the excipients which can be achieved through the study of the interaction between drug and excipients in the solid state [3].

There are many methods for evaluating the drug–excipient compatibility. In recent years, differential scanning calorimeter (DSC) technique has been extensively reported in the literature for testing compatibility of excipients with number of drugs [3–14]. Use of DSC has been proposed as a rapid method for evaluating the physicochemical interaction between two components. However, caution need to be exercised in the interpretation of DSC results. This is because of high temperature conditions required and the lack of moisture in conducting the experiments. Moreover, evaluation of DSC curves can be difficult and the conclusions based on the DSC results alone can be often misleading [8–10].

Isothermal stress testing (IST) is another commonly employed for evaluating the drug–excipient compatibility. The method involves storage of the drug–excipient blends with or without moisture at high temperature for a specific period of time (about 3 weeks) and determining the drug content by high-performance liquid chromatography (HPLC) [8, 15, 16]. The IST has specific application in pharmaceutical industry where the interaction between drug and excipients is visually observed and the drug content determined quantitatively [15–18]. During the experiment, DSC should be used in combination with IST to evaluate compatibility of drugs with the selected excipients.

Like infrared (IR) spectra, Raman spectra can also be used to estimate the drug–excipient compatibility. Moreover, the sample preparation of Raman is simpler than IR. The comparison of Raman spectra of pure drug and drug–excipient mixture could further verify the drug–excipient compatibility.

In this study, seven excipients used as filling agent, disintegrating agent, adhesive, and lubricant were selected to determine the compatibility with ITR for the development of ITR dispersible tablets through the application of DSC, IST, and Raman spectroscopy.

Experimental

Materials

Itraconazole (purity 99.9 %), the following chemicals and excipients were purchased from commercial sources and used as such ITR (Nifty Labs Pvt. Ltd, India), hydroxy propyl methyl cellulose (HPMC, methocel E5, Dow, USA), cross-linked polyvinylpyrrolidone (PVPP, XL, BASF, Germany), macrogol 4000 (PEG-4000, Sasol, Germany), sodium carboxymethyl starch (CMS-Na, Roquette, France), lactose (Foremost, USA), magnesium stearate (Mg stearate, Peter Greven, Netherlands), titanium dioxide (TiO2, Sensient, USA), tetrabutylammonium hydrogen sulfate (Cheng Hu chemical plant, China). Acetonitrile used for the preparation of mobile phase was of HPLC grade (Tedia, USA) and water used throughout the HPLC analysis was prepared by water purifier (AJC-2001-P, Aquapro, China).

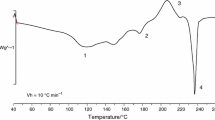

Differential scanning calorimetry

A DSC (821e, Mettler Toledo, Switzerland) was used for thermal analysis of drug and mixtures of drug and excipients. Excipients that were expected to be used in the development of formulation and the appropriate ratio were selected for the present study. Individual samples (drug and excipients) as well as physical mixtures of drug and selected excipients (all passed through 60-mesh sieve) were weighed directly in the pierced DSC aluminum pan (Table 1) and scanned in the temperature range of 40–300 °C under an atmosphere of dry nitrogen. Heating rate of 10 °C min−1 was used and the curves obtained were observed for any interaction.

Raman spectroscopy

Raman spectra of drug and drug–excipient blends were recorded on an DXR Raman microscope (DXR 532 nm, Thermo, USA) in the range of 40–4,000 cm−1.

Isothermal stress testing

For IST studies [19], drug and different excipients (Table 2) were weighed directly in 4 mL glass vials (n = 2) and mixed on a vortex mixer for 2 min. In each of the vials, 10 % w/w water was added and the drug–excipient blend was further mixed with a glass capillary (both the ends of which were heat sealed). To prevent any loss of material, capillary was broken and left inside the vial. All of the vials were sealed using teflon-lined screw caps and stored at 50 °C in a hot air oven (DHP-9032, Yi Heng technology co. Ltd, China). These samples were periodically examined for any unusual color change. After 3 weeks of storage at the above conditions, samples were quantitatively analyzed using HPLC. Drug–excipient blends without added water and stored in refrigerator served as controls.

For sample preparation, 2 mL of methanol was added into each vial. The mixture was vortexed and transferred to 100 mL volumetric flask. Vials were rinsed twice with methanol and the volume were made up. The samples were centrifuged and the supernatant was filtered through 0.45 μm nylon membrane filters. After appropriate dilutions, samples were analyzed using HPLC and drug content determined from the calibration curve prepared within the expected range. The remaining drug content of drug–excipient mixture was corresponding to the drug alone (take the drug content of drug alone as 100 %).

For the analysis of drug–excipient mixtures, Shimadzu HPLC system equipped with LC-10 AT VP pump, DGU-14AM on-line degasser, SIL-10 AD VP autoinjector, CTO-10 AS VP column oven, and SPD-10 AVP UV–Vis detector was utilized. Shimadzu CLASS-VP software (Version 5.03) was used for data acquisition and mathematical calculations. Chromatographic separation of ITR was performed on a C18 Spherisorb column (4.6 × 250 mm; 3 μm particle size). Mobile phase used was acetonitrile-tetrabutylammonium hydrogen sulfate solution (0.01 mol L−1), in the ratio of 50:50 v/v at a flow rate of 1 mL min−1. Temperature of the column oven was maintained at 40 °C. All the samples (20 μL) were injected and analyzed at 225 nm using a UV detector.

Results and discussion

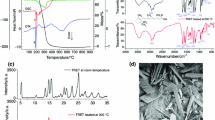

Selected DSC scans of drug and drug–excipient mixtures are shown in Figs. 2, 3, 4, 5, 6, 7, and 8a. The thermal behavior of pure drug, respective excipient, and the combination of drug and excipient is compared in the DSC curves. Peak, onset transition temperature (T peak, T onset), and heat of fusion or enthalpy (ΔH f) of ITR in various excipient mixtures is summarized in Table 1.

The DSC trace of ITR showed a sharp endothermic peak at 170.06 °C and the heat of transition (ΔH f) was 71.05 J g−1. In majority of the cases, melting endotherm of drug was well preserved with slight changes in terms of broadening or shifting toward the lower temperature. It has been reported that the quantity of material used, especially in drug–excipient mixtures, affects the peak shape and enthalpy [8, 9]. Thus, these minor changes in the melting endotherm of drug could be due to the mixing of drug and excipient, which lowers the purity of each component in the mixture and may not necessarily indicate potential incompatibility [13, 20, 21].

The Raman spectra of drug and drug–excipient mixtures were shown in Figs. 2, 3, 4, 5, 6, 7, and 8b. We can determine the compatibility in accordance with the changes of main bands.

In the DSC curve of HPMC, a broad endothermic peak at 66.22 °C, due to evaporation of adsorbed moisture, was observed (Fig. 2a). The melting endotherm of drug was present at 170.73 °C with a little change in ΔH f value (64.60 J g−1) in the DSC trace of ITR–HPMC mixture, which ruled out any incidence of incompatibility. Also, the Raman spectrum of mixture of ITR and HPMC showed the presence of characteristic band of ITR (1,610 cm−1) and there were no new bands (Fig. 2b). Thus, it was concluded that ITR is compatible with HPMC.

In case of PVPP, a broad endotherm was observed at 70.20 °C due to loss of adsorbed moisture (Fig. 3a). The curve of ITR–PVPP mixture showed an endothermic peak of drug at 169.89 °C and the ΔH f value (64.42 J g−1) was close to the expected value, indicating that there was no interaction. Characteristic band of ITR(1,610 cm−1) was well retained in the Raman spectrum of ITR–PVPP mixture without any new bands, indicating that there was no change in the structure of drug (Fig. 3b). On the basis of above results, it was concluded that PVPP is compatible with ITR.

DSC trace of PEG-4000 showed a sharp endothermic peak at 63.60 °C, retained well in ITR and PEG-4000 (63.46 °C) (Fig. 4a). However, in the curve of ITR and PEG-4000 mixture, the drug peak was missing and a broad endothermic peak was observed at 157.71 °C with reduction in ΔH f (34.63 J g−1). DSC results points toward some incompatibility between ITR and PEG-4000. However, after analyzing the Raman spectrum, the characteristic band of ITR (1,610 cm−1) was observed and it was concluded that ITR is compatible with PEG-4000 (Fig. 4b).

The DSC trace of CMS-Na showed a broad endotherm at 72.44 °C, probably because of evaporation of adsorbed moisture (Fig. 5a). The melting endotherm of ITR was well retained in the DSC trace of ITR–CMS-Na mixture (168.96 °C with accompanying ΔH f of 63.83 J g−1). In Raman spectrum of ITR–CMS-Na mixture, band corresponding to ITR (1,610 cm−1) was observed without any new bands (Fig. 5b). It was concluded that ITR is compatible with CMS-Na.

The DSC scan of lactose showed two endothermic peaks at 153.97 °C (corresponding to dehydration of bound water) and 220.52 °C (melting point) (Fig. 6a). DSC curve of ITR and lactose mixture showed the features of both ITR and lactose with drug’s melting endotherm present at 170.72 °C, the accompanying ΔH f value was 60.50 J g−1. Raman spectrum of ITR–lactose mixture showed the presence of characteristic band of ITR (1,610 cm−1) confirming that there was no change in the drug structure (Fig. 6b). Therefore, based on the above results, it was concluded that ITR is compatible with lactose.

In DSC trace of Mg stearate, two endothermic peaks were observed at 101.68 and 116.99 °C (Fig. 7a). The DSC scan of ITR–Mg stearate showed the melting endotherm of ITR (169.50 °C with ΔH f value of 61.70 J g−1) clearly. In addition, Raman spectrum of ITR–Mg stearate mixture showed the presence of band corresponding to ITR (1,610 cm−1) (Fig. 7b). No extra bands were present in the Raman spectrum, which confirmed that there is no chemical interaction between the two.

In the DSC scan of TiO2, no peak was observed in the temperature range of 40–300 °C (Fig. 8a). The melting endotherm of ITR was well retained in the DSC trace of ITR–TiO2 mixture (170.30 °C with ΔH f value of 62.56 J g−1). In Raman spectrum of ITR–TiO2 mixture, band corresponding to ITR was observed (1,610 cm−1) without any new bands (Fig. 8b) (changes of drug peak intensity was due to the drawing). It was concluded that ITR is compatible with TiO2.

Results of analysis of IST samples are shown in Table 2, the changes of drug content could reveal the compatibility of drug–excipient. It has been observed from the Table 2 that there is a little change in the drug content of the samples after storage of drug–excipient blends under stressed conditions of IST studies. Moreover, when the HPLC chromatogram (Fig. 9) of the mixture of ITR and individual excipients was compared with that of pure ITR during the analysis of IST sample, it was found that the retention time and the shape of the peak of ITR remained unchanged, and no extra peaks were observed. It indicates that ITR was not degraded in drug–excipients mixture of IST sample. Therefore, the IST results further verify that all the selected excipients are compatible with ITR.

Conclusions

The results confirmed that DSC could be used as the rapid methods to evaluate the compatibility between drug and excipients. However, caution need to be exercised while interpreting the DSC results alone. Wherever possible, other techniques such as Raman spectroscopy and quantitative analysis after storage under stressed conditions should be taken in conjunction with DSC results to reach any definite conclusion. From the results of the DSC studies an interaction was suspected between ITR and PEG-4000. However, based on the results of Raman spectroscopy and IST study, the possibility of incompatibility between ITR and PEG-4000 was ruled out. The change of the drug peak and reduction in ΔH f in case of ITR and PEG-4000 mixture could be because of melting of PEG-4000 and partial dissolution of drug in the molten excipient [9, 10].

In the present study, results of DSC along with Raman spectroscopy and HPLC (for IST studies) were successfully employed to assess the compatibility of ITR with the excipients used in the development of dispersible tablets.

References

El-Barghouthi MI, Masoud NA, Al-Kafawein JK, Abdoh AA. Inclusion complexation of itraconazole with β- and 2-hydroxypropyl-β-cyclodextrins in aqueous solutions. Russ J Phys Chem. 2006;80(7):1050–5.

Feola D, Rapp RP. Effect of food intake on the bioavailability of itraconazole. Clin Infect Dis. 1997;25(2):344–5.

Tonder ECV, Lotter AP, Botha SA. Compatibility study between doxylamine succinate with other drugs and excipients using differential scanning calorimetry. Drug Dev Ind Pharm. 1990;16(14):2125–33.

Ganesh G, Ramadoss A, Kannan PS. SubbiahPandi, A Crystal growth, structural, thermal, and dielectric characterization of Tutton salt (NH4)2Fe(SO4)2·6H2O crystals. J Therm Anal Calorim. 2013;112(2):547–54.

Singh AV. A DSC study of some biomaterials relevant to pharmaceutical industry. J Therm Anal Calorim. 2013;112(2):791–3.

Venkataram S, Khohlokwane M, Wallis SH. Differential scanning calorimetry as a quick scanning technique for solid-state stability studies. Drug Dev Ind Pharm. 1995;21(7):847–55.

Luo YH, Wang Y, Zou ZZ, Sun BW. Pharmaceutical co-crystals of pyrazinecarboxamide (PZA) with various carboxylic acids: crystallography, Hirshfeld Surfaces and dissolution study. Cryst Growth Desi. 2013;13(5):2098–106.

Kandarapu R, Grover V, Chawla HPS. Evaluation of the compatibility of ketorolac tromethamine with selected polymers and common tablet excipients by thermal and isothermal stress testing. STP Pharm Sci. 2001;11(6):449–57.

Mura P, Manderioli A, Bramanti G, Furlanetto S, Pinzauti S. Utilization of differential scanning calorimetry as a screening technique of determine the compatibility of Ketoprofen with excipients. Int J Pharm. 1995;11(1):971–9.

Mura P, Faucci MT, Manderioli A, Bramanti G, Ceccarelli L. Compatibility study between ibuproxam and pharmaceutical excipients using differential scanning calorimetry, hot-stage microscopy and scanning electron microscopy. J Pharm Biomed Anal. 1998;18(1–2):151–63.

Luo YH, Zhou Q, Sun BW. Synthesis, crystal structure and DNA binding properties of a new member of [Mn3Zn2]13+ family. J Chem Res. 2012;36(9):505–8.

Luo YH, Ma YT, Bao QQ, Sun BW. Syntheses, crystal structure and properties of two 1-D coordination polymers bridged by dicyanamides. J Chem Crystallogr. 2012;42(6):628–32.

Botha SA, Lotter AP. Compatibility study between naproxen and tablet excipients using differential scanning calorimetry. Drug Dev Ind Pharm. 1990;16(4):673–83.

Luo YH, Wu GG, Sun BW. Antisolvent crystallization of biapenem: estimation of growth and nucleation kinetics. J Chem Eng Data. 2013;58(3):588–97.

Serajuddin AT, Thakur AB, Ghoshal RN, Fakes MG, Ranadive SA, Morris KR, Varia SA. Selection of solid dosage form composition through drug–excipient compatibility testing. J Pharm Sci. 1999;88(7):696–704.

Gu L, Strickley RG, Chi L, Chowhan ZT. Drug–excipient incompatibility studies of the dipeptide angiotensin-converting enzyme inhibitor, moexipril hydrochloride: dry powder versus wet granulation. Pharm Res. 1990;7(4):379–83.

Kandarapu R, Grover V, Chawla HPS, Garg S. Evaluation of compatibility of ketorolac tromethamine with selected polymers and common tablet excipients by thermal and isothermal stress testing. STP Pharm Sci. 2001;11(6):449–57.

Verma RK, Garg S. Selection of excipients for extended release formulation of glipizide through drug–excipient compatibility testing. J Pharm Biomed Anal. 2005;38(4):633–44.

Pani NR, Nath LK, Acharya S, Bhuniya B. Application of DSC, IST, and FTIR study in the compatibility testing of nateglinide with different pharmaceutical excipients. J Therm Anal Calorim. 2012;108(1):219–26.

Durig T, Fassihi AR. Identification of stabilizing and destabilizing effects of excipient-drug interactions in solid dosage form design. Int J Pharm. 1993;97(1–3):161–70.

Malan CE, de Villiers MM, Lotter AP. Application of differential scanning calorimetry and high performance liquid chromatography to determine the effects of mixture composition and preparation during the evaluation of niclosamide-excipient compatibility. J Pharm Biomed Anal. 1997;15(4):549–57.

Acknowledgements

This work has been supported by the prospective joint research project of Jiangsu province (BY2012193) and the Fundamental Research Funds for the Central Universities (CXZZ12_0119).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Y., Luo, YH., Zhao, J. et al. Selection of excipients for dispersible tablets of itraconazole through the application of thermal techniques and Raman spectroscopy. J Therm Anal Calorim 115, 2391–2400 (2014). https://doi.org/10.1007/s10973-013-3330-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-013-3330-x