Abstract

Thirty-micrometer thick polyvinylidenefluoride (PVDF)–zinc oxide (ZnO) nanocomposite samples in the mass ratio of ZnO (1–6% (w/w)) have been prepared by solution mixing method. The nano- and microstructures of PVDF–ZnO nanocomposite of different mass ratios were characterized by using high-resolution techniques such as atomic force microscopy (AFM) and scanning electron microscopy (SEM). The SEM and AFM images show the presence of different components such as nanoparticles, amorphous and crystalline phases in nanocomposite samples. Dielectric properties of polymer nanocomposite based on PVDF and ZnO of different mass/% compositions have been studied to understand the molecular motion at different frequencies in the temperature range from 300 to 500 K. The permittivity of the nanocomposites decreases with frequency, while increases with the increasing temperature and ZnO content. The loss peak that disappeared at higher frequency is the remarkable result of this study.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The filling of inorganic nanofillers into polymer has resulted in polymer nanostructured materials exhibiting multi-functional, high performance polymer characteristics beyond what traditional polymer composites possess. Little attention has been paid to study the nanometric structure of polyvinylidenefluoride (PVDF)–zinc oxide (ZnO) nanocomposites. However, some of the reports show the effect of low electric field in nano- and microstructures of PVDF for piezosensor applications [1–3]. Optical microscope can observe the size of object if it is not less than 1 micron; it is the resolution limit of optical microscope. SEM visualization is adequate, although it provides neither a 3D image nor precise line profile measurements for the features of interest. SEM is the most commonly used technique for the study of nano level; however, it requires complex sample preparation as well as the help of a highly skilled operator. The operation of AFM and sample preparation method is very simple when compared to other techniques. AFM images have great lateral and vertical resolution. AFM is able to perform precise line profile measurements along X, Y, Z as well as any arbitrary direction in the XY plane. Studies and measurements can help in understanding the fundamental problems such as the kinetics of coarsening and the influence of external and internal stresses on the equilibrium shape of samples. Structural heterogeneity is a common feature even for polymer and polymer nanocomposites in which amorphous phase is a necessary component. In addition to the compositional imaging of multicomponent polymers and polymer nanocomposite samples, visualization of all components is another important application of AFM [4, 5].

Recently Lewis proposed that as the size of filler particles decreases to the nanometer scale, the properties of the polymer–filler interface would become dominant over the bulk properties of the constituents [6]. This concept goes beyond that of modifying the filler surface to achieve better dispersion of the dielectric filler particles. The interfacial properties in nanocomposite material could be amplified by the high surface area of nanofillers. This concept was experimentally explored by Sun et al. who studied the influence of the interface on the dielectric properties of epoxy/silica composites [7].

A dielectric material has an arrangement of electric charge carriers that can be displaced by an electric field. The charges become polarized to compensate for the electric field such that the positive and negative charges move in opposite directions. At the microscopic level, several dielectric mechanisms can contribute to dielectric behavior. Dipole orientation and ionic conduction interact strongly at microwave frequencies. In general, the dielectric permittivity and the loss factor were found to be higher for nanocomposites than for microcomposites at low frequencies. The higher dielectric loss for the nanocomposites was attributed to the enhanced ionic conductivity caused by the contaminants introduced during preparation. Theoretical models have also suggested regarding the influence of interface on nanodielectrics. Tanaka et al. have proposed a multi-core model to understand the dielectric properties of polymer nanocomposites [8]. They proposed that the interface of a spherical inorganic filler particle embedded in polymer matrix consists of three distinct regions: a bonded layer (first layer), a bound layer (second layer), and a loose layer (third layer), with an electric double layer overlapping the three layers. The first layer corresponds to a contact layer where the polymer is in intimate contact with the filler surface, and the second layer corresponds to the interfacial region. Finally, there is the third layer, where the properties of the bulk polymer are approached. The second layer contributes to the reduction in the permittivity by disturbing the motion of dipoles originating from some polar groups. The free volume in the composite, mostly associated with the third layer, also causes a reduction in the dielectric constant of the composite. Though the first layer directly links the particle to the polymer and establishes direct contact, the second and the third layers are suggested to be most influential in affecting the dielectric properties of the polymer composite. The incorporation of suitable group of filler particle in polymer directly affects the interfacial properties of resultant composite. The selection of the surface organic groups, in terms of polarity, polarizability, mobility, and size, could have a major impact on the dielectric properties of the polymer nanocomposites. Tuncer et al. evaluated the dielectric properties of cobalt iron-oxide (CoFe2O4) nanoparticle that modified poly (methyl methacrylate) nanodielectric system [9]. With the addition of small quantities of COFe2O4, the dielectric permittivity of the nanocomposite decreased. Numerical modeling was performed to analyze the dielectric data. They found that the relaxation behavior of the composite system at high frequencies was different from that of the unfilled polymer. This phenomenon was suggested as arising from interfacial polarization.

The objective of this study is to (i) develop simple processes to disperse ZnO nanofillers in the PVDF, (ii) identify the different regions (such as amorphous, crystalline, and nanoparticles) in PVDF–ZnO nanocomposite samples to observe the uniformity of nanoparticle dispersion and surface morphology, (iii) use scanning electron microscopy (SEM) and atomic force microscopy (AFM) techniques to characterize polymer matrix structures, and (iv) investigate the thermally stimulated dielectric properties at different temperatures and frequencies.

Experimental

PVDF in granular form, supplied by Redox (India), and ZnO nanoparticles of size less than 100 nm, purchased from Sigma-Aldrich, New Delhi (India), have been used in this study. The dimethylformamide (DMF) was used as received from Merck India ltd. The pristine and nanocomposite samples in the form of thin film were prepared by solution mixing method. The following steps have been taken to prepare the samples:

-

1.

The 5 g PVDF was dissolved in 100 ml of DMF and then kept for 6 h on magnetic stirrer to become a homogeneous and transparent solution at 343 K.

-

2.

The optical glass plates are slowly drawn from solution and kept in oven at 323 K for a period of 2 h.

-

3.

The solvent was then evaporated to yield circular thin film shape. The thin films were further dried at room temperature with out gassing of 10−5 torr for a further period of 24 h to remove volatile residual solvent.

-

4.

The ZnO of certain amount was dissolved in 20 mL of DMF and added drop by drop in solution of PVDF for preparation of PVDF–ZnO nanocomposite samples of different mass ratio. The nanocomposite samples could be easily peeled off from glass plate followed by the method stated above.

The morphology and phase images were obtained using an Atomic Force Microscope (Model NTEGRA, NT-MDT, IIT Roorkee, India) and SEM (Model EVO-40, ZEISS, AIF-JNU, New Delhi, India). The roughness of PVDF and PVDF–ZnO nanocomposites were measured using both an Atomic Force Microscope and a profilometer.

The samples were vacuum aluminized over the central circular area of 1.4 cm diameter using High Vacuum Coating Unit (Vacuum Equipment Company Ltd, Noida, India) for the dielectric measurements. The AC dielectric relaxation measurements were made using Hioki 3532-50 LCR HiTESTER. The sample was sandwiched between two brass-plated stainless steel electrodes. The assembly was placed in a thermostatic furnace and the temperature was measured with digital multi-thermometer (CE Company, New Delhi, India). The dielectric measurements (i.e., permittivity and loss) for PVDF and PVDF–ZnO nanocomposite samples with different mass/% of ZnO were carried out in the frequency range 0.12–100 kHz at different temperatures.

Results and discussion

SEM analysis

Figure 1a–d shows that the influence of ZnO nanoparticles in the PVDF matrix could be observable. It is clearly seen (i.e., Fig. 1d) that nanoparticles are embedded with the pores. The uniformity of ZnO nanoparticle dispersion could be clear from SEM image of Fig. 1d.

The uniformity of dispersion could be further observed by measuring the transparency. The transparency of nanocomposite samples at certain wavelength range (400–800 nm) is almost constant. The results also show that the ZnO nanoparticles were uniformly dispersed in the polymer matrix. The cellular pores in the PVDF sample could be easily seen in SEM of pristine PVDF (Fig. 1a). It shows the cellular nature of PVDF. However, the size of these pores is reduced by filling of ZnO nanoparticles. It is shown in SEM image of nanocomposites (Fig. 1a–d) that the structural density of the nanocomposite samples is increased with the increase of concentration of ZnO nanoparticles.

AFM analysis

In large scales AFM topography images of PVDF and PVDF–ZnO nanocomposites, one can see the bright and dark strips or spots (Fig. 2a–d). It has been observed from Fig. 2a that homogeneous structure of crystalline and amorphous phases of PVDF in form of bright and dark strips. However, this structure is changed by introducing the ZnO nanoparticles. In PVDF–ZnO nanocomposites, the ZnO spherulites are with elevated centers and borders. ZnO spherulites are smaller tightly packed in PVDF samples. Figure 2b–d shows the bundles of lamellae (brighter contrast) separated by amorphous region (darker regions). The wider bright regions are crystalline; however, amorphous region exhibits the darker contrast. Therefore, two different phases in PVDF–ZnO nanocomposites are very clearly visible. The increase in concentration of ZnO nanoparticles in morphology of nanocomposites is clearly seen in AFM and SEM images.

The comparison of three dimensional AFM analyses of PVDF and nanocomposite samples (Fig. 3a–d) indicates the change in surface topography occurred due to filling of nanoparticles. This means that the surface energy of the nanocomposite is higher than the pristine sample. The surface energy is caused by change in number of polar functional groups in material [10]. It is due to fact that the number of polar functional groups in nanocomposites increase with increase in concentration of ZnO nanofillers. Table 1 show that the surface roughness of nanocomposite sample increases with increase in concentration of nanoparticles. This outcome of present investigation is very important to understand the utility of nanocomposite material for sensor application [11, 12].

For example the semicrystalline polymers are piezoelectric due to alignment of polar, ferroelectric crystals dispersed in the amorphous phase. In both types the magnitudes of the piezo and pyroelectric effects are in accord with the expected temperature and pressure dependence of the dipolar polarization. Space charges embedded in the polymer normally will not produce a piezo or pyroelectric current. It is very clear from our previous studies that influence of space charge in PVDF is common feature [13]. Since the certain roughness value of polymer/polymer nanocomposite is desirable for stable mechanical, electrical, and material properties. Therefore, we have observed the roughness of PVDF and PVDF–ZnO nanocomposite samples and found that the surface roughness increases with increase in concentration of ZnO nanofiller as shown in Table 1. It means that the shallow traps are more effective rather than deeper traps. These shallow traps will capture the charge under influence of low field and pressure and minimize the role of space charge.

Dielectric study

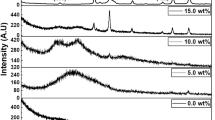

The permittivity (ε) and tangential loss (tan δ) of PVDF/PVDF–ZnO nanocomposite samples were observed at different frequencies and temperatures. The dielectric permittivity of nanocomposite is found to be the function of temperature, frequency, and ZnO content. The variations of dielectric permittivity with ZnO nanoparticles concentration are shown in Figs. 4 and 5. Zn2+ ions are located in the interstitial position to preserve charge neutrality and the Zn2+–O pairs represent dipoles. Therefore, the increasing trend is ascribed to the rise of dipolar density and hence increases the polarization. The increase in permittivity above the room temperature may be due to the increase in molecular mobility, expansion of the lattice, and excitation of charge carriers present inside the nanocomposite at the defect sites [14].

For PVDF–ZnO nanocomposites, the permittivity increased considerably with the increase of ZnO filler loading as a result of interfacial and space charge polarization (i.e., Fig. 4). The increase in dielectric permittivity in polymer nanocomposite is also due to the dipole density and free volume available for movement of dipoles, due to increase of total polarization, arising from dipoles orientation and trapped charge carriers and molecular chain of the polymer at high temperature. The PVDF is a polar type of porous polymer having pores of the micro dimension. The density of dipoles increases with the concentration of ZnO nanoparticles, therefore, the resultant permittivity in nanocomposite is due to the orientation of PVDF as well as ZnO dipoles. The orientation of large number of dipoles together with field is one reason for increase of permittivity. At lower temperature, as the dipoles are rigidly fixed in the dielectric, the field can not change the condition of dipoles but on increasing the temperature, the dipoles become comparatively free and they respond to the applied electric field [15]. Thus polarization increased and hence dielectric permittivity is also increased with the temperature [16]. The increase in dielectric permittivity is attributed to the higher orientational polarization of the polymer at higher temperatures due to greater mobility of molecules [17].

The permittivity gradually decreases with the increase of the frequency for all the composites, which is mainly attributed to interfacial polarization in the composites. The rapid decrease of permittivity at higher temperature with frequency was also attributed to the increase in chaotic thermal oscillations of the molecules and to the diminishing degree of order of dipoles orientation. The slow migration of charge carriers may be assumed to be because of decrease in the dielectric permittivity in this region. With increasing value of frequency the charge carriers migrating through the dielectric get entrapped against a defect site and induce opposite charge in its vicinity. The dielectric permittivity presented in Fig. 5 decreases with increasing frequency due to dielectric dispersion, and as a result of the lag of the molecules behind the alternation of the electric field at higher frequency [18].

For polar polymer the alternating current is an important factor because of the time taken to align the polar dipoles. At very low frequencies the dipoles have sufficient time to align with the field before it changes direction and the dielectric permittivity is high. At very high frequencies the dipoles do not have time to align before the field changes direction and the dielectric permittivity is lower. At intermediate frequencies the dipoles move but have not completed their movement before the field changes direction and they must realign with the change in field. In polar polymers, both the atomic and electronic polarization is often negligible compared to orientation and space charge polarization. The electrical properties are influenced more by dipole asymmetry than by the presence of polar groups. When the dipoles are able to respond readily to change in temperature and electric field, the dielectric permittivity is high [19–21]. This explains the increase in dielectric permittivity of the nanocomposite with the addition of ZnO. When raising the temperature of a polar polymer like PVDF, which allows faster movement of the polymer chains and faster alignment of the dipoles. This is particularly true if the temperature is raised above T g because above T g much more molecular movement is possible.

Figure 5 shows the variation of dielectric permittivity with frequency at different temperatures for different nanocomposite samples. It is evident from these figures that there is a large dielectric dispersion as the dielectric permittivity decreases with increasing frequency at fixed temperature. The dielectric dispersion appearing at high temperature is said to be α-relaxation and generally caused by rotatory diffusional motion of the molecules from one quasi stable position to another around the skeletal bond involving large scale conformational rearrangement of the main chain. The origin of this relaxation is due to the slowed down rotation of the side group attached to the main chain. However, the low temperature dielectric dispersion is due to the dielectric response of the side groups, which are considered to be more mobile or the small displacement of the dipoles near the frozen in position and is generally known as β-relaxation. The α-relaxation is related to the micro Brownian motion of the main chain segments due to the flexibility of their molecules [22, 23]. It is also seen from these figures that the decrease in dielectric permittivity is very prominent at both low frequencies and at high temperature. The decrease of dielectric permittivity with increasing frequency is the expected behavior in most dielectric materials [24]. This is due to dielectric relaxation which is the cause of anomalous dispersion. From a structural point of view, the dielectric relaxation involves the orientation polarization which in turn depends upon the molecular arrangement of dielectric material. Thus, at higher frequencies, the rotational motion of the polar molecules of dielectric is not sufficiently rapid for the attainment of equilibrium with the field; hence dielectric permittivity seems to be decreasing with increasing frequency [25]. The measurement of dielectric permittivity reveals that its value for the nanocomposite sample is increasing with increase in the ZnO concentration. This may be attributed to the polar nature of polymer.

Figures 4, 5, 6, and 7 illustrate the dielectric properties of the nanocomposites measured at different frequencies. The permittivity of nanocomposites containing ZnO nanoparticles is larger than those of a pristine sample (i.e., without ZnO) in the whole frequency range. The frequency and the temperature dependence of dielectric permittivity of the polymer nanocomposite studied resemble the change in behavior of the polymer component by filling the ZnO nanoparticles. The decreased tan δ for nanocomposites is observed (Fig. 7) in the low frequency range (i.e., 0.12–100 kHz) only. These observations might be explained as the fact that the conduction loss, which is related to the dc electrical conductivity of the materials, contributes to the entire tan δ value less significantly as the frequency increases.

where ε′, ε″, σ are the real and imaginary part of the dielectric constant and the electrical conductivity of the materials, respectively, and f is the frequency. Therefore, the effect of ZnO nanoparticles on suppressing dielectric loss is not obvious at higher frequency. In addition, the contribution of interfacial loss is more evident in the high frequency range. Accordingly, the tan δ values of nanocomposites containing ZnO nanoparticles are higher than those without ZnO nanoparticles at higher frequencies. The increase in losses is due to the formation of large number of polymer–nanoparticles interfaces in polymer matrix and decrease in porosity of PVDF by mixing of nanoparticles.

Figure 6 shows the variation of tangential loss with temperature at different frequencies for PVDF–ZnO nanocomposite samples. The tangential loss increases with temperature, particularly at lower frequencies for which tangential loss due to chain motion is more effective above the glass transition temperature of the polymer. It has been observed that ZnO nanoparticles obstruct the chain motion and reduces the loss with increase in temperature. Therefore, the dielectric loss decreases with increase in concentration of ZnO nanoparticles.

The tangential loss decreases with the increase of frequency at fixed temperature in both the samples. In general, the loss peak is observed in many polymers, but it has been observed that the loss peak is almost disappeared in nanocomposite samples at higher frequencies (Fig. 6), because conductivity of PVDF significantly increases by filling of ZnO nanoparticles and polymer does not show the plasticization effect, which is generally observed [26]. In general, with the increase in frequency, polarization decreases and becomes very small at higher frequencies. The decrease in losses with frequency as observed in our experiment also seems to show the decrease in the number of charges and delay in settling of dipoles due to availability of very short time in one half-cycle of alternating voltage [27, 28].

The variation of tangential losses in PVDF–ZnO composite with frequency at different concentrations of ZnO nanoparticles are shown in Fig. 7. We have observed that the dielectric losses in PVDF–ZnO composite system were lower when compared to pure PVDF system at lower concentrations in lower frequency region. At higher temperature and in the range of higher frequencies we observed a minor change in the dielectric loss, which becomes constant.

The measured dielectric loss tangent at a given frequency can be roughly attributed to polarization loss and conduction loss. The polarization occurs through several mechanisms involving microscopic and/or macroscopic charge displacement such as space charge or interfacial polarizations. The permittivity increased and tan δ decreased with the increase of the filling of ZnO nanoparticles. The remarkable increase of permittivity may be due to the piling of charges at the extended interface and/or more conducting particles. In general, dielectric loss of the dielectric material results from distortional, dipolar, interfacial, and conduction loss. The distortional loss is related with electronic and ionic polarization mechanisms. The interfacial loss originates from the excessive polarized interface induced by the fillers and specifically the movement or rotation of the atoms or molecules in an alternating electric field. The conduction loss is attributed to the dc electrical conductivity of the materials, representing the flow of actual charge through the dielectric materials. More specifically it could be understood from the behavior of dielectric loss characteristics that the dipolar and interfacial losses are more significant in PVDF–ZnO nanocomposite samples.

Conclusions

In this study, we prepared and characterized the PVDF and PVDF–ZnO nanocomposite samples. It is concluded from AFM and SEM images that there were at least two different morphological patterns in the sample. Nanoparticles are responsible for increase in surface roughness of samples, which is more important to reduce the effect of space charge for piezoelectric sensor application. We have found that permittivity decreases with frequency due to the orientation polarization and increases with temperature due to greater freedom of movement of molecular chain of nanocomposites at high temperature and this agreed with the dielectric response of a polar dielectric. The variations in frequency and temperature are attributed to polarization and ion diffusion. Dielectric permittivity results indicate that dipolar density is raised on account of Zn2+ ions which tend to localized at interstitial instead of substitution positions within the polymer matrix. The disappearance of dielectric loss peak at higher frequency indicates that the conductivity of PVDF increases with increase in concentration of ZnO nanoparticles. On the basis of experimental data obtained from this study, we conclude our discussion that influence of ZnO nanofiller in PVDF matrix will enhance its properties for sensor application.

References

Hyungoo L, Rodrigo C, Ke W, Hong L. Nano-scale characterization of a piezoelectric polymer, (polyvinylidenedifluoride, PVDF). Sensors. 2008;8:7359–68.

Sarid D. Scanning force microscopy with applications to electric, magnetic, and atomic forces. New York: Oxford University Press; 1991.

Matei A, Cernica I, Cadar O, Roman C, Schiopu V. Synthesis and characterization of ZnO–polymer nanocomposites. Int J Mater Forming. 2008;1:767–70.

Magonov SN. Atomic force microscopy in analysis of polymers. In: Myers RA, editor. Encyclopedia of analytical chemistry. Chichester: Wiley; 2000. p. 7432–91.

Basire C, Ivanov DA. Evolution of the lamellar structure during crystallization of a semi crystalline-amorphous polymer blend: time-resolved hot-stage SPM study. Phys Rev Lett. 2000;85:5587–90.

Lewis TJ. Interfaces are the dominant feature of dielectrics at the nanometric level. IEEE Trans Dielectr Electr Insul. 2004;11:739–53.

Sun Y, Zhang Z, Wong CP. Influence of interphase and moisture on the dielectric spectroscopy of epoxy/silica composites. Polymer. 2005;46:2297–305.

Tanaka T, Kozaka M, Fuse N, Ohki Y. Proposal of a multi-core model for polymer nanocomposite dielectrics. IEEE Trans Dielectr Electr Insul. 2005;12:669–81.

Tuncer E, Rondinone AJ, Woodward J, Sauers I, James DR, Ellis AR. Cobalt iron-oxide nanoparticle modified poly(methyl methacrylate) nanodielectrics. Appl Phys A. 2009;94:843–52.

Kwonwoo S, Sang Yoon Y, Chanwoo Y, Hayoung J, Chan Eon P. Effects of polar functional groups and roughness topography of polymer gate dielectric layers on pentacene field-effect transistors. Org Electron. 2007;8:336–42.

Pascu M, Duraccio D, Cimmino S, Vasile C. Modification of PVDF properties by dielectric barrier discharge treatment. e-Polymers. 2010;16:1–12.

Gaur MS, Rathore BS, Singh PK, Indolia A, Awasthi AM, Bhardwaj S. Thermally stimulated current and differential scanning calorimetry spectroscopy for the study of polymer nanocomposites. J Therm Anal Calorim. 2010;101:315–21.

Shukla P, Gaur MS. Short circuit depolarization current study in polyvinyledenefluoride-polymethylmethacrylate double layered samples. Polym Plast Technol Eng. 2009;48:1–5.

Bhimasankaram T, Suryanarayana SV, Prasad G. Piezoelectric polymer composite materials. Curr Sci. 1998;74:967–76.

Raju GG. Dielectrics in electric field. New York: Marcel Dekker Inc.; 2003.

Nakamura K, Wada Y. Piezoelectricity, pyro-electricity and the electrostriction constant of poly vinylidene fluoride. J Polym Sci A2. 1971;9:161–73.

Bunget I, Popescu M. Physics of solid dielectrics, vol. 19. Amsterdam: Elsevier; 1984.

Nada AMA, Dawy M, Salama AH. Dielectric properties and Ac-conductivity of cellulose polyethylene glycol blends. Mater Chem Phys. 2004;84:205–15.

Kremer F, Schonhals A, Luck W. Broadband dielectric spectroscopy. Berlin: Springer-Verlag; 2002.

Smith GD, Bedrov D. Relationship between α and β relaxation process in amorphous polymer: insight from atomistic molecular dynamics simulations of 1,4-polybutadiene melts and blends. J Polym Sci B. 2006;45(6):627–43.

Mansour SF. Frequency and composition dependence on the dielectric properties for Mg-Zn ferrite. Egypt J Solids. 2005;28(2):263.

Popielarz R, Chiang CK, Nozaki R, Obrzut J. Dielectric properties of polymer/ferroelectric ceramic composites from 100 Hz to 10 GHz. Macromolecules. 2001;34:5910–5.

Rao BP, Rao KH, Trinadha K, Caltunb OF. Dielectric behaviour of niobium doped Ni-Zn ferrites. J Optoelectron Adv Mater. 2004;6(3):951–4.

Beam WR. Electronics of solids. New York: McGraw Hill; 1965.

Veronica L, Heiko H, Christoph S, Michael W. Specific heat and dielectric relaxations in ultra-thin polystyrene layers. Thermochim Acta. 2005;432(2):222–8.

Rao Narasimha VVR, Rao SB, Reddy NV. Dielectric properties of polyacrylamide polymer films. Nuovo Cimento D. 1992;14(3):253–60.

Singh R, Kumar J, Singh RK, Kaur A, Sinha RDP, Gupta NP. Low frequency ac conduction and dielectric relaxation behavior of solution grown and uniaxially stretched poly (vinylidene fluoride) films. Polymer. 2006;47:5919–28.

Chiang CK, Popielarz R. Polymer composites with high dielectric constant. Ferroelectrics. 2002;275:1–9.

Acknowledgements

This research study was supported by a grant from Defence Research & Development Organization (Vide letter no. ERIP/ER/0804419/M/01/1113), New Delhi (India). We are thankful to Director, AIF-JNU and IIT Roorkee (India) for providing SEM and AFM characterization facility.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gaur, M.S., Indolia, A.P. Thermally stimulated dielectric properties of polyvinylidenefluoride–zinc oxide nanocomposites. J Therm Anal Calorim 103, 977–985 (2011). https://doi.org/10.1007/s10973-010-1190-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-010-1190-1