Abstract

In the present study, the fabricated nanocomposites were prepared by the casting technique by adding titanium dioxide (TiO2) to polyvinyl alcohol (PVA) with different weight percentages (0.037, 0.185, 0.370, 1.852, 3.704 and 37.037 wt%). SEM micrographs declared that PVA polymer matrix contains a distributed set of cluster of TiO2 nanoparticles. AC electrical characteristics and dielectric relaxation of nanocomposite polymeric films in the frequency range 100 kHz–1 MHz were presented as temperature changes from 303 to 413 K. The results indicated that the dielectric performance and electrical properties of the nanocomposites differ anomalously with increasing TiO2 nanoparticles content. It was demonstrated that there is a stronger temperature-reliance of the dielectric properties of the 1.852 wt% of TiO2/PVA nanocomposite polymeric film. Moreover, there is an interfacial polarization effect, which obeys Arrhenius behaviour that increased nonlinearly with increasing temperature at a fixed frequency. The electrical relaxation dynamics containing dielectric was examined. The dielectric properties were investigated through the electric modulus.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Over the recent years, polymeric nanocomposites based on ceramic metal oxide have been shown great interest among the scientific community because of their outstanding achievement in electronic properties [1, 2] such as batteries, solar cells, sensors, supercapacitors and fuel cells. Ceramic materials are generally brittle and very hard to process [3]. Otherwise, polymer materials at low temperatures are flexible, easy to process and display very high dielectric breakdown [4]. Electrical properties such as conductivity, dielectric constant and dielectric loss can be improved by mixing polymers with ceramic nanomaterials in the composite structure.

Titanium dioxide (TiO2) is a transition metal oxide with three distinct crystallization structures such as rutile, anatase and brookite that can be used in many studies because of its excellent optical and electronic properties [5, 6]. In general, TiO2 nanoparticles have been preferred for the photocatalytic and device applications because it has many modified physical and chemical properties such as thermal stability, non-toxic nature, and best catalytic property with wide band gap [7,8,9,10]. Recent attention has concentrated on poly (vinyl alcohol) (PVA) owing to its individual chemical and physical properties. PVA is a semi-crystalline polymer, which is responsible for most physical properties of PVA from the existence of the OH group, which leads to the multiplicity of industrial applications. When PVA polymer is mixed with TiO2, it may interact in an amorphous part or in the crystalline part of the polymer causing a change in its electrical, structural and optical properties.

Therefore, all the information about the influence of the additives on a certain polymer helps to characterize for a given application [11]. The formation of TiO2 cluster in the PVA matrix is due to the formation of covalent bonds (Ti–O–C) among PVA and TiO2 nanoparticles [12]. Also, the structural adjustment of the PVA matrix is resulting from the formation of Ti–OH bond between TiO2 nanoparticles with the OH groups presented in PVA polymer [13, 14]. In recent years, intensive work has been carried out on optical, thermal, mechanical and structural characteristics of PVA/TiO2 nanocomposites [15], but the studies carried out to study its dielectric properties are very few.

The current work is focused on the preparation of PVA/TiO2 polymeric nanocomposite films using the method of solution casting. The microstructural study of PVA/TiO2 nanocomposites was carried out by SEM. The studies of dielectric properties, electric modulus and AC electrical conductivity in a wide range of temperature and frequency have been recorded for describing the molecular motion and dielectric relaxation studies of the nanocomposites.

Experimental procedures

Preparation of PVA/TiO2 polymeric nanocomposite films

PVA (from LOBA Co., the molecular weight of PVA is 77,000 g/mol) and TiO2 (21 nm, Sigma-Aldrich Co.) were utilized without refinement. The concentration of PVA is 45 g/L in aqueous solution. The appropriate amount of PVA in aqueous solution was left on the magnetic stirrer for 48 h at 60 °C to have a fully dissolved PVA as a host matrix. Different percentages of TiO2 of pure PVA samples and PVA nanocomposites are as follows: 0.037, 0.185, 0.370, 1.852, 3.704 and 37.037 wt%. Sixty millilitres of PVA aqueous solution was used to prepare all the specimens under investigation. After that, the solution was poured on glass Petri dishes, then left for five days in a drying furnace at 40 °C to evaporate water residuals. Pure PVA film was obtained from the previous solution. For TiO2/PVA polymeric nanocomposite samples; the required quantity of TiO2 to PVA aqueous solution with respect to the following percentages 0.037, 0.185, 0.370, 1.852, 3.704 and 37.037 wt% was introduced. Ultrasonic homogenizer system was operated at 110 watts for a period of 5 min to obtain a good and homogeneous dispersion of TiO2 nanoparticles in PVA. TiO2–PVA was poured inside a glassy Petri dishes, then left in drying furnace as mentioned before. The samples were cut in size 2 × 2 cm2, which makes them compatible with the required characterizations and measurements. Finally, the as-prepared samples were left in desiccators.

Devices and measurements

The morphologies of the specimens were done using a Quanta 250 FEG (Field Emission Gun) microscope on the surface of PVA/TiO2 nanocomposites.

Programmable automatic LCR meter (Model Fluke PM6306) was used to measure the dielectric properties (real and imaginary parts) of dielectric permittivity (ε′, ε″) dissipation factor (tan δ) and AC electrical conductivity (σac), measured as a function of frequency (100 Hz to 1 MHz) and in the temperature range from 303 to 413 K.

Results and discussion

Structure characterization of PVA/TiO2 polymeric nanocomposite films

The morphology of PVA, TiO2 and PVA/TiO2 nanocomposites with different TiO2 contents is shown in Fig. 1. The SEM image of pure PVA shows that the PVA film surface is smooth with some few pores (Fig. 1a). The SEM image of TiO2 shows a homogeneous distribution with spherical particles (Fig. 1b), where the average diameter is about 20 nm [16, 17]. The white portions display TiO2 phase in Fig. 1c–h. From SEM micrographs, it can be noticed that the morphology of the nanocomposites differs as the content of TiO2 nanoparticles changes which result from cluster formation within the composites. As the concentration of TiO2 increases, the cluster size increases due to the existence of hydroxyl group in the structure of nanocomposites which is the essential factor for the bonding of TiO2 nanoparticles to the polymer leading to stability of the nanocomposites. As shown in Fig. 1g and h, when TiO2 nanoparticles increase, the large cluster is formed, and these affect the properties of the films. Thus, through morphological studies, we can infer that TiO2 nanoparticles are well dispersed, forming clusters within the PVA matrix and no phase separation occurs [18].

Dielectric spectra of PVA/TiO2 polymeric nanocomposite films

The dielectric properties (dielectric constant ε′, dielectric loss ε″ and the loss tangent tan δ = ε″/ε′), respectively, at 303 K for PVA–TiO2 nanocomposites with frequency, are illustrated in Fig. 2. It is known that the ε′ value is the energy storage ability, which can be considered as a gauge of the polarization of prepared dielectric material. Therefore, it is noted that the values of ε′ are decreased monotonically with increasing frequency and reach a constant value at higher frequencies (Fig. 2a). In pure PVA, bipolar polarization returns to the bipolarity-arrangement of hydroxyl groups [OH] that are connected to the chain but in PVA–TiO2 nanocomposite polymeric films; the resultant polarization is due to the alignment of the ion–dipolar (Ti–OH) interfacial charges that formed complex electric dipoles which, at low frequencies, obey the time-changing electric field; however, they can no longer obey the varying field as the frequency increases, thus reducing the values of ε′ [8, 9]. The frequency dependence \({\varepsilon }^{{\prime}}\) values of the 37.037 wt% of TiO2/PVA nanocomposites got to be relatively low (< 15).

Figure 3 shows the change in dielectric constant, ε′ of the nanocomposites as a function of TiO2 content at fixed frequencies. These results indicate that the dipolar arrangement of the hydroxyl group in the PVA and other polarization in the nanocomposites changed anomalously upon increasing the TiO2 nanoparticles content. With regard to the nanocomposites, sample no. 4 (PVA–1.852 wt% TiO2 nanocomposite polymeric film) has the highest value of the dielectric constant and there are many studies displaying that the dielectric performance changes anomalously and diminishes upon increasing the doping content of inorganic nanofillers [19]. It is noted that the value of ε′ decreases at high frequency (1 MHz) for all samples, and this enhances their expediency as low-value nano-dielectric composites. It is clear that the dielectric performance of PVA/TiO2 nanocomposites did not possess any apparent association with their structural characteristics. This means that the crystalline polymer (PVA) bipolar structures varied irregularly with TiO2 nanoparticles content. To realize the behaviour of dielectric materials, the characterization of ε″ and tan δ is desired. The nanocomposites had dielectric relaxation peak in ε″ and tan δ at low frequency which is attributed to its structural dynamics as shown in Fig. 2b and c.

In addition, PVA–37.037 wt% TiO2 nanocomposite polymeric film can be used as high-quality dielectric material because it has the lowest values of ε″ and tan δ. It is also clear from Fig. 2b and c that 1.852 wt% of TiO2/PVA nanocomposite polymeric film has the highest relaxation peak in ε″ and tan δ spectra, confirming our earlier discussion of the irregular change in ε″ and tan δ spectra with the structural dynamics in the nanocomposite upon increasing TiO2 content in PVA matrix. MWS relaxation was related to the influence of the blocked charge at the interfaces between PVA polymer matrix and TiO2 nanoparticles, while the α-relaxation demonstrated the segmental movement of polymer chains (local chain dynamics) [12].

The electric modulus spectra of PVA/TiO2 polymeric nanocomposite films

The electric modulus M∗ is calculated as:

where M′ is the real part and M′ is the imaginary part. Figure 4 shows the frequency dependence of real M′ and imaginary M′ parts of the electric modulus for PVA/TiO2 nanocomposites at 303 K. These modulus spectra negate the contribution of different undesirable effects containing electrode polarization (EP) deliver a bulk response of the material. It is clear from Fig. 4a that the relationship between M′ and frequency has shoulders at intermediate and high frequencies, while there are sharp relaxation peaks in M″ spectra (Fig. 4b); these coincided with the PVA main-chain dynamics [20]. By comparing our results with the previous studies on the M″ spectra, we detected that the relaxation process changed anomalously upon increased TiO2 nanoparticles content in the nanocomposites, i.e. the interaction of PVA polymer and TiO2 nanofiller changed irregularly with TiO2 contents [21].

AC electrical conductivity of PVA/TiO2 polymeric nanocomposite films

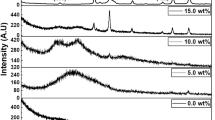

Figure 5 displays the plots of AC electrical conductivity, σac (ω) with ln ω for PVA–TiO2 nanocomposite polymeric films at 303 K. The values of σac increased linearly with increasing frequency which has different slope values. This is due to the semi-crystalline nature of PVA [22]. The values of σac (ω) have been changed anomalously with the concentration of filler and based on the nanofiller contents.

Dielectric Performance of PVA/TiO2 polymeric nanocomposite films under the effect of temperature

Figure 6 displays frequency dependence ε′, ε″ and tan δ for 1.852 wt% TiO2/PVA nanocomposites at different temperatures. Dielectric constant ε′ values increased by increasing the temperature as shown in Fig. 6a, confirming the role of heat in facilitating the free orientation of polar parts in the PVA chain. The variation of ε′ as a function of the temperature at different frequencies for PVA–1.852 wt% TiO2 nanocomposite polymeric film is depicted in Fig. 7. The values of ε′ increased nonlinearly by increasing the temperature, and this increase in ε′ became stronger when the frequency is low. This increase is due to interfacial polarization [23, 24]. In addition, at high frequencies (100 kHz, 500 kHz and 1 MHz), the increase in ε values with temperature is almost the same which assures that the bipolar arrangement in the nanocomposite polymeric film stays the same. Figure 6b exhibits that the values of ε″ increased by increasing temperature; however, for frequencies more than 100 kHz, the values of ε″ varied slightly by increasing temperature, which assures their suitability as a fixed dielectric loss material. Figure 6c shows the existence of loss tangent peak in the low-frequency region shifted to a higher frequency by increasing temperature [25]. Moreover, the values of tan δ increased by increasing temperature. The dielectric losses are large at lower frequencies because of more time relaxation, but at higher frequencies, the losses decreased by the smaller time relaxation, then the conductivity increases [26].

Figure 8a and b exhibits the variation of M′ and M" versus tan f at different temperatures for PVA–1.852 wt% TiO2 nanocomposite polymer film. From Fig. 8a, it is obvious that M′ values decreased with increasing temperature at a constant frequency. It is observed that M′ of 37.037 wt% of TiO2/PVA was the highest among the tested nanocomposites for all frequency ranges and increased slowly with the increase in frequency, while the M′ of the 1.852 wt% of TiO2/PVA was the lowest among the tested nanocomposites. Moreover, the M″ spectra presented a relaxation peak where its intensity increases by increasing temperature with a clear shift to high frequency. This behaviour proposes that the relaxation is activated thermally, and charge carrier hopping occurs [27]. The values of the modulus τM were calculated, by the relation \(\tau_{{\text{M}}} = {1 \mathord{\left/ {\vphantom {1 {2\pi f_{{\text{p}}} }}} \right. \kern-\nulldelimiterspace} {2\pi f_{{\text{p}}} }}\), where (fp) is the frequency corresponding to the M" peaks [13]. This τM was referred to the flexible chain segmental motion of the polymer chain. Evidently, the relaxation time decreases with increasing temperature as shown in Fig. 9 [28].

The variation of AC conductivity for 1.852 wt% of TiO2/PVA nanocomposite polymeric film as a function of frequency within the temperature range of 303 and 413 K is shown in Fig. 10. An increase in conductivity with temperature is noticeable due to the increase in both the dissociation of salts and flexible chain segmental motion. TiO2 nanoparticles form a new kinetic path across polymer–ceramic boundary leading to increasing in conductivity [18]

To know the conduction mechanism, the frequency dependence of σ (ω) can be expressed as

where A is a constant and s is frequency exponent that is between 0 and 1. The value of s was calculated at each temperature from the slope of ln σac against ln ω. s value was calculated from the most linear part of the curve. It was found that its values are between (0.1 < s < 0.9) for all nanocomposites as shown in Fig. 11. As noted, the s values decreased by increasing temperatures, indicating that the correlated barrier hopping model (CBH) is the conduction mechanism [13]. Polymer chain flexibility is due to changes in the chemical composition of repeated polymer units owing to the arrangement of hydrogen bonds with hydroxyl groups during the polymerization phase, thereby increasing electrical conductivity [26, 29].

Conclusion

In this work, we have synthesized PVA/TiO2 by solution casting and characterization. SEM micrograph confirms that cluster of TiO2 was fully dispersed in the polymer matrix. The effect of TiO2 on the dielectric and electrical properties of PVA nanocomposites was studied. Dielectric constant, dielectric loss, tan δ, electric modulus and AC conductivity were changed anomalously by increasing TiO2 content of the nanocomposites. The difference in dielectric constant with frequency displays the existence of dipole polarization processes. Loss tangent and real electric modulus peaks, which exhibit a characteristic frequency, propose the existence of relaxation dipoles in all the nanocomposites. The values of relaxation time decrease with increasing temperature; the AC conductivity increased with increasing frequency and temperature in all nanocomposites. The behaviour of the power factor interpreted the CBH model. Among all nanocomposites, 1.852 wt% of TiO2/PVA displayed dielectric properties values as well as high conductivity which in turn appeared to be usable in future studies.

References

Qian X, Gu N, Yang X, Wang E, Dong S (1829) Impedance study of (PEO)10LiClO4–Al2O3 composite polymer electrolyte with blocking electrodes. Electrochim Acta 2001:46

Chahal P, Tummala RR, Allen MG, Swaminathan M (1998) A novel integrated decoupling capacitor for MCM-L technology. IEEE Trans Compon Packag Manuf Technol Part B Adv Packag 21:184

Bai Y, Chang ZY, Bharti V, Xu HS, Zhang QM (2000) High-dielectric-constant ceramic-powder polymer composites. Appl Phys Lett 76:3804

Quan H, Chen D, Xie X, Fan H (2013) Polyvinylidene fluoride/vanadium pentoxide composites with high dielectric constant and low dielectric loss. Phys Status Solidi 210:2706

Kovtyukhova N, Ollivier PJ, Chizhik S, Dubravin A, Bzaneva E, Gorchinskiy A, Marchenko A, Smirnova N (1999) Self-assembly of ultrathin composite TiO2/polymer films. Thin Solid Films 337:166

Kontos GA, Soulintzis AL, Karahaliou PK, Psarras GC, Georga SN, Krontiras CA, Pisanias MN (2007) Electrical relaxation dynamics in TiO2—polymer matrix composites. Express Polym Lett 1:781

Linsebigler AL, Lu G, Yates JT (1995) Photocatalysis on TiO2 surfaces: principles, mechanisms, and selected results. Chem Rev 95:735

Enachi M, Lupan O, Braniste TT, Sarua A, Lee Chow L, Mishra YK, Gedamu D, Adelung R, Tiginyanu T (2015) Integration of individual TiO2 nanotube on the chip: nanodevice for hydrogen sensing. Phys Status Solidi RRL 9:171

Chakravadhanula VSK, Mishra YK, Kotnur VG, Avasthi DK, Strunskus T, Zaporotchenko V, Fink D, Kienle L, Faupel F (2014) Microstructural and plasmonic modifications in Ag–TiO2 and Au–TiO2 nanocomposites through ion beam irradiation. Beilstein J. Nanotechnol. 5:1419

Khutia M, Joshi GM, Bhattacharya S (2016) Study of electrical relaxation mechanism of TiO2 doped Bi-polymer systems. Adv Mater Lett 7(3):201–208

Elhosiny Ali H, Khairy Y (2019) Optical and electrical performance of copper chloride doped polyvinyl alcohol for optical limiter and polymeric varistor devices. Phys B Condens Matter 572:256

Ren M, Frimmel FH, Abbt-Braun G (2015) Multi-cycle photocatalytic degradation of bezafibrate by a cast polyvinyl alcohol/titanium dioxide (PVA/TiO2) hybrid film. J Mol Catal A 400:42

Choudhary S, Sengwa RJ (2017) Anomalous behavior of the dielectric and electrical properties of polymeric nanodielectric poly(vinyl alcohol)–titanium dioxide films. J Appl Polym Sci 134:44568–44579

Yahia IS, Mohammed MI, Nawar AM (2019) Multifunction applications of TiO2/poly(vinyl alcohol) nanocomposites for laser attenuation applications. Phys B Condens Matter 556:48–50

Lian Z, Zhang Y, Zhao Y (2016) Innov, Nano-TiO2 particles and high hydrostatic pressure treatment for improving functionality of polyvinyl alcohol and chitosan composite films and nano-TiO2 migration from film matrix in food simulants. Food Sci Emerg Technol 33:145

Ahmad J, Deshmukh K, Habib M, Hägg MB (2014) Influence of TiO2 nanoparticles on the morphological, thermal and solution properties of PVA/TiO2 nanocomposite membranes. Arab J Sci Eng 39:6805–6814

Wang M, Cai L, Jin Q, Zhang H, Fang S, Qu X, Zhang Z, Zhang Q (2017) One-pot composite synthesis of three-dimensional graphene oxide/poly(vinyl alcohol)/TiO2 microspheres for organic dye removal. Sep Purif Technol 172:217–226

Hdidar M, Chouikhi S, Fattoum A, Arous M, Kallel A (2018) Influence of TiO2 rutile doping on the thermal and dielectric properties of nanocomposite films based PVA. J Alloys Compd 750:375–383

Smith RC, Liang C, Landry M, Nelson JK, Schadler LS (2008) The mechanisms leading to the useful electrical properties of polymer nanodielectrics. IEEE Trans Dielectr Electr Insul 15:187

Sengwa RJ, Choudhary S, Sankhla S (2010) Dielectric properties of montmorillonite clay filled poly (vinyl alcohol)/poly (ethylene oxide) blend nanocomposites. Compos Sci Technol 70:1621

Davidson DW, Cole RH (1950) Dielectric relaxation in glycerine. J Chem Phys 18:1417

Choudhary S, Sengwa RJ (2014) Structural characterization of hydrophilic polymer blends/montmorillonite clay nanocomposites. J Appl Polym Sci. https://doi.org/10.1002/app.40617

More SS, Dhokane RJ, Mohril SV (2016) Study on structural characterization and dielectric properties of PVA–TiO2 composite. IOSR J Appl Phys 8:28–32

Makled MH, Sheha E, Shanap TS, El-Mansy MK (2013) Electrical conduction and dielectric relaxation in p-type PVA/CuI polymer composite. J Adv Res 4(6):531–538

Batool SS, Imran Z, Rafiq MA, Hasan MM, Willander M (2013) Investigation of dielectric relaxation behavior of electrospun titanium dioxide nanofibers using temperature dependent impedance spectroscopy. Ceram Int 39:1775

Harun MH, Saion E, Kassim A, Mahmud K, Hussain MY, Mustafa IS (2009) Dielectric properties of poly (vinyl alcohol)/polypyrrole composite polymer films. J Adv Sci Arts 1:9–16

Sugumaran S, Bellan CS (2014) Transparent nano composite PVA–TiO2 and PMMA–TiO2 thin films: optical and dielectric properties. Optik 125:5128–5133

Kinlen PJ, Silverman DC, Jeffrevs CR (1997) Corrosion protection using polyanujne coating formulations. Synth Met 85:1327

Mohamed Ali T, Padmanathan N, Selladurai S (2013) Structural, conductivity, and dielectric characterization of PEO–PEG blend composite polymer electrolyte dispersed with TiO2 nanoparticles. Ionics 19(8):1115–1123

Acknowledgements

The authors extend their appreciation to the Deanship of Scientific Research at King Khalid University for funding this work through research groups program under Grant No. R.G.P.1/59/39.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Khairy, Y., Elsaeedy, H.I., Mohammed, M.I. et al. Anomalous behaviour of the electrical properties for PVA/TiO2 nanocomposite polymeric films. Polym. Bull. 77, 6255–6269 (2020). https://doi.org/10.1007/s00289-019-03028-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-019-03028-y