Abstract

The effect of microwave heating was studied in six varieties of edible oil. Variations in physicochemical properties were observed and compared with the data obtained by hot plate heating. Fourier-transform infrared spectra of the oils showed substantial variations after both types of heating in the region of hydrogen’s stretching (C–H) vibration, region of double bond’s stretching (C=O), and fingerprint region. The visible spectra of mustard and olive oil showed the reduction in carotenoid, flavonoid, and chlorophyll pigments after heating. The oil samples were discriminated as saturated, monounsaturated, and polyunsaturated fats using chemometric techniques on physical and spectroscopic measurements.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Vegetable oils are the key ingredient of almost all food products containing nutritional and indispensable monounsaturated fatty acids (MUFA) and polyunsaturated fatty acids (PUFA). Heating of edible oil changes it’s physical and chemical states [1, 2] and develops an unpleasant taste and smell due to the formation of primary and secondary oxidation products. The use of microwave is increasing day-by-day for warming, cooking, baking, drying, pasteurization, sterilization, and thawing of various food products because of time saving and convenient [3]. The chemical constituents of edible oils degrade during microwave heating with a rate that varies with heating temperature and time [4]. Hence, there is an increasing need to focus on the effects of microwave heating on the physicochemical properties of edible oils. Recently, few studies concerning the influence of microwave heating on composition and quality of edible oils have been reported using thermogravimetric analyzer [5], differential scanning calorimeter [6], ultraviolet (UV) spectrophotometer [7], visible spectrophotometer [8], and Fourier-transform infrared spectrophotometer [9–11]. These studies revealed that heating of oil causes thermal oxidation which is strongly dependent on type of oil, composition of oil, and the conditions during heating.

This study was aimed to elucidate the influence of microwave heating on common edible oils having dissimilar fatty acid composition. A 10-min was selected for heating in this study because this time period has been assumed to be sufficient for food stuff. Since deterioration of oil is a complex process and no single method may represent all the oxidative outputs; hence, variations in physicochemical properties were noted using the combination of physical methods, and spectroscopic techniques. Furthermore, with the utilization of different chemometric techniques, i.e., principal component analysis (PCA) and cluster analysis (CA) [12], the edible oils were discriminated and hence classified.

Experimental

Reagents and equipments

All reagents and solvents used were of analytical reagent grade. Six varieties of edible oils (olive, mustard, corn, canola, coconut, and soybean) were purchased from local supermarket.

The oil samples were subjected to heating using hot plate (Jenway1000) and domestic-type microwave oven (National, Model NN-5656F, Matsushita Electric Industrial Co., Ltd., Osaka, Japan) separately. Viscosity was measured by cannon LV model 2020 (Cannon Instrument company, State college, PA, USA). Refractive indices were determined using Abbe refractometer (Atago Co., Ltd., Japan). The density data were obtained using relative density bottle of 25 cm3 that had been previously calibrated with distilled water. The infrared spectra were recorded using IRPRESTIGE-21, Fourier-transform infrared spectrophotometer (Schimadzu Corporation, Japan) interfaced with a computer operating under Windows-based IR solution software (version 3.1). UV and visible spectra of the oils were measured using UV–Vis 160 spectrophotometer (Schimadzu Corporation, Japan). All measurements were performed at 25 °C.

Thermal oxidation

The samples were treated using microwave and hot plate heating systems as follows.

Hot plate heating

20 g of oil sample was transferred into a 50-cm3 beaker, and placed on a hot plate at frying temperature (150–170 °C) for 10 min with constant stirring using magnetic bar. The sample was analyzed immediately after cooled down at room temperature.

Microwave heating

20 g of each sample was introduced into polytetraflouro ethylene vessel separately and placed on the turntable rotary plate of microwave oven at equal distances. All samples were exposed at a frequency of 2450 MHz and 800 W electric power. Analyses were carried out immediately after cooled down the samples at room temperature.

Method

The sample chamber of the viscometer was cleaned with warm water using mild detergent. Rinsed thoroughly with distilled water, and allowed to dry at room temperature followed by rinsing with acetone. The sample chamber was loaded in the viscometer with 7–10 cm3 of oil sample and the force necessary to overcome the resistance to the rotation was measured using the appropriate spindle (SC4-18 or SC4-31). The speed of rotation was chosen as 60 rpm as suggested in (ASTM-D445-86) [13]. The viscosity of each oil was measured at least three times and the average was reported.

For the measurement of FTIR spectral properties of the oil, one drop of sample was deposited between two well-polished KBr disks. The spectrum was recorded from 4000 to 400 cm−1 with 2 cm−1 resolution. The disk was rinsed with n-hexane and dried before the next run.

UV spectrum of the oil was measured in n-hexane at 200–400 nm and visible spectra at 400–800 nm.

Minitab version 14 was used for the chemometric analysis of the results.

Results and discussion

Physical changes

The changes in physical properties of the oils were measured after heating with microwave oven and hot plate. The first visual indication of the oil deterioration was the change in color due to heating. All varieties of oil were darkened due to accumulation of decomposed products after both types of heating. It is quiet possible that most of the volatile decomposed products were evaporated from the oil during heating. Nonvolatile oxidation products such as oxidized triglycerols were considered to responsible for physical and chemical changes in the residual oil samples.

The pattern in the variation of density and viscosity measurements was almost similar (Table 1). The samples are classified into two groups on the basis of the heating effect on apparent viscosities (ηapp). The first group covers soybean, canola, corn, and coconut oils, whereas the second group comprises olive and mustard oils. Three factors may be accounted for this change, i.e., intermolecular forces operating within the oil, molecular structure of the fatty acid, and the mode of heating. Since all the oils contain saturated (SFA) and unsaturated fatty acids (UFA) with no other functional group, so it can be assumed that the intermolecular forces in the oils are similar in nature and hence the first factor may be neglected. Therefore, the trends in viscosity variations are based on the molecular structure of fatty acids and the mode of heating.

Since no pronounced change in viscosity with heating was observed in the oils of the first group, showing thermal stability of these oils at least during the studied time (Table 1). The lower tendency to change the viscosity of the oils richer with PUFA is due to the presence of π bonds, which makes bonding more rigid and decreased the opportunity of rotational changes between C–C bonds. The viscosity of olive oil increased from 50 to 54 cP after both types of heating, showing the thermal response of the oil against the intermolecular arrangements. The presence of 24–50% erucic acid (22:1) allowed entanglement with the adjacent molecules in mustard oil; hence, slow the torque of the oil, and therefore it showed the higher viscosity compare to others. The hot plate heating caused a great increase in the viscosity of mustard oil than microwave irradiation. It is due to the fact that hot plate heating weakens cis bonds more rapidly.

The increase in the density was due to the formation of oxidized triglycerides [11]. No considerable variations were observed in the refractive indices for all varieties of oil samples.

Spectral changes

When the oil samples were subjected to heating (either by microwave or hot plate), the FTIR spectra undergo several changes due to the production of saturated aldehyde or other secondary oxidation products [14]. It is important to note that the band position remains unaltered after heating except mustard and olive oils which show a sharp increase in the absorbance intensity (Fig. 1) and a considerable decrease was observed for the remaining oils. The consistency in the band position reflects the stability in the intermolecular distance, the spatial arrangement, the environment polarity, and the field effect of the neighboring groups [15].

Figure 1 shows that hot plate heating effect is more pronounced in mustard oil as compare to olive oil. Erucic acid is the major component of mustard oil while olive oil is mainly composed of oleic acid. Since erucic acid triglycerides (C22:1) are larger than oleic acid triglycerides (18:1), therefore, it is supposed that hot plate heating generated more oxidation products in mustard oil. Hence, the spectral variations in the region of C–H stretching vibration (3007 cm−1) and C=O (1746 cm−1) are more prominent in mustard oil.

The UV spectra (Fig. 2) evaluated the oxidative stability during microwave and hot plate heating. However, at 232 and 270 nm, the increase in absorbance for mustard and canola oil was observed after hot plate heating and the decrease was observed after microwave heating. The UV spectra of olive oil showed the inverse trend. The absorbance of corn oil increased considerably after both heating processes. The increase in absorbance at 232 and 270 nm indicates the formation of conjugated dienes or peroxides and trienes or unsaturated aldehydes and ketones, respectively [8].

Most triglycerides do not absorb in the visible region possibly due to the decoloration or removing of colored pigments during refining. Therefore, coconut, canola, corn, and soybean oils exhibited spectra similar to those of linoleic and linolenic acids; hence, they were not amenable to visible spectrophotometric analysis. Figure 3 shows the variations in the absorption spectra of mustard and olive oils between visible regions (400–800 nm). Three types of colored pigments were observed in olive oils; carotenoids (412, 454, and 483 nm), flavonoids (535 and 560 nm), and chlorophylls (610 and 670 nm). These colored pigments served as effective antioxidants in edible oils [16]. Carotenoid content was also found to be associated with a lower risk for various epithelial cancers in epidemiologic studies [17]. Hot plate heating reduced the content of these pigments and microwave heating caused the loss of these pigments in olive oil. In contrast, the strong bands for carotenoids (420, 446, and 474 nm) and weak band for chlorophylls (610 and 664 nm) were reduced after microwave heating and lost after hot plate heating in mustard oil. The content of chlorophyll was also significantly reduces in the result of both types of heating processes in mustard oil.

Visible spectrum of a olive oil and b mustard oil; showing changes in colored pigments. c carotenoid, f flavonoid, ch chlorophyll. Filled circle original oil, triangle microwave-heated oil, and square hot plate-heated oil. Insets of a and b provide the magnified view of the spectra from 500 to 750 nm

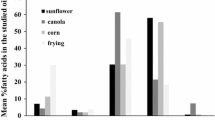

Figures 4 and 5 show PCA and CA, respectively, applied on FTIR and other physical properties. The oil samples are separated with respect to saturation or unsaturation in the fatty acids. The PCA explains 45.8% of the total variability for first factor and is made up of the IR shifts (1097, 1163, 1373, 3007 cm−1), and refractive index value. The second PC explaining 17.6% of the total variance is made up of IR shifts (1097, 1507, 1653 cm−1), viscosity and density values, whereas the third component explaining 12.3% of the total variance and is correlated with the IR shifts (1022, 1458, and 1507 cm−1), viscosity, and density values. The oils are clearly separated into two groups; groups ‘A’ (SFA) and ‘B’ (UFA). Group ‘B’ is further subdivided into ‘B1’ (MUFA) and ‘B2’ (PUFA). Analyzing MUFA, samples 4–6 comprised of olive oil (original, microwave-heated and hot plate-heated, respectively), closely resembles to each other, whereas samples 7 and 8 (mustard oil original and microwave-heated samples) are identical. Sample 9 (mustard oil heated by hot plate) is grouped with olive oil samples. Based on the data, it is clear that the spectral properties of mustard oil in the result of hot plate heating closely resemble with olive oil samples; such as the wavelength at 1020.34 nm is shifted to 1022.27 nm, 1510 to 1508 nm, 1651 to 1653 nm, 1689 to 1683 nm. All shifting are the characteristics of olive oil samples. A mixed grouping in PUFA was observed for canola, corn, and soybean oils, possibly due to the adulteration of these oils.

PCA applied on FTIR and physical data (viscosity, density, and refractive index) a components I and II; b components I and III; and c components II and III; λ1, λ2, and λ3 are eigenvalues and EV1, EV2, and EV3 explained variance%. SFA (cross coconut oil), MUFA (filled square olive oil, filled triangle mustard oil), PUFA (open square canola oil, open circle corn oil, open triangle soybean oil)

Conclusions

The considerable variations in the physicochemical properties of edible oils were found when they were heated either by microwave or hot plate. The variations were strongly dependent on the chain length and different proportions of fatty acid components (oleic, linoleic, and linolenic acyl groups). During heating the viscosities of the oils increased, whereas a marked decrease was observed in their unsaturation. Mustard and olive oils were found to be more sensitive to thermal treatment with greater variations in viscosity, FTIR, and UV–Vis spectrum. Microwave heating is accountable for the loss of color pigments responsible to antioxidant property in olive oil. Hot plate heating increased the absorbance intensity of UV spectra in mustard and canola oils. The results also indicate that both types of heating did not affect the physiochemical properties of the soybean and corn oils. Hence, it is concluded that the oils having greater proportion of SFA and PUFA show higher stability under thermal stress with less development of degradation products. The oil samples having dissimilar proportion of fatty acids were classified successfully on the basis of saturation or unsaturation using PCA and CA.

References

Vecchiol S, Campanella L, Nuccilli N, Tomassetti M. Kinetic studies of thermal breakdown of triglycerides contained in extra-virgin olive oil. J Therm Anal Cal. 2008;91:51–6.

Queiroz RM, Luiza HO, Ruth de Souza CP, Zamian JR, de Souza AG, da Rocha Filho GN, et al. Thermal characterization of hydrotalcite used in the transesterification of soybean oil. J Therm Anal Cal. 2009;97:163–6.

Mudgett RE. Microwave food processing. Food Technol. 1989;43:117–26.

Tan CP, Che Man YB, Jinap S, Yusoff MSA. Effects of microwave heating on the quality characteristics and thermal properties of RBD palm olein Innovative. Food Sci Emerg Technol. 2002;3:157–63.

Santos JCO, Santos MGI, Dantas JP, Medeiros CA, Conceicao MM, Athaide-Filho PF, et al. Thermal analysis in sustainable development–thermoanalytical study of faveleira seeds (Cnidoscolus quercifolius). J Therm Anal Cal. 2005;79:271–5.

Vasconcelos AFF, Dantas MB, Filho MGR, Rosenhaim R, Cavalcanti EHS, Filho NRA, et al. Influence of drying processes on oxidative stability of ethyl corn biodiesel by differential scanning calorimetry. J Therm Anal Cal. 2009;97:657–60.

Regitano-d’ Arce Marica AB, Vieira Thais MFS. Canola oil thermal oxidation during oven test and microwave heating. Lebensm-Wiss u Technol. 2001;34:215–21.

Albi T, Lanzon A, Guinda A, Perez-Camino MC, Leon M. Microwave and conventional heating effects on some physical and chemical parameters of edible fats. J Agric Food Chem. 1997;45:3000–3.

Dahlberg DB, Lee SM, Wenger SJ, Vargo JA. Classification of vegetable oils by FT-IR. Appl Spectrosc. 1997;51(8):1118–24.

Muik B, Lendl B, Molina-Diaz A, Ayora-Canada MJ. Direct monitoring of lipid oxidation in edible oils by Fourier transform Raman spectroscopy. Chem Phys Lipids. 2005;134:173–82.

Dobarganes MC. Aspectos generals de las grasa calentadas. Grasas Aceites. 1980;31:417–22.

Wesolowski M. Application of chemometrically processed chemical and thermoanalytical data for quality control of soybean oils. J Therm Anal Cal. 1997;48:485–90.

ASTM D445-04 standard. Standard test method for kinematic viscosity of transparent and opaque liquids (and the calculation of dynamic viscosity). Annual Book of ASTM Standards (2005), Section 5. Petroleum products and lubricants (1), volume 05.01. doi:10.1520/D0445-04.

Baeten V, Hourant P, Maria TM, Aparicio R. Oil and fat classification by FT-Raman spectroscopy. J Agric Food Chem. 1998;46:2638–46.

Guillen MD, Cabo N. Relationships between the composition of edible oils and lard and the ratio of the absorbance of specific bands of their Fourier transform infrared spectra. Role of some brands of the fingerprint region. J Agric Food Chem. 1998;46:1788–93.

Khan MA, Shahidi F. Oxidative stability of stripped and nonstripped borage and evening primrose oils and their emulsions in water. J Am Oil Chem Soc. 2000;77:963–5.

Micozzi MS, Beecher GR, Taylor PR, Khachik F. Carotenoid analysis of selected raw and cooked foods associated with a lower risk for cancer. J Natl Cancer Inst. 1990;82:282–5.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khan, M.N., Sarwar, A. & Wahab, M.F. Chemometric assessment of thermal oxidation of some edible oils. J Therm Anal Calorim 102, 369–374 (2010). https://doi.org/10.1007/s10973-010-0703-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-010-0703-2