Abstract

A novel silica-based anion exchange resin (SAER) was prepared to treat the uranium-contaminated water. SAER was characterized by SEM, TG, FT-IR and BET. Batch experiments were conducted to investigate its potential in removing uranium. Experimental results suggested that SAER could efficiently eliminate uranium in water solution with pH ranging from 5 to 9, and showed an amazing exchange speed and large working capacity. However, SO4 2−, Ca2+ and Mg2+ showed some effects on the adsorption of uranium. It was observed that uranyl carbonate complexes could promote Ca2+ and Mg2+ to be adsorbed onto SAER. According to the batch results, Feasible adsorption mechanism to uranium was proposed. At last, tap water containing uranium was mixed with SAER to test its performance. Results showed that uranium was removed successfully with equilibrium pH below 7 but near neutral.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

With the global development of nuclear industry, environmental effects resulted from nuclear energy have aroused great attention of many countries, such as US, Canada, Germany, Norway and Finland et al. [1]. Uranium mining, milling, processing as well as spent fuel reprocessing, each of them can cause the concentration of uranium in groundwater to exceed the recommended value proposed by the World Health Organization (WHO). Uranium is harmful to human body because of its chemical and radioactive toxicity, but uranium levels in drinking water are so low that the radioactive toxicity can be neglected in most situations. Uranium compounds have high affinities for phosphate, carboxyl, and hydroxyl groups and are readily to combine with proteins and nucleotides to form stable complexes [2]. So it is very important to pay more attention to the groundwater pollution of uranium. To date, the value recommended by WHO in drinking water is 15 μg/l [2].

The distribution of uranium species are easily affected by the water compositions. The typical case is that UO2 2+ compounds with CO3 2− and readily form into UO2(CO3) 2−2 or UO2(CO3) 4−2 anions. In the presence of calcium ion, non-charged species Ca2UO2(CO3)3 may be predominant [3]. Table 1 shows the different uranium species with different pH [4].

There are many methods to remove uranium, such as ion exchange [3, 5, 6], coprecipitation [7, 8], membrane filtration [9, 10], coagulation [5], solid phase extraction [11,12,13] and so on. Katsoyiannis IA used to compare these methods and found that ion exchange and reverse osmosis (RO) have the optimum removal efficiency of uranium from groundwater [1]. However, ion exchange is more simple and cheaper. Some chelate resins can even reach the level of RO.

The adsorbent used for removing uranium can be classified with inorganic material, organic material and composite material. Inorganic adsorbents were extensively investigated, such as hydroxyapatite [14], iron oxyhydroxide [15], quartz [16], natural clinoptilolite zeolite [17] or zero-valent iron [7] et al. They usually concentrate uranium by ion exchange, reductive precipitation or porous physical adsorption. However, in terms of selectivity, inorganic adsorbents are usually inferior to organic ones. Many researches have proved that carbonate had impacts on the adsorption efficiency of inorganic adsorbents [1, 15, 18,19,20]. The most typical organic adsorbents are ion exchange resins. According to soft and hard acid base (SHAB) theory, uranyl cation can be regarded as a hard acid, so it requires hard base ligands as much as possible, like functional groups with oxygen or nitrogen atoms. Although Ion exchange resins have been used for the treatment in some countries and territories, they still face some limitations, such as low adsorption kinetics, high pressure loss for columns, high swelling and poor mechanics [21]. Theoretically they have very high removal efficiencies, but actual working capacity depends on the concentrations of other co-existing ions. In recent years many researchers have shown great interests to the composite materials which can remove uranium, such as Schiff base functionalized SBA-15 mesoporous silica material [22], polyacryloamidoxime resin coated quartz sand [16], functionalized magnetic mesoporous silica nanoparticles [23], zero-valent iron/graphene [8] and reduced grapheme oxide based [24] and so on [11,12,13]. They showed excellent performance when compared with single material. It’s a pity that these investigations still don’t take carbonate and other important ions into consideration.

The key of composite material is to select proper supports and functional groups. Wei et al. used to report a kind of silica-based ion exchanger named AR-01 for spent fuel reprocessing [25]. This kind of material had a rapid ion exchange rate, relatively excellent radiation-resistance and low pressure loss in a packed column. So we selected this kind of porous silica as support. The N-substituted polyacrylamide resin is not only a kind of ion exchange resin, but also a kind of chelate resin. It can concentrate uranium in pure water [26]. However, to our knowledge few investigations were reported about using it to remove uranium from groundwater. The systems of uranium in groundwater are usually quite complicated. We adopted solution polymerization to synthesize this resin but not traditional suspension polymerization, and combine it with the porous silica. This study was to report our results about the novel resin’s synthesis and its potential used in removing uranium from drinking water. The new material was abbreviated as SAER and compared with commercial IRA67 resin in some performances.

Experimental

Materials

A kind of macroporous silica (SiO2) was used as support to synthesize the silica-based anion exchange resin. The silica’s particle size ranges from 75 to 150 μm, and the average porosity is 69%. The divinyl benzene (DVB) and tetraethylenepentamine (TEPA) were provided by Shanghai Aladdin Bio-Chem Technology Co.LTD. The DVB was a m/p-mixture of 80% purity, mixed with ethyl-vinyl benzene (EVB) and stabilized with 1000 mg/L tert-butyl-catechol (TBC). The TEPA was of technical grade and used as amination agent. The AIBN (α,α′-azobisisobutyronitrile) in chemical pure grade was from Tianjin Guangfu Fine Chemical Research Institute and used as initiators. The methyl acrylate (MA) provided by Sinopharm Chemical Reagent Co.LTD, was of analytical grade. UO2(NO3)·6H2O was purchased from Aladdin Chemistry Co.LTD. IRA67 was produced by Rohm and Haas company. It is a gel-type acrylic-divinylbenzene resin and possesses tertiary and secondary amine groups. The other reagents were all of analytical grade and purchased from Sinopharm Chemical Reagent Co. LTD.

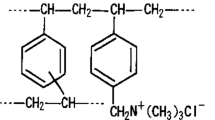

Synthesis of SAER

The preparatory flow sheet of SAER was illustrated in Scheme 1. The silica particles were placed in a glass flask and evacuated by a vacuum pump. After about 30 min, a mixture of monomers composed of 93 wt% MA and 7 wt% m/p-DVB, initiators AIBN, diluents consisted of methylbenzene and n-heptane were sucked into the flask in a vacuum state. The flask was kept rotating continuously to make sure the mixture could be sucked into the pores completely and then were protected by N2 gas. After that, the flask was heated in oil bath for 1 h at 60 °C, 2 h at 70 °C, and 8 h at 90 °C. The synthesized silica/polymethyl acrylate (SPMA) was washed by deionized water and alcohol alternately and then converted to SAER by reacting with tetraethylenepentamine (TEPA) for 13 h at the temperature of 130 °C.

Characterization

The surface morphologies of SAER were examined by scanning electron microscopy (SEM, Sirion 200). FT-IR was used to determine functional groups. The BET specific surface area and pore volume were measured by ASAP 2010. The synthesized SPMA and SAER were also analyzed by TG–DTA (Shimadzu T-60) in oxygen atmosphere with a flow rate of 25 mL/min, and the samples were heated from room temperature to 110 °C to remove the water completely (quite few), then to 600 °C in a heating rate of 1 °C/min. The total exchange capacity was 1.97 mmol/g determined by titration.

Batch adsorption experiments

Before experiments IRA67 was pretreated with 1 M HCl, deionized water, 1 M NaOH respectively, and then washed by deionized water until the effluent’s pH reached neutral. The resins were vacuum-dried at 60 °C for 48 h. Given that uranium level in groundwater is quite low, the initial concentration of uranium was set as 10 mg/L. In addition, uranium usually exists as uranyl carbonate compounds in groundwater. To select proper bicarbonate concentration the China national standard GB/T5750-2006—sanitary standard for drinking water and some literature [16, 20, 27, 28] were referred to, at last the bicarbonate level was determined as 3 mmol/L in order to simulate the real water condition. Subsequent experiments all used this value unless otherwise noted. A stock solution of 2000 mg/L U(VI) was prepared by dissolving appropriate amount of UO2(NO3)·6H2O in deionized water (DW). Another stock solution of 300 mmol/L NaHCO3 was also prepared in this way. Working standards were freshly prepared by proper dilution of stock solutions in deionized water. The initial pH of the working solutions was adjusted by 1 M HNO3 or NaOH solution, and the pH value was measured by a pH meter (FE20, Mettler-Toledo) with a solid-state electrode. No attempt was made to purge atmospheric CO2(g) and O2(g) from the solutions. The adsorption experiments were performed under shaking at 25 °C with a shaking frequency of 120 r/min. Then the solutions were separated by membrane filters with mean pore size of 0.45 μm and diluted by 2.5% HNO3. The concentration of metal ions before and after experiments was determined by ICP-AES instrument (Shimadzu ICP-7510). All the data used in this part were the average values of two parallel samples.

As the solutions were kept in closed container and contacted with atmosphere only for a short time, CO2 dissolved in solutions was neglected. Moreover, the equilibrium constant of UO2(OH)2 is much smaller than that of others (listed in Table 2), so precipitation of uranium was also neglected. Then the equilibrium adsorption capacity and removal efficiency were calculated by following equations:

where Q e (mg/g) is the equilibrium adsorption capacity; C 0 and C e denote the initial and equilibrium concentration in aqueous solutions, respectively; V is the volume of the working solution; m is the mass of resins; and D represents the removal efficiency.

Results and discussion

Materials characterization

The SEM images were examined to get the surface information. Figure 1 shows the SEM images of SPMA and SAER. The particle size is estimated to be about 75–150 μm, which is consistent with that of silica. The surface of SPMA is smooth while that of SAER shows a little rough. Two silica-based materials both exhibit regular and homogenous surface morphology.

Figure 2 shows the TG curves of SPMA and SAER. Obvious difference can be seen between SPMA and SAER. For SPMA the weight starts to loss at about 242 °C then drops sharply from 272 to 330 °C. After that, it decreases slowly until the weight shows constant. For SAER the weight loss curve declines fast from 150 to 305 °C then changes more and more slowly. This indicates that reactions had occurred between SPMA and TEPA. The acid–base titration results also prove that the amine groups have been grafted to SPMA successfully. The overall weight loss of SAER was estimated about 27.2%, which means about 27.2 wt% anion exchange resin was impregnated inside the silica substrates.

Figure 3 gives the FT-IR spectrum of silica, SPMA and SAER. The broad and strong peak at 3428.16 cm−1 can be attributed to the stretching vibration of adsorbed water-hydroxyl. The peaks at 1647.6 and 1401 cm−1 are resulted from the bending vibrations of the adsorbed water-hydroxyl. And the three peaks at 1108.8, 799.3 and 475.87 cm−1 were the characteristic peaks of silica [31]. These six peaks were common for the three materials. However, SAER had a unique peak at 1566.7 cm−1, which corresponds to the bending vibration of N–H. It proved that TEPA had been grafted onto the silica particles successfully.

Table 3 gives the BET results of SAER and SiO2. It can be seen that SiO2 possesses larger surface area, average pore diameter and pore volume compared with SAER, which is due to that polymer would occupy some space. The information of average pore diameter and pore volume suggests that SAER is a kind of mesoporous material. For comparison the physical properties of IRA67 is also listed in Table 3.

Batch adsorption experiment

Aqueous phase pH

As can be seen in Fig. 4, both SAER and IRA 67 can remove uranium from aqueous solutions very effectively in a wide pH range. The highest removal efficiencies of SAER and IRA67 have little difference and both approach 100%. It should be noted that such results are hard to explain with some geochemical models [15, 16, 18, 20], because according to those data and models, the anion exchange resins should be effective in neutral and alkaline conditions. On the contrary, experimental results show the effective pH ranges from 5 to 9. The adsorption mechanisms were discussed in latter sections (Scheme 2).

Adsorption kinetics

The effect of contact time on the adsorption of uranium is illustrated in the Fig. 5. Figure 5a shows SAER has more notable adsorption rate than IRA67. Uranium adsorption of SAER can reach equilibrium within 8 min while IRA67 needs more than 90 min. This phenomenon can be explained by the previously mentioned BET results which suggest that SAER has larger specific surface area and pore diameter.

The data points were fitted by the pseudo-first order kinetics model and pseudo-second kinetic model to investigate the mechanism of adsorption [32], as shown in Fig. 5. The two models can be illustrated by the following equations respectively:

where Q t (mg/g) and Q e (mg/g) are the adsorbed amount at time t and equilibrium, respectively. k 1 and k 2 are the constants related to the speed of adsorption. The kinetic parameters calculated from the fitted curves are listed in Table 4. The value of R 2 suggests the pseudo-second order model is better when fitting the experimental data, which means the adsorption of uranium is a chemical process for both kinds of material. The calculated rate constant of SAER is much larger than that of IRA67, which also conforms to expectation.

Optimum liquid–solid ratio and adsorption capacity

Actually, if a kind of material is expected to be applied on industrial scale, the adsorption capacity should be known. In some simple situation the largest adsorption capacity can be calculated by fitting the data of adsorption isotherms. But in this experiment where uranium is compounded with carbonate and existed as anion species, it is not suitable to get the adsorption capacity through above-mentioned method, because the proportion of uranyl ions to carbonate ions has impacts on the adsorption. Moreover, a high concentration of uranium could also precipitate by compounding with hydroxyl ions when the water’s pH approaches 7. Thus, different liquid–solid ratios were conducted to get the optimum liquid–solid ratio and speculate the largest working capacity.

From the Fig. 6a, we can see the curve of SAER changes slowly while that of IRA67 changes quickly. For SAER, the removal efficiency is kept in high level until the ratio of liquid to solid reaches 3 L/g. As for IRA67, the removal efficiency begins to drop when the ratio approaches 1 L/g. So the optimum ratios of liquid to solid are 3 and 1 L/g in such a specific experimental condition, respectively. It means if packed in column with the same mass and treating time, SAER can treat more uranium-polluted water than IRA67. The maximum working capacity can be speculated from Fig. 6b. For SAER, The curve rises quickly until the L/S reaches 3 L/g, then it climbs slowly. It suggests that adsorption starts to approach saturation. The adsorption amount is 124 mg/g when the L/S equals to 5. Compared with SAER, the curve for IRA67 rises like a line within the whole range. The adsorption amount is 174 mg/g when L/S equals to 5. It can be estimated that the maximum working capacity will be larger than 174 mg/g. In terms of working capacity per unit mass, IRA67 is superior to SAER. Given that SAER only has 27.2 wt% effective constituent and the density of silica is larger, it’s proper to present such a result. More accurate data will be obtained in our later column tests.

Effect of temperature on the removal of uranium

In order to obtain the effect of temperature on the removal of uranium, SAER and IRA67 were mixed with solutions at different temperature, respectively. From Fig. 7, adsorption amount of both resins increased firstly and then decreased with the rise of temperature. The optimum temperature for uranium adsorption was about 45 °C for both resins. It can be explained by following speculation: the adsorption process was endothermic. When the temperature was lower than 320 K, rising temperature was helpful to adsorption. However, when it continued to increase, the factor of thermal stability of two resins may be predominant.

Effect of major ions on uranium adsorption onto SAER

The major interfering ions in drinking water include Cl−, NO3 −, SO4 2−, Na+, K+, Ca2+ and Mg2+ So following experiments were designed to investigate the effect of them on the removal of uranium. In this part pH was not adjusted and consistent with that of DW. It was observed that NaCl, KNO3 and Na2SO4 had little effect on the removal of uranium when the concentrations were below 5 mmol/L. However, when the concentrations were high, all of them could prevent uranium from being adsorbed, which could be explained by competition adsorption. Compared with Cl− and NO3 −, SO4 2− had more obvious effect on the removal of uranium. These results suggested SAER showed selectivity to uranyl carbonate complexes (Fig. 8).

Considering calcium and magnesium have similar chemical performance, CaCl2 and Mg(NO3)·6H2O were mixed together to investigate the effect of them on the removal of uranium. Figure 9 indicated that Ca2+ and Mg2+ couldn’t be adsorbed onto the surface. However, when uranium and bicarbonate were added to the solution, some Ca2+ and Mg2+ were adsorbed. Moreover, removal efficiency of uranium decreased with the increasing total concentration of Ca2+ and Mg2+ while the adsorption amount of Ca2+ and Mg2+ increased. It implied that Ca2+ and Mg2+ may compound with \({\text{UO}}_{2}^{{ 2 { + }}}\) and \({\text{CO}}_{3}^{ 2- }\) and then formed into new compounded anion species. At last the new-formed anions were adsorbed onto the surface of SAER. In fact, some literature has reported that \({\text{Ca(UO}}_{2} ) ( {\text{CO}}_{3} )_{3}^{ 2- }\) and \({\text{Mg(UO}}_{2} ) ( {\text{CO}}_{3} )_{3}^{ 2- }\) could exist in such a condition [4, 33]. The reverse effects could also be attributed to the formation of Ca2(UO2)(CO3)3 [4], which was a kind of neutral molecule that couldn’t be adsorbed onto the surface of SAER by ion exchange.

According to the investigation of Fox PM et al. [4], calcium has notable impact on the uranium speciation in the solution containing CO2. Aqueous speciation calculated by FITEQL 4.0 suggests that calcium uranyl carbonate complexes are dependent on the pH value [4]. Although the experimental conditions used in our research are different from those used by Fox PM, results still indicate that changing the pH may make uranium exist as anion and then it can be removed by ion exchange. So 2000 mg/L of uranium stock solution was appropriately diluted by the tap water from the laboratory room. pH was changed to investigate whether uranium could be removed efficiently in natural condition.

From Fig. 10, it can be seen that SAER could eliminate uranium completely when the equilibrium pH was below 7, but the removal efficiency may be not so satisfactory when the water’s initial pH was neutral or alkaline (as the equilibrium pH must be larger than 7 this time). So the pH of tap water should be adjusted a little before SAER was used to remove uranium. According to our experimental results, it was enough when the initial pH value ranged from 5 to 6.5.

Discussion

The experimental results suggested SAER could remove uranium from tap water effectively. One of its noble properties is its excellent adsorption kinetics, which means it can be applied to the fast processing of uranium-polluted groundwater. As for pressure loss when packed in column and mechanical property, some researchers have pointed out silica-based adsorbents showed to be more excellent than conditional resins [21, 25, 34]. Although in terms of adsorption capacity SAER can’t catch up with conditional resins, it still excesses many other materials, and details were presented by Table 5.

SAER had exhibited excellent performance, but we still don’t know about the adsorption mechanism. If SAER just concentrate uranium by ion exchange, it would be unreasonable that its removal efficiency should reach 100% in solution containing uranium when the pH ranged from 5 to 9, even in the presence of non-charged species. At the same time, we also observed that pH changes during the adsorption process. From above analysis, it can be inferred that maybe ion exchange and chelation both dominate the adsorption process (Scheme 2).

Conclusion

A silica-based anion exchange resin was prepared to treat the uranium-polluted drinking water quickly. Characterization tests showed that SAER was successfully synthesized with large pores and surface area. Batch experiments suggested SAER could remove uranium from aqueous solutions (without adding interfering ions) with pH ranging from 5 to 9; Compared with commercial anion exchange resin IRA67, SAER had more excellent adsorption kinetics and a larger ratio of liquid to solid, and both of them followed the pseudo-second order kinetic model and shared the optimum adsorption temperature − 45 °C. The largest adsorption capacity of SAER was larger than 124 mg/g. Experiments about interfering ions suggested that SO4 2−, Ca2+ and Mg2+ had important effects on the adsorption of uranium. It was also observed that uranyl carbonate complexes could promote Ca2+ and Mg2+ to be adsorbed by SAER. When used for tap water containing uranium, SAER had excellent performance with equilibrium pH below 7 but near neutral. At last, the adsorption mechanisms were proposed. In general, SAER is quite potential to be applied in the fast-treating of water containing uranium on a large scale.

References

Katsoyiannis IA, Zouboulis AI (2013) Removal of uranium from contaminated drinking water: a mini review of available treatment methods. Desalin Water Treat 51(13–15):2915–2925. https://doi.org/10.1080/19443994.2012.748300

Organization WH (2004) Uranium in drinking-water: Background document for development of WHO Guidelines for Drinking-water Quality

Riegel M, Tokmachev M, Hoell WH (2008) Kinetics of uranium sorption onto weakly basic anion exchangers. React Funct Polym 68(6):1072–1080. https://doi.org/10.1016/j.reactfunctpolym.2008.02.009

Fox PM, Davis JA, Zachara JM (2006) The effect of calcium on aqueous uranium(VI) speciation and adsorption to ferrihydrite and quartz. Geochim Cosmochim Acta 70(6):1379–1387. https://doi.org/10.1016/j.gca.2005.11.027

Lee SY, Bondietti EA (1983) Removing uranium from drinking water by metal hydroxides and anion-exchange resin. J Am Water Works Assoc 75:536–540

Phillips DH, Gu B, Watson DB, Parmele CS (2008) Uranium removal from contaminated groundwater by synthetic resins. Water Res 42(1–2):260–268. https://doi.org/10.1016/j.watres.2007.07.010

Dickinson M, Scott TB (2010) The application of zero-valent iron nanoparticles for the remediation of a uranium-contaminated waste effluent. J Hazard Mater 178(1–3):171–179. https://doi.org/10.1016/j.jhazmat.2010.01.060

Li ZJ, Wang L, Yuan LY, Xiao CL, Mei L, Zheng LR, Zhang J, Yang JH, Zhao YL, Zhu ZT, Chai ZF, Shi WQ (2015) Efficient removal of uranium from aqueous solution by zero-valent iron nanoparticle and its graphene composite. J Hazard Mater 290:26–33. https://doi.org/10.1016/j.jhazmat.2015.02.028

Shen J, Schäfer A (2014) Removal of fluoride and uranium by nanofiltration and reverse osmosis: a review. Chemosphere 117:679–691. https://doi.org/10.1016/j.chemosphere.2014.09.090

Favre-Reguillon A, Lebuzit G, Murat D, Foos J, Mansour C, Draye M (2008) Selective removal of dissolved uranium in drinking water by nanofiltration. Water Res 42(4–5):1160–1166. https://doi.org/10.1016/j.watres.2007.08.034

Wang H, Ma L, Cao K, Geng J, Liu J, Song Q, Yang X, Li S (2012) Selective solid-phase extraction of uranium by salicylideneimine-functionalized hydrothermal carbon. J Hazard Mater 229–230:321–330. https://doi.org/10.1016/j.jhazmat.2012.06.004

Singhal P, Jha SK, Pandey SP, Neogy S (2017) Rapid extraction of uranium from sea water using Fe3O4 and humic acid coated Fe3O4 nanoparticles. J Hazard Mater 335:152–161. https://doi.org/10.1016/j.jhazmat.2017.04.043

Sadeghi S, Sheikhzadeh E (2009) Solid phase extraction using silica gel modified with murexide for preconcentration of uranium (VI) ions from water samples. J Hazard Mater 163(2–3):861–868. https://doi.org/10.1016/j.jhazmat.2008.07.053

Liu J, Zhao C, Zhang Z, Liao J, Liu Y, Cao X, Yang J, Yang Y, Liu N (2016) Fluorine effects on U(VI) sorption by hydroxyapatite. Chem Eng J 288:505–515. https://doi.org/10.1016/j.cej.2015.12.045

Wazne M, Korfiatis GP, Meng X (2003) Carbonate effects on hexavalent uranium adsorption by iron oxyhydroxide. Environ Sci Technol 37(16):3619–3624

Barton CS, Stewart DI, Morris K, Bryant DE (2004) Performance of three resin-based materials for treating uranium-contaminated groundwater within a PRB. J Hazard Mater 116(3):191–204. https://doi.org/10.1016/j.jhazmat.2004.08.028

Camacho LM, Deng S, Parra RR (2010) Uranium removal from groundwater by natural clinoptilolite zeolite: effects of pH and initial feed concentration. J Hazard Mater 175(1–3):393–398. https://doi.org/10.1016/j.jhazmat.2009.10.017

Katsoyiannis IA (2007) Carbonate effects and pH-dependence of uranium sorption onto bacteriogenic iron oxides: kinetic and equilibrium studies. J Hazard Mater 139(1):31–37. https://doi.org/10.1016/j.jhazmat.2006.05.102

Wazne M, Meng X, Korfiatis GP, Christodoulatos C (2006) Carbonate effects on hexavalent uranium removal from water by nanocrystalline titanium dioxide. J Hazard Mater 136(1):47–52. https://doi.org/10.1016/j.jhazmat.2005.11.010

Katsoyiannis IA, Althoff HW, Bartel H, Jekel M (2006) The effect of groundwater composition on uranium(VI) sorption onto bacteriogenic iron oxides. Water Res 40(19):3646–3652. https://doi.org/10.1016/j.watres.2006.06.032

Arai T, Wei Y, Kumagai M, Horiguchi K (2006) Separation of rare earths in nitric acid medium by a novel silica-based pyridinium anion exchange resin. J Alloy Compd 408–412:1008–1012. https://doi.org/10.1016/j.jallcom.2004.11.092

Dolatyari L, Yaftian MR, Rostamnia S (2016) Removal of uranium(VI) ions from aqueous solutions using Schiff base functionalized SBA-15 mesoporous silica materials. J Environ Manag 169:8–17. https://doi.org/10.1016/j.jenvman.2015.12.005

Li D, Egodawatte S, Kaplan DI, Larsen SC, Serkiz SM, Seaman JC (2016) Functionalized magnetic mesoporous silica nanoparticles for U removal from low and high pH groundwater. J Hazard Mater 317:494–502. https://doi.org/10.1016/j.jhazmat.2016.05.093

Lingamdinne LP, Choi YL, Kim IS, Yang JK, Koduru JR, Chang YY (2017) Preparation and characterization of porous reduced graphene oxide based inverse spinel nickel ferrite nanocomposite for adsorption removal of radionuclides. J Hazard Mater 326:145–156. https://doi.org/10.1016/j.jhazmat.2016.12.035

Wei YZ, Yamaguchi M, Kumagai M, Takashima Y, Hoshikawa T, Kawamura F (1998) Separation of actinides from simulated spent fuel solutions by an advanced ion-exchange process. J Alloy Compd 271–273:693–696. https://doi.org/10.1016/S0925-8388(98)00189-3

Yue-shuang Q (2013) Study on synthetilization of weak alkaline acrylic resin. Hydrometall China 32:109–112. https://doi.org/10.13355/j.cnki.sfyj.2013.02.003

Dimiropoulos V, Katsoyiannis IA, Zouboulis AI, Noli F, Simeonidis K, Mitrakas M (2015) Enhanced U(VI) removal from drinking water by nanostructured binary Fe/Mn oxy-hydroxides. J Water Process Eng 7:227–236. https://doi.org/10.1016/j.jwpe.2015.06.014

Stucker V, Ranville J, Newman M, Peacock A, Cho J, Hatfield K (2011) Evaluation and application of anion exchange resins to measure groundwater uranium flux at a former uranium mill site. Water Res 45(16):4866–4876. https://doi.org/10.1016/j.watres.2011.06.030

Waite TD, Davis JA, Payne TE, Waychunas GA, Xu N (1994) Uranium(VI) adsorption to ferrihydrite: application of a surface complexation model. Geochim Cosmochim Acta 58(24):5465–5478. https://doi.org/10.1016/0016-7037(94)90243-7

Grenthe I, Fuger J, Konings RJ, Lemire RJ, Muller AB, Nguyen-Trung C, Wanner H (1992) Chemical thermodynamics of uranium, vol 1. Elsevier Science Publishers B. V., Amsterdam

Song X, Jiang N, Li Y, Xu D, Qiu G (2008) Synthesis of CeO2-coated SiO2 nanoparticle and dispersion stability of its suspension. Mater Chem Phys 110(1):128–135

Ho Y, McKay G (1998) A comparison of chemisorption kinetic models applied to pollutant removal on various sorbents. Process Saf Environ Prot 76(4):332–340

Dong W, Brooks SC (2006) Determination of the formation constants of ternary complexes of uranyl and carbonate with alkaline earth metals (Mg2+, Ca2+, Sr2+, and Ba2+) using anion exchange method. Environ Sci Technol 40(15):4689–4695. https://doi.org/10.1021/es0606327

Wei Y, Kumagai M, Takashima Y, Asou M, Namba T, Suzuki K, Maekawa A, Ohe S (1998) The application of an advanced ion exchange process to reprocessing spent nuclear fuels, (I). J Nucl Sci Technol 35(5):357–364. https://doi.org/10.1080/18811248.1998.9733872

Cao Q, Liu Y, Kong X, Zhou L, Guo H (2013) Synthesis of phosphorus-modified poly(styrene-co-divinylbenzene) chelating resin and its adsorption properties of uranium(VI). J Radioanal Nucl Chem 298(2):1137–1147. https://doi.org/10.1007/s10967-013-2500-4

Donat R (2009) The removal of uranium (VI) from aqueous solutions onto natural sepiolite. J Chem Thermodyn 41(7):829–835. https://doi.org/10.1016/j.jct.2009.01.009

Jamali MR, Assadi Y, Shemirani F, Hosseini MR, Kozani RR, Masteri-Farahani M, Salavati-Niasari M (2006) Synthesis of salicylaldehyde-modified mesoporous silica and its application as a new sorbent for separation, preconcentration and determination of uranium by inductively coupled plasma atomic emission spectrometry. Anal Chim Acta 579(1):68–73. https://doi.org/10.1016/j.aca.2006.07.006

Acknowledgements

This work was supported by Major Science and Technology Program for Water Pollution Control and Treatment [Grant Numbers 2015ZX07406006], and National Natural Science Foundation of China [Grant Numbers 91126006]. The authors would like to acknowledge the help of Doctor Shu Qiding and Doctor Zha Feixiang.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, L., Chen, Y., Wang, X. et al. A novel silica-based anion exchange resin used for removing uranium from drinking water. J Radioanal Nucl Chem 314, 2569–2578 (2017). https://doi.org/10.1007/s10967-017-5611-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-017-5611-5