Abstract

The advantages of instrumental neutron activation analysis applied to archaeological ceramics have been enhanced through the analysis of entire objects, using both the k 0 method and the relative method, respectively, to determine the concentrations of chemical elements in aliquots of replicate objects used as comparators and in the sample object. Twenty-two chemical elements of archaeological importance were measured in mud figurines from Caral civilization (5000 year BC), irradiated inside a well-characterized radial channel facility of the nuclear research reactor at IPEN, Peru. The results showed less than 10 % of bias for most of the elements.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Instrumental neutron activation analysis (INAA) is widely recognized as an important technique for studying siliceous samples, above all, archaeological matrixes, because of its powerful advantages: easy sample preparation, possibility of using only a few milligrams to perform multielemental analysis by non-destructive methods, minimum manipulation and absence of matrix interferences.

The application of INAA in archaeology began with the pioneering research of Sayre and Dodson in 1957 [1], which opened the way to the work of other scientists [2]. Afterwards, the efforts of archaeologist like Rands and Bishop, working together with analytical chemists, contributed to demonstrate how data on chemical elements could effectively address specific questions, and helped to establish INAA as an integral part of the archaeological tool kit [3].

INAA is usually applied in archaeology through the analysis of powder ceramic extracted from fragments; however, the intrinsic value of the archaeological specimens is such that a mandatory requirement to keep the object as intact as possible. Such demand implies the need for carrying out the analysis of entire objects, using a non-destructive approach. To solve this challenge, the authors have developed a method [4], that add the preservation of the samples, without any damage or modification to the above mentioned advantages of INAA.

In the present work, a variation of the method is described, which has been applied to the analysis of figurine samples. The experimental work comprises the use of k 0 method based INAA to determine chemical elements in samples taken from duplicate objects, which are then used as comparators for the analysis of the archaeological samples, by the relative method.

Experimental

Preparation of samples and comparators

The original samples were archaeological specimens from Caral civilization (5000 year BC) made of raw mud. Two figurines with approximate dimensions 0.07 × 0.04 × 0.02 m, and masses of 72.2 and 70.2 g, respectively (labelled A and B), and one head of figurine, with approximate dimensions of 0.020 × 0.024 × 0.018 m, and 9.1 g of mass (labelled C). An artisan exactly replicated these objects, and the masses of the replicates were 71.0, 72.0 and 9.3 g, respectively. Samples of powder were extracted by scraping with a tungsten carbon drill, at three points of each replicate, in order to make the respective composite samples.

A mass of 0.250 g of each powder sample was sealed in a clean, labelled polyethylene container. The comparator for k 0 method was prepared depositing 1,000 μg of a sodium primary standard solution on 0.050 g of cellulose powder placed in the polyethylene container. The comparator was dried under controlled temperature, sealed and placed in the irradiation vial, together with the samples. A certified reference material (SRM 1633b Coal Fly Ash) was prepared and irradiated in similar conditions, as quality control for the analysis of the powder samples.

The original figure samples and their duplicate were placed into polyethylene bags, labelled, sealed and irradiated in a 0.17 m diameter disk of aluminium, where hollows of the size of the figurines allowed arranging both the originals (samples) and the duplicates (comparators) side by side (Fig. 1).

Irradiation and measurement

Irradiations were performed in the nuclear research reactor at IPEN, Peru. It is a circular pool type reactor (open tank), which use 20 % enriched uranium fuel and light water, with a maximum operation power of 10 MW. A thermal channel, four radial channels and a pneumatic channel allow performing specific experiments. Irradiation facilities are located close to the core and in the periphery.

For the analysis based on the k 0 method, powder samples, SRM and comparators were irradiated for 900 s, using the pneumatic transfer system, as shown in Fig. 2, with the reactor operating at maximum power. The N°4 radial channel of the reactor (Fig. 2) was used for the analysis of the entire objects by the relative method. The irradiation time was 9 h at a thermal flux of about 7.5 × 109 cm−2 s−1. The aluminium disk with the figurines was placed at the opposite end of a square rod of 0.200 m length and inserted inside the radial channel, using long tweezers.

The characterization of neutron flux at the pneumatic irradiation position was performed using a set of 197Au, 98Mo, 59Co and 177Lu monitors. Gold was used as alloy foil (IRMM-530 R Al–0.1 % Au) and lutetium as alloy wire (0.1 % Lu–Al). Molybdenum and cobalt were irradiated as aliquots of a multielemental solution, deposited on cellulose placed in the irradiation container. The experimental details are described elsewhere [5].

As the radial channel had not been previously used for INAA, the neutron flux at this position was characterized through a set of monitors: 177Lu, 65Ni, 51Cr, 198Au, 95Zr, 97Zr and 65Zn, as wires or foils, which were attached to the samples.

The measurement of both the powder samples and the figurines was performed using an HPGe Canberra GC 7019 detector (FWHM = 1.9 keV at the 1332.5 keVpeak from 60Co). The powder samples were firstly measured for 5,000 s, after 8 days of decay, to quantify 76As, 42K, 140La, 24Na, 239Np, 122Sb, 153Sm and 175Yb. Additional 30,000 s measurements, in order to quantify the remaining elements, were made after 18–20 days. Similarly, the figurine samples were measured twice, after decay periods of 7 and 15 days. The spectrum acquisition was performed by the Canberra Genie 2000 software. The results for k 0 method were obtained using a MS-Excel spread sheet with macro commands, in-house developed, whereas those for the relative method were obtained using a simple MS-Excel spread sheet.

Results and discussion

The parameters obtained from the characterization of both irradiation positions used in this work are shown in Table 1. As can be noted, the pneumatic irradiation position, which was used for analysing the powder samples by the k 0 method, is relatively well thermalized; approximately 92 % of the neutron flux comes from the thermal component and 2–6 %, respectively, from the epithermal and fast components; the f value is 58.0 ± 2.0. Conversely, the neutron flux in the radial channel is much less thermalized; the components of thermal, epithermal and fast neutrons are respectively 60, 2 and 38 % of total; the f value is 30.0 ± 1.0. The α-values obtained in both irradiation positions are positive and indicate a softened epithermal neutron spectrum for the configuration used in the reactor, which is shown in Fig. 2. As can be expected, the neutron temperature is much higher in the radial channel, because it is a slightly collimated irradiation position. These parameters, together with detection efficiency [6] and the data of Table 2 [7, 8], were used to obtain the results of element concentrations and to determine the concentrations in the comparators for the application of the relative method.

The results of the SRM 1633b, analysed together with extracted powder samples, to accomplish the internal quality control, are summarized in Table 3. These results are shown because of mass comparator used for the relative method is determined with the results of concentration obtained by the k 0 method (powder samples), as well as, to obtain the percentage recovery of entire samples, relating them with the concentration of powder samples analysis. Although more elements were determined in powder samples and in the standard reference material, only those used to calculate the concentration in the entire objects were considered for quality control. The concentrations obtained were compared with the certified values (E n1), and also with the results of other laboratories (E n2 and E n3) [9, 10], respectively, using the E n Number [11]. This approach takes into account the average and the expanded uncertainty of the results reported and of the reference data. As only eight, out of the twenty-two elements, are certified, the fourteen elements remaining are reported as information values, without declaration of uncertainty. In these cases, the relative biases were used for evaluation. The E n scores indicate satisfactory or unsatisfactory performances for |E n| ≤ 1.0 and |E n| > 1.0, respectively. As seen in Table 3, the results presented are in reasonable agreement with the certified value and with results from other laboratories. Values higher that 1 are computed for potassium with respect to the certificate value, and for potassium and lanthanum in comparison to Lab2 results; however, they are perfectly comparable with Lab3 values. Other unsatisfactory scores are 1.3 and 1.9 for antimony and samarium, respectively, with respect to Lab3 values, but they are satisfactory, if compared with Lab2 values (scores of 0.13 and 0.90). In the case of relative bias, using data from the certificate, lanthanum, antimony, scandium and uranium show bias higher than 5 %.

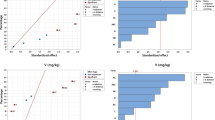

The recovery of the relative method applied to entire figurine samples is shown in Fig. 3. The concentrations obtained in figurines were compared with those from the analysis of powder extracted from the replicates that acted as comparators. The percentage recovery of each element in the sample was better than 90 %, good enough to assure the reliability of the results obtained in the entire object.

The results of the analysis of figurine samples are shown in Table 4 with its associated expanded uncertainty, which was calculated combining the standard uncertainty of the comparator mass calculation by k 0 method and the standard uncertainty of the entire sample calculation by the relative method. It can be seen that the results obtained, include some elements that have a remarkable differentiation during the processes of formation of igneous rocks, namely rare earth elements, Cr, Co, Th and Sc, which provide information that reveals differences in the clay composition [12].

Conclusion

The developed method and its application in the radial irradiation facility to determine elements in entire archaeological objects showed reliable results and can be considered as a method that enhance the advantages of INAA technique.

The set of elements determined is suitable to the purpose of providing significant data related to provenance studies.

References

Sayre EV, Dodson RW (1957) Neutron activation analysis of mediterranean potsherds. Am J Archaeol 61:35

Smithsonian Centre for Materials Research and Education (1999) A festschrift in honour of Dr. Edward V. Sayre patterns and process

Bishop RL (2003) In: IAEA technical report series 416, Vienna

Bedregal P, Mendoza P, Cohen IM, Baltuano O, Montoya E (2012) Neutron activation analysis of archaeological artifacts using the conventional relative method: a realistic approach for analysis of large samples. J Radioanal Nucl Chem 291:31–42

Montoya E, Bedregal P, Mendoza P, Ubillús M, Torres B, Cohen IM (2010) The development of k 0 method: past, present and future perspectives. Nucl Instrum Methods Phys Res A 622:381–384

Mendoza P, Bedregal P, Torres B, Ubillús M (2005) Evaluación de la eficiencia relativa de detectores de GeHP para su utilización en el método del k 0 ISSN 1684-1662 ICT IPEN 3

Blaauw M (1999) The k 0 consistent IRI gamma-ray catalogue for INAA. ISBN 903861322

De Corte F, Simonits A (2003) Recommended nuclear data for use in the k 0 standardization of neutron activation analysis. Atomic Data Nucl Data Tables 85:47–67

Greenberg RR, Mackey EA, Becker DA (1995) The application of instrumental neutron activation analysis for the certification of the new NIST fly ash. J Radioanal Nucl Chem 193(1):7–14

Kubesova M, Kucera J (2012) Inconsistencies of neutron flux parameters for k 0 standardization in neutron activation analysis determined with the use of Au + Zr and Au + Mo + Cr monitor sets at the LVR-15 reactor in Řež. J Radioanal Nucl Chem 293:665–674

EURACHEM (2011) Selection, use and interpretation of proficiency testing schemes, 2nd edn

Several Authors (2003) Chapter 1 techniques used and results obtained. In: IAEA technical report series 416, Vienna

Acknowledgments

The authors want to express gratitude to the archaeologist of the Caral Archaeological Zone and to the International Atomic Energy Agency.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bedregal, P.S., Mendoza, P.A., Ubillús, M.S. et al. The k 0 and relative INAA methods to determine elements in entire archaeological pottery objects. J Radioanal Nucl Chem 300, 673–678 (2014). https://doi.org/10.1007/s10967-014-3080-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-014-3080-7