Abstract

A series of poly(ester amide)s (PEAs) derived from the nontoxic building blocks, isosorbide, α-amino acids (L-phenylalanine, L-alanine, L-valine and glycine) and dicarboxylic acids was synthesized by interfiactial polymerization using a two-step method. The majority of PEAs were amorphous except for some glycine containing polymers. The PEAs showed good thermal stabilities and had Tg temperatures from 115.9 to 182.6 °C. The hydrolytic degradation behavior of the PEAs was followed by weight loss in both alkaline solution (pH 9) and under stimulated physiological conditions (pH 7.4) in phosphate buffer saline solution at 37 °C. The polymers with hydrophobic pendent or rigid dicarboxylic acid groups prevent degrading media from penetration into the polymer bulk leading to slow degradation rate. The monomers synthesized were characterized by FTIR, 1H and 13C NMR spectroscopy, the PEAs structures were confirmed by FTIR, 1H and 13C NMR spectroscopy and their thermal properties were studied by TGA and DSC.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

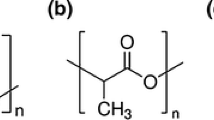

Biodegradable polymers are naturally occurring or synthetically designed polymers that can degrade hydrolytically or enzymatically into water-soluble products [1,2,3]. Synthetic biodegradable polymers are normally prepared to have hydrolytically cleavable bonds in the polymer backbone; they are considered good replacement to non-degradable polymers especially for biomedical applications [4, 5]. So far, majority of the studies have been directed toward modification and application of synthetic polyesters such as poly(lactic acid), poly(ε-caprolactone) and their copolymers [6, 7]. However, their use in the biomedical field is restricted due to lack of desirable properties such as high hydrophilicity, bio-adhesion, thermal and mechanical stabilities [8, 9]. For these reasons, scientific interest have been focused recently toward the development of poly(ester amide)s (PEAs), these are a class of polymers containing amide and ester linkages in the backbone and are generally biodegradable materials. This feature arises from the embedment of the cleavable ester group in the polymer chains [8, 10,11,12]. PEAs can be synthesized from various monomers (i.e. aminoalcohols and cyclic ester amides) via several synthetic methods such as ring opening polymerization (ROP) and solution polycondensation reaction [9]. Such polymers would probably have properties that can mediate those of polyamides and polyesters; while polyamides afford good thermal and mechanical properties due to the formation of strong hydrogen bonds among amide groups, ester linkages in polyesters are generally degradable by hydrolytic cleavages, which make PEAs promising materials for the use in biomedical applications [13,14,15,16].

The synthesis of α-amino acids-based PEAs (AA-PEAs) containing renewable diols and dicarboxylic acids units is an attractive way to obtain PEAs from renewable resources, having building blocks that are metabolizable and having interesting thermal properties [13, 17,18,19,20,21,22,23,24,25,26,27]. This family of polymers was tested and found to be promising materials for biomedical applications [25, 27,28,29]. AA-PEAs can be polycondensed by interfacial, active solution or melt polymerization. Interfacial polymerization is considered the most attractive method for the synthesis of this class of PEAs for certain reasons, such as fast reaction, low reaction temperature and reaction irreversibility [28].

In this work, we report the synthesis, characterization and a hydrolytic degradation study of a series of novel AA-PEAs derived from isosorbide and α-amino acids (L-phenylalanine, L-alanine, glycine, and L-valine). Isosorbide is a renewable, rigid, chiral and non-toxic molecule that can be produced from natural resources, it belongs to the 1,4:3,6-dianhydrohexitols family [30], 1,4:3,6-dianhydrohexitols are starch-derived nontoxic diols that exists in three isosorbide, isomannide and isoidide [31]. Among the three isomers (Fig. 1), isosorbide is the most promising precursors for materials synthesis due to its large-scale availability compared to isoidide, and higher reactivity compared to isomannide [32]. For the mentioned reason, we decided to synthesize a new series of AA-PEA derived from the non-toxic diol (isosorbide) and α-amino acids; this series is expected to degrade to give final products with low cytotoxicity, which makes them valuable materials for biomedical applications.

Experimental

Materials

Most of the chemicals were of analytical grades and used as received unless otherwise mentioned. The chemicals were purchased from the following companies: D-sorbitol 97%, L-alanine 99%, terephthalic acid 99%, fumaryl chloride 95%, oxalyl chloride 98%, cis/trans-1,4-cyclohexanedicarboxylic acid 99%, methane sulfonic acid 70% (w/w), sodium hydroxide 98%, potassium carbonate 99%, tetrahydrofuran (THF) and sulfuric acid 95% (w/w) were purchased from Acros Organics. Dry chloroform (CHCl3) and ethyl acetate (EtOAc) from VWR, p-toluenesulfonic acid monohydrate 99% from Koch-Light Laboratories Ltd., L-phenylalanine 99% and L-valine 99% from Janssen Chimica, glycine 99% from BDH, N,N-dimethylformamide (DMF) from Daejung, acetone from Pharmacos, dimethyl sulfoxide (DMSO), toluene from TEDIA and 1-methyl-2-pyrrolidone (NMP) from AppliChem.

Measurements

Fourier transform infrared (FTIR) spectra were recorded at room temperature in the range 4000–550 cm−1 using a Thermo Nicolet Nexus 670 FTIR spectrophotometer equipped with attenuated total reflection (ATR) accessory.

The 1H and 13C NMR spectra were recorded at room temperature in deuterated dimethylsulfoxide (DMSO-d6) on a 500 MHz and 125 MHz spectrophotometer (Bruker Avance III), respectively. Chemical shifts (δ) were recorded in ppm using tetramethylsilane (TMS) as internal standard.

The glass transition temperatures (Tg) were studied using the instrument Netzsch DSC 204 F1 differential scanning calorimeter (Selb Bavaria, Germany). Sample masses ranging from 5 to 11 mg were used and a heating rate of 10 °C min−1. To eliminate the thermal history, the samples were first heated from ambient temperature to 170 °C, and maintained at this temperature for 4 min, and were then subjected to rapid cooling with liquid nitrogen to a suitable starting temperature. After which, the thermal behaviors of the samples were probed by heating to the molten state at a heating rate of 10 °C min−1 and the Tg values were taken as the inflection of the step transition.

The inherent viscosities of dilute polymers solutions were measures in dimethylsulfoxide using a dilution Ubbelohde glass capillary viscometer (Rheotek, PoultenSelfe& Lee Ltd., Essex, England) in a thermostated water bath at 35.0 ± 0.1 °C. The solutions were temperature equilibrated for approximately 15 min before conducting the viscosity measurements. The measurements were repeated until reproducible efflux times were obtained.

Thermal stabilities of the samples were studied by thermogravimetric analysis (TGA) using a Netzsch STA 409 PG/PC thermal analyzer (Selb Bavaria, Germany). Sample masses ranging from 5 to 11 mg were used and the measurements were conducted in the range 25–1000 °C at a heating rate of 10 °C min−1, the measurements were recorded under dry nitrogen gas purging at a flow of 50 mL min−1.

In vitro hydrolytic degradation tests were done in alkaline solution at pH = 9 and in phosphate buffer saline (PBS) at pH = 7.4, at 37 ± 1 °C. 200 mg of poly(ester amide) samples were immersed in 15 mL of alkaline or PBS solution and incubated at 37 °C. At predetermined times; the samples were filtered, washed with distilled water and dried at 60 °C under vacuum to constant weight. The degree of degradation was estimated from the weight loss percentage of poly(ester amide)s using Eq. 1.

Equation 1 Weight loss % of PEAs

Herein, Wo is the initial weight of the PEA sample before immersion, and Wt is the weight of the PEA sample incubation for t time after drying.

Monomers and polymer nomenclature

The monomers studied in this work are labeled by their first three letters of the diol name (Iso for isosorbide) the first letter of the amino acid name (P, L-phenylalanine; A, L-alanine; V, L-valine; G, glycine). The diacid chlorides are labeled by the first letter of their names (T, terephthaloyl chloride; F, fumaryl chloride; C, cis/trans-1,4-cyclohexanedicarbonyl dichloride). For example, IsoA represents di-p-toluenesulfonic acid salts of O,O′-bis-(L-alanine)-isosorbide monomer, while IsoAT represents the polymer derived from di-p-toluenesulfonic acid salts of O,O′-bis-(L-alanine)-isosorbide and terephthaloyl chloride.

Isosorbide synthesis

Isosorbide was synthesized based on the procedure described by Jung and coworkers [33]. 600 g (3.30 mol) of D-sorbitol was placed in a 1 L round-bottomed flask; the temperature was raised to 110 °C under stirring to melt D-sorbitol. 3.5 mL of conc. H2SO4 (95%) and 2.5 mL of methanesulfonic acid 70% (v/v) were added consecutively to the molten D-sorbitol. Under stirring, the reaction temperature was raised to 135 °C and the water produced from the dehydration reaction was distilled. The described conditions were maintained for 4 h until no more water was produced. The temperature of reaction mixture was then lowered to 110 °C; 18 mL 50% NaOH solution (w/v) was added to neutralize the acid, then the mixture temperature was gradually increased to 220 °C under vacuum (3 mmHg) to distill the product. The produced isosorbide was purified by double recrystallization from ethyl acetate. Yield: 71%. Tm: 61.5–63.0 °C. FTIR: 3446 cm−1 (-O-H), 1122 cm−1(-CO-).C6H10O2 = 146.14 g mol−1. 1H NMR (500 MHz, DMSO-d6) δ (ppm): 3.19–3.23 (t, 1H, H6), 3.63–3.70 (m, 3H, H1, H1’ & H6’), 3.99 (s, 1H, H2), 4.03–4.07 (m, 1H, H5), 4.18–4.19 (d, 1H, H3), 4.31–4.32 (t, 1H, H4), 4.60–4.62 (d, 1H, OH5 (endo)), 5.03–5.04 (d, 1H, OH2 (exo)). 13C NMR (125 MHz, DMSO-d6) δ (ppm): 71.3 (C6), 72.7 (C5), 75.7 (C1), 76.1 (C2), 81.7 (C4), 88.1 (C3).

Synthesis of di-p-toluenesulfonic acid salts of O,O′-bis-(α-aminoacyl)-isosorbide monomers

Monomers were synthesized following a published method [19], α-amino acid (60.5 mmol), isosorbide (27.5 mmol) and p-toluenesulfonic acid monohydrate (66 mmol) in 100 mL of toluene were placed in a 150 mL round-bottomed flask equipped with a Dean-Stark trap and a condenser. The reaction mixture was heated at reflux for 24–96 h with vigorous stirring until 2.2 mL (121 mmol) of water was evolved. The reaction mixture was then left to cool to room temperature; toluene was removed by decantation to leave a hard solid product accumulated in the bottom of reaction flask, the product was dissolved in methanol, filtered off to remove any unreacted α-amino acid then recrystallized from methanol/acetone mixture.

IsoP:Yield: 84%, Tm: 261–263 °C. FTIR: 1750 cm−1(-C=O), 1163 cm−1 (C-O-Cether and C(=O)-O-Cester), IsoA: Yield: 85%, Tm.: 238–239 °C. FTIR: 1747 cm−1(-C=O), 1155 cm−1 (C-O-Cether and C(=O)-O-Cester), IsoV: Yield: 71%, Tm.: 259–261 °C. FTIR: 1751 cm−1(-C=O), 1153 cm−1 (C-O-Cether and C(=O)-O-Cester), IsoG: Yield: 90%, hygroscopic solid. FTIR: 1751 cm−1(-C=O), 1159 cm−1 (C-O-Cether and C(=O)-O-Cester).

Synthesis of dicarbonyl dichlorides of monomers

A mixture of dicarboxylic acid (60 mmol) suspended in dry chloroform (100 mL), oxalyl chloride (19 g, 150 mmol) and a drop of DMF was refluxed for 14 h. Upon reaction completion, the solvent and excess oxalyl chloride were distilled off under reduced pressure, the product obtained was used without any further purification.

PEAs synthesis

The polymers were synthesized according to a reported procedure [23]. Dicarbonyl dichloride (5 mmol, 1eqv.) was dissolved in dehydrated chloroform (15 mL), the solution was added drop-wise over a vigorously stirred, ice cold aqueous solution (0–5 °C) of the di-p-toluenesulfonic acid salts of O,O′-bis-(α-aminoacyl)-isosorbide (5 mmol, 1 eqv.) and potassium carbonate as a base (20 mmol, 4 eqv.) in 15 mL of water. The reaction mixture was stirred at a high speed in the ice bath for 5 min then at room temperature for 2 h. The resulting polymer was filtered, washed extensively with water and dried in vacuo at 60 °C. The crude polymers were purified by precipitation from DMF solution in large amount of methanol.

Results and discussion

Isosorbide synthesis and characterization

Starting from polysaccharides, the enzymatic hydrolysis of the glycosidic bonds produces D-glucose. The hydrogenation of glucose gives D-sorbitol, which can undergo two acidic dehydrations to produce isosorbide (Scheme 1).

In this work, isosorbide was synthesized from D-sorbitol in our laboratories and its structure was studied by FTIR, 1H and 13C Nuclear Magnetic Resonance (NMR) and Distortionless Enhancement by Polarization Transfer spectroscopy (DEPT 135). Isosorbide structure was also characterized using the two-dimensional NMR experiments, COrrelation SpectroscopY (COSY) and Heteronuclear Multiple-Quantum Correlation (HMQC); COSY experiment was utilized for observing useful proton-proton correlation information, while HMQC experiment was performed to provide carbon-proton one bond correlation.

The NMR data of the synthesized isosorbide were consistent with those obtained for the commercially available compound (Sigma-Aldrich, CAS Number: 652–67-5), the 13C NMR spectra of the synthesized isosorbide show six signals at 71.3, 72.7, 75.7, 76.1, 81.7 and 88.1 ppm assigned to the six different carbons in bicyclic diol structure (Fig. 2, b). The DEPT 135 experiment confirmed the presence of two non-equivalent methylene carbons (C6 (71.3 ppm) and C1 (75.7 ppm)), and four non-equivalent tertiary carbons (C5 (72.7 ppm), C2 (76.1 ppm), C4 (81.7 ppm) and C3(88.1 ppm)) (Fig. 2, c), these values were found to be in agreement with the values reported by Goodwin and coworkers [34]. From 1H NMR spectrum, ten protons were observed in the range from 3.21 to 5.02 ppm (Fig. 2, a).

Due to the complexity of isosorbide proton signals, HMQC was performed to correlate each proton in the bicyclic diol with the carbon atom it is directly bonded to, the hydroxyl protons at C2 (OH2) and C5 (OH5) are observed as doublets at 4.60 and 5.03 ppm. The HMQC spectrum show a correlation between C6 and the triplet proton signal at 3.21 ppm, C6 and the multiplet proton signal at 3.68 ppm, C1 and the multiplet signal at 3.68 ppm. C2 and the singlet proton signal at 3.99 ppm, C5 and the quintet proton signal at 4.04 ppm, C3 and the doublet proton signal at 4.18 ppm and between C4 and the triplet proton signal at 4.31 ppm (Fig. 2, d). COSY experiment was conducted to distinguish between the two hydroxyl protons at C2 and C5 positions. As shown in the COSY spectrum, the peak centered at 4.60 ppm is coupled to the peak centered at 4.04 ppm (H5), whereas the peak at 5.03 ppm is coupled to the peak at 3.99 ppm (H2), thus confirming the assignment of the peak at 4.60 to hydroxyl proton at OH5 and the peak at 5.03 to hydroxyl proton at OH2 (Fig. 2, e). Moreover, the COSY experiment revealed the presence of proton-proton correlation (H/H) between H3/H4 and H4/H5 and the absence of correlation between the protons H2/H3, H2/H4, this result indicates the presence of the protons H3 and H4 and H5 in the same configuration (exo-position), while H2 proton occupies a different configuration (endo-position).

Di-p-toluenesulfonic acid salts of O,O′-bis-(α-aminoacyl)-isosorbide monomers synthesis and characterization

Four different di-p-toluenesulfonic acid salts of O,O′-bis-(α-aminoacyl)-isosorbide monomers were successfully synthesized by condensing isosorbide with various α-amino acids (L-phenylalanine, glycine, L-alanine and L-valine) according to Scheme 2. The condensation reaction was conducted in a nonpolar solvent (toluene) in the presence of p-toluenesulfonic acid monohydrate (PTSA). PTSA serves as both a reaction catalyst and an amino group protector by preventing the amino-ester side reaction and by giving the monomers higher stability throughout reaction work up. The yields of the di-p-toluenesulfonic acid salt monomers were relatively high ranging from 71 to 90%.

The FTIR spectra of the synthesized monomers showed strong absorption bands due to the C=O stretching vibration of the ester group in the range 1747–1751 cm−1. The characteristic absorption bands observed from 1155 to 1163 cm−1 were assigned to the stretching vibration of ether (C-O-C) and ester (C(=O)-O-C) groups.

NMR spectroscopy

1H NMR spectra

Proton spectra of the synthesized monomers confirmed their proposed structures. A singlet broad peak appeared from 8.27 to 8.45 ppm was assigned to the protons of the quaternary amine group (-NH3+), a pair of doublets appeared at 7.08 and 7.46 ppm were assigned to protons of the aromatic ring of p-toluene sulfonic acid salt. The signal for the protons of the methyl group attached to the aromatic ring (Ar-CH3) appeared as a singlet at 2.25–2.30 ppm. The signals corresponding to isosorbide protons underwent shifts to down or upfield depending on the α-amino acid moiety. The signals for the proton attached to the central carbon in α-amino acid moiety (the chiral or methylene carbons neighboring the ester group), appeared in part of the monomers as two closely shifted signals due to bonding to the non-equivalent hydroxyl groups of isosorbide.

13C NMR spectra

Structures of the monomers were also confirmed by 13C NMR, 6 peaks were observed in the range 70.5 to 85.8 ppm that were assigned to isosorbide carbons, the aromatic carbons of p-toluenesulfonic acid salt were observed at 138.1–138.8, 128.6, 125.5–125.9 and 145.2–146.1 ppm. The non-symmetrical structure of isosorbide had an evident effect on the chemical shifts of the neighboring atoms, for example; two ester signals were observed in each monomer due to the non-equivalent bonding with the endo and exo-positions of isosorbide, this effect was also observed on the long-range bonding but with a lower intensity. Because of this non-equivalent bonding, the peak due to the chiral or methylene carbon of the amino acid units linked to the ester carbon were displayed as two closely shifted peaks in all p-toluenesulfonic acid salts in the range 39.9 to 57.8 ppm.

The complete assignment of 1H and 13C chemical shifts of the di-p-toluenesulfonic acid salts of O,O′-bis-(α-aminoacyl)-isosorbide monomers is presented in Table 1. The 1H and 13C NMR spectra of the monomer IsoP are presented in Fig. 3 a and b, respectively.

PEAs synthesis and characterization

Twelve novel PEAs based on the renewable diol isosorbide were prepared via interfacial polymerization from the reaction of diester-diamines derived from isosorbide and α-amino acids with different dicarbonyl dichlorides (Scheme 3).

In this method, the polymerization reaction takes place at the interface between aqueous layer where the diamine is dissolved and the organic layer (chloroform) where the acyl chloride is dissolved. The presence of an inorganic base in the aqueous layer plays two important roles, the first is to deprotonate the ammonium group and the second is to neutralize the acid produced from the amine-acyl chloride reaction. Efficient stirring is another important requirement for obtaining long polymer chains, it guarantees the dispersion of the two layers, interface refreshment and increases the surface available for the reaction. Moreover, the vigorous stirring facilitates the formation of fine particles of the polymer with reduced reactants and solvents encapsulation inside the polymer chain.

PEAs FTIR

Generally, the FTIR spectra of the PEAs show the characteristic absorption bands of the N-H stretching vibration (amide A) in the range 3320–3267 cm−1; overtone of N-H bending of the amide group (amide B) in the range 3070–3029 cm−1; stretching vibration for the amide carbonyl group (amide I) in the range 1651–1629 cm−1; N-H bending vibration (amide II) in the range 1536–1506 cm−1 and stretching vibration ester carbonyl group in the range 1745–1736 cm−1 [13, 35,36,37,38]. Table 2 presents the total assignment of the main IR bands and yields of the produced PEAs while Fig. 4 shows the FTIR spectrum of IsoVF polymer as a representative of PEA.

PEAs solubility test

The solubility’s of the PEA polymers were tested at a concentration of 3 to 5% (w/v) at room temperature in different organic solvents. All of the polymers were found to be soluble in DMF, DMSO and NMP but insoluble in methanol, THF and ethyl acetate. All of the PEAs synthesized were insoluble in acetone except the ones containing cis/trans-1,4-cyclohexanedicarboxylic unit which were found only partially soluble in acetone.

PEAs NMR

Chemical structures of the isosorbide, α-amino acids based PEAs were elucidated and confirmed by 1H and 13C NMR spectroscopy.

1H NMR spectra

In the 1HNMR spectra the disappearance of the p-toluenesulfonic salt signals and the appearance of new signals were observed indicating new amide bond formation. The fumaryl unit protons (-CH=CHCONH-) appeared as singlet peak at 6.82–7.01 ppm. The protons of the tertiary carbon of the cis/trans-1,4-cyclohexanedicarbonyl unit ((-CH2)2CHCONH-) appeared at 2.07–2.23 ppm, while the protons of the secondary carbon of the cis/trans-1,4-cyclohexanedicarbonyl unit ((-CH2)2CHCONH-) appeared at 1.26–1.41 and 1.63–1.72 ppm. The aromatic protons of the terephthaloyl unit appeared in the region at 7.83–7.98 ppm.

13CNMR spectra

The chemical structures of the polymers were also confirmed by 13C NMR spectroscopy. Various isosorbide carbon peaks were observed in the range from 70.6 to 85.9 ppm. The effect of non-symmetrical structure of isosorbide was observed on the chemical shifts of isosorbide neighboring atoms, two pairs of carbonyl signals appeared that were assigned to the non-equivalent ester and amide carbonyl carbons, the fumarate unit carbons (-NHOC-CH=CH-CONH-) were observed as two peaks in the range from 132.1 to 133.9 ppm. The signals of the tertiary carbon of the aromatic rings of the terephthalate unit were observed at 127.9 ppm, while the aromatic quaternary carbons of the same unit was observed as a pair of peaks in the chemical shift range from 136.6 to 137.0 ppm. The signals of the tertiary carbon of the cis/trans-1,4-cyclohexylene ring was observed at 43.0 to 43.5 ppm, while the signals of the secondary carbons of the same ring were observed in the range from 26.2 to 28.9 ppm. The assignment of main 1H and 13C chemical shifts of this series of PEAs are presented in Table 3, Fig. 5 shows the NMR spectra of IsoAF taken as representative PEA.

Solution viscosity measurements

Many factors affect the molecular weights of the polymers produced via interfacial polymerization, such as the dicarbonyl dichloride flexibility and conformation, the partition coefficient of the diamine monomers between aqueous and organic phases, the solubility of low molecular weight polymers, the swelling capacity of the polymers and the diffusion coefficients of the diamine monomers [39, 40]. The PEAs of this series had inherent viscosities in the range from 0.20 to 0.47 dL/g (Table 2) indicating formation of fair molecular weight polymers. Comparing the inherent viscosities, no obvious trend can be concluded, except that the L-valine-containing PEAs showed considerably good inherent viscosities. This may be due to the balance between moderate hydrophobic characters and the bulkiness of the isopropyl pendent group that might act as spacer between the polymer chains which allows the diffusion of the reactants to the reaction zone during the polymerization process.

Thermal stability

Thermogravimetric scans of the isosorbide, α-amino acids containing PEAs was studied by TGA and indicated that the majority of these polymers undergo two stage mass-losses in the temperature range between 25 and 600 °C (Fig. 6, a-d). The two-stage mass-losses can be observed under dry nitrogen atmosphere, all of the polymers were stable up to approximately 200 °C, 5% of the polymers mass (Td5%) decomposed in the temperature range 250 to 340 °C. The observed two stages of decomposition is most probably attributed to breaking of first ester and then amide linkages in the polymer backbone [41]. Figure 6 summarizes the initial thermal decomposition temperature Td1% and the Td5%, Td10%, Td20%, Td50% decomposition temperatures, which correspond to temperatures at which 1, 5, 10, 20 and 50% loss of weight of the corresponding polymer. Furthermore, Table 4 summarizes the residual mass percent remaining after the PEAs samples were heatedto 600 °C.

Thermal transition

The Tg of the polymers were measured by DSC and reported in Table 4. The DSC data showed that the PEAs synthesized exhibit rather high Tg values (115.9–182.6 °C). The introduction of the stiffening isosorbide unit in the structure of this class of polymers has dramatically increased the Tg values of the PEAs compared to their α,ω-alkylene diols analogous polymers. Table 5 gives a comparison of the Tg values of reported PEAs based on α,ω-alkylene diols and the isosorbide-based PEAs synthesized in this work. The presence of a bulky pendant group in the α-amino acid unit is known to reduce the crystallinity of this class of PEAs by increasing the conformational or steric constraints, these bulky groups are likely to function as spacer between the polymer chains that inhibits the efficient chain packing needed for crystallization.

Form the DSC thermograms; it was observed that all the PEAs produced in this series were amorphous except for some glycine containing PEAs. Figure 7 shows the DSC thermograms obtained for IsoGT and IsoVT, in Fig. 7 IsoGT showed a simple melting behavior, this semicrystalline characteristic was not observed in its analogue polymers (i.e. IsoVT) due to the presence of the spacer pendent side group that works effectively as a crystallinity inhibitor. Moreover, the presence of the rigid aromatic, cyclohexyl and the unsaturated groups in the polymers backbone had a significant influence on the Tg values, these units make the chain-segment movement more difficult and decrease polymer flexibility, which is observed as an increase in the Tg values.

Hydrolytic degradation of PEAs

Studies related to PEAs synthesis and hydrolytic degradable products showed that this class of polymers degrade by ester group cleavage [35, 36, 42, 43], while the stiff amide group stays intact [44]. In this work, the hydrolytic degradation of the newly synthesized PEAs was studied in both alkaline solution (pH 9) and under stimulated physiological conditions (pH 7.4) in phosphate buffer saline (PBS) solution at 37 °C. Figures 8 and 9 show the weight loss patterns of the synthesized PEAs under different test conditions, degradation at pH 7.4 mimics physiological conditions while pH 9 presents accelerated degradation condition that provides a prediction of the long-term degradation process. As shown in Figs. 8 and 9 the harsher degradation conditions (pH 9) resulted in faster degradation rates in general, this might be due to the higher concentration of hydroxyl ions that leads to the formation of smaller, water-soluble oligomers as a degradation products. Moreover, the results obtained showed higher weight loss rates for glycine and L-alanine based PEAs under both conditions. Apparently, the pendent group of the α-amino acids plays a critical role in the degradation process; the hydrophilic pendent group allows better penetration of the media, which enhances the degradation process. Regarding the influence of the central unit, the PEAs derived from terephthalate unit showed the least weight losses compared to cyclohexane and fumarate-containing PEAs. The presence of the rigid aromatic terephthalate unit gives well-packed polymer chains and due to the hydrophobic character of this unit, that prevents the degrading media from efficient penetrate into the polymer bulk, thus, slowing the hydrolytic degradation process. Overall, the hydrolytic degradation of the novel isosorbide-α-amino acids based PEAs was tested, the material showed a weight loss range from 2 to 60% after 27 days of immersion in the degradation medium at pH 7.4. The results obtained indicate it is possible to tune hydrophilic / hydrophobic properties of this class of PEAs, with the aim of obtaining materials with different hydrolysis rates for different applications.

Conclusion

Twelve new PEAs derived from isosorbide and the amino acids L-phenylalanine, L-alanine, L-valine and glycine were successfully prepared by interfacial polymerization via a two-step methodology. The PEAs synthesized showed two-stage mass-loss under dry nitrogen atmosphere, were stable up to approximately 200 °C and 5% of the PEAs mass (Td5%) decomposed in the temperature range 250 to 340 °C and had Tg ranging from 115.9 to 182.6 °C. The hydrolytic degradation study preformed for this series indicated that the polymers containing hydrophilic pendent group allows better penetration of the media, which enhances the degradation process leading to faster hydrolysis rates. Thus, tuning hydrophilic/hydrophobic properties by structural manipulation in either chain backbone or pendant groups results in materials with varied degradation rates.

References

Nair LS, Laurencin CT (2007) Biodegradable polymers as biomaterials. Prog Polym Sci 32:762–798. https://doi.org/10.1016/j.progpolymsci.2007.05.017

Okada M (2002) Chemical syntheses of biodegradable polymers. Prog Polym Sci 27:87–133. https://doi.org/10.1016/S0079-6700(01)00039-9

Shivam P (2016) Recent developments on biodegradable polymers and their future trends. Int Res J Sci Eng 4:17–26

Vroman I, Tighzert L, Vroman I, Tighzert L (2009) Biodegradable Polymers. Materials (Basel) 2:307–344. https://doi.org/10.3390/ma2020307

Tian H, Tang Z, Zhuang X, Chen X, Jing X (2012) Biodegradable synthetic polymers: preparation, functionalization and biomedical application. Prog Polym Sci 37:237–280. https://doi.org/10.1016/j.progpolymsci.2011.06.004

Lasprilla AJR, Martinez GAR, Lunelli BH, Jardini AL, Filho RM (2012) Poly-lactic acid synthesis for application in biomedical devices — a review. Biotechnol Adv 30:321–328. https://doi.org/10.1016/j.biotechadv.2011.06.019

Malikmammadov E, Tanir TE, Kiziltay A, Hasirci V, Hasirci N (2018) PCL and PCL-based materials in biomedical applications. J Biomater Sci Polym Ed 29:863–893. https://doi.org/10.1080/09205063.2017.1394711

Fonseca AC, Gil MH, Simões PN (2014) Biodegradable poly(ester amide)s - a remarkable opportunity for the biomedical area: review on the synthesis, characterization and applications. Prog Polym Sci 39:1291–1311. https://doi.org/10.1016/j.progpolymsci.2013.11.007

Rodriguez-Galan A, Franco L, Puiggali J (2011) Degradable poly(ester amide)s for biomedical applications. Polymers (Basel) 3:65–99. https://doi.org/10.3390/polym3010065

Díaz A, Katsarava R, Puiggalí J, Díaz A, Katsarava R, Puiggalí J (2014) Synthesis, properties and applications of biodegradable polymers derived from diols and dicarboxylic acids: from polyesters to poly(ester amide)s. Int J Mol Sci 15:7064–7123. https://doi.org/10.3390/ijms15057064

Winnacker M, Rieger B (2016) Poly(ester amide)s: recent insights into synthesis, stability and biomedical applications. Polym Chem 7:7039–7046. https://doi.org/10.1039/C6PY01783E

Rodríguez-Galán A, Franco L, Puiggalí J (2011) Biodegradable poly(ester amide)s: synthesis and applications

Han S-I, Kim BS, Kang SW, Shirai H, Im SS (2003) Cellular interactions and degradation of aliphatic poly(ester amide)s derived from glycine and/or 4-amino butyric acid. Biomaterials 24:3453–3462. https://doi.org/10.1016/S0142-9612(03)00223-0

Sun H, Cheng R, Deng C, Meng F, Dias AA, Hendriks M, Feijen J, Zhong Z (2015) Enzymatically and reductively degradable α-amino acid-based poly(ester amide)s: synthesis, cell compatibility, and intracellular anticancer drug delivery. Biomacromolecules 16:597–605. https://doi.org/10.1021/bm501652d

Tsitlanadze G, Kviria T, Katsarava R (2004) In vitro enzymatic biodegradation of amino acid based poly(ester amide )s biomaterials. J Mater Sci Mater Med 15:185–190

Ghosal K, Latha MS, Thomas S (2014) Poly(ester amides) (PEAs) – scaffold for tissue engineering applications. Eur Polym J 60:58–68. https://doi.org/10.1016/J.EURPOLYMJ.2014.08.006

Asín L, Armelin E, Montané J, Rodríguez-Galán A, Puiggalí J (2001) Sequential poly(ester amide)s based on glycine, diols, and dicarboxylic acids: thermal polyesterification versus interfacial polyamidation. Characterization of polymers containing stiff units. J Polym Sci Part A Polym Chem 39:4283–4293. https://doi.org/10.1002/pola.10082

Katsarava R, Beridze V, Arabuli N, Kharadze D, Chu C-C, Won CY (1999) Amino acid-based bioanalogous polymers. Synthesis, and study of regular poly(ester amide)s based on bis(α-amino acid) α,ω-alkylene diesters, and aliphatic dicarboxylic acids. J Polym Sci Part A Polym Chem 37:391–407. https://doi.org/10.1002/(SICI)1099-0518(19990215)37:4<391::AID-POLA3>3.0.CO;2-E

Gomurashvili Z, Kricheldorf HR, Katsarava R (2000) Amino acid based bioanalogous polymers. Synthesis and study of new poly(ester amide)s composed of hydrophobic Α-amino acids and dianhydrohexitoles. J Macromol Sci Part A 37:215–227. https://doi.org/10.1081/MA-100101089

Liu C, Jia W, Qian Z, Huang M, Gu Y, Chao G, Gou M, Gong C, Deng H, Lei K, Huang A, Tu M (2007) In vitro degradation behavior of polyesteramide copolymer fiber based on 6-aminocaproic acid, adipic acid, and 1,6-hexane diol. J Polym Res 14:31–37. https://doi.org/10.1007/s10965-006-9077-3

Okada M, Yamada M, Yokoe M, Aoi K (2001) Biodegradable polymers based on renewable resources. V. Synthesis and biodegradation behavior of poly(ester amide)s composed of 1,4:3,6-dianhydro-D-glucitol, α-amino acid, and aliphatic dicarboxylic acid units. J Appl Polym Sci 81:2721–2734. https://doi.org/10.1002/app.1718

Nagata M (1999) Synthesis and enzymatic degradation of poly(ester-amide) stereocopolymers derived from alanine. Macromol Chem Phys 200:2059–2064. https://doi.org/10.1002/(sici)1521-3935(19990901)200:9<2059::aid-macp2059>3.0.co;2-n

Paredes N, Rodriguez-Galán A, Puiggalí J (1998) Synthesis and characterization of a family of biodegradable poly(ester amide)s derived from glycine. J Polym Sci Part A Polym Chem 36:1271–1282. https://doi.org/10.1002/(SICI)1099-0518(199806)36:8<1271::AID-POLA10>3.0.CO;2-3

Knight DK, Gillies ER, Mequanint K (2011) Strategies in functional poly(ester amide) syntheses to study human coronary artery smooth muscle cell interactions. Biomacromolecules 12:2475–2487. https://doi.org/10.1021/bm200149k

Del Valle LJ, Roca D, Franco L, Puiggalí J, Rodríguez-Galán A (2011) Preparation and release study of ibuprofen-loaded porous matrices of a biodegradable poly(ester amide) derived from L-alanine units. J Appl Polym Sci 122:1953–1967. https://doi.org/10.1002/app.34017

Soleimani A, Drappel S, Carlini R, Goredema A, Gillies ER (2014) Structure-property relationships for a series of poly(ester amide)s containing amino acids. Ind Eng Chem Res 53:1452–1460. https://doi.org/10.1021/ie4035219

Karimi P, Rizkalla AS, Mequanint K (2010) Versatile biodegradable poly(ester amide)s derived from α-amino acids for vascular tissue engineering. Materials (Basel) 3:2346–2368. https://doi.org/10.3390/ma3042346

Paredes N, Rodriguez-Galán A, Puiggalí J, Peraire C (1998) Studies on the biodegradation and biocompatibility of a new poly(ester amide) derived from L-alanine. J Appl Polym Sci 69:1537–1549. https://doi.org/10.1002/(SICI)1097-4628(19980822)69:8<1537::AID-APP8>3.0.CO;2-D

Fonseca AC, Coelho JFJ, Valente JFA, Correia TR, Correia IJ, Gil MH, Simões PN (2013) Poly(ester amide)s based on (L)-lactic acid oligomers and α-amino acids: influence of the α-amino acid side chain in the poly(ester amide)s properties. J Biomater Sci Polym Ed 24:1391–1409. https://doi.org/10.1080/09205063.2012.762293

Spiridon I, Popa VI (2008) Hemicelluloses: major sources, properties and applications

Fenouillot F, Rousseau A, Colomines G, Saint-Loup R, Pascault JP (2010) Polymers from renewable 1,4:3,6-dianhydrohexitols (isosorbide, isomannide and isoidide): a review. Prog Polym Sci 35:578–622. https://doi.org/10.1016/j.progpolymsci.2009.10.001

Celli A, Gandini A, Gioia C, Lacerda TM, Vannini M, Colonna M (2016) Polymers from pristine and modified natural monomers. Chem fuels from bio-based build blocks 275–314. https://doi.org/10.1002/9783527698202.ch12

Jung YJ, Kim YS, Ryu H (2012) Methods for distilling and manufacturing anhydrosugar alcohols. WO 2012081785:A1

Goodwin JC, Hodge JE, Weisleder D (1980) Preparation of bicyclic hexitol anhydrides by using acidic cation-exchange resin in a binary solvent. p13C-N.m.r. spectroscopy confirms configurational inversion in chloride displacement of methanesulfonate in isomannide and isosorbide derivatives. Carbohydr Res 79:133–141. https://doi.org/10.1016/S0008-6215(00)85138-1

Armelin E, Franco L, Rodríguez-Galán A, Puiggalí J (2002) Study on the degradability of poly(ester amide)s related to nylons and polyesters 6,10 or 12,10. Macromol Chem Phys 203:48–58. https://doi.org/10.1002/1521-3935(20020101)203:1<48::AID-MACP48>3.0.CO;2-E

Fonseca AC, Serra AC, Coelho JFJ, Gil MH, Simões PN (2013) Novel poly(ester amide)s from glycine and L-lactic acid by an easy and cost-effective synthesis. Polym Int 62:736–743. https://doi.org/10.1002/pi.4356

Kaczmarczyk B (1998) FTi.r. study of hydrogen bonds in aliphatic polyesteramides. Polymer (Guildf) 39:5853–5860. https://doi.org/10.1016/S0032-3861(98)00024-X

Kaczmarczyk B, Sek D (1995) Hydrogen bonds in poly(ester amide)s and their model compounds. Polymer (Guildf) 36:5019–5025. https://doi.org/10.1016/0032-3861(96)81631-4

Dhumal SS, Suresh AK (2010) Understanding interfacial polycondensation: experiments on polyurea system and comparison with theory. Polymer (Guildf) 51:1176–1190. https://doi.org/10.1016/j.polymer.2010.01.004

Dhumal SS, Wagh SJ, Suresh AK (2008) Interfacial polycondensation - modeling of kinetics and film properties. J Memb Sci 325:758–771

Zuo J, Li S, Bouzidi L, Narine SS (2011) Thermoplastic polyester amides derived from oleic acid. Polymer (Guildf) 52:4503–4516. https://doi.org/10.1016/j.polymer.2011.08.002

Armelin E, Paracuellos N, Rodríguez-Galán A, Puiggalí J (2001) Study on the degradability of poly(ester amide)s derived from the α-amino acids glycine, and L-alanine containing a variable amide/ester ratio. Polymer (Guildf) 42:7923–7932. https://doi.org/10.1016/S0032-3861(01)00315-9

Helder J, Dijkstra PJ, Feijen J (1990) In vitro degradation of glycine/DL-lactic acid copolymers. J Biomed Mater Res 24:1005–1020. https://doi.org/10.1002/jbm.820240804

Zhang H, He Y, Li S, Liu X (2005) Synthesis and hydrolytic degradation of aliphatic polyesteramides branched by glycerol. Polym Degrad Stab 88:309–316. https://doi.org/10.1016/j.polymdegradstab.2004.11.005

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Al-Tayyem, B.H., Sweileh, B.A. Synthesis, characterization and hydrolytic degradation of novel biodegradable poly(ester amide)s derived from Isosorbide and α-amino acids. J Polym Res 27, 120 (2020). https://doi.org/10.1007/s10965-020-2021-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-020-2021-0