Abstract

Sulfonamide-containing linear copolymers were synthesized via copolymerization of N-(4-methacrylamido)-N′-(4,6-dimethylpyrimidin-2-yl) benzene-1-sulfonamide (SAM) and N,N′-dimethylacrylamide (DMAAm) via free-radical polymerization at room temperature using redox initiators. The redox-initiated polymerization could undergo nearly complete reaction in which the copolymer composition was almost the same as the feeding monomer ratio. These linear copolymers could be dissolved in water and displayed pH-sensitive properties around the physiological pH value of human body with a very sharp transition window less than 0.1 pH unit. Moreover, by introducing N-methyloyl acrylamide (NMA) monomer into the reaction system, the resulting copolymers could become crosslinked hydrogels when subjected to post thermo-curing through the NMA units. The crosslinking density and pH-sensitivity could be manipulated by changing the curing time and temperature. Therefore, swelling ratio and gel fraction of hydrogels could be accurately tailored. The pH-sensitive windows of these hydrogels were found to maintain in between 6.80 to 7.40, which implied that these hydrogels would be a suitable candidate for biomedical materials.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Hydrogels are basically three-dimensional, water-swollen materials formed by chemical or physical crosslinking of hydrophilic polymers [1, 2]. They are capable of retaining large amount of water and staying as insoluble gelatinous mass due to their crosslinked network [2]. Owing to their high water-content and good biocompatibility, hydrogels are the ideal candidate for biomedical applications which can mimic the in vivo microenvironment for tissue engineering, cell encapsulation, and drug delivery [1,2,3,4,5,6,7,8]. Particularly, hydrogels that can undergo structural changes such as swelling and shrinking in response to the environmental stimuli are termed smart hydrogels which are generally synthesized by introducing specific functional monomers. The environmental stimuli include physical stimuli such as temperature, electric field, light, and magnetic field; and chemical stimuli, for examples, pH, ionic strength and molecular events [7,8,9,10,11,12,13,14,15,16]. Among them, pH-sensitive hydrogels have attracted a great deal of attention in both scientific and technological aspects [17,18,19,20,21,22]. Conventional pH-sensitive hydrogels have been studied for decades, which are mostly synthesized from weak acidic or basic monomers. They can be ionized under some certain pH range depending on their pKa values, thus forming polyelectrolyte polymers. Lee et al. [17] showed that the structures of various block copolymers which could form polyelectrolyte micelles in dilute aqueous solution were affected by pH value and ionic strength. By changing the pH value of solution, the authors were able to adjust the fractional charge on the block copolymers; while increasing the fractional charge increased the swelling extent of the copolymer micelles due to electrostatic repulsion. Moreover, the swelling extent and pH-sensitivity of hydrogels can be adjusted by copolymerization of the acidic or basic monomer with neutral co-monomers, such as 2-hydroxyethyl methacrylate [18], methyl methacrylate [19] and maleic anhydride [20].

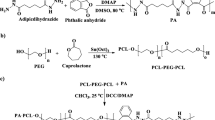

It is well known that the physiological pH condition always remains at about 7.4 owing to the buffer capacity of tissue fluid and blood. Though there might be some fluctuations on the illness sites, the fluctuations are generally small within ±1.0 pH unit. However, it was found that the pH values in human tumors were on an average approximately 0.4 unit lower than those in normal tissues as discussed in a review article by Wike-Hooley et al. [23]. Lardner [24] revealed that the extracellular pH (pHe) values of solid tumors were in the range of 6.5–6.8, which would become the main difficulty for materials designing to tumor therapies. This is because conventional pH-sensitive polymers have pKa values typically ranging from 4 to 6 or higher than 8. Moreover, those conventional pH-sensitive polymers generally have a broad pH-sensitivity window. Thus, it is necessary to investigate smart hydrogels which can response in high sensitivity and accuracy to tumor pHe within such a narrow window of pH values for direct tumor targeting. It has been found that several sulfonamide-containing polymers are able to exhibit pH-sensitivity close to physiological pH values with a narrow responsive window [25,26,27,28,29,30]. Bae et al. [25,26,27,28,29] were the first group to synthesize various kinds of sulfonamide-based monomers with different pKa values ranging from 6.10 to 8.57 by changing the substituted R group at the sulfonamide. The sulfonamide monomer is generally the derivative of para-aminobenzene sulfonamide, as shown in Fig. 1, in which the hydrogen atom on the amide nitrogen (N1) can be ionized to proton in the solution. Owing to the electronegativity of oxygen atoms of the sulfonyl group, the electron density of sulfur atom is insufficient, which draws the electrons from the nitrogen atom (N1-H) and thus resulting the ionization. By introducing sulfonamide group into water-soluble polymers, pH-sensitive polymers which undergo the structure changes with narrow pH range around physiological condition can be synthesized for biomedical applications. These sulfonamide-based polymers would be ionized and become water soluble when the pH value is higher than their respective pKa. On the contrary, deionized or neutral sulfonamide groups have a strong π-π interaction between benzene rings as well as hydrogen bonding among them, leading to the aggregation and precipitation of the polymers. Therefore, sulfonamide-based polymers with tailored structure can have controlled swelling and phase-transition properties under desired pH range. For example, Park and Bae [26] synthesized pH-sensitive polymers by copolymerization of the sulfonamide monomer derived from sulfamethazine (SMZ) with N,N′-dimethylacrylamide (DMAAm) in an organic solvent (DMSO) at 65 °C; and by further introducing a chemically crosslinking agent N,N′-methylene bis(acrylamide) (MBA) during the reaction, they were able to synthesize crosslinked hydrogels that exhibited a relatively sharp transition in swelling around physiological pH value. Shim et al. [30] synthesized a pH- and thermo-sensitive block copolymer by adding pH-sensitive sulfamethazine oligomers to either end of a thermo-sensitive poly(ε-caprolactone-co-lactide)–poly(ethylene glycol)–poly(ε-caprolactone-co-lactide) block copolymer and studied its biodegradable and biocompatible properties. The resulting pH- and thermo-sensitive block copolymer solution did not form a gel at high pH (pH 8.0), but did form a stable gel under physiological conditions (pH 7.4 and 37 °C).

The focus of the present work was not only to prepare sulfonamide-based copolymer hydrogels in which their pH-sensitivity was in a narrow window within 0.2 to 0.4 pH units, but crosslinking density of these hydrogels can be adjusted by controlling the post thermo-curing process owing to the addition of N-methyloyl acrylamide (NMA) co-monomer. The NMA was added with both sulfonamide monomer (SAM) and N,N′-dimethylacrylamide (DMAAm) monomer, and underwent free-radical copolymerization to first prepare linear copolymers. To prevent the pre-mature crosslinking reaction, a redox system was applied which could initiate polymerization at room temperature, instead of using azobisisobutyronitrile (AIBN) in which the initiation reaction generally takes place at high temperatures as adopted in the previous work [25, 26]. Subsequently, the produced linear copolymers were converted into three-dimensional network gels through the post-curing process at moderate temperatures by reaction of NMA units on different copolymer chains. Degree of gelation and also swelling behavior could be adjusted by changing post-cure temperature and curing time. Structures, swelling properties and morphology of the copolymer hydrogels under various aqueous solutions with different pH values were all characterized in this study. The pH-sensitive properties within the pH range of physiological environment of human body (pH 6.8–7.4) and the narrow pH-sensitivity window can provide versatile tools in biomedical applications.

Experimental

Materials

Methacryloyl chloride, 4-amino-N-(4,6-dimethylpyrimidin-2-yl) benzene-1-sulfonamide (also named sulfamethazine, SMZ), N,N′-dimethylacrylamide (DMAAm), and N-methyloyl acrylamide (NMA) were purchased from Sigma-Aldrich and used as received. Potassium persulfate (KPS) and sodium metabisulfite (SMBS) were also purchased from Sigma-Aldrich and employed as redox initiators. All other chemicals and solvents were purchased from Sigma-Aldrich or Acros and used as received except otherwise noted.

Synthesis of sulfonamide monomer (SAM)

Sulfonamide monomer of N-(4-methacrylamido)-N′-(4,6-dimethylpyrimidin-2-yl) benzene-1-sulfonamide (SAM) was synthesized following the protocol proposed by Park and Bae [26]. In short, sulfamethazine (2.78 g, 0.010 mol) was first dissolved in 40 mL of water/acetone (1/1) containing sodium hydroxide. Equimolar amount of methacryloyl chloride was then added dropwise to the solution with constant stirring at 5 °C. After 4 h of reaction, the precipitate was collected by filtration and washed with distilled water repeatedly for several times. Finally, fine white powder of SAM was obtained after drying in vacuo at room temperature for 48 h. 1H NMR (ppm) of SAM: δ = 1.92 (s, 3H, H2C=C-CH3), 2.24 (s, 6H, pyrimidine-CH3), 5.55 (s, 1H, H-CH=C<), 5.82 (s, 1H, H-CH=C<), 6.73 (s, 1H, pyrimidine-H), 7.9 (q, 4H, phenylene-H), 10.08 (s, 1H, -SO2NH-, -CONH-), FTIR (cm−1): 3389 (amide N-H stretching), 1675 (amide C=O stretching), 1624 (C=C stretching), 1592, 1510 (phenylene ring), 1320 and 1160 cm−1 (O=S=O symmetric and asymmetric vibration).

Synthesis of pH-sensitive poly(SAM-DMAAm) copolymers

Two random copolymers of poly(SAM-DMAAm) were synthesized by free-radical polymerization at room temperature using redox-initiators. SAM and DMAAm monomers with molar ratios of 2/8 and 3/7 were fed into the reactor to produce two poly(SAM-DMAAm) copolymers which were denoted as PS2D8 and PS3D7, respectively. The recipe for the synthesis of copolymers is shown in Table 1. First, monomers and KPS were dissolved in DMSO, and bubbled with nitrogen gas for at least 30 min. SMBS (the redox initiators of KPS and SMBS = 2.0 mol% to total monomers) was then added to start the polymerization at room temperature for 5 h. The produced poly(SAM-DMAAm) copolymer was precipitated with the addition of excess acetone. To remove any un-reacted monomers and impurities, the precipitated copolymer was re-dissolved in aqueous NaOH solution and dialyzed (MWcut-off = 2000) against deionized water for three days. The final product was freeze-dried.

Synthesis of pH-sensitive poly(SAM-DMAAm-NMA) hydrogels

Linear copolymers of poly(SAM-DMAAm-NMA) were prepared via free-radical polymerization similar to the synthesis of poly(SAM-DMAAm) with the same recipe except the additional feeding of NMA monomer (5 mol% to the total SAM and DMAAm monomers). The produced poly(SAM-DMAAm-NMA) copolymers could become crosslinked hydrogels afterwards by thermo-induced self-crosslinking. Briefly, SAM, DMAAm, NMA and KPS were first dissolved in DMSO and the reactor was purged with nitrogen for 30 min. Under stirring, SMBS was added to start the polymerization at room temperature. The reaction proceeded for 5 h. The as-synthesized poly(SAM-DMAAm-NMA) copolymers with the feeding molar ratios of SAM/DMAAm = 2/8 and 3/7 then underwent crosslinking upon heating to obtain two hydrogels, denoted as g-PS2D8 and g-PS3D7, respectively. Two different temperatures (60 and 90 °C) and two heating periods (3 and 12 h) were applied for studying the influence of curing extent on the properties of hydrogels. The crosslinked hydrogels were then immersed in NaOH(aq) solution (pH 10.0) for 12 h and soaked in buffer solution (pH 4.0) for another 12 h for purification. After repeating the purification process for three times, the hydrogels were then washed with deionized water for several times.

Structure characterizations

Fourier transform infrared (FTIR) absorption spectra of copolymers were recorded by using Perkin-Elmer Spectrum 100 spectrometer at wavenumbers ranging from 400 to 4000 cm−1 with a resolution of 4 cm−1. Copolymer sample was mixed with KBr powder and pressed into pellet. In addition, the molar ratio of SAM to DMAAm in the as-synthesized poly(SAM-DMAAm) copolymer chain was determined from nuclear magnetic resonance (1H NMR) spectrum recorded on a Bruker AV-500 NMR spectrometer. d6-DMSO was used as the solvent. For the hydrogels, the molar composition of individual components after crosslinking was determined by 13C NMR spectra (AVIII 600 WB, Bruker).

pH-sensitivity of poly(SAM-DMAAm) copolymers

The pH-sensitive characteristics of poly(SAM-DMAAm) copolymers in aqueous solutions were determined by measuring their optical transmittance using a UV-Visible spectrophotometer (ThermoSpectronic, USA). Copolymer solutions were prepared at a concentration of 3 wt.% in buffer solutions at various pH values by adding 0.10 N HCl(aq) or 0.10 N NaOH(aq) solution. The light transmittance at 460 nm of the copolymer solutions was then measured at 37 °C. The pH-sensitive ranges of poly(SAM-DMAAm) copolymers could be determined by plotting their transmittance versus pH value.

Gel fraction and swelling ratio of poly(SAM-DMAAm-NMA) gels

The gel fraction (GF) and swelling ratio (SR) of copolymer hydrogels after crosslinking were determined by weight analysis. First, the weight of copolymer hydrogel after drying was measured and denoted as Wo. Subsequently, the hydrogel was soaked in water at 25 °C for one day and the weight of the swollen hydrogel was denoted as Ws. Finally, the hydrogel was dried by lyophilization, and its weight was measured again as Wd. Swelling ratio and gel fraction were then determined by the following equations.

Morphology of hydrogels

Hydrogel was first immersed in buffer solution (pH = 6.0 or 8.0) for 3 days and followed by lyophilization. The freeze-dried hydrogel was mounted on the copper stub by conductive adhesion tape and sputter-coated with platinum for sample preparation. The morphology of the pH-sensitive hydrogel which was pre-swollen under acidic or basic condition was then observed via scanning electron microscope (SEM, JOEL JSM-6700F, Japan).

Results and discussion

Synthesis of sulfonamide monomer (SAM) and poly(SAM-DMAAm) copolymers

The sulfonamide monomer (SAM) with reactive double bond was synthesized from sulfamethazine and methacryloyl chloride following the procedure proposed by Park and Bae [26]. The reaction was through the acid chloride of methacryloyl chloride and primary amine of sulfamethazine to form an amide linkage (C=O)NH as indicated in Fig. 1. The structure of the synthesized SAM was characterized via FTIR and 1H NMR analyses. FTIR spectrum showed that there was a strong absorption peak at 3389 cm−1 for the N-H stretching of the amide linkage. Moreover, C=C stretching of the reactive alkene and C=O stretching of the amide (amide I) were found at 1624 and 1675 cm−1, respectively. The symmetric and asymmetric vibrations of sulfone group (O=S=O) were observed at 1320 and 1160 cm−1. NMR spectrum revealed the most important characteristic absorption peaks of >C=CH2 at 5.55 and 5.82 ppm indicating the existence of active double bond in the monomer. The results of structure characterizations are therefore agreed to the literature [25]. In short, the sulfonamide monomer was successfully synthesized from sulfamethazine and methacryloyl chloride and therefore could be applied for the synthesis of pH-sensitive polymers.

The synthesized sulfonamide monomer (SAM) was then copolymerized with N,N′-dimethylacrylamide (DMAAm) by redox initiation at room temperature for the purpose of producing environmentally sensitive polymers with a specific, narrow pH-sensitive range. Two copolymers were synthesized, namely, PS2D8 and PS3D7 with the respective feeding molar ratios of SAM to DMAAm at 2/8 and 3/7. Their characteristic absorption peaks in the NMR spectra are shown in Fig. 2. The molar ratio of SAM unit to DMAAm unit on the copolymer chain was calculated by the area ratio of pyrimidine peak in the SAM unit (1H, pyrimidine-H, 6.10–6.55 ppm) to the dimethyl absorption peak of DMAAm unit (6H, -N < (CH3)2, 2.65–3.10 ppm). Though there was a slight overlap of the N-dimethyl peak with the solvent peak, the results are satisfactory as summarized in Table 2. The molar compositions of SAM to DMAAm on the PS2D8 and PS3D7 copolymer chains were close to their respective feeding molar ratios, indicating that a complete reaction could be achieved under the reaction conditions used for this study. For comparison, we also tried to use azobisisobutyronitrile (AIBN) as an initiator for the polymerization proceeded at 75 °C for 22 h, which was similar to the reaction condition adopted by Park and Bae [26]. The molar ratios of SAM/DMAAm in the corresponding PS2D8 and PS3D7 copolymers calculated from NMR spectra could only reach 2/6.28 and 3/6.01, respectively. This because in the thermo-initiated free radical polymerization in which homolytic cleavage of covalent bonds in the initiator takes place for generating radical species, the bond dissociation energy required is in the range of 125–160 kJ/mol [31]. As a result, moderate high temperatures are required for the reaction and also lower yield is obtained for the as-synthesized copolymers. On the other hand, KPS and SMBS used in this study were applied for the redox-initiated free radical polymerization. The redox-initiated polymerization is a very effective method of generating free radicals at room temperature. In addition to the almost negligible induction period, a lower energy of activation around 40–80 kJ/mol allows the reaction to be carried out at room temperature when redox initiators were used for free-radical polymerization. This lowers the possibility of side reactions and can give high-molecular-weight polymers with a high yield [31].

pH-sensitivity of poly(SAM-DMAAm) copolymers

Generally, pH-sensitive polymers are able to accept or release protons in their functional groups and undergo conformational or morphological changes in aqueous solutions in some limited range of pH value. However, sulfonamide-containing polymers exhibited their pH-sensitivity near human-body condition and could be adjusted from pH 7.4 in the body fluid to pH 6.8 in the tumor tissues via copolymerization of sulfonamide monomer with other monomers. The pH-sensitivity of the as-synthesized PS2D8 and PS3D7 copolymers were measured by light transmittance of their aqueous solutions under various pH values as shown in Fig. 3. It was found that the pH-sensitive ranges of PS2D8 and PS3D7 were 6.88–6.97 and 7.20–7.29, respectively. As the PS3D7 copolymer had a higher content of SAM, consequently it would have more π-π interaction and H-bonding among polymer chains than the PS2D8. As a result, higher pH value, i.e. more basic environment, was required to ionize the sulfonamide group and solubilize the copolymer. Moreover, the higher the amount of sulfonamide group in the copolymer chain, the narrower the pH-sensitive range of the copolymer solution. The presence of more hydrophobic DMAAm segments would have an influence on the degree of proton dissociation on the sulfonamide groups, causing a slight broaden of the pH-sensitive range. Nevertheless, both PS2D8 and PS3D7 copolymers had narrow window of pH-sensitivity (< 0.1 pH units) and their pH-sensitive ranges were close to the human-body conditions. These are beneficial for the biomedical applications of these pH-sensitive copolymers.

Characterization of pH-sensitive hydrogels

According to the aforementioned results, sulfonamide-containing copolymers are the suitable candidates for biomedical applications. For synthesizing a crosslinked hydrogel with network structure and also improving mechanical properties, a thermo-crosslinkable monomer, NMA, was introduced to the reaction system. Thus, a small amount of NMA monomer was added at the same time with the SAM and DMAAm monomers (SAM/DMAAm = 2/8 and 3/7) under the same reaction conditions as in the synthesis of poly(SAM-DMAAm). The usage of a redox system for initiation of free-radical polymerization at room temperature could prevent the early crosslinking from the NMA units. Therefore, the produced poly(SAM-DMAAm-NMA) copolymers were still linear in the structure and dissolvable in water. Yet, upon further heating of copolymers, any two N-methyloyl groups in the nearby chains were able to condense together and gave off a water molecule, forming a three-dimensional network structure as indicated in Fig. 4. Owing to their insoluble nature of the crosslinking poly(SAM-DMAAm-NMA) hydrogels, solid state 13C NMR was applied as the implement for their structure analysis. The molar ratio of SAM to DMAAm in the hydrogels was estimated by the integrated area ratio of absorption peak of pyrimidine-(CH3)2 in the SAM unit at 23.0 ppm to the peak of -N(CH3)2 in the DMAAm unit at 37.4 ppm. The results showed that the molar ratios of SAM/DMAAm estimated from 13C NMR were 2.0/7.69 and 3.0/6.82 for the g-PS2D8 and g-PS3D7 hydrogels, respectively (Table 3). They were very close to their respective feeding molar ratios, indicating the addition of a small amount of NMA monomer did not affect the reactivity of the SAM and DMAAm monomers. The addition of NMA monomer was only 5 mol% to the SAM and DMAAm monomers and served mainly as a post-crosslinking agent.

For better understanding the effect of crosslinking on the properties of hydrogels, several post-curing conditions were utilized for the hydrogel preparation. Table 4 shows the measured gel fraction (GF) of hydrogels under different crosslinking conditions. It is obvious that for both g-PS2D8 and g-PS3D7 hydrogels, the higher the curing temperature, the higher the GF was. Moreover, increasing the curing time also increased the GF value. For example, after curing at 90 °C for 12 h, the GF could reach a value of 58%.

pH-sensitivity of poly(SAM-DMAAm-NMA) hydrogels

Owing to their insoluble nature, swelling ratio of the g-PS2D8 and g-PS3D7 hydrogels with crosslinking structure was measured to monitor their pH-sensitivities, instead of light transmittance as adopted previously for the linear copolymers. The samples were immersed in aqueous solutions under pH values ranging from 6.0 to 8.0 and the weights of these swollen gels after reaching equilibrium were then measured. Figure 5 shows the swelling ratio of the hydrogels with various gel fractions as obtained under different crosslinking conditions. It can be seen that that all the hydrogels had very low swelling ratio under acidic environment, regardless of their gel fraction. As the pH value increased to a certain point, the swelling ratio of the hydrogels started to increase rapidly. This is because the sulfonamide unit in the hydrogels would be ionized and become very hydrophilic, when the pH value was higher than the threshold value. The threshold value was defined as the intersection of the linear regions at low pH- and high pH-values. The threshold value of the individual hydrogel was found to be nearly the same as that observed for the abrupt change in the light transmittance of its linear counterpart. It was originally expected that the threshold value would depend on the pKa value of sulfonamide, copolymer composition and crosslinking density. Yet, it was found that the gel fraction would not have much effect on the threshold value of the hydrogels; and thus the starting point of pH-sensitive window of g-PS2D8 and g-PS3D7 could maintain at the pH values close to the human body conditions. After the threshold value, the swelling ratio rapidly increased with increasing pH value owing to the increasing dissociation extent of sulfonamide units. Still, it could be observed from Fig. 5 that the swelling ratio was lower for the hydrogel with higher gel fraction. For example, for the g-PS2D8 at pH 7.4, the swelling ratio was 15 for the hydrogel with a gel fraction of 37%, but it decreased to a value of 10.5 when the gel fraction was 52%. In other words, the hydrogels with higher crosslinking density would restrict the expansion of the network and thus the water retention of the hydrogel.

The previous data clearly show that the hydrogels have high swelling ratio at pH 7.4 as in the blood or near the normal tissues, but have low swelling ratio at pH 6.8 as in tumor tissues. In other words, when these hydrogels encapsulated with drugs and injected into blood once are close to the tumor tissues, they would shrink and thus discharge the encapsulated drug. For further understanding these hydrogels from the aspect of practical applications, a specific value (SV) was then defined as shown in Eq. (3) for comparing the swelling ratios of hydrogels at pH 7.4 and at 6.8. The results are summarized in Table 4. Compared to the g-PS2D8, the g-PS3D7 hydrogels had higher SV values, indicating that the g-PS3D7 hydrogels could undergo more considerable morphology changes than the g-PS2D8 samples. This is because the g-PS3D7 had more sulfonamide units that would enable the hydrogels to be more pH-sensitivity. This also suggests that the g-PS3D7 hydrogels would have a higher drug-release rate and thus would be a better candidate for biomedical applications.

Morphology of pH-sensitive hydrogels

For comparing the morphologies of hydrogels in different pH-environments, SEM images of the cross-section area of a representative g-PS3D7 hydrogel after being soaked in acidic and basic solutions separately are shown in Fig. 6. Clearly, the micro-structure of the hydrogel under acidic environment (pH 6.0) was compact; while the hydrogel soaked in the basic environment (pH 8.0) had a loose and porous structure. This is because in an acidic environment, the hydrogel was hydrophobic owing to the π-π interaction and hydrogen bonding among the polymer chains. As a result, a condensed structure was observed. On the other hand, in a basic environment, the dissociation of protons on sulfonamide groups provided sufficient hydrophilicity of hydrogel, resulting in a high swelling ratio and a high water retention capacity. After freeze-drying, water was removed and a porous structure was thus observed. The g-PS2D8 hydrogel had almost the same microstructure as the g-PS3D7 hydrogel when soaked in the same aqueous solution.

Conclusions

Two pH-sensitive sulfonamide-containing copolymers of poly(SAM-DMAAm) were first synthesized by redox-initiated free radical polymerization with the feeding molar ratios of SAM/DMAAm = 2/8 and 3/7. The produced PS2D8 and PS3D7 copolymers could change rapidly from a hydrophobic state to a very hydrophilic state, i.e. dissolution in water, at pH values close to human body condition with a very narrow transition less than 0.1 pH unit. Moreover, thermo-crosslinkable poly(SAM-DMAAm-NMA) copolymers were synthesized by further introducing the NMA monomer into the reaction system. After post-cure, hydrogels of g-PS2D8 and g-PS3D7 with a three-dimensional network structure were thus produced. Degree of gelation as well as swelling ratio of the hydrogels could be adjusted by changing the curing temperature and time. Though the transition of hydrogels responding to pH value became larger based on the measurement of swelling ratio, the onset points of pH-sensitive window of both g-PS2D8 and g-PS3D7 hydrogels were still in between 6.8 to 7.4, i.e., in the physiological environment of human body. The ratio of swelling ratio from pH 7.4 as in the blood or near the normal tissues to pH 6.8 as in tumor tissues (denoted as SV) was also calculated for the hydrogels to illustrate the potential for biomedical applications. The results showed that the g-PS3D7 hydrogel with higher SAM composition had higher SV value than the g-PS2D8. This indicated that the g-PS3D7 hydrogel had more morphological change when the environment was changed from normal tissues to tumor tissues. This is beneficial for the applications in target controlled-drug release.

References

Qiu Y, Park K (2001) Environment-sensitive hydrogels for drug delivery. Adv Drug Deliv Rev 53(3):321–339. https://doi.org/10.1016/S0169-409X(01)00203-4

Hennink WE, van Nostrum CF (2012) Novel crosslinking methods to design hydrogels. Adv Drug Deliv Rev 64:223–236. https://doi.org/10.1016/j.addr.2012.09.009

Lee KY, Mooney DJ (2001) Hydrogels for Tissue Engineering. Chem Rev 101(7):1869–1880. https://doi.org/10.1021/cr000108x

Babaladimath G, Badalamoole V (2018) Pectin-graft-poly(2-acrylamido-2-methyl-1- propane sulfonic acid) silver nanocomposite hydrogel beads: evaluation as matrix material for sustained release formulations of ketoprofen and antibacterial assay. J Polym Res 25(9):202

Peppas NA, Bures P, Leobandung W, Ichikawa H (2000) Hydrogels in pharmaceutical formulations. Eur J Pharm Biopharm 50(1):27–46. https://doi.org/10.1016/S0939-6411(00)00090-4

Kabanov AV, Vinogradov SV (2009) Nanogels as pharmaceutical carriers: finite networks of infinite capabilities. Angew Chem Int Ed 48(30):5418–5429. https://doi.org/10.1002/anie.200900441

Satarkar NS, Hilt JZ (2008) Magnetic hydrogel nanocomposites for remote controlled pulsatile drug release. J Control Release 130(3):246–251

Ma L, Liu M, Liu H, Chen J, Cui D (2010) In vitro cytotoxicity and drug release properties of pH- and temperature-sensitive core-shell hydrogel microspheres. Int J Pharm 385(1–2):86–91. https://doi.org/10.1016/j.ijpharm.2009.10.037

Lin C-L, Chiu W-Y, Lee C-F (2006) Preparation, morphology, and thermoresponsive properties of poly(N-isopropylacrylamide)-based copolymer microgels. J Polym Sci Part A: Polym Chem 44(1):356–370. https://doi.org/10.1002/pola.21134

Traitel T, Cohen Y, Kost J (2000) Characterization of glucose-sensitive insulin release systems in simulated in vivo conditions. Biomaterials 21(16):1679–1687

Liu Y, Meng L, Lu X, Zhang L, He Y (2008) Thermo and pH sensitive fluorescent polymer sensor for metal cations in aqueous solution. Polym Adv Technol 19:137–143

Zrínyi M (2000) Intelligent polymer gels controlled by magnetic fields. Colloid Polym Sci 278(2):98–103

Gil ES, Hudson SM (2004) Stimuli-responsive polymers and their bioconjugates. Prog Polym Sci 29(12):1173–1222

Zha L, Banik B, Alexis F (2011) Stimulus responsive nanogels for drug delivery. Soft Matter 7(13):5908. https://doi.org/10.1039/c0sm01307b

Che Y, Li D, Liu Y, Yue Z, Zhao J, Ma Q, Zhang Q, Tan Y, Yue Q, Meng F (2018) Design and fabrication of a triple-responsive chitosan-based hydrogel with excellent mechanical properties for controlled drug delivery. J Polym Res 25(8):169

Khan A, Sajjad M, Khan E, Md. Akil H, Shah LA, Farooqi ZH (2017) Synthesis, characterization and physiochemical investigation of chitosan-based multi-responsive Copolymeric hydrogels. J Polym Res 24(10):170

Lee AS, Bütün V, Vamvakaki M, Armes SP, Pople JA, Gast AP (2002) Structure of pH-dependent block copolymer micelles: charge and ionic strength dependence. Macromolecules 35(22):8540–8551

Weaver JVM, Bannister I, Robinson KL, Bories-Azeau X, Armes SP, Smallridge M, McKenna P (2004) Stimulus-responsive water-soluble polymers based on 2-hydroxyethyl methacrylate. macromolecules 37(7):2395–2403. https://doi.org/10.1021/ma0356358

Gan LH, Roshan Deen G, Gan YY, Tam KC (2001) Water sorption studies of new pH-responsive N-acryloyl-N′-methyl piperazine and methyl methacrylate hydrogels. Eur Polym J 37(7):1473–1478. https://doi.org/10.1016/S0014-3057(00)00250-0

Yin X, Stöver HDH (2003) Hydrogel microspheres formed by complex coacervation of partially MPEG-grafted poly(styrene-alt-maleic anhydride) with PDADMAC and cross-linking with polyamines. Macromolecules 36(23):8773–8779. https://doi.org/10.1021/ma034617n

Kurdtabar M, Koutenaee RN, Bardajee GR (2018) Synthesis and characterization of a novel pH-responsive nanocomposite hydrogel based on chitosan for targeted drug release. J Polym Res 25(5):119

Ghamkhari A, Agbolaghi S, Poorgholy N, Massoumi B (2018) pH-responsive magnetic nanocomposites based on poly(2-succinyloxyethyl methacrylate-co-methylmethacrylate) for anticancer doxorubicin delivery applications. J Polym Res 25(2):37

Wike-Hooley JL, Haveman J, Reinhold HS (1984) The relevance of tumour pH to the treatment of malignant disease. Radiother Oncol 2(4):343–366. https://doi.org/10.1016/S0167-8140(84)80077-8

Lardner A (2001) The effects of extracellular pH on immune function. J Leukoc Biol 69(4):522–530

Kang SI, Bae YH (2002) pH-induced solubility transition of sulfonamide-based polymers. J Control Release 80(1–3):145–155. https://doi.org/10.1016/S0168-3659(02)00021-4

Park SY, Bae YH (1999) Novel pH-sensitive polymers containing sulfonamide groups. Macromol Rapid Commun 20(5):269–273

Bae YH, Park SY (2000) pH-sensitive polymer containing sulfonamide and its synthesis method. US patent 6:103,865

Kang SI, Na K, Bae YH (2001) Sulfonamide-containing polymers: a new class of pH-sensitive polymers and gels. Macromol Symp 172:149–156

Na K, Bae YH (2002) Self-assembled hydrogel nanoparticles responsive to tumor extracellular pH from pullulan derivative/sulfonamide conjugate: characterization, aggregation, and adriamycin release in vitro. Pharm Res 19(5):681–688

Shim WS, Kim J-H, Park H, Kim K, Chan Kwon I, Lee DS (2006) Biodegradability and biocompatibility of a pH- and thermo-sensitive hydrogel formed from a sulfonamide-modified poly(ε-caprolactone-co-lactide)–poly(ethylene glycol)–poly(ε-caprolactone-co-lactide) block copolymer. Biomaterials 27(30):5178–5185. https://doi.org/10.1016/j.biomaterials.2006.05.038

Sarac AS (1999) Redox polymerization. Prog Polym Sci 24(8):1149–1204. https://doi.org/10.1016/S0079-6700(99)00026-X

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Kuo, CY., Don, TM., Lin, YT. et al. Synthesis of pH-sensitive sulfonamide-based hydrogels with controllable crosslinking density by post thermo-curing. J Polym Res 26, 18 (2019). https://doi.org/10.1007/s10965-018-1672-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-018-1672-6