Abstract

This paper describes the synthesis and physicochemical characterization of Poly(N-isopropylacrylamide)-Chitosan-Poly(Acrylic acid) [PNIPAAm-CS-PAA] based polymeric microgels. Three different samples of multi-responsive (PNIPAAM-CS-PA) microgels were synthesized using various amounts of N Nˡ- Methylene bis-acrylamide (MBA) and Acrylic acid (AA) by free radical emulsion polymerization. The redox initiator Ammonium per sulfate (APS) was used to initiate the reactions while MBA was used as a crosslinking agent. The purified polymeric microgels were then characterized using UV-Visible spectroscopy, Fourier transform infrared spectroscopy (FT-IR), Laser light scattering (LLS), Ostwald viscometry, dynamic Rheology and swelling/de-swelling measurements. From the spectroscopic result it was observed that all the reactions have been completed and the resultant microgels were successfully synthesized. The influence of various parameters such as, chemical composition and some external stimuli like temperature and pH on the physicochemical behavior of polymeric microgels was investigated through visual stability test, laser light scattering, viscometry and rheological measurement. The LLS analysis was performed to deduce the size, in the terms of hydrodynamic radius (Rh), of the microgel samples in aqueous media at different pH and temperature. From LLS analysis the microgels were found to be stable at all pH values above the pKa values (4.2) of AA in temperature ranges from 20 °C to 50 °C. With rising in temperature and pH causes aggregation of particles and decrease in stability of microgels due to the decrease in hydrophobicity. From the Rheological measurements, various physiochemical properties such as, elasticity, viscosity, shear stress, storage modulus, loss modulus, phase angle and complex viscosity of the microgels were gathered. The Ostowald viscometry was used to measure the flow viscosity of microgels at different pH and temperatures. The present observations reflect that the prepared samples are multi-responsive and their physicochemical behavior can be tuned very easily by changing their composition and/or varying the external stimuli.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Polymeric microgels have received considerable attention in the drug-release system because of their ability to deliver drugs to the therapeutic targets at appropriate times and doses. Because of their small particle size, they could pass through the capillary vessels and avoid rapid clearance by phagocytes. Hence, their duration in blood stream is greatly prolonged. In addition, they could penetrate cells by transcytosis and/or overcome biological barriers to arrive at target organs. Furthermore, by using materials with biodegradability or environmental sensitivity to the pH, ion, chemicals, glucose and/or temperature, they could exhibit controlled-release properties [1]. Poly (N-isopropyl acrylamide) (PNIPAAm) exhibits a lower critical solution temperature (LCST) in aqueous solutions, and its crosslinked nanogels show high swelling thermo sensitivity in water [2]. These nanogels have been investigated for molecular separation, sorption-desorption of solutes, control of enzyme activity, and release of solutes. PNIPAAm are constantly copolymerized with other monomers due to its weak mechanic properties and applications. Fine particles (microparticles) have been widely studied to deliver drugs, polypeptides, proteins, vaccines, nucleic acids, genes and so on [3].

Natural biopolymers have been widely used to prepare responsive microgels for biomedical application due to their biocompatibility, low toxicity, and a high content of functional groups [4]. Recently, polymeric materials with biodegradable and biocompatible properties used for drug delivery have been developed. These materials include poly (lactic acid), poly (lactideco-glycolide), polycaprolactone, polyanhydrides, polyhydroxyalkanoates, polypeptides and polysaccharides. Among them, polysaccharides are the most popular polymeric materials to prepare nanoparticles (NPs) for drug delivery. The polysaccharide NPs can be prepared mainly by covalent crosslinking, ionic crosslinking, polyelectrolyte complexation, and self-assembly of hydrophobically modified polysaccharides [3, 4].

Chitosan (CS) is the common name of the linear, random copolymer that consists of β-(1–4)-linked D-glucosamine and N-acetyl-D-glucosamine. Chitosan is the major component of crustacean shells such as crab, shrimp, krill and crawfish shells [5]. Additionally, chitosan is the second most abundant natural biopolymer after cellulose. CS is an extremely promising biopolymer that is isolated primarily from seafood processing wastes. This polymer possesses a number of valuable properties. It is practically a single polycation of natural origin. Chitosan is nontoxic, biocompatible, and biodegradable; as a result, it is not accumulated in the body and in the environment [6]. Broadly, it can be said that chitosan based gels include few classes. One of them is the hydrogen bonded complexes and/or covalently crosslinked chitosan microgels. This can be further divided into three types: chitosan crosslinked with itself, hybrid polymer networks (the cross-linking reaction occurs between a structural unit of a chitosan chain and a structural unit of a polymeric chain of another type) and semi- or full-interpenetrating networks (IPN) [7]. Another class includes the coordination complexes or ionically crosslinked chitosan microgels. Here, the reacting entities react with chitosan are normally negatively charged species (ions or molecules), forming a network through ionic bridges between polymeric chains. The other two classes are mostly the grafted chitosan hydrogels and polyelectrolyte complexes [8].

In order to enhance the application ability of polymeric small sized microgels, especially in the fields of biomedical and nano-technology, recently we have papered and studied some microgel samples with tunable physicochemical properties [9, 10]. In addition to make the sample the temperature and ionic strength sensitive, the pH sensitivity can also be very important. Among the various potential options available such as acrylic acid (AA), the methacrylic acid (MAA)-based complexation and pH-sensitivity of the micogels could be the most promising one. The polymerization and crosslinking of the AA monomers can result in a chemically crosslinked PAA network where the PAA can be complexed and semi-interpenetrated by the chitosan chains. In addition to the pH responsive behavior of PAA, its presence in the microgel can also play a part towards the stability of the microgels due to various interactions, such as hydrophilic contribution of acrylic groups of PAA chains [9].

In this study we intended to further explore the temperature sensitivity, pH sensitivity, particle stability, swelling/de-swelling and volume phase transition behaviour of the Chitosan-based responsive polymer gels. Therefore, few samples of multi-responsive Poly(N-isopropyl acrylamide-Chitosan-Poly(AcrylicAcid), [PNIPAAm-CS-PAA] gels were synthesized by emulsion polymerization and studied the above mentioned physicochemical properties of these gels in detail in aqueous medium.

Experimental

Materials

Water soluble chitosan (CS) with average molecular weight 3.7 × 10 4 g/ mol was purchased from Aldrich by university of science Malaysia (USM). Acitic acid (AAc) was obtained from cromoline (Brazil). Methylene bisacrylamide (MBA) and Ammonium persulfate (APS) were purchased from Sigma-Aldrich (Germany). Dionized water was used for solution preparation and their dilution. All the chemicals were of analytical grade and used without further particular treatment.

Preparation of the gels

The microgel samples that containing different amount of Chitosan, NIPAAm, AA and MBA crosslinker were synthesized by free radical emulsion polymerization. A general procedure for the preparation is summarized here. For the solutions preparation, an appropriate amounts of CS, NIPAAm, MBA and AA, that are listed in the Table 1, were dissolved in 100 ml of doubly distilled and deionized water in three-neck round bottom flask equipped with an inlet of inert gas (N2) system (for the removal of oxygen) and condenser. Approximatly 2–3 ml of acetic acid were added to the solutions and then stirred for 24 h at normal temperature (30 °C) to create the active sites in chitosan by ionizing the NH2 group to NH3 + respectively. Afterward the reaction temperature was then raised gradually up to about 70–75 °C and about 10–15 ml of APS (0.8 M) solution was added to the reaction mixture to initiate the reactions under constant temperature and inert condition. The reaction was allowed to proceed for 5–6 h to complete the polymerization reaction upon reaction of APS with solubilized monomers and crosslinker. The resultant microgels were purified by dialysis against water with frequent water change for about two weeks. The collected samples were then subjected to various physicochemical studies.

Characterizations

The following techniques were mainly used for characterization and physicochemical investigation.

FT-IR spectroscopy

The infrared spectra for the chemical structure of PNIPAAm-CS-PAA gels were recorded with “FTIR spectrophotometer, Shimadzu Japan” in the wave number ranging from 500 to 4000 cm−1. For analysis the solid samples were prepared by using KBR pellet method. Preliminary characterizations of PNIPAAm-CS-PAA hydrogels were performed by using double beam UV spectrophotometer (Shimadzu 160) within the wave length range of 200–800 nm.

Viscosity measurement

Relative viscosity of hydrogels samples were measured by using Ostwald viscometer. The viscosity of the hydrogels relative to the viscosity of distilled water was checked for each sample at different concentrations, temperature and pH, while during temperature and pH measurement the concentration of all the three samples was kept 5% and 1% respectively. The viscometer was calibrated with standard liquid and each measurement was repeated three times. The relative viscosity was (ηrel) was then plotted verses concentration to get inherent viscosity.

Rheological study

The steady state shear rheological measurements and oscillatory share measurements were accomplished with “MCR 301 from Anton Paar with parallel plate geometry”. The plate-plate distance was 1 mm. A measuring system PP25 was used for this purpose. The measurements as a function of temperature were performed in a range of 10–50 °C using rheoplus software. Oscillatory shear response (elastic/storage modulus or G′ and viscous/loss modulus or G″) were determined over the frequency range 0.009–100 rad/s. Various other rheological parameters (complex velocity, viscous modulus and elastic modulus) were directly obtained using the manufacturer supplied computer software.

Dynamic laser light scattering (DLLS)

The DLS measurements were made by means of commercial laser light scattering instrument composed of a BI-200SM motor-driven goniometer and BI-9025AT photon counter or BI-9025AT digital autocorrelator at scattering angle Θ = 90°. A cylindrical 22 mW uniphase He-Ne laser (λ = 637 nm) with a pinhole of 100 nm. For analysis of data BI-ISTW software was used in the equipment.

Result and discussion

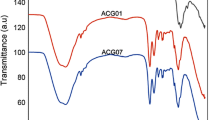

Fourier transform infrared spectroscopy

The FTIR study was used to detect the functional groups of CS, NIPAAm and AA in the resultant microgel particles. In all of the three gels the broad and intense peaks at about 3369, 3366, 3367 and 3364 cm−1 corresponding to the overlapped N-H and O-H group stretching vibration. The peaks at about 1316 cm−1 and 1392 cm−1 corresponding to C-N stretching of amine group of the amide content of the hydrogel. The peak at 1596 cm−1 and 1659 cm−1 represent the N-H bending and C = O stretching (primary amide); the peak at 1475 cm−1 attributed to CH2 scissoring, and the peaks at about 1450 cm−1 represent C-N stretching of amide group and CH3 antisymmetric bending. Moreover, the polysaccharide bands are also detected in the region from 890 to 1156 cm−1 which shows the presence of chitosan in the resultant samples [10]. The Poly(NIPAAm-CS-AA) microgels display two peaks at 1365 and 1385 cm−1, representing the umbrella bent (or symmetric bent) of isopropyl groups [10, 11]. According to the FT-IR spectra of NIPAAm a strong peak was observed in the range of 1640–1680 cm−1 which is a characteristic peak for carbon –carbon double bond. But in case of resultant microgels there is no prominent peak in the carbon–carbon double bond region, which also confirms the successful preparation of the desired gel samples. Similarly, in crosslinker (MBA) the peak was observed in the region of 3032 cm−1. Which is a characteristic peak for = C-H stretching, but the FT-IR spectrum of Poly (NIPAAm-CS-AA) microgels lacked peak of the carbon-carbon double bond. The peaks of all other residual functional groups of crosslinker and monomers are recovered in the FT-IR spectrum of the gels, conforming that polymerization reaction has occurred and the desired microgel samples were prepared successfully. The summary of FTIR can be further seen from Fig. 1. In addition, the UV-Visible spectroscopy was also applied to the hydrogels to see whether the unsaturation is present at any part of the polymer chain. It was seen that there exist no peak in the visible region of the spectrum. This means that the hydrogels are fully saturated and there is no unsaturation in the structure of the gels. It further supports the idea that the reactions have been completed and hence the hydrogels were being synthesized successfully.

Rheological studies

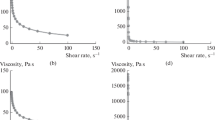

Viscosity versus shear rate analysis

The variation in viscosity versus shear rate profile curves for sample SG2 under various temperatures is plotted and shown in Fig. 2 while the effect of composition on the viscosity-shear rate profile of SG1, SG2 and SG3 microgel samples at constant temperature (40 °C) is shown in Fig. 3. An overall investigation of these figures show that viscosity of these gels decreases with an increase in the shear rate; this trend can be attributed to the shear thinning behavior of the gels. This phenomenon further shows that our gel samples are pseudo-plastic in nature. Initially the viscosity of the gels is very high at very low share rate, it is due to the share thickening phenomenon of the gels. The pseudo plasticity and viscosity are interrelated. In simple words when the shear force is applied the tougher the shear thinning effect and hence the tougher the reduction in viscosity.

For the sample having same chemical composition (SG1) the viscosity of the gel was found to increases with increase in temperature. It means that under the same chemical composition, the share thickening behavior of the gel can be adjusted with varying the experimental temperature (10 °C – 50 °C). The gel expels its hydration water and become harder that lead to increase in the viscosity of the gel. Figure 2 shows the viscosity versus shear rate profile curves of SG2 sample at different temperature. This hydrogel sample does not show the same trend as observed for sample SG1. It is because of the difference in the chemical composition of these two samples. In case of SG2, the concentration of acrylic acid is greater than in SG1 sample as shown in the Table 1. Initially at lower temperature (10 °C) the SG2 gel shows greater viscosity due pseud plasticity of the gel, and at temperature from 10 to 30 °C the gel shows decrease in the viscosity with temperature; this decrease is attributed to the strong interaction that take place between the water molecules and polymer particles due to the upper critical solution temperature (UCST) behavior of AA, the gel is expected to absorb appreciable amount of water and becomes thinner that lead to decrease in the solution viscosity [13, 14]. At T > 30 °C, the viscosity of the gel again shows an increase in its inherent viscosity. This variance in viscosity is due to the effect of lower critical solution temperature (LCST) of the PNIPAAm present in the gel. The gel expels their H-bonded hydration water and become harder that lead to increase in the overall viscosity [12]. It was also found that SG3 sample also exhibits almost the same behavior as SG2 but here the amount of crosslinker (MBA) is less than SG2, therefore, its shows lower viscosity value as compared to SG2 sample because the higher content of crosslinker decreases the particle size of the gel.

Figure 3 shows the viscosity versus shear rate profile curves of hydrogel samples (SG1 to SG3) at 40 °C. Based on their chemical composition SG1 has the same ratio of constituents and shows the initial viscosity at about 700 Pa·s which decreases with increasing shear rate, comparing to SG1 in samples SG2 the amount of crosslinker is greater and it shows the viscosity of about 23 Pa at lower shear rate which is relatively less than that of SG1 sample, the lower viscosity of SG2 is attributed to the high degree of crosslinking that lead to the decreasing in the size of the gel particle and increasing in the surface area of the particle and hence a greater interaction took place between the water molecules and gel particles which might lead to the increase in the hydrophilic behavior of the microgels. In sample SG3 the amount of AA is greater as can be seen in the Table 1 and shows the initial viscosity at about 4.7 Pa.s which is relatively less than that of SG1 and SG2 micorgels. The lower viscosity of SG3 is due to the upper critical solution temperature (UCST) behavior of AA, the gel-water interaction is greater therefore absorbed more and more water and become hydrophilic in nature and hence decreasing occurred in the viscosity of the gel [13]. In SG3 microgel the amount of MBA crosslinker is also greater and shows relatively lesser viscosity. It is because the crosslinker decreases the particle size and increases the surface area of the gels particles. Therefore more water molecules surrounded the microgels particles and hence increasing occurred in the hydrophilic behavior of the gel.

Shear stress versus shear strain analysis

Figure 4 represent the effect of composition on the shear stress versus shear stain profile curves of SG1 to SG3 at 40 °C. By comparing the results, it is cleared that the required shear stress value for each sample is different. This difference in shear stress is due to the change in the composition of samples. For sample SG1 the composition of each constituent is of the same ratio and it shows a maximum shear stress value of about 26 Pa. In contrast to SG1, in sample SG2 the concentration of MBA crosslinker greater and shows the required shear stress of about 271 Pa which is quite higher compared to that of SG1. The high shear stress of SG2 sample is due to the high degree of crosslinking in the gel particles, the particles are closely packed and hence harder which requires high shear stress to deform [11]. Besides this; SG3 shows the maximum shear stress at about 27.5 Pa which is lesser than that of SG2 and a bit greater than that of SG1. The lower shear stress value of SG3 is due to the lower concentration of MBA crosslinker and high amount AA monomer in the gel. AA has UCST behavior and therefore a strong interaction is expected between the water molecules and the gel particles and ultimately requires less shear stress to deform. In contrast to SG3 in SG2 the gel particles are more hard and closely packed due to the high crosslinking density in the gel and due to LCST behavior of NIPAAm which is present in the structure of microgel and hence high shear stress required to deform [14].

Figure 5 represents typical plots of the behavior of the shear stress versus shear strain profile curves for sample SG2 at various temperatures. According to the figure, the gel initially shows higher shear stress at lower temperatures but decreases with increase in temperature. This high shear stress is attributed to the high degree of crosslinking in the polymer gel. There is a strong gel-gel interaction instead of gel-water interaction and hence the gel particles are closely packed which needs high shear stress to deform. Furthermore, as the temperature is raised the gel-gel repulsion take place and gel-water interaction occurred due to the hydrophilic nature of NIPAAm below its LCST value and therefore a decrease occurred in the required shear stress of the gel. At temperature above 30 °C the gel showed again an increase in the shear stress upto about 40 °C, this increase in shear stress is due to the hydrophobic nature of NIPAAm above LCST which is present in the structure of polymer gel. By further increasing the temperature a considerable decrease occurred in the required shear stress, this decrease in shear stress at high temperature is attributed to the high critical solution temperature (UCST) behavior of AA that shows hydrophilic behavior and minimizes the required shear stress of the gel.

In case of SG1 (Figure not shown here), the hydrogel showed a considerable increase in shear stress with increase in temperature up to ≈ 40 °C. The high shear stress showed that the shear thickening occurred in the hydrogel sample in this temperature range. The hydrogel remove its H-bonded hydration water and gets hydrophobic nature, as a result of which the gel particles shrink and become closely packed due to which a greater force is then required to deform the hydrogel sample. Beyond 40 °C the required shear stress is going to decrease as the temperature is rising. The decrease in shear stress is attributed to the UCST behavior of AA and hence the gel absorbed more water and become hydrophilic in nature which then can easily be deformed when shear stress is applied. In sample SG3 the amount of AA is greater and showed more shear stress below 30 °C. The high shear is due to the larger size and pseudo plasticity of the gels because AA enlarges the gel size and hence more shear stress is required to deform the gel. At T > 30 °C as the temperature is increased, the decreasing occurred in the required shear stress; it is again assigned to the upper critical solution temperature (UCST) behavior of AA and the gel absorbed more hydrated water and become hydrophilic in nature which then can easily be deform [11].

Oscillatory shear measurements

All microgel samples were also subjected to oscillatory shear measurements. In this case, the top plate of rheometer instead of rotating it oscillates back and forth on the sample. The Frequency Sweep Method was used to investigate the viscoelastic properties and to categorize the present polymeric material into three common behaviors like viscoelastic solid, gel and viscoelastic liquid. Various parameters, such as complex viscosity (η*), phase angle, elastic (storage) modulus (G') and loss (viscous) modulus (G'') were achieved. In elastic modulus (G') the extent of the elastic component (contributed by aggregation, entanglement, crosslinking) is measured. In viscous modulus the extent of viscous component (attributed by the liquid portion) is measured. Moreover, the modulus is dominant will specify whether the material seems viscous or elastic [15].

Representative curves showing the variation of storage modulus (G') and loss modulus (G'') versus angular frequency at different temperatures are shown in Figs. 6 and 7 respectively. These moduli for all microgel samples (SG1-SG3) were measured in the frequency range ω = 0.5–500 rad/s and at different temperatures. As can be seen from the Fig. 6, a considerable increase occurred in the storage modulus of the gels with temperature up to ≈ 30–35 °C. The increase in storage modulus is because of the high concentration of MBA crosslinker in the structure of the gel that causes to increase the density of crosslinking and surface area as well, as a result of which more water molecules surrounded the gel particles and the microgel become hydrophilic in nature and hence decreasing occurred in the storage modulus [16]. At T > 35 °C the gels showed a considerable decrease in the storage modulus with increasing in temperature. The decrease in the storage modulus is because of the presence of NIPPAm monomer in the gels structure which has LCST and showed hydrophobic behavior above this temperature range and therefore the shrinkage occurred in the structure of the gel and become less elastic in nature. Opposite to this, the loss modulus of SG2 sample below 35–40 °C is decreasing while above this temperature an increase is observed as can be seen in the Fig. 7. This shows that at initial temperature the gel is more elastic and less viscous while at higher temperature the gel become harder and viscous in nature.

For sample SG1, the variation of storage and loss modulus versus angular frequency profile (Figs. not shown) showed that initially a considerable increase in the storage modulus with increasing in temperature (10-35 °C) was observed. This increase is attributed to the presence of NIPAAm monomer in the gels that swell up by absorbing water and become elastic till 30 to 35 °C. Above this temperature the gels lose its hydration water and become shrink that lead to decrease in the elastic behavior of the gel due to which the storage modulus of the gel decreased. Beside this the loss modulus of the gels is decreases with increasing in temperature up to 30–35 °C. This decrease in loss modulus is due to the decreasing in the resultant viscosity of the microgel [17]. At T > 30 °C a substantial increase in the loss modulus occurred. This increase is corresponding to the increase in the viscosity of the gel due to removal of hydration water of the gel. Furthermore, at the end of storage modulus versus angular frequency profile, the gel showed an abrupt drop in the storage modulus. It is because for all the gels the storage modulus remained constant with an upsurge in the amplitude of strain up until a threshold limit of the linear viscoelastic (LVE) range, beyond which an abrupt drop observed in the storage modulus. In other words it can be seen from the storage modulus-angular frequency behavior that initially the storage modulus is smaller at lower value of angular frequency, while further increasing the angular frequency increase the values of corresponding modulus in linear fashion until it reaches to its maximum value at optimum frequency value beyond which an abrupt drop was observed by further increasing the frequency values, and finally the storage modulus attained its minimum value at highest frequency value [18].

In cases of SG3, the storage modulus was found higher when the temperature is rising; the effect can be attributed to the greater amount of AA monomer in this sample which makes the gel more hydrophilic in nature and swells up with increase in temperature and therefore an increase in its elastic behavior is observed [16]. At T > 35 °C the gels showed a considerable decrease in the value of storage modulus, this low storage modulus of the gel is attributed to the presence of NIPPAm monomer in the polymer structure that shows LCST behavior and therefore the gel become more hard and thick by losing its hydration water and become less elastic in nature. Beside this the loss modulus of this gel decreases below the LCST level. The decreases in the loss modulus showed that the viscous components of the gels is decreases by absorbing much water and hence become susceptible to flow. However, at T > 35–40 °C the gel showed again an increase in the loss modulus, which means that the microgel loses its hydration water due to the hydrophobic nature of NIPAAm in this temperature range.

By comparing the entire three samples, it was found that the storage modulus of SG2 sample is higher than the storage modulus of SG1 and SG3. The high storage modulus of SG2 sample is due to the more ratio of cross-linker that causes to increase the surface area of the gel particles due to its high degree of crosslinking and hence greater amount of water molecules surrounded the gels particle as a result of witch the gel become hydrophilic and elastic in nature. On the reverse of this the loss modulus of SG2 is lower than the other two SG1 and SG3 samples showing its lesser viscoelastic behavior. Furthermore, SG3 has greater elastic modulus and lower loss modulus compared to SG1 microgel sample. It is due to the fact that, AA is present in greater amount in SG3 and has USCT and due to which the gel sample absorbed much water and become hydrophilic in nature, that may lead to the increase in the elastic components rather than the viscous components of the gel. Generally the gels showed a considerable increase in the storage modulus (G') with increasing in temperature from 10 °C to 35 °C. This variation in storage modulus of the microgels as a function of temperature is due to the increase in the elastic behavior of the gels in the initial stage of temperature. The high elasticity indicates a higher degree of internal structure. The elastic modulus (G') arises from the network structure which is a good elastic solid-like character. Similarly the loss modulus of the microgels is decreasing initially below 30 °C. This decrease in loss modulus showed that our gels samples lose their viscous behavior in the initial stage. At T > 30 to35 °C the storage modulus of the gels are decreased. The decrease in storage modulus showed that the gels lose their elastic behavior and become hard. On the other side the loss modulus of the gels increases due to increase in their viscosity [18].

Loss factor/phase angle of the gels

The ratio of loss modulus to storage modulus (G'/ G'' = tan d) is called as damping factor which is used for the measurement of the strength of interaction of the internal structure of the gels. The greater G'' (or smaller the tan d), the higher will be the interaction. Plotting of loss factor (tan d) versus frequency is used to express the viscoelastic spectrum of the gels. Loss factor compare both the elastic and viscous parameter of the gels system. The value of tan d less than 1 represents the elastic behavior while the value of tan d greater than 1 indicates the viscous behavior of particles.

Figure 8 represents the tan d versus angular frequency curves of the gels (SG1-SG3) at different temperatures. As can be seen from the figures, the gels show high tan d value at lower frequency while decreases as the frequencies are increased. This means that the gels exhibited high viscous behavior and low elastic behavior. But as the frequency is increasing gradually a corresponding decrease in the tan d values of the gels reflects an increase in the elastic behavior of microgels. For samples SG1 and SG3 the tan d value is <1. This shows that these samples have higher elastic behavior and lower viscous behavior and therefore exhibited high interaction in the internal structure. Besides SG1 and SG3, the tan d value of SG2 sample is >1, this mean that this microgel sample is more viscous and have lower strength of internal structure [19, 20].

Complex viscosity of hydrogels

A typical and representative Figure (Fig. 9) represent the complex viscosity (η*) of hydrogels SG2 measured in the frequency range of 0.5–500 rad/s. Generally the angular frequency dependency of the (η*) tells us about the solid-like and liquid-like behavior of the gels. It can be observed from the figure that a considerable increase in the complex viscosity occur with the angular frequency. This increase in complex viscosity can be an indirect reflection of the growing in the shear thickening behavior of the gels.

Further, the effect of temperature on the initial viscosity of these hydrogel samples showed that with increase in temperature the viscosity of the microgels decreases up to about 30–35 0C, this decrease in viscosity is attributed to the hydrophilic behavior of the gel sample because the more crosslinker in SG2 decrease the particle size and increasing the surface area of the gel as a result of which greater amount of water molecules are surrounding the gel particle and hence increasing occurred in the liquid behavior of the microgel. At T > 30–35 °C the microgels showed a considerable increase in the final complex viscosity of the gels. This variance in the complex viscosity is attributed to the hydrophobic behavior of NIPAAm that are present in the samples up to some extent. The hydrogels eject their hydration water and become hard that may results to increase the solid contents of the hydrogels sample and hence the gels behaved as solid-like [21].

In the case of SG1, at the beginning the gel showed a sharp decrease in η* with increasing in angular frequency up to certain extent. It showed that initially the gel loses its solid components, the breaking of inter and intra molecular bond take place and the particles has no enough time to recombine and hence the gel behaved a liquid-like. By further increasing the angular frequency the η* of the gel increases again, this shows that the gel particle recombine once again and hence increases the size of the particle that lead to increase in the solid-like behavior of the gel. Similarly, the effect of temperature on SG1 hydrogel is almost similar to that of SG2. However, at T > 30 to 35 °C the gel show again a decrease in the complex viscosity of the gel, which specify that the decreasing occurred in the solid contents and the gel behave as a liquid-like [21, 22]. The effect of temperature on the final viscosity of SG3 sample showed that with increasing in temperature the final viscosity of the microgels is decreases up to about 30–35 °C, this decrease in viscosity is attributed to the hydrophilic behavior of AA that are present in excess amount in this samples. The gels absorbed more water due to a strong interaction that take place among the polymer particles and hydration water. Due to this phenomenon, the solid contents of the microgel samples are going to decrease and hence the increasing occurred in the liquid-like behavior of the microgels. AT T > 35–40 °C the microgel exhibit the same behavior as can be observed for SG2 microgel.

Figure 10 represents relative viscosity versus temperature profile curves of SG1-SG3 microgel samples. The sample SG1 initially shows a considerable increase in the flow viscosity with increasing in temperature up to 35–40 °C. The increase in viscosity is attributed to the hydrophilic behavior of NIPAAm that absorbed more water with temperature and become swell up due to which an increase occurred in the size of particles that may lead to the increase in the flow viscosity of the microgel. At T > 40 °C the microgel showed a considerable decrease in ηrel with increasing in temperature. The decrease in ηrel was due to the hydrophobic nature of NIPAAm, because above the volume phase transition temperature (VPTT) range the microgel losses its hydration water and become shrink which lead to the decrease in the particle size of the gel and hence the decrease occurred in the flow viscosity of microgel. Similarly in sample SG2 the amount of MBA crosslinker is greater than in the other two samples and at lower temperature range showed the flow viscosity of about 1.7 which is relatively less than that of SG1 and SG3 samples. The low viscosity of SG2 is attributed to the smaller sizes of the particles because crosslinker increases the degree of crosslinker that lead to the decrease in the dimension of the gel particles. Furthermore, in sample SG3 the amount of AA is greater than in the other two samples and at lower temperature showed the flow viscosity of about 1.9 that is relatively less than that of SG1 sample. Because the AA is acidic in behavior that decrease the pH of the solution further and increases the hydrophobic behavior of the polymeric gel and hence the reduction occurred in the size of the gel that might lead to the decrease in the flow viscosity of the gel [23].

The effect of pH on the relative viscosity of microgels

The effect of pH on the relative viscosity of SG1-SG3 microgel samples can be seen from Fig. 11. It has been observed that the microgels show a considerable increase in the flow viscosity with increase in pH. The change in flow viscosity of the gels is due to the presence of AA as well as chitosan monomers in the structure of all these polymeric gels. As AA is and acid and it has pH-responsive carboxylic group that can protonate above its pKa value of about 4 and deprotonate below 4 [8, 17]. So in the above gels due the increase in pH above the pKa value the degree of ionization of the polymeric gels was also increases due to which an electrostatic repulsion took place between the chains of polymers that result an increase in the capability of gels particles to absorbed more and more water molecules and become hydrophilic in nature. Due to this hydrophilic behavior the sizes of the gels were expanded and hence an increased occurred in the flow viscosity of polymeric gels [24]. Also the presence of chitosan in the polymer structure of microgels exhibit pH sensitivity for swelling profile. Chitosan has primary amino (NH2) group with pKa of about 6.5. Below this pKa value protonation of NH2 took places that impart a positive charge to the chain of microgel and hence the expansion and swelling of microgel occurred due to repulsion of polymer chains. Hence the increasing occurred in the flow viscosity of microgels due to the expansion of polymer particles [25, 26].

Furthermore on the basis of composition it was observed that SG2 sample has greater flow viscosity at high pH than both the SG3 and SG1 samples. The degree of flow viscosity of SG2 sample was attributed to the high amount of crosslinker as well as AA. Because MBA crosslinker increases the degree of crosslinking and hence more number of charged particles were being produced at high pH which in turn made the microgel more hydrophilic, furthermore the high amount of AA also made the gel more hydrophilic in behavior and hence an increased occurred in the flow viscosity of the microgels [27].

Temperature responsive swelling/de-swelling behavior of the synthesized hydrogels

The temperature sensitive swelling/de-swelling behavior of the hydrogel samples was investigated in the terms of average hydrodynamic size as a function of temperature. Dynamic Laser light scattering (DLLS) was employed to determine the average size of the hydrogel particles as a function of temperature at constant pH. Figure 12 shows the variation of hydrodynamic radius (Rh) with temperature of all the three samples at constant pH = 4.0.. It can be seen that Rh is regularly increasing with temperature upto 38 °C. Above this temperature the size of all gels decreases with an increase in temperature. However, this decrease in size (Rh) with temperature becomes less prominent beyond 44 °C. This variation in the hydrogel size with temperature is due to the presence of N-Isopropyl acrylamide (NIPAAM) in the composition of the gel sample. As N-Isopropyl acrylamide (NIPAM) is known to be the temperature sensitive moiety of the hydrogels [19]. The different behavior of the gel size with temperature is due to the different behavior of NIPAAM at different temperature. NIPAM is a thermosensitive polymer and the pure NIPAM shows its maximum size in the temperature range of 30–32 °C. Above this temperature (LCST), it shows increase in the size which is due to the swelling of particles and also arising of hydrophobic forces among the particles, Which leads to a type of particle aggregation. In other words the aggregation number of the hydrogel particle gets increases with increase temperature. It is important to note that the present hydrogel samples not only contain PNIPAAM but also chitosan and PAA components. It can also be said that at higher temperature the hydrophobic behavior of the chitosan also increased and due to which appreciable hydrophobic forces developed between the various chains of polymer and hence a sort of increases in aggregation or association number of the hydrogel’s particles resulted. Also the hydrophilicity of AA fluctuating with temperature. On the general real it can be said that by increasing the temperature from starting temperature (15 °C) upto around (38 °C), the size of the microgel increases. This effect can be assigned to the combined contribution of swelling of the particles as well as the increase in association of polymer chains due to hydrophobic forces between the chains of polymer. It can be further seen from the figure of hydrodynamic radius (Rh) versus temperature for all samples, that after reaching a maximum size at a specific temperature, the size of the hydrogels starts to decrease with further increasing the temperature. At temperature above the 38 °C the deswelling of the microgel was observed and the decrease in the size can be attributed to the dehydration effect at higher temperature. This decrease in the hydrogel’s size with temperature becomes less prominent above 45 °C. It means no more hydration occur above this temperature. There is also a possibility of dehydration but the decrease in size due to dehydration with temperature can be balanced by the aggregation of particles due to hydrophobic-hydrophobic interactions. Thus, the cumulative effect of various factors balances each other and resultantly, the size of hydrogel becomes insensitive to temperature (higher than 45 °C). From the effect of temperature on Rh (Rh versus temperature profile), it can be also supposed that the phase of hydrogel changes with varying the temperature of the hydrogel solution in aqueous medium. Below the Lower critical solution temperature (LCST), a decreasing in the size can be seen due to the collapsing of polymer particles and dominance of hydrophilic forces [28, 29].

Conclusion

On the basis of results obtained in this research project, it can be concluded that the surfactants-free emulsion polymerization technique was successfully applied to prepare the PNIPAAm-CS-PAA microgel samples. Due to the presence of PNIPAAm the samples got temperature sensitive properties, while because of the presence of PAA the microgel samples were expected to have pH sensitive behavior as well. The FT-IR, UV-Visible, viscometry and rheometry were used to study the dual-responsive based physicochemical properties of the synthesized hydrogels. The results of these techniques show that various physicochemical properties such as the physical states, stability, size, flow behavior and viscoelastic nature are greatly dependent on the chemical compositions of the samples. Further, these properties were also found to depend on various experimental variables like temperature and pH of the medium. It is further concluded that the insertion of pH-sensitive polymers/components to the crosslinked PNIPAM particles, not only produce dual-sensitive materials but also to regulate the stability of these hydrogel particles in aqueous media. This is further slowing or accelerating their phase separation, depending on the desired application, and hence, it is probable to regulate the material to various hydrophilic environments. The CS monomer helped to control the shrinkage process of PNIPAn-CS-PAA particles above the LCST at all pH values. Mostly the amino (NH2) groups of CS, are no longer protonated at high pH values, the chains of CS that are chemically bonded to the network of polymer remained in the particles, and hence increases the stability of the polymeric material. The PNIPAM-CS-PAA particles with greater amount of PNIPAAm showed higher stability below LCST of PNIPAM, whereas the PNIPAm-CS-PAA particles with relatively greater amount of PAA showed higher stability above LCST of PNIPAAm. The higher the concentration of PNIPAAm the greater will be the amount of hydrophilic component, hence more stable may be the gel particles. On the other hand greater the amount PAA greater is the hydrophilic components above the LCST and hence more stable is the microgel particles. Furthermore, the microgel with relatively high concentration of crosslinker, possibly made the microgel relatively more stable due to higher crosslinking density. The overall results show that the microgels were found to be quite stable at all pH values above the pKa values (4.2) of AA while increasing the pH causes aggregation of particles and decrease in stability of microgels due to the decrease in hydrophobicity. Also the variation in various physicochemical properties of these hydrogels with temperature and pH impart them dual-sensitive behavior, and due to this the hydrogels can be used as potential materials for biomedical and biotechnological purposes in the future.

References

Angar N-E, Aliouche D (2016). Polym Sci Ser A 58:541–549

Seddiki N, Aliouche D (2013). Bull Chem Soc Ethiop 27:447–457

Huang CH, Wang CF, Don TM, Chiu WT (2013). Cellulose 20:1791–1805

Wu W, Shen J, Banerjee P, Zhou S (2010). Biomaterials 31:8371–8381

Lee S-M, Liu K-H, Liu Y-Y, Chang Y-P, Lin C-C, Chen Y-S (2013). Materials 6:1391–1402

Philippova O, Korchagina EV (2012). Polym Sci Ser A Chem Phys 54:552–572

Carreira A, Gonçalves F, Mendonça P, Gil M, Coelho J (2010). Carbohydr Polym 80:618–630

Berger J, Reist M, Mayer JM, Felt O, Gurny R (2004). Eur J Pharm Biopharm 57:35–52

Farooqi ZH, Khan HU, Shah SM, Siddiq M (2013). Arab J Chem 10:329–335

Don T-M, Chen H-R (2005). CarbohydrPolym 61:334–347

Hyun Jung H, Jang MK, Nah JW, Kim YB (2009). Macromol Res 17:265–270

Alvarez-Lorenzo C, Concheiro A (2002). J Control Release 80:247–257

Naeem H, Farooqi ZH, Shah LA, Siddiq M (2012). J Polym Res 19:1–10

Lee C-F, Wen C-J, Lin C-L, Chiu W-Y (2004). J Polym Sci A Polym Chem 42:3029–3037

Seddiki N, Aliouche D (2013). Bull Chem Soc Ethiop 27:447–457

Geever LM, Higginbotham CL (2011). J Mater Sci 46:3233–3240

Jiang H, Su W, Mather PT, Bunning TJ (1999). Polymer 40:4593–4602

Chen H, Hou S, Ma H, Li X, Tan Y (2016). Sci Rep 6:20722

Rudraraju VS, Wyandt CM (2005). Int J Pharm 292:63–73

Higham AK, Bonino CA, Raghavan SR, Khan SA (2014). Soft Matter 10:4990–5002

Taki A, John B, Arakawa S, Okamoto M (2013). Eur Polym J 49:923–931

Eddhahak A, Zidi M (2015). Bio-Med Mater Eng 26:103–114

Marques NDN, Curti PS, Silva-Maia AM, Balaban RC (2013). J Appl Polym Sci 129:334–345

Nesrinne S, Djamel A (2017). Arab J Chem 10:539–547

Stephen AH, Jian-Xin L (2008). AAPS Pharm SciTech 9:651–659

Kratz K, Hellweg T, Eimer W (2000). Coll Surf A 170:137–149

Zhang J, Chu L-Y, Li Y-K, Lee YM (2007). Polymer 48:1718–1728

Khan A, Othman MBH, Razak KA, Akil HM (2013). J Polym Res 20:1–8

Khan A, Othman MBH, Chang BP, Akil HM (2015). Iran Polym J 24:317–328

Acknowledgments

Dr. Abbas Khan and HM Akil wish to thank to the Ministry of Science, Technology and Innovation (MOSTI) Malaysia for sponsoring the project under the Fundamental Research Grant Scheme FRGS/203/PBAHAN/6071242.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khan, A., Sajjad, M., Khan, E. et al. Synthesis, characterization and physiochemical investigation of chitosan-based multi-responsive Copolymeric hydrogels. J Polym Res 24, 170 (2017). https://doi.org/10.1007/s10965-017-1332-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-017-1332-2