Abstract

The concept of crosslinking natural rubber (NR) latex particles bearing diacetone acrylamide (DAAM) functional groups with a hydrazide crosslinker during film formation has been investigated using dynamic mechanical thermal analysis (DMTA). First, graft copolymers of NR and poly(diacetone acrylamide) prepared using 5 and 10 wt% of DAAM (abbreviated as NR-g-PDAAM5 and NR-g-PDAAM10, respectively) were synthesized. Then the dynamic mechanical properties of the cast NR-g-PDAAM latex films were measured. Two separate peaks were observed in tan δ versus temperature. The first peak appeared at −62 °C, which corresponds to glass transition of the NR phase. The second peak at −23 °C for NR-g-PDAAM5 (-18 °C for NR-g-PDAAM10) was tentatively attributed to the characteristics of NR-g-PDAAM phase. Furthermore, a shift to higher temperature of the tan δ peak corresponding to the NR-g-PDAAM phase was observed in the NR-g-PDAAM latex films, when adipic acid dihydrazide (ADH) was added prior to film casting. The added ADH increased the thermal energy required for molecular mobility in the NR-g-PDAAM phase of the cast film, providing evidence of crosslinking between the DAAM functional groups and the ADH during film formation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Natural rubber (NR) latex has been used as a raw material in manufacturing products for various end-use applications (i.e., dipped goods, extruded threads, molded and cast articles, foam products, carpet underlay and water-based adhesives) [1]. The mechanical properties, chemical stability, and solvent resistance of NR latex products can typically be enhanced by crosslinking of the NR molecules. NR latex can be vulcanized by several vulcanization systems (i.e., sulfur/accelerator, peroxide, and radiation vulcanizations), leading to the formation of a three-dimensional network of bonded NR chains. Among these systems, sulfur/accelerator vulcanization is the most popular, and it gained industry acceptance mainly due to the relatively fast rate of vulcanization, low cost, and a good balance of vulcanizate properties [2]. The most important accelerators for this vulcanization system are the salts of dialkyldithiocabamic acids, which are commonly used in combination with zinc activators (most commonly zinc oxide, ZnO) [3]. However, dithiocarbamates (e.g., zinc dimethyldithiocarbamate) are considered as precursors of carcinogenic nitrosamines according to the European law in Regulation TRGS 552 [4, 5]. There is also increasing concern about the release of zinc from rubber products into the environment, which can take place during the production, service, disposal or recycling of rubber vulcanizates containing ZnO. Lately, the International Programme on Chemical Safety (IPCS) formed a Task Force on Zinc to establish Environmental Health Criteria for Zinc [6]. Hence, it is desirable that the rubber products should contain the lowest possible levels of both ZnO and vulcanization accelerators capable of generating nitrosamine precursors. Moreover, the process of crosslinking NR latex using a sulfur/accelerator system is typically carried out at elevated temperatures.

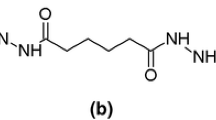

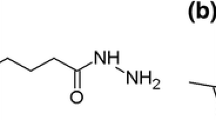

Crosslinking a film of acrylic latex bearing ketone pendant groups can typically be achieved by reactions with a dihydrazide crosslinker. The crosslinking reaction in this system occurs preferentially after the loss of water during drying [7–9]. Diacetone acrylamide (DAAM) has generally been the monomer of choice for providing ketone pendant groups in acrylic latexes, since the ketone carbonyl of DAAM reacts rapidly with hydrazide at ambient temperatures [10, 11]. Adipic acid dihydrazide (ADH) is one of the most widely used di-functional crosslinkers in this system. The coupling reaction between a ketone group and a hydrazide is termed the keto-hydrazide reaction, and the resulting product is an imine (-C = N-) [7].

The chemical grafting of NR with vinyl monomers in the latex stage have been extensively studied (most commonly styrene [12], methyl methacrylate [13], and styrene/methyl methacrylate [14]) since it is considered as the convenient and efficient way to introduce some desirable properties of vinyl monomers into NR. In the present work, poly(diacetone acrylamide), PDAAM, was grafted on NR latex particles to provide sites for crosslinking with ADH crosslinker. In addition to crosslinking under ambient temperature, another benefit is that this vulcanization system uses no dithiocarbamate accelerators or zinc activators. Hence, the NR latex products vulcanized by this system are nitrosamine precursor-free and zinc-free. Graft copolymers of NR and PDAAM containing 5 and 10 wt% of DAAM (labeled here as NR-g-PDAAM5 and NR-g-PDAAM10) were prepared via seeded emulsion polymerization. The particle morphologies of the synthesized graft copolymers were characterized using a transmission electron microscope (TEM). The chemical structure of NR-g-PDAAMs was confirmed using 1H NMR, 13C NMR, and HMQC (Heteronuclear Multiple-Quantum Correlation) experiment.

It is well-known that dynamic mechanical thermal analysis (DMTA) provides information on the viscoelastic properties of materials over a wide temperature range, and reflect molecular mobility. As the mobility of polymer chains is constrained by crosslinking, a higher thermal energy is required to mobilize the polymer chains, so crosslinking tends to increase the glass transition temperature (T g) and modulus of latex films [15, 16]. Thus, changes in the level of crosslinking in a latex film can be monitored through effects on T g and modulus, as observed by the DMTA technique. The principal objective of this work was to study the crosslinking of NR-g-PDAAM latex film by reaction with ADH crosslinker using DMTA.

Experimental

Materials

High ammonia concentrated natural rubber (HANR) was manufactured by Yala Latex Co., Ltd. The dry rubber content (DRC) of the HANR latex was 61.2 %. DAAM with purity 99 %, adipic acid dihydrazide (ADH), cumene hydroperoxide (CHP, 80 %) and tetraethylene pentamine (TEPA, 85 %) were manufactured by Sigma-Aldrich Chemicals and were used as received.

The preparation of NR-g-PDAAM latex

The grafting reaction was conducted under a flowing nitrogen atmosphere in a thermostatic water bath. A solution of sodium dodecyl sulfate (1 g) in 2.5 % (v/v) ammonium hydroxide (68.9 g) was added into the reaction vessel containing NR latex (155.2 or 142.1 g). The reaction mixture was stirred at room temperature for 30 min before CHP (0.47 g) was added. After that, the mixture was heated to 50 °C before a solution of TEPA (0.47 g) in deionized water containing DAAM monomer (5 or 10 g) was added into the reaction vessel at 10 min intervals over a period of 2 h. When the addition of the TEPA solution was complete, the reaction was allowed to proceed for a further 4 h at 50 °C under stirring.

1H NMR, 13C NMR and HMQC characterizations

The crude graft copolymers are expected to contain three main components: ungrafted natural rubber (free NR), ungrafted homopolymer (free PDAAM), and the graft copolymers formed. Thus, solvent extraction was employed to remove free NR and free PDAAM from the crude graft copolymers before NMR analyses. The free NR was extracted from the graft copolymers using light petroleum ether for 24 h. The removal of free PDAAM from the graft copolymers was by extraction with acetone for 24 h. All the NMR spectra (i.e., 1H NMR, 13C NMR, and HMQC spectra) were recorded on a Bruker Avance III 400 MHz spectrometer in deuterated chloroform (CDCl3) using the solvent peak as internal reference (i.e., 7.26 ppm for 1H NMR and 77 ppm for 13C NMR). Two-dimensional HMQC measurements were performed to correlate direct carbon to hydrogen connectivity, as this technique enables the correct attribution of individual proton signals to the directly attached carbons.

Morphological studies

Particle morphology of the crude graft copolymers was investigated using a JEOL JEM-2010 transmission electron microscope (TEM). Each TEM sample was prepared by allowing a drop of diluted latex to dry on a 400-mesh copper TEM grid. After that, the dried latex film on the TEM grid was exposed to osmium tetroxide vapour for 1 h in order to enhance the contrast between NR and PDAAM phases.

Study of keto-hydrazide reaction

The crude NR-g-PDAAM5 latex, with or without the addition of ADH crosslinker, was cast in a silicon mould and allowed to dry at 30 °C for a week before being subjected to analysis. The keto-hydrazide reaction within the corresponding films was investigated by DMTA. DMTA analyses were carried out using a dynamic mechanical thermal analyzer (DMTA − V, Rheometric Scientific). The temperature dependences of dynamic storage modulus (E′), loss modulus (E″), and their ratio (tan δ), were determined in the temperature range from -80 to 100 °C with a 5 °C/min heating rate. The DMTA experiments were conducted in tension mode at the strain amplitude of 0.01 % and the fixed frequency of 1.0 Hz, so that the measurements were within linear viscoelasticity. The test samples were of 5 mm (W) × 50 mm (L) size with varying thicknesses from 1.0 to 1.5 mm.

Results and discussion

Morphological and structural characterization

Particle morphologies of unmodified NR and NR grafted with 5 or 10 wt% of DAAM are presented in Fig. 1. The TEM images clearly reveal the relatively smooth surfaces of NR particles. In contrast, the surfaces of grafted NR particles were coarse due to aggregated PDAAM particles. As osmium tetroxide (OsO4) was used to stain the C = C bonds in NR molecules, the NR seed particles appear dark. The presence of grafted PDAAM chains on the NR particles is confirmed by their comparatively bright appearance, and the graft copolymerization of DAAM mostly occurred on the NR particle surfaces. The observed morphology suggests that once a grafting site was formed on the surface of NR particles, the addition of DAAM monomers propagated into the aqueous phase, and subsequently clusters of PDAAM particles formed onto the NR seed particles. Moreover, such extension of grafted PDAAM chains into the aqueous phase tended to increase with the initial concentration of DAAM in the grafting reaction.

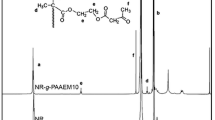

Figure 2 shows the overlaid 1H NMR spectra of NR and NR-g-PDAAM10. The characteristic signals from cis-1,4-polyisoprene were observed in both of these. These signals appear at 5.13, 2.03, and 1.67 ppm, which correspond to the unsaturated methyne proton (-C = CH-), methylene proton (-CH 2-C(CH3) = CH-CH 2-), and methyl proton (-C(CH 3) = CH-) in isoprene units, respectively [17, 18]. However, the appearance of a signal at 2.17 ppm could only be seen in the spectrum of NR-g-PDAAM10. The corresponding signal indicates the presence of methyl protons (CH 3-(C = O)-) in ketone end groups, as expected with grafted chains of PDAAM. Additionally, a signal at 1.35 ppm was assigned to the methyl groups that are attached to the methine carbon in PDAAM repeat units. A multiplet signal centered at about 1.85 ppm is probably due to the protons of methylene groups in the grafted PDAAM chains.

The structure of NR-g-PDAAM10 was also studied by 13C NMR spectroscopy in order to confirm the assessments. The 13C NMR spectra for NR and NR-g-PDAAM10 are shown in Fig. 3 Five characteristic signals of cis-1,4-polyisoprene (i.e., 23.4, 26.2, 32.2, 124.9 and 135.2 ppm) are observed in the 13C NMR spectra of both NR [19] and NR-g-PDAAM10. The 13C-NMR signals at 124.9 and 135.2 ppm correspond to the carbon-carbon double bonds (C = C) of isoprene units. The additional three signals that appeared at 23.4, 26.2, and 32.2 ppm are due to the methyl and two methylene carbons in isoprene units, respectively (see Fig. 3).

However, the two signals that appeared in the aliphatic region at 25.6 and 30.9 ppm could only be observed in the 13C NMR spectra of NR-g-PDAAM10. The signal at 25.6 ppm is probably due to the methylene carbon in the PDAAM units. The peak at 30.9 is assigned to the methyl carbons attached to a carbon-oxygen double bond in the ketone end groups. However, a characteristic signal for carbonyl carbons of ketone (typically appearing in the range of 200 to 220 ppm) could not be seen, as the intensity of this signal is typically low. Figure 4 shows HMQC spectra for NR-g-PDAAM10, which provide information on direct carbon to hydrogen connectivity within a NR-g-PDAAM10 molecule. It can be seen that the 13C NMR signal at 30.9 ppm showed correlation to the 1H NMR signals at 2.17 ppm, which was assigned to methyl protons in the ketone end groups of the DAAM unit. These results confirm the previous assessment of both 1H NMR and 13C NMR spectroscopy. Thus, the weight percentages of grafted PDAAM in the graft copolymers were estimated from the integrals of the peaks at 2.17 ppm and at 5.13 ppm, which represents the olefinic protons in NR molecules, using the following relationship:

where I 2.17 = the integrated peak area of the methyl-ketone protons in PDAAM repeat units; and I 5.13 = the integrated peak area of the olefinic protons of NR. The weight percentage of grafted PDAAM in the NR-g-PDAAM was then determined as follows:

where mol%PDAAM = the mole percentage of PDAAM in the graft copolymers; mol%NR = the mole percentage of NR in the graft copolymers; MDAAM = the molar mass of repeating units for DAAM; and MNR = the molar mass of repeating units for NR.

The estimated amounts of grafted PDAAM on the NR molecules were 2.65 and 5.36 wt%, when using 5 and 10 wt% of DAAM in the grafting reaction, respectively. It was also found that the grafting efficiency (GE) decreased when the initial concentration of DAAM was raised from 5 (%GE = 66.15 at 71.34 % conversion) to 10 wt% (%GE = 50.84 at 79.38 % conversion). The grafting efficiency was determined using a method described in detail elsewhere [17, 18, 20].

Dynamic mechanical properties

The dynamic mechanical properties of the cast films of NR and NR-g-PDAAM latexes without ADH crosslinker were studied first. This analysis provides information about the storage modulus E′ and tan δ of the NR and NR-g-PDAAM films as a function of temperature. Furthermore, the temperature corresponding to the maximal tan δ, (tan δ) max, defines the T g of a polymer [21].

The temperature dependences of E′ for the cast films of NR and NR-g-PDAAMs are presented in Fig. 5a. In the E′ for NR, a large drop with temperature began at about −68 °C. This signifies the beginning of the glass transition region of NR molecules, from a glassy state to a rubbery state. However, two major drops in E′ with temperature were observed for both types of NR-g-PDAAM (i.e., NR-g-PDAAM5 and NR-g-PDAAM10). The first drop started at approximately the same temperature as that of NR, followed by a second drop beginning at −31 °C for NR-g-PDAAM5, and at −29 °C for NR-g-PDAAM10. Moreover, the E′ in the rubbery plateau region for either type of NR-g-PDAAM was consistently higher than for NR. The values of E′ at 30 °C were 2.12 MPa for NR-g-PDAAM5, and 2.11 MPa for NR-g-PDAAM10, which are significantly higher than the 0.83 MPa for NR. This indicates that the grafted PDAAM chains on the NR backbone improved stiffness. The crude graft copolymers are expected to consist mainly of three phases: ungrafted natural rubber phase (free NR phase), ungrafted homopolymer phase (free PDAAM phase), and graft copolymer phase (NR-g-PDAAM phase). Thus, it is possible that the PDAAM phase present in the graft copolymers could act as filler due to its higher T g, resulting in the higher moduli in the second plateau for both types of NR-g-PDAAM. The T g for PDAAM homopolymer prepared by emulsion polymerization was 83 °C, measured by differential scanning calorimetry (DSC), as illustrated in Fig. 6.

Figure 5b presents a comparison of tan δ at 1.0 Hz as a function of temperature for the cast films of NR and the NR-g-PDAAMs. A single tan δ peak was observed for NR, around −57 °C. However, the DMTA thermograms for both types of NR-g-PDAAM reveal two strong transitions. As discussed previously, the free NR, free PDAAM, and NR-g-PDAAM phases are the three main components in these crude graft copolymers. Hence, the first tan δ peak at −62 °C corresponds to the transition of NR, while the second peak at −23 °C for NR-g-PDAAM5 (at −18 °C for NR-g-PDAAM10) is probably due to the NR-g-PDAAM phase. It is well accepted that the T g values determined by DMTA are typically higher than those from DSC analysis. The maximal tan δ, (tan δ)max, is generally considered to represent T g in DMTA analysis [22, 23]. Thus, the tan δ peak for the PDAAM phase present in the graft copolymers is expected to occur at a temperature above 83 °C (i.e., the T g of PDAAM homopolymer determined by DSC = 83 °C, see Fig. 6). Moreover, it was also observed that PDAAM latex prepared by emulsion polymerization did not form a continuous film at ambient temperature. The T g of polymer in the latex particles is a major factor controlling the film formation of latex [24]. As the T g of PDAAM is significantly above ambient temperature, the interdiffusion of PDAAM molecules across interfaces and between particles is unlikely during film formation under ambient conditions. This leads to poor cohesion between the latex particles and, thereby, the formation of a discontinuous film upon drying. However, no tan δ peak appeared in the DMTA thermograms of NR-g-PDAAMs at temperatures above 83 °C (see Fig. 5b). This indicates that the PDAAM homopolymer amount was relatively low in the graft copolymers, at least as a separate phase.

Hence, films cast from a blend of NR and PDAAM latexes were prepared with NR/DAAM = 90/10 by weight (abbreviated as NR-blend-PDAAM10), in order to determine T g of the PDAAM phase. The dynamic mechanical properties of the NR-blend-PDAAM10 film were subsequently investigated and compared to those of NR. It can be seen from Fig. 7a that the E′ of NR-blend-PDAAM10 decreased noticeably at about -68 °C, indicating the point at which the NR phase in the corresponding blend underwent its phase transition from glassy to rubbery state. However, the decline in the value of E′ above the T g of NR phase was less pronounced than of the neat NR. As temperature increased above the T g of NR, the E′ of NR-blend-PDAAM10 decreased only gradually. Moreover, two separate peaks of tan δ versus temperature at a frequency of 1.0 Hz were observed for NR-blend-PDAAM10, indicating that the phase separation was not a very clear cut case. The first tan δ peak appeared at about −60 °C, which is slightly lower than the T g of NR (−57 °C). The second was a broad peak appearing over the wide 20–100 °C range of temperatures. This suggests that some PDAAM chains in the latex blend were entangled with the NR molecules. Thus, phase mixing between these two polymers is indicated, as this would give rise to a broad tan δ peak when the glass transition varies over a wide range of temperatures.

Additionally, it was also observed that the magnitude of tan δ peak corresponding to the transition of NR phase in the NR-blend-PDAAM10 was much lower than that observed for the unblended NR. This suggests that mobility of the NR phase in the NR-blend-PDAAM10 was restricted due to entanglement with the PDAAM phase. Annealing may refine the phase-separated morphology of polymer blends, and annealing of the NR-blend-PDAAM latex film was conducted at 100 °C for 1 h under vacuum in order to avoid the oxidative degradation of the polymers. When the thermal transitions were evaluated, an increase of the E′ in the rubbery plateau region of NR-blend-PDAAM10 was observed due to annealing. This implies morphology development in the NR-blend-PDAAM10 latex film during annealing, since the rubbery plateau modulus is sensitive to the morphological changes [25]. It can also be observed that the tan δ peak corresponding to PDAAM phase became much narrower with annealing, and the centre of the peak was at about 89 °C. Moreover, the observed value of T g for PDAAM phase in the annealed NR-blend-PDAAM10 film coincides with the T g value of pure PDAAM homopolymer (83 °C) as determined by DSC. This suggests that the thermal annealing process induces the phase separation of entangled chains in the NR-blend-PDAAM latex film. Hence, these data support the idea that the tan δ peak observed at -18 °C, in the DMTA thermograms of NR-g-PDAAM10, corresponds to a transition of the NR-g-PDAAM phase. The results also show that the value of T g for PDAAM phase (~ −18 °C) in the graft copolymers is much lower than that of the PDAAM homopolymer (~ 89 °C). PDAAM can undergo intra- and inter-molecular hydrogen bonding between the amide hydrogen atoms and the oxygen atoms in the carbonyl groups, as shown in Fig. 8. The ability to hydrogen bond between the PDAAM chains increases the interchain attraction, which reduces chain mobility and, subsequently, gives rise to an increased T g. Thus, the T g for PDAAM homopolymer was expected to be higher than that of the grafted PDAAM on NR molecules. This is because the NR molecules impede the ability of PDAAM chains to undergo interchain hydrogen bonding, which leads to a reduction in the interchain forces and, thus, lowers the T g.

Study of keto-hydrazide reaction

As reported earlier, the grafting efficiency was highest when using a 95/5 weight ratio of NR/DAAM in the grafting reaction. Therefore, the NR-g-PDAAM5 graft copolymer obtained from the corresponding reaction was selected for a study of the keto-hydrazide reaction. The crosslinking in this system is expected to take place between the ketone carbonyl groups in the DAAM repeat units and the hydrazide groups of ADH. This coupling reaction is commonly referred to as the keto-hydrazide reaction. It can be seen from Scheme 1 that an 0.5:1 molar ratio of ADH:DAAM is stoichiometric for this reaction. In the current study, the intention was to investigate by DMTA technique the feasibility of ADH as a crosslinker for NR-g-PDAAM latex films. Therefore, two levels of ADH, namely 2.42 g (14.01 mmol) or 4.86 g (27.89 mmol), were thoroughly mixed into a 50 g of NR-g-PDAAM5 latex (i.e., comprising 27.78 mmol of DAAM) prior to film casting. The former is the stoichiometrically minimal level with ADH:DAAM molar ratio of 0.5:1, while the latter has a two-fold excess of ADH (ADH:DAAM molar ratio of 1:1).

Figure 9a presents the experimental data on E′ against temperature, for the cast films of NR-g-PDAAM5 with the two levels of ADH crosslinker. In all cases, two large drops in E′ can be seen in the DMTA thermograms. The first drop in E′ appears when the temperature reaches the T g of NR (~ −68 °C). After that, a slight decline in E′ is observed, indicating that only the NR phase in the graft copolymers went through a glass transition, whereas the NR-g-PDAAM phase remained intact at temperatures slightly above the T g of NR. As the temperature continues to increase, the second drop in E′ is reached, signifying the NR-g-PDAAM phase undergoing its transition from glassy to rubbery state. The onset of the second drop in E′ for the cast film without ADH is observed at about −31 °C. However, the fall in E′ that corresponds to the transition of NR-g-PDAAM phase had shifted to higher temperatures with the addition of ADH, which was incorporated into the latex prior to film casting. This indicates that the crosslinking reaction occurred through DAAM functional groups by reaction with ADH during film formation. The values of E′ in the rubbery plateau for the cast films with ADH are higher than those without ADH. Moreover, in Fig. 9a the E′ in the rubbery plateau clearly increased with the molar ratio of ADH:DAAM. This is probably because of a higher level of interfacial crosslinking between the NR-g-PDAAM particles with increased amounts of ADH.

Figure 9b reveals that the tan δ peak corresponding to the transition of NR phase in the NR-g-PDAAM5 film did not shift significantly with the varying amounts of ADH. However, a noticeable decrease in the value of (tan δ)max for the NR phase in the films was observed. The value of tan δ is related to the mobility of polymer chains at a given temperature. A low value of tan δ indicates low mobility of the chain segments [26]. Thus, these results indicate that the mobility of NR chains in the film with a two-fold excess of ADH was more restricted than with a stoichiometric amount of ADH. This is attributed to increased crosslinking with an excess of ADH. It is well-known that the degree of swelling is inversely dependent on the crosslink density of rubber networks. Reduced swelling indicates increased crosslink density. Thus, the crosslink density of vulcanized rubber can typically be estimated from equilibrium swelling measurements [27–29]. The value of crosslink density (ν) is usually calculated from equilibrium swelling data using the Flory-Rehner equation, as follows [30, 31]:

where V s is the molar volume of solvent (toluene = 106.28 cm3/mol) and χ is the interaction parameter for a specific polymer-solvent pair. It should be noted that the value of χ for NR-toluene system (0.38) was used in this calculation. V r is the volume fraction of polymer in the swollen film, which can be calculated according to the method of Ellis and Welding [32]:

where D is the deswollen weight of latex film, F is the weight fraction of insoluble components (i.e., other than the rubber) in the latex film, T is the initial weight of the latex film before swelling, A s is the weight of solvent in the swollen film. ρ r and ρ s are the densities of rubber and solvent (toluene = 0.865 g/cm3), respectively.

Crosslink densities of the NR-g-PDAAM films with the two levels of ADH (i.e., ADH:DAAM molar ratios of 0.5:1 and 1:1) were estimated, to compare with the results from DMTA analysis. The NR-g-PDAAM films were first immersed in toluene at 25 °C in a dark environment until equilibrium swelling was reached. After that, the crosslink density (ν) in latex film was estimated from the swelling data (i.e., V r) according to the Flory-Rehner equation, Eq. (3). Table 1 shows parameters used for estimating the V r of NR-g-PDAAM5 films formed in the presence of two corresponding levels of ADH. The estimates of crosslink densities reveal that a two-fold excess of ADH (ν = 6.49 × 10−5 mol/cm−3) gave a higher crosslink density in the latex film than a stoichiometric amount of ADH (ν = 5.95 × 10−5 mol/cm−3). This corroborates the observed higher storage modulus E′ in the rubbery plateau region for the former type of film.

It can also be seen from Fig. 9b that the tan δ peak, corresponding to the T g of NR-g-PDAAM phase, broadened and shifted to a higher temperature when ADH was incorporated into the graft copolymer latex before film casting. The T g can be defined as the temperature at which the onset of cooperative segmental motion becomes feasible. A higher thermal energy is required for substantial rotational and translational motions of polymer chain segments with crosslinking than without [26]. An increase in T g is thus caused by the molecular mobility restrictions due to crosslinking. Hence, a clear shift towards higher temperatures of the tan δ peak assigned to NR-g-PDAAM phase corroborates interfacial crosslinking between the DAAM functional groups that reacted with ADH during film formation.

Conclusion

The feasibility of using the DMTA technique to assess crosslinking was demonstrated for the case of NR-g-PDAAM particles reacted with ADH during film formation. It was also demonstrated that ADH is an effective crosslinker for NR-g-PDAAM latex films under ambient conditions. The loss tangent tan δ, at T g for the NR phase, decreased as ADH was added into NR-g-PDAAM latex before film casting. Additionally, a clear shift to higher temperatures of the tan δ peak that corresponds to T g of the NR-g-PDAAM phase, was also observed. These results provide irrefutable evidence that crosslinking occurred in the NR-g-PDAAM latex film when reacted with ADH during film formation. Hence, grafting of DAAM repeat units onto NR particles offers new opportunities for crosslinking NR latex film under ambient temperature via keto-hydrazide reaction, which is a nitrosamine precursor-free and zinc-free vulcanization system.

References

Kabara JJ, Lopez J, Robert CF (2006) Natuurrubber 41:1–2

Kuriakose AP (1996) In: Salamone JC (ed) Polymeric materials encyclopedia. New York, CRC Press

Blackley DC (1997) Polymer latices: science and technology, vol 3, 2nd edn. Chapman and Hall, London

Chauvin B, Mangere JL (2002) U.S. Patent 20020180078 A1

Higashira T, Yokota A, Matsumoto N (2010) U.S. Patent 20100261004 A

WHO (2001) Environmental health criteria 221: Zinc, World Health Organization. International Programme on Chemical Safety, Geneva

Kessel N, Illsley DR, Keddie JL (2008) J Coat Technol Res 3:285–297

Foster AB, Lovell PA, Rabjohns MA (2009) Polymer 50:1654–1670

Zhang X, Liu Y, Huang H, Li Y, Chen H (2012) J Appl Polym Sci 123:1822–1832

Mori A, Tashiro K, Makita K, Takatani M, Okamato T (2005) J Wood Sci 41:33–37

Mori A, Tashiro K, Makita K, Takatani M, Okamato T (2005) J Wood Sci 41:38–41

Tho NV, Kadir MOA, Hashim AS (2002) Rubber Chem Technol 75:111–118

Kalkornsurapranee E, Sahakaro K, Kaesaman A, Nakason C (2009) J Appl Polym Sci 114:587–597

Man SHC, Hashim AS, Akil HM (2008) J Polym Res 15:357–364

Mark HF (2007) Encyclopedia of polymer science and technology, concise, 2nd edn. Wiley, New Jersey

Lamb DJ, Anstey JF, Fellows CM, Monteiro MJ, Gilbert RG (2001) Biomacromolecules 2:518–525

Kangwansupamonkon W, Gilbert RG, Kiatkamjornwong S (2005) Macromol Chem Phys 206:2450–2460

Kochthongrasamee T, Prasassarakich P, Kiatkamjornwong S (2006) J Appl Polym Sci 101:2587–2601

Saito T, Klinklai W, Kawahara S (2007) Polymer 48:750–757

Arayapranee W, Prasassarakich P, Rempel GL (2002) J Appl Polym Sci 83:2993–3001

Menard KP (2008) Dynamic mechanical analysis: a practical introduction, 2nd edn. Taylor & Francis Group, Florida

Lee D-Y, Subramaniam N, Fellows CM, Gilbert RG (2002) J Polym Sci A Polym Chem 40:809–822

Diez J, Bellas R, López J, Santoro G, Marco C, Ellis G (2010) J Polym Res 17:99–107

Wicks ZW, Jones FN Jr, Pappas SP, Wicks DA (2007) Organic coatings: science and technology, 3rd edn. Wiley, New Jersey

Harrats C, Mekhilef N (2005) In: Harrats C, Thomas S, Groeninckx G (eds) Micro- and nanostructured multiphase polymer blend systems: phase morphology and interfaces. New York, CRC Press

Ebewele RO (2000) Polymer science and technology. CRC Press, New York

Radhakrishnan CK, Kumari P, Sujith A, Unnikrishnan G (2008) J Polym Res 15:161–171

Wang J, Yang K, Zheng X (2009) J Polym Res 16:427–436

Keawkumay C, Jarukumjorn K, Wittayakun J, Suppakarn N (2012) J Polym Res 19:9917

Flory PJ, Rehener J (1943) Statistical mechanics of crosslinked polymer networks II. Swelling J Chem Phys 11:521–526

Hagen R, Salmen L, Stenberg B (1996) J Polym Sci B Polym Phys 34:1997–2006

Ellis B, Welding GN (1964) Rubber Chem Technol 37:563–570

Acknowledgments

This work was supported by the Higher Education Research Promotion and National Research University Project of Thailand, Office of the Higher Education Commission. The authors would like to thank the Research and Development Office (RDO) and Assoc. Prof. Seppo Karrila for editing this article.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Thongnuanchan, B., Ninjan, R., Kaesaman, A. et al. Studies on the ambient temperature crosslinking of latex films based on natural rubber grafted with poly(diacetone acrylamide) using DMTA. J Polym Res 22, 115 (2015). https://doi.org/10.1007/s10965-015-0760-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-015-0760-0