Abstract

In this work, we have studied the effect of thickness \(\delta\) on the microstructural and magnetic properties of nanocrystalline Zr\(_{6}\)Co\(_{23}\) films grown on MgO(001) substrate. A series of Zr\(_{6}\)Co\(_{23}\)/MgO(001) films have been prepared for different thickness \(\delta\). The coercivity H\(_{c}\), the squareness factor S* and the anisotropy field H\(_{a}\) are investigated as a function of \(\delta\) thickness and grain sizes \(\Phi\). The excellent magnetic properties are found for \(\delta\) = 100 nm: the coercivity H\(_{c}\) = 3020 Oe, maximum energy product (BH)\(_{max}\) of 28 MGOe and magnetic anisotropy constant K\(_{1}\) \(\simeq\) 1.35 \(\times\) 10\(^{7}\) erg/cm\(^{3}\). The relationships between exchange interaction, magnetic domain structure and anisotropy parameters are discussed. The obtained results provide the fundamental reference to adapt the magnetic properties of Zr\(_{6}\)Co\(_{23}\)/MgO(001) films for potential applications in the permanent magnet domain.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The development of thin films based on Co alloys is of major interest in industrial application fields [1,2,3].Their important magnetic properties thus give them use in permanent magnets, magnetic recording high density and spintronic devices [4,5,6]. Among these alloys, ZrCo alloys exhibit a high coercivity H\(_C\) and magnetocrystalline anisotropy H\(_{a}\). These properties place them among the best performing magnetic materials [7,8,9,10]. In the binary Zr-Co system, several compounds are formed: ZrCo, Zr\(_{2}\)Co, Zr\(_{3}\)Co, ZrCo\(_{5}\), Zr\(_{2}\)Co\(_{11}\), ZrCo\(_{2}\), Zr\(_{4}\)Co, Zr\(_{6}\)Co\(_{23}\) and Zr\(_{3}\)Co\(_{2}\) which have quite diverse structural and magnetic properties [12,13,14] ZrCo type of magnets are known an industrial and technological scale mainly under three stoichiometries: ZrCo\(_5\), Zr\(_{2}\)Co\(_{11}\) and Zr\(_{6}\)Co\(_{23}\), which have very important magnetic properties related to 3d-3d hybridization and 3d-3d exchange interactions [15,16,17]. Burzo et al. [13, 18, 19] reported that the ZrCo5 compound exhibits ferromagnetic behavior with uniaxial anisotropy greater than 99902 Oe and the Curie temperature T\(_{C}\) is around 800 Gabay et al. [13, 14, 18] found a H\(_c\) of 2488 Oe and a maximum energy product (BH)\(_{max}\) of 10.1 MGOe for Zr\(_{16.4}\)Co\(_{83.6}\) (Zr\(_{2}\)Co\(_{11}\)) compound produced arc melting. The magnetic anisotropy H\(_{a}\) = 9927 Oe and the Curie temperature T\(_{C}\) = 773 Saito et al. [8, 9] studied the magnetic properties of Zr\(_{18}\)Co\(_{80}\)B\(_{2}\) melt-spun ribbons. The (BH)\(_{max}\) = 46.5 MGOe and H\(_{c}\) = 5026 Oe, consecutively. The Zr\(_{2}\)Co\(_{11}\)/Si(100) films (for thickness \(\delta\) = 1 nm) have a high H\(_{c}\) = 3041 Oe and (BH)\(_{max}\) \(\simeq\) 24 MGOe [20]. The best magnetic properties of ZrCo\(_{5}\)/MgO(100) film are found for thickness \(\delta\) = 40 nm [21]. The H\(_{c}\) is around 65 Oe, (BH)\(_{max}\) \(\simeq\) 9.4 MGOe and uniaxial anisotropy constant K\(_{u}\) \(\simeq\) 7.8 \(\times\) 10\(^{5}\) erg/cm\(^{3}\). The Zr\(_{6}\)Co\(_{23}\) alloy presents fascinating magnetic properties. The Curie temperature T\(_{C}\) of 766 K, saturation polarization J\(_{s}\) \(\simeq\) 25132 Oe and H\(_{a}\) = 101159 Oe [10, 11]. The interesting obtained results suggest that films of Zr6Co\(_{23}\) compound can also have excellent magnetic properties. The preparation of these films with different thicknesses can result in varying surface morphology (island/grain size, roughness), domain patterns, magnetic anisotropies that can significantly influence the overall magnetic properties and magnetization reversal mechanism of films. In this context, in the present work, a detailed study has been undertaken to understand the structure, surface morphology, magnetic microstructure and magnetic properties of Zr\(_{6}\)Co\(_{23}\) films over a wide range of thicknesses. The Zr\(_{6}\)Co\(_{23}\) films were prepared by Pulsed Laser Deposition (PLD) on MgO(001) substrate. The influence of thickness \(\delta\) on microstructure and magnetic properties was investigated. The relationships between morphology, exchange interaction and magnetic anisotropy properties are discussed. We optimized the microstructure of Zr\(_{6}\)Co\(_{23}\)/MgO(001) films in order to find high extrinsic magnetic properties.

2 Experimental Procedures

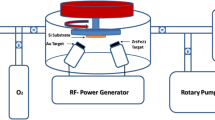

2.1 Nanocrystalline Zr\(_{6}\)Co\(_{23}\)/MgO(001) Film Preparation

Zr\(_{6}\)Co\(_{23}\)/MgO(001) films were prepared by Pulsed Laser Deposition (PLD) from nanocrystalline Zr\(_{6}\)Co\(_{23}\) powder, using a Nd:YAG laser with wavelength \(\lambda\) = 535 nm, repetition rate of 10 Hz and max pulse energy of 2 \(\times\) 10\(^{8}\) J [22, 23]. The nanocrystalline Zr6Co\(_{23}\) powder was prepared by mechanical alloying method for 72 h of milling time (Sect. 3.1). Before deposition, the Zr\(_{6}\)Co\(_{23}\) target (Zr: Zirconium, Co: Cobalt, purity: 99.999 %) was ablated for 40 s to remove the contaminations. During deposition, the laser beam was at 45\(^\circ\) incidence on the Zr\(_{6}\)Co\(_{23}\) target. The Zr\(_{6}\)Co\(_{23}\) target and the MgO(001) substrate were rotated for uniform ablation and homogeneous deposition. Eight samples of Zr\(_{6}\)Co\(_{23}\) films were deposited on [1mm \(\times\) 0.5 mm] MgO(001) substrate wafers using several laser shots from 1500 to 6000, by ablating the laser beam on Zr\(_{6}\)Co\(_{23}\) target at deposition temperature 673 K. The thickness of Zr\(_{6}\)Co\(_{23}\) layer was 10, 50, 100, 150, 200, 250, 300 and 400 nm. After deposition, a 20 nm thick Au overlay layer was deposited on the top of Zr\(_{6}\)Co\(_{23}\) films to avoid oxidation. The growth parameters during the Pulsed Laser Deposition (PLD) are summarized in Table 1.

2.2 Microstructure and Magnetic Characterizations

The microstructural characterizations of Zr\(_{6}\)Co\(_{23}\)/MgO(001) film were analyzed by grazing incidence X-ray diffraction (GIXRD) technique. The surface morphologies, chemical compositions and cross-sectional images were detected by Field Emission Scanning Electron Microscope (FESEM) equipped energy-dispersive spectrometer (SEM-EDS). High-resolution transmission electron microscopy (HRTEM) imaging was performed using Tecnai G20 TEM. Atomic force microscopy (AFM, 3SPA-300HV) was employed to characterize the surface roughness (R\(_{rms}\)) and grain size (\(\Phi\)) of films. The magnetic properties are investigated using a superconducting quantum interference device (SQUID) magnetometer Quantum Design MPM-SXL, vibrating sample magnetometer (VSM, BHV-525) and magnetic force microscopy (MFM).

3 Results and Discussion

3.1 Microstructure and Magnetic Properties of Nanocrystalline Zr\(_{6}\)Co\(_{23}\) Powders

The nanocrystalline Zr\(_{6}\)Co\(_{23}\) powders were prepared by high-energy ball milling [24, 25]. After milling for 5 hours with ball to powder ratio of 15/1, under high purity Ar atmosphere, the Zr6Co\(_{23}\) samples, enveloped in tantalum foil, were annealed for 72 h in sealed silica tube under 10\(^{-6}\) Torr at several annealing temperature T\(_a\) from 600 K to 1750 K. The crystal structure of Zr\(_{6}\)Co\(_{23}\) sample was detected by X-ray diffraction (XRD) with CuK\(_\alpha\) radiation. The pattern refinement was performed with the FULLPROF computing code based on the Rietveld technique [26,27,28]. The goodness-of-fit parameters \(\chi ^2\) and R\(_B\) were used as numerical criteria to describe the quality of the fit between calculated and experimental XRD data [29,30,31]. Zr\(_{6}\)Co\(_{23}\) powders annealed at 1173 K. The result of the structure refinement shows the presence of a main phase with the cubic Th\(_{6}\)Mn\(_{23}\) type structure (Fm-3m space group (No.225)). We note minor quantities of the oxide phases appearing due to selective oxidation of ZrO\(_{2}\) and Zr\(_{6}\)O. The lattice parameters are a = b = c = 8.2662 Å. The Zr atoms occupy the crystallographic 24e sites while Co atoms occupy two 32f sites, 24d and 4e sites. The lattice parameters, R\(_a\) and \(\chi ^2\) factors from Rietveld fit are given in Table 2. These values of structural parameters are in agreement with the results obtained previously [32, 33]. The T\(_{C}\) temperature of Zr\(_{6}\)Co\(_{23}\) compound was determined from the M(T) curve by extrapolating the linear part of the M(T) curve and finding the temperature value of the intersection with the extended baseline [34, 35] (Fig. 1(b)). The T\(_{C}\) temperature is around 768 K. In order to study the extrinsic properties, we have optimized the Zr\(_{6}\)Co\(_{23}\) microstructure, which can lead us to the best coercivity H\(_{c}\). We have therefore used, for this compound, several annealing at different temperatures T\(_a\). The optimum extrinsic magnetic properties are obtained for T\(_a\) = 1173 K: H\(_{c}\) = 10172 Oe, M\(_{r}\) = 50.12 emu/g and (BH)\(_{max}\) = 50.73 MGOe. Figure 2 shows the hysteresis loop at 298 K, for the nanocrystalline Zr\(_{6}\)Co\(_{23}\) sample annealed at 1173 K.

3.2 Microstructure Properties of Nanocrystalline Zr\(_{6}\)Co\(_{23}\)/MgO(001) Films

Figure 3 illustrates the GIXRD patterns of Zr\(_{6}\)Co\(_{23}\)/MgO(001) films deposited at 673 K for different thickness: \(\delta\) = 10 nm, 100 nm, 200 nm and 400 nm. The peak at 2\(\theta\) = 44.37\(^{\circ }\) and 69.48\(^{\circ }\) corresponds to (4 4 0) and (6 6 0) reflections, consecutively, indexed as cubic structure Th\(_{6}\)Mn\(_{23}\) type with Fm-3m space group [10]. The identification of the obtained peaks was made by assigning Miller indices (hkl) to the various recorded peaks using the Bragg condition and X’Pert high score database [36]. The majority of diffraction peaks of the films for \(\delta\) < 400 nm correspond to plane families (h k 0). For \(\delta\) = 400 nm, the appearance of peaks at 2\(\theta\) = 37.20\(^{\circ }\) and 66.7\(^{\circ }\) corresponds to Zr\(_{6}\)Co\(_{23}\)(4 4 2) and Zr\(_{6}\)Co\(_{23}\)(7 3 3) reflection can be seen. The additional peak at 2\(\theta\) = 39.7\(^{\circ }\) and 45.5\(^{\circ }\) corresponds to Au(1 1 1) and MgO(0 0 1) reflections, consecutively. The grains size \(\Phi\) is evaluated from Scherrer’s formula [37,38,39]: Φ = \(\kappa\) \(\lambda\)/(\(\beta _{L}\).Cos\(\theta\)), where \(\beta _{L}\) is the full-width at half-maximum (FWHM) of the peaks at the diffraction angle \(\theta\) [29, 40, 41]. κ is the shape factor, equal to 0.9 in the present study. The calculation of the FWHM has been achieved for all films considering the most intense peak (4 4 0) at 2\(\theta\) = 44.37\(^{\circ }\). The average grain size \(\Phi\) is around 14 nm , 17 nm , 40 nm , 76 nm , 110 nm , 178 nm, 201 nm and 232 nm for thickness: \(\delta\) = 20 nm , \(\delta\) = 50 nm , \(\delta\) = 100 nm, \(\delta\) = 150 nm, \(\delta\) = 200 nm, \(\delta\) = 250 nm, \(\delta\) = 300 nm and \(\delta\) = 400 nm, consecutively (Table 4).

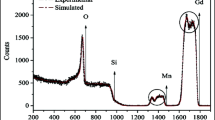

Figure 4 shows the cross-sectional STEM HAADF micrograph of Zr\(_{6}\)Co\(_{23}\)/MgO(001) films for \(\delta\) = 10 nm (a), 100 nm (b) and 400 nm (c). The boundary MgO/Zr\(_{6}\)Co\(_{23}\) and Zr\(_{6}\)Co\(_{23}\)/Au interfaces between the different layers: MgO, Zr\(_{6}\)Co\(_{23}\), and Au are clearly seen. ESEM micrographs illustrate typical overviews of granular morphology of each sample (Fig. 4(a*, b*, c*)). Figure 5(a) presents the energy-dispersive x-ray spectroscopy (EDS) data analysis of Zr\(_{6}\)Co\(_{23}\) layers. EDS analysis was performed by scanning field emission electron microscopy (FESEM). The atomic percentage of Zr and Co, was 20.7 % and 79.3 %, consecutively (Fig. 5(a)). The stoichiometric proportions of Zr\(_{6}\)Co\(_{23}\) were roughly maintained. An EDX line profile was carried through between the grains (Fig. 5(c)), presenting the intensity distribution profiles of the Zr, Co and O elements. The black line corresponds to the Zr profile, the red line to Co. The O is plotted using a blue line (Fig. 5(b)). A slight diminution of Zr intensity between the grains indicates a phase richer in O. Elemental maps carried on the location shown in Fig. 5(d), (e) and (f) confirm a O enrichment in the area in between the large grains. The appearance of oxygen in the films is due to the residual oxygen used during the deposition. We note the presence of some traces of impurities (C, Si and Ni) with low atomic percentage. The atomic compositions obtained by EDX analysis for different thickness \(\delta\) are summarized in Table 3.

By making a statistic on the grain size, the grain size distribution of thickness: \(\delta\) = 10 nm, 100 nm and 400 nm is illustrated in Fig. 6. The average grain size \(\Phi _{TEM}\) was estimated to be 15 nm, 35 nm and 230 nm, consecutively. The corresponding selected area electron diffraction (SAED) patterns are presented in the inset; it exhibits brilliant diffraction rings, which is a typical characteristic of nanocrystalline phase.

Cross section SEM HAADF micrograph of nanocrystalline Zr\(_{6}\)Co\(_{23}\)/MgO(001) films for thickness: \(\delta\) = 10 nm (a), 100 nm (b) and 400 nm (c). ESEM micrographs of nanocrystalline Zr\(_{6}\)Co\(_{23}\)/MgO(001) films for thickness: \(\delta\) = 10 nm (a*), 100 nm (b*) and 400 nm (c*). The corresponding selected area electron diffraction (SAED) patterns are presented in the inset

The surface topography images were obtained from the atomic force microscope (AFM) used as a source of information on root-mean-square roughness R\(_{rms}\) and grain size \(\Phi\) [42]. Figure 7 shows (2D) AFM images of Zr\(_{6}\)Co\(_{23}\)/MgO(001) films as a function of \(\delta\) thickness, over an area of 500 nm \(\times\) 500 nm. The grains were evenly distributed over the surface of the substrate. The grain size estimation \(\Phi\) in each case was given in the respective figures. The found values of \(\Phi\) are in good agreement with the results obtained by GIXRD and TEM analysis. The surface roughness can be quantitatively defined by the root-mean-square roughness R\(_{rms}\) given by [43]:

where h\(_{n}\) represents the height of particle number n, \(\hbar\) is the average of the heights h\(_{n}\) and N is the total number of particles measured by AFM [44]. The variation of R\(_{rms}\) as a function of \(\delta\) thickness is shown in Table 4.

3.3 Magnetic Properties of Nanocrystalline \(\text {Zr}_{6}\text {Co}_{23}/\text {MgO}(001)\) Films

The hysteresis loops of \(\text {Zr}_{6}\text {Co}_{23}/\text {MgO}(001)\) film for different \(\delta\) thickness are given in Fig. 8. We extracted the extrinsic magnetic properties. The evolution of the coercivity \(\text {H}_\text {c}\), the maximum energy product \((\text {BH})_{max}\), the remanent magnetization \(\text {M}_{r}\) and the squareness factor S* were investigated as a function of \(\delta\) thickness and grain size \(\Phi\). Table 5 summarizes the evolution of \(\text {H}_{c}\), \(\text {M}_{r}\) and \((\text {BH})_{max}\) as a function of \(\delta\) thickness. The \(\text {H}_{c}\) increases with the thickness \(\delta \, <100 \text { nm}\). Then, a monotonous decrease of \(\text {H}_{c}\) was observed from 3020 Oe for \(\delta\) = 100 nm to 513 Oe for \(\delta\) = 400 nm. The high extrinsic magnetic properties were obtained for \(\delta\) = 100 nm: \(\text {H}_{c}\) = 3020 Oe, \(\text {M}_{r} = 222 \text { emu}/\text {cm}^{3}\) and \((\text {BH})_{max}\) = 28 MGOe. The small \(\text {H}_{c}\) and \((\text {BH})_{max}\) for thickness \(\delta\) = 400 nm due to an unfavorable microstructure related to the large grain size \(\Phi \,\simeq\) 232 nm. The \(\text {H}_{c}\) variation as a function of \(\Phi\) can be described by \(\text {H}_{c}(1/\Phi )\) [45, 46]. The critical grain size \((\Phi_c)\) from single domain to multi-domain can be determined from the following formula [47]:

where \(\kappa\) = (2k\(_{B}\).K\(_{1}\).T\(_{C}\)/\(\varrho\))\(^{1/2}\) is the domain wall energy. k\(_{B}\) is Boltzmann constant, K\(_{1}\) is anisotropy constant, T\(_{C}\) is Curie temperature, \(\varrho\) is the lattice coefficient. The value obtained of \(\Phi _c\) from formula (2) is around 41.5 nm. This result is in good agreement with the experimental value (\(\Phi _c\) = 40 ± 2 nm) for Zr\(_{6}\)Co\(_{23}\)/MgO(001) (\(\delta\) = 100 nm) films. MFM is becoming one of the most used techniques for imaging magnetic domains [48]. Figure 9 presents the topographic MFM images of Zr\(_{6}\)Co\(_{23}\)/MgO(001) films for \(\delta\) = 10 nm, 100 nm, 300 nm and 400 nm. The MFM images show that the films surface majority interacts magnetically with MFM probe. The observed contrasts clearly exhibit the existence of magnetic domains dispersed in the surface analyzed. A large number of uniform magnetic domains were seen in thickness \(\delta\) between 10 nm and 100 nm (Fig. 9(a) and (b)). For \(\delta\) = 10 nm did show a significant contribution of magnetic moments on the surface, whilst films for \(\delta\) = 100 nm presented the single domains formation ranging in size 15 - 30 nm. At \(\delta\) greater than 150 nm, the magnetic domains became larger. The domains were less distinct for \(\delta\) = 400 nm (Fig. 9(d)). This implies that there is a rise in the grains number that are in a magnetic multi-domain state. The magnetic structure change of Zr\(_{6}\)Co\(_{23}\)/MgO(001) film is the reason for the reduction of H\(_{c}\) and (BH)\(_{max}\) for 400-nm film. Note that the average magnetic domain size is much larger than the average grain size. That is, one domain includes several grains, which is called an interaction domain [49]. This indicates the presence of a strong exchange coupling interaction between neighboring grains [50, 51]. The variation of the interaction domain size with thickness is attributed to the varied grain morphology and non-uniform grain size [52].

The magnetization curves M(H) of Zr\(_{6}\)Co\(_{23}\)/MgO(001) films as a function of \(\delta\) thickness are given in Fig. 10. The determination of saturation magnetization \(M_s\) was performed using the following approximate expression [53,54,55]

H is the applied magnetic field. The coefficient is related to anisotropy field H\(_{a}\), a = - \(\frac{2}{105}\) H\(_{a}^{2}\). Expression (3) describes the magnetization approaching saturation in a system of randomly oriented particles with a cubic anisotropy [56]. The Zr\(_{6}\)Co\(_{23}\) compound has a cubic type crystal lattice in the nanocrystalline state. The magnetic moments in this compound are oriented toward several particular directions, so it has several easy magnetization axes (i.e., multiaxial) exhibiting a cubic anisotropy. The magnetization in a grain is supposed to be oriented in the same direction [2]. Each crystal grain has a cubic form in which the magnetic moment is uniformly distributed. The values of anisotropy constant K\(_{1}\) have been calculated using the relation K\(_{1}\) = \(\frac{H_{a} M_{s}}{2}\). The saturation magnetization (M\(_{s}\)) increases from 249 emu/cm\(^{3}\) at \(\delta\) = 10 nm to 327 emu/cm\(^{3}\) at \(\delta\) = 200 nm, then decreases for \(\delta\) > 200 nm. The M\(_{s}\) decrease also leads to a decrease of K\(_{1}\) from 1.35 \(\times\) 10\(^{7}\) erg/cm\(^{3}\) to 0.18\(\times\) 10\(^{7}\) erg/cm\(^{3}\) (Table 6) and may be an additional reason for the disagreement on the thickness \(\delta\) = 400 nm. The squareness factor S* > 0.5 indicates strong exchange interactions between the adjacent crystallites [57,58,59,60]. The H\(_{c}\) is correlated with M\(_{s}\) and K\(_{1}\), which goes well with the Stoner Wohlfarth theory [43, 61]: \(H_{c} = \alpha \frac{2K_1}{M_s} - N \frac{M_s}{\mu _0}\). \(\alpha\) = f(a\(_{k}\), a\(_{j}\), a\(_{ex}\)) and N are microstructural parameters. a\(_{k}\), a\(_{j}\), and a\(_{ex}\) coefficients are correlated consecutively with the grain sizes \(\Phi\) and the pinning defect area and exchange interaction on the H\(_{c}\). N is the demagnetization factor [43, 62]. Figure 10(b) presents the H\(_{c}\) experimental values as a function of \(\frac{K _1}{M_s}\). H\(_{c}\) fits vary linearly with \(\frac{K _1}{M_s}\) (purple line). The N value has been calculated to be around 2.23. The N value is not negligible. This confirms that the demagnetization impact is existent. The energy product (BH)\(_{max}\) calculated for the 100-nm film from the M(H) curves, being about 28 MGOe. (BH)\(_{max}\) is the maximum product of B and H for the B(H) demagnetization curve, where B = H + 4\(\pi\)M and H = H - N. M are the magnetic field induction [63]. The S* value is 0.72 and K\(_{1}\) \(\simeq\) 1.35 \(\times\) 10\(^{7}\) erg/cm\(^{3}\). These properties are important for technical interest and very promising for magnetic recording high density and spintronic applications. By comparing the results obtained for Zr\(_{6}\)Co\(_{23}\)/MgO(001) films with those found in the case of Zr\(_{6}\)Co\(_{23}\) films deposited on Al\(_{2}\)O\(_{3}\) (0001) substrate by RF magnetron sputtering [11], it is observed in the second case that we have good quality films surfaces lead to values of H\(_{c}\) between 7916 Oe and 19352 Oe. The H\(_{c}\) values of the Zr\(_{6}\)Co\(_{23}\)/MgO(001) films are lower to those Zr\(_{6}\)Co\(_{23}\)/Al\(_{2}\)O\(_{3}\) (0001) films. The K\(_{1}\) values of Zr\(_{6}\)Co\(_{23}\)(100 nm)/MgO(001) and Zr\(_{6}\)Co\(_{23}\)(100 nm)/Al\(_{2}\)O\(_{3}\) (0001) films are consecutively around 1.35 \(\times\) 10\(^{7}\) erg/cm\(^{3}\) and 1.36 \(\times\) 10\(^{8}\) erg/cm\(^{3}\). The magnetic anisotropy of Zr\(_{6}\)Co\(_{23}\) films is very sensitive to substrate nature, preparation conditions, surface roughness and intergrain exchange coupling.

4 Conclusion

Nanocrystalline Zr\(_{6}\)Co\(_{23}\) films of varying thickness \(\delta\) were deposited by Pulsed Laser Deposition (PLD) on MgO(001) substrate. Grazing incidence X-ray diffraction (GIXRD) technique, atomic force microscopy (AFM) superconducting quantum interference device (SQUID), vibrating sample magnetometry (VSM) and magnetic force microscopy (MFM) were used to study the microstructural and magnetic properties of these films. The coercivity H\(_{c}\), the squareness factor S* and the anisotropy field H\(_{a}\) were investigated as a function of \(\delta\) thickness and grain sizes \(\Phi\). The coercivity H\(_{c}\) values are correlated with the saturation magnetization M\(_{s}\) and constant anisotropy K\(_{1}\), which is consistent with the Stoner-Wohlfarth theory. The magnetic structure change of the Zr\(_{6}\)Co\(_{23}\)/MgO(001) film is the reason for the decrease in the magnetic anisotropy H\(_{a}\) and coercivity H\(_{c}\) as a function of \(\delta\). The excellent magnetic properties were found for \(\delta\) = 100 nm: the coercivity H\(_{c}\) = 3020 Oe, maximum energy product (BH)\(_{max}\) of 28 MGOe and magnetic anisotropy constant K\(_{1}\) = 1.35 \(\times\) 10\(^{7}\) erg/cm\(^{3}\). The found results represent a fundamental reference for adapting the magnetic properties of Zr\(_{6}\)Co\(_{23}\)/MgO(001) films to potential applications in the field of permanent magnets.

References

Sharma, N., Jones, G.A., Casey, S.M., Grundy, P.J.: J. Phys. D: Appl. Phys. 31, 3020 (1998)

Fersi, R., Bezergheanu, A., Patroic, D., Cizmas, C.B., Bessais, L., Mliki, N.: J. Magn. Magn. Mater. 494, 165816 (2020)

Fersi, R., Bouzidi, W., Bezergheanu, A., Cizmas, C.B., Bessais, L., Mliki, N.: J. Magn. Magn. Mater. 451, 473 (2018)

Bland, J.A.C., Heinrich, B.: Springer PP1, 65, 66, 67 (2005)

Fersi, R., Mliki, N., Bessais, L.: Magnetochemistry 8(2), 20 (2022)

Yamkane, Z., Fersi, R., Rachid, F.Z., Moubah, R., Lassri, H., Mliki, N., Bessais, L.: J. Magn. Magn. Mater. 449 461 (2018)

Fõahler, S., Neu, V., Weisheit, M., Hannemann, U., Leinert, S., Singh, A., Kwon, A., Melcher, S., Holzapfel B., Schultz. L.: Proc. 18th Int. Workshop on High Performance Magnets and their Applications, 2, 566 (2004)

Saito, T.: Mater. Trans. 44, 1713 (2003)

Saito, T.: Appl. Phys. Lett. 82, 2305 (2003)

Dalia, A.P., Fersi, R.: J. Magn. Magn. Mater. 532, 167874 (2021)

Pareti, L., Solzi, M., Paoluzi, A.: J. Appl. Phys. 73, 2941 (1993)

Binary Alloy Phase Diagrams, II Ed., Ed. T.B. Massalski, 2, 1264, H. Okamoto (1990)

Gabay, A.M., Zhang, Y., Hadjipanayis, G.C.: J. Magn. Magn. Mater. 236, 37 (2001)

Saito, T.: Mater. Trans. 39 (No.5) 2890 (2003)

Stroink, G., Stadnik, Z.M., Viau, G., Dunlap, R.A.: J. Appl. Phys. 67, 4963 (1990)

Hou, Z., Wang, W., Xu, S., Zhang, J., Wu, C., Su, F.: Phys. B: Cond. Matter. 407, 1047 (2012)

Ishikawa, T., Ohmori, K.: IEEE Trans. Magn. 26, 1370 (1990)

Burzo, E.: J. Appl. Phys. 70, 6550 (1991)

Sakurai, M., Wu, S., Zhao, X., Nguyen, M.C., Wang, C.Z., Ho, K.M., Chelikowsky, J.R.: Phys. Rev. Materials 2, 084410 (2018)

You, J., Guo, Y.: Mater. Lett. 241, 84 (2019)

Bhardwaj, V., Prakash Pal, S., Rama Rao, N.V., Chatterjee R.: Mater. Lett. 260, 126869 (2020)

Mitu, A., Dumitruc, M., Suvailaa, R., Opreaa, A., Gheorghea, I., Mereuta, P., Brajnicov, S., Burducea, I., Florea, N.M., Marginean, N., Glodariu, T., Dinescu, M., Danil, G.C.: Vacuum 161, 162 (2019)

O’Hanlon J.F.: A User’s Guide to Vacuum Technology. John Wiley and Sons. 385 (2015)

Dunlap, R.A., Small, D.A., MacKay, G.R., O’Brien, J.W., Dahn, J.R., Cheng, Z.H.: Can. J. Phys, 78, 211 (2000)

Phejar, M., Paul-Boncour, V., Bessais, L.: Intermetallics. 18, 2301–2307 (2010)

Rietveld, H.: J. Appl. Crystallogr. 2, 65 (1969)

Rodrguez-Carvajal, J.: Physica B. 192, 55 (1993)

Bessais, L., Fersi, R., Cabié, M., Mliki, N.: TMS2013 Supplemental Proceedings 97–104 (2013)

Fersi, R., Cabié, M., Mliki, N., Bessais, L.: Int. J. Hydrog. Energy. 44, Issue 39 22011 (2019)

Jaballah, H., Bouzidi, W., Fersi, R., Mliki, N., Bessais, L.: J. Phys. Chem. 161, 110438 (2022)

Yamkane, Z., Fersi, R., Rachid, F.Z., Moubah, R., Lassri, H., Mliki, N., Alleg, S., Sajieddine, M., Bessais, L.: SPIN, 2050016 (2020)

Servant, C., Guau, C., Ansara, I.J.: Alloys Compd. 220, 19 (1995)

Svechnikov, V.N., Pan, V.M., Russ Spektor, A.T.: J. Inorg. Chem. 8, 1106, 963 (2021)

Bakkari, K., Fersi, R., El Kebir, H., Bessais, L., Mliki, N.: J. Phys. Condens. Matter, 9, 30 (2018)

Fersi, R., Mliki, N., Bessais, L.: IOP Conf. Series: Mater. Sci. Eng. 28, 012014 (2012)

High Score software for crystallography, Philips analytical (2002)

Fersi, R., Mliki, N., Cabié, M., Bessais, L.: Phys. Status Solidi (a) 211(4), 910 (2014)

Fersi, R., Mliki, N., Bessais, L., Guetari, R., Russier, V., Cabié, M.: J. Alloys Compd. 522, 14 (2012)

Fersi, R., Cabié, M., Mliki, N., Bessais, L.: J. Alloys Compd. 576, 415 (2013)

Fersi, R., Bouzidi, W., Mliki, N., Bessais, L.: Intermetallics 100, 181 (2018)

Bessais, L., Fersi, R., Mliki, N.: TMS 2014: 143rd Annual Meeting & Exhibition, 2016, Springer International Publishing, Cham, 23-29 (2016)

Akhtar, M.S., Riaz, S., Mehmood, R.F., Ahmad, K.S., Alghamdi, Y., Azad Malik, M., Naseem, S.: Mater. Chem. Phys. 89, 28 (2017)

Fersi, R., Jabbalah, H., Bezergheanu, A., Patroic, D., Cizmas, B., Bessais, L., Mliki, N.: Vacuum 174, 109168 (2020)

Liu, Z., Yang, W., Li, M., Zhou, P., Yao, X., Chen, Y.: Ziyuan Hao IFAC-Papers OnLine 51(17), 689 (2018)

Cullity, B.D., Wesley, A.: Reading. Mass, USA (1974)

George, M., John, A.M., Nair, S.S., Joy, P.A., Anantharaman, M.R.: J. Magn. Magn. Mater. 302(1), 190 (2006)

Caizer, C.: Mater. Sci. Eng., B, 100, 1 63 (2003)

Cheérif, S.M., Layadi, A., Ben Youssef, J., Nacereddine, C., Roussigne, Y.: Physica B. 387, 281 (2007)

Woodcock, T.G., Khlopkov, K., Walther, A., Dempsey, N.M., Givord, D.: L. Schultz O. Gutfleisch. Scr. Mater. 60, 826 (2009)

Dahal, J.N., Neupane, D., Mishra, S.R.: Ceramics 2, 10 (2019)

Liang, Y., Deng, Q., Tan, X.H., Li, H., Xu, H.: Sci. Rep. 9(1), 1758 (2019)

Huang, Y.L., Wang, Y., Hou, Y.H., Wang, Y.L., Wu, Y., Ma, S.C., Liu, Z.W., Zeng, D.C., Tian, Y., Xia, W.X. and Zhong, Z.C.: J. Magn. Magn. Mater. 399, 175 (2016)

Chikazumi, S.: Physics of Ferromagnetism. 2nd ed. 672 p (2009)

Akulov, N.S.: Zeitschrift Phys. 69, 822 (1931)

Komogortsev, V., Patrusheva, T.N., Balaev, D.A., Denisova, E.A., Ponomarenko, I.V.: Tech. Phys. Lett. 35, 882 (2009)

Akulov, N.S., Kirensky, L.V., Tekh, Zh.: Fiz. 9, 1145 (1939)

Fersi, R., Mliki, N., Bessais, L.: EPJ Web of Conferences 29, 00018 (2012)

Bez, R., Fersi, R., Zehani, K., Moscovici, J., Bessais, L., Mliki, N., Fonda, E., Michalowicz, A.: J. Alloys Compd 666, 317 (2016)

Fersi, R., Mliki, N., Bessais, L.: IOP Conf. Series Mater Sci Eng, 28, 012014 (2012)

Fersi, R., Mliki, N., Bessais, L.: Supplemental Proceedings: Materials Properties. Characterization, and Modeling 1, 863–869 (2012)

Long, E., Xiaoqiang, T., Lezhong, L., Rui, W.: J. Rare. Earth. 31, 988 (2013)

Li, Y.F., Chen, D.X., Vázquez, M., Vázquez, M., Hernando, A.: J. Phys. D Appl. Phys. 35(6), 508 (2002)

Balasubramanian, B., Das, B., Skomski, R., Zhang, W.Y., Sellmyer, D.J.: Adv. Mater. 25, 6090–93 (2013)

Acknowledgements

This work is main supported by the Romanian Ministry of Research and Innovation (Romania) and the “Ministère de l’Enseignement Supérieur et de la Recherche Scientifique” (Programme d’Encouragement des Jeunes Chercheurs (PEJC) - Session 2021 - Reference: 20PEJC 01-15) (Tunisia). The authors acknowledge the “Agence Universitaire de la Francophonie AUF” for his support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fersi, R., Dalia, A.P. Microstructure, Exchange Interaction and Magnetic Properties of Nanocrystalline Zr\(_{6}\)Co\(_{23}\)/MgO(001) Films. J Supercond Nov Magn 35, 2923–2932 (2022). https://doi.org/10.1007/s10948-022-06281-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-022-06281-x