Abstract

In this paper, crystal structure, morphology and magnetic properties of nanocrystalline Zr\(_{6}\)Fe\(_{23}\) thin films have been reported. Zr\(_{6}\)Fe\(_{23}\) films with different thickness X were grown by RF magnetron sputtering onto Si(001) substrate. The X thickness varies from 18 to 500 nm. From grazing X-ray diffraction patterns (GIXRD), the Zr\(_{6}\)Fe\(_{23}\)/Si(001) films have a single phase with cubic structure Th\(_{6}\)Mn\(_{23}\) type (Fm-3m space group) structure. We showed the presence of a strong preferred orientation (4 4 0) for X between 18 and 402 nm. However, for higher thicknesses X \(\ge \) 402 nm, multiple peaks are observed show the polycrystalline nature of the films and textured along (4 4 2), (5 3 3) and (6 6 0) orientations. The magnetic properties were affected by the thickness due to the morphology, roughness R\(_{rms}\) and intergrain exchange coupling (IEC). The correlations between these properties are investigated using the magnetic force microscopy (MFM) analysis. The 200 nm-thick Zr\(_{6}\)Fe\(_{23}\)/Si(001) film showed a high coercivity H\(_{c}\) = 3580 Oe, maximum energy product (BH)\(_{max}\) of 2.45 MGOe, magnetic anisotropy field H\(_a\) = 11230 Oe and Curie temperature T\(_C\) \(\simeq \) 821 K. The results found in this work could potentially pave the way for the future exploration and of magnetic recording development or spintronic devices made from nanocrystalline Zr\(_{6}\)Fe\(_{23}\) films.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Nowadays, the magnetic materials have taken much interest because of their potential applications in various magnetic technologies. Among these materials, the nanocrystalline powders and thin films based on transition metals (Fe, Co, Ni ...) have received a lot of attention, due to their interesting magnetic properties and their performance [1,2,3,4,5]. In particular, the nanocrystalline ZrCo or ZrNi alloys have been used in several applications including magnetic recording, spintronic devices and magneto-optical switches [6,7,8,9,10]. In this context, the ZrFe\(_{x}\) alloy seems a good promising for many applications, due to the possibility of adjusting and optimizing its magnetic properties by varying the Fe concentration x and the preparation conditions. In the binary Zr–Fe system, several compounds are formed: Zr\(_{2}\)Fe, Zr\(_{3}\)Fe, Zr\(_{4}\)Fe, Zr\(_{6}\)Fe\(_{23}\) and ZrFe\(_{2}\) which have quite diverse structural and magnetic properties [11, 12]. These compounds exhibit ferromagnetic behavior and excellent intrinsic magnetic properties as Curie temperature T\(_{C}\), the magnetocrystalline anisotropy H\(_{A}\) and a important saturation magnetization M\(_{s}\) [13, 14]. Little quantitative information on the magnetic properties of Zr\(_{6}\)Fe\(_{23}\) alloys has been reported. From the phase diagram of the Zr–Fe system [15], the Zr\(_{6}\)Fe\(_{23}\) phase can exist only in a very narrow range where the Zr atomic composition is between 26 % and 31 %, and can be obtained in the temperature range from 1173 K to 1756 K . The Zr\(_{6}\)Fe\(_{23}\) compound crystallize in the Th\(_{6}\)Mn\(_{23}\)-type cubic structure with Fm-3m space group. The lattice parameters are \(a = b = c = 8.2662\) Å. The Zr atoms occupy the crystallographic 24e sites while Fe atoms occupy two 32f sites, 24d and 4e sites [16, 17]. The Zr\(_{6}\)Fe\(_{23}\) compound has the highest T\(_{C}\) compared to other ZrFe compounds. The T\(_{C}\) is around 821 K, a saturation magnetostriction \(\lambda _{Ms}\) of 8 \(\times \) 10\(^{-6}\) and magnetic moment per Fe atom is 1.65 \(\mu _{B}\) at 300 K and 1.876 \(\mu _{B}\) at 5 K [13]. These magnetic properties suggest that the films of Zr\(_{6}\)Fe\(_{23}\) compound may also have significant magnetic properties. Much less works has been devoted thin Zr–Fe films. In particular, mainly films with low Zr concentration have been studied [19,20,21,22,23]. We could only find few studies reports of Zr-rich epitaxial films, although no evidence of epitaxial growth of the film has been given.

In this article, we present a systematic study of crystal structure, morphology and magnetic properties of Zr\(_{6}\)Fe\(_{23}\) alloy thin films grown on Si(001) substrate by RF magnetron sputtering. The correlation between the microstructure, exchange interaction and magnetic anisotropy properties is discussed, using the magnetic force microscopy (MFM) analysis.

2 Elaboration and characterization methods

2.1 Elaboration and characterization methods of Zr\(_{6}\)Fe\(_{23}\)/Si(001) films

Zr\(_{6}\)Fe\(_{23}\) films were grown by radio frequency (RF) magnetron sputtering deposition technique (Fig. 1) from nanocrystalline Zr\(_{6}\)Fe\(_{23}\) compact powders (\(\S \) Section 3.1). The Zr\(_{6}\)Fe\(_{23}\) thin films were prepared on Si(001) substrates sized [20 \(\times \)10\(^{-2}\) m] \(\times \) [20 \(\times \)10\(^{-2}\) m] with about 2 \(\times \)10\(^{-2}\) m thickness. The distance from the target to the substrate was 15 \(\times \)10\(^{-2}\) m throughout. A power supply operated at a crystal-controlled frequency of 13.60 MHz. The sputtering chamber was evacuated to a base pressure of 8 \(\times \) 10\(^{-3}\) Pa using rotating and oil diffusion pumps. The deposition was done at constant RF power of 60 Watt at substrate temperature T\(_{s}\) of 873 K. The flow rates of the O\(_{2}\) and Ar sputtering gases were set at a ratio of 2:8. The coatings were realized out from 15 min to 195 min leading to a variation in the Zr\(_{6}\)Fe\(_{23}\) thickness X from 18 to 500 nm. The RF power source was switched to a Au target to form a 20 nm-thick Au overlay layer on Zr\(_{6}\)Fe\(_{23}\) layers to prevent oxidation. The process parameters employed during deposition of Zr\(_{6}\)Fe\(_{23}\)/Si(001) films are listed in Table 1. The thickness measurement and structural characterization of Zr\(_{6}\)Fe\(_{23}\)/Si(001) films were determined by X-ray reflectivity and grazing incidence X-ray diffraction (GIXRD) techniques, respectively. The ex situ X-ray reflectivity with best fit theoretical curve measurements was performed using a Bruker 4-circle diffractometer equipped with a Cu-sealed tube point source and a Göbel Mirror optic to produce a 2D-collimated parallel beam. The incidence angle for GIXRD measurements has been fixed to 1\(^{\circ }\) with 2\(\theta \) varying from 20\(^{\circ }\) to 90\(^{\circ }\). The surface morphologies, cross-sectional images were observed by scanning electron microscopy (SEM) coupled to energy-dispersive X-ray analysis (EDX). High-resolution transmission electron microscope (HRTEM) imaging was performed using Tecnai G2 F20 FEI TEM. The roughness R\(_{rms}\) was examined using atomic force microscopy (AFM, 3SPA-300HV). The magnetic properties are investigated by a physical property measurement system equipped with vibrating sample magnetometer (PPMS-VSM/Quantum Design, Dynacool 7), SQUID magnetometer and magnetic force microscopy (MFM).

3 Results and discussion

3.1 Microstructure and magnetic properties of nanocrystalline Zr\(_{6}\)Fe\(_{23}\) powders

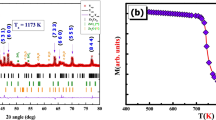

The nanocrystalline Zr\(_{6}\)Fe\(_{23}\) powders were prepared by high-energy ball milling [24, 25]. After milling for 5 hours with ball to powder ratio of 15/1, under high-purity Ar atmosphere, the Zr\(_{6}\)Fe\(_{23}\) samples, enveloped in tantalum foil, are annealed for 72 hours in sealed silica tube under 10\(^{-4}\) Pa at different annealing temperature T\(_a\) from 800 to 1725 K. The crystal structures of Zr\(_{6}\)Fe\(_{23}\) sample were detected by X-ray diffraction (XRD) with CuK\(_\alpha \) radiation. The pattern refinement was performed with the FULLPROF computing code based on the Rietveld technique [26,27,28]. The goodness-of-fit parameters \(\chi ^2\) and R\(_B\) were used as numerical criteria to describe the quality of the fit between calculated and experimental XRD data [35, 36]. Figure 2a presents the Rietveld analysis result of XRD pattern of nanocrystalline Zr\(_{6}\)Fe\(_{23}\) powders annealed at 1425 K. The result of the structure refinement shows the presence of a main phase with the cubic Th\(_{6}\)Mn\(_{23}\) type structure (Fm-3m space group (No.225)). We note minor quantities of the oxide phases appearing due to selective oxidation of ZrO\(_{2}\). The lattice parameters are \(a = b = c = 8.2662\) Å. The Zr atoms occupy the crystallographic 24e sites while Fe atoms occupy two 32f sites, 24d and 4e sites. The lattice parameters, R\(_a\) and \(\chi ^2\) factors from Rietveld fit are given in Table 2. These values of structural parameters are in agreement with the results obtained previously [16, 17]. The T\(_{C}\) temperature of Zr\(_{6}\)Fe\(_{23}\) compound was determined from the M(T) curve by extrapolating the linear part of the M(T) curve and finding the temperature value of the intersection with the extended baseline [18] (Fig. 2b). The T\(_{C}\) temperature is around 821 K. To study the extrinsic properties, we have optimized the Zr\(_{6}\)Fe\(_{23}\) microstructure, which can lead us to the best coercivity H\(_{c}\). We have therefore used, for this compound, several annealing at different temperatures T\(_a\). The optimum extrinsic magnetic properties are obtained for T\(_a\) = 1425 K: H\(_{c}\) = 9258 Oe, M\(_{r}\) = 39.9 emu/g and (BH)\(_{max}\) = 4.92 MGOe. Figure 3 shows the hysteresis loop at 298 K, for the nanocrystalline Zr\(_{6}\)Fe\(_{23}\) sample annealed at 1425 K.

3.2 X-ray reflectivity of Zr\(_{6}\)Fe\(_{23}\)/Si(001) films

The X-ray reflectivity experiments have been realized on Zr\(_{6}\)Fe\(_{23}\)/Si(001) films for different thickness X. Figure 4 presents a typical example of X-ray reflectivity for X = 48 nm. The experimental X-ray reflectivity data were analyzed with the Diffrac Plus LEPTOS software [29]. Using a genetic algorithm [30], the best simulation suited to experimental data was performed by adjusting the parameters: film thickness X, density d* and root mean square roughness R\(_{rms}\) values. The found results from the X-ray reflectivity adjustment are listed in Table 3.

3.3 Crystal structure and morphology of Zr\(_{6}\)Fe\(_{23}\)/Si(001) films

The crystal structure of the thin layers was followed by Grazing Incidence X-ray Diffraction (GIXRD). Figure 5 shows the GIXRD patterns of Zr\(_{6}\)Fe\(_{23}\)/Si(001) films for different thickness X: 18 nm, 98 nm, 200 nm and 500 nm. No peak appeared for the thickness \(X = 18\) nm. This layer consists of small grains oriented randomly due to the amorphous state of the Si(001) substrate, so no diffraction peak could be detected. For films with intermediate thickness (between 48 and 298 nm), we observed the presence of a single peak located at 43.2\(^{\circ }\) was indexed as the (4 4 0) plane of the cubic structure Th\(_{6}\)Mn\(_{23}\) type (Fm-3m space group) of the phase Zr\(_{6}\)Fe\(_{23}\). For these films, a strong (4 4 0) texture is evidenced. For the thickest films (X\(\ge \) 400 nm), we can see in addition to (4 4 0) peak, which increases in intensity with increasing X thickness, the appearance of secondary peaks located at positions: 2\(\theta \) = 36.1\(^{\circ }\), 52.2\(^{\circ }\) and 69.3\(^{\circ }\) corresponding respectively to the (4 4 2), (5 3 3) and (6 6 0) planes of Zr\(_{6}\)Fe\(_{23}\) structure. We conclude, that for the highest thickness, the films exhibit a polycrystalline structure. The grains size D was calculated for the intense diffraction peak (4 4 0) using Scherrer’s equation [31,32,33]: D = 0.9\(\lambda \)/\(\beta _{2}\)Cos\(\theta \), where \(\lambda \) = 1.54 Å is the wavelength of the incident X radiation, \(\beta _{2}\) represents the full-width at half-maximum of the peaks at the diffraction angle \(\theta \) [34, 35]. The grain sizes D of the Zr\(_{6}\)Fe\(_{23}\)/Si(001) films corresponding to (4 4 0) reflection have been found to increase with the increase of X thickness. The results calculated by Scherrer’s equation show that, the average grain size D was 6 nm, 17 nm 28 nm, 39 nm, 49 nm, 82 nm, 105 nm, 111 nm, 120 nm for thickness X = 18 nm , X = 48 nm, X = 98 nm, X = 149 nm, X = 200 nm, X = 249 nm, X = 298 nm, X = 402 nm and X = 500 nm, respectively (Table 4). The increase in the grain size D as a function of d thickness is related to the increase in the magnetic domains (\(\S \) Section 3.4).

Figure 6a, b shows examples of SEM micrographs for samples with X = 48 nm and 500 nm. The micrographs clearly revealed the uniformity of the surfaces. The boundary Si/ZrFe and ZrFe/Au interfaces between the different layers Si, ZrFe, and Au and a relatively rough surface of all layers are clearly visible. Figure 7a presents the energy-dispersive X-ray spectroscopy (EDS) data analysis of Zr\(_{6}\)Fe\(_{23}\) layers. EDS analysis was performed by scanning field emission electron microscopy (FESEM). The atomic percentages of Zr and Fe, were 19.25 % and 78 %, respectively (Fig. 7a). We note the presence of some traces of oxidations (O) and impurities (C, Si, Au and Ni) with low atomic percentage. The Zr\(_{6}\)Fe\(_{23}\) stoichiometric proportions were roughly maintained. The composition distribution of the films was studied by STEM-EDX mapping (Fig. 7b). The Zr and Fe elements were distributed evenly in the surface mapping. The composition of Zr and Fe ranges from 19.5 to 21 % and 78 to 77 %, respectively. Figure 6.(a*) and (b*) shows the bright field images of the microstructure of Zr\(_{6}\)Fe\(_{23}\) films for X = 48 nm and 500 nm. The corresponding selected area electron diffraction (SAED) pattern exhibits bright diffraction rings, which are a typical characteristic of nanocrystalline phase [4, 37, 38]. Figure 6a** and b** shows the size distribution histograms for thickness X = 48 nm and 500 nm, respectively. The average grain size increased D from 6 to 120 nm with increasing X thickness from 18 to 500 nm. Figure 8 shows the surface morphologies (3D and 2D) for different thickness: X = 18 nm ((a), (a*)), X = 98 nm ((b), (b*)), X = 200 nm ((c), (c*) and X = 500 nm ((d), (d*)). From the AFM images analysis, we have extracted the root means square roughness R\(_{rms}\). The values found are listed in Table 4. All Zr\(_{6}\)Fe\(_{23}\)/Si(001) films present a morphological structure composed of very tight grains, indicating a continuous surface. The grain size is in the nanometer range confirming the observation performed by the SEM microscopy. The R\(_{rms}\) increases with increasing X thickness and its value varies from 2.92 nm for X = 18 nm to 11.52 nm for X = 500 nm.

3.4 Magnetic and exchange interaction properties of Zr\(_{6}\)Fe\(_{23}\)/Si(001) films

The hysteresis loops of Zr\(_{6}\)Fe\(_{23}\)/Si(001) film for different X thickness are given in Fig. 9. It can be seen that the films exhibit different magnetic behaviors, and the magnetic properties are listed in Table 5. We note that H\(_{c}\) decreases with increasing thickness, except for 200 nm-thick film, where a maximum in the H\(_{c}\) vs X curve was observed (H\(_{c}\) \(\simeq \) 3580 Oe). The minimum value of H\(_{c}\), equal to 651 Oe, was obtained for the 500 nm-thick films. The evolution of H\(_{c}\) with thickness may be attributed to the surface roughness and grains morphology effect [41]. The films with smooth surfaces are characterized by large H\(_{c}\). For X > 249 nm, the grain size D and surface roughness R\(_{rms}\) become large, range from 105 to 120 nm and 7.56 nm to 11.52 nm, respectively. This allows the appearance of crystalline defects, such as twins or grain boundaries and which contribute to the fall of H\(_{c}\).

The intergrain exchange coupling analysis (IEC) between the magnetic particles was evaluated by measuring Henkel curves [42, 43]. The \(\Delta \)m\(^{*}\)-H curves of Zr\(_{6}\)Fe\(_{23}\)/Si(001) films with different X thickness shown in Fig. 10a. It can be seen that the film with X = 200 nm possesses the higher positive peak value, which is in accordance with coercivity result. As the X thickness increases, the positive peak value for each of \(\Delta \)m\(^{*}\) plots (\(\Delta \)m\(^{*}\) > 0) shows a “first increasing and then decreasing” tendency, which means that the thickness of Zr\(_{6}\)Fe\(_{23}\) layer has an impact on intergrain exchange coupling. The \(\Delta \)m\(^{*}\)-H curve was determined by the relation [43]:

where m\(_{init}\) is the initial magnetization curve. m\(_{\uparrow }\) and m\(_{\downarrow }\) are respectively the up (\(\uparrow \)) and down (\(\downarrow \)) parts of the hysteresis loop (H > 0). If,

- \(\Delta \)m\(^{*}\) < 0, the magnetic dipolar interaction is predominant,

- \(\Delta \)m\(^{*}\) > 0, the intergrain exchange coupling is dominant.

Figure. 10b shows the variation of the magnetization M(H) curves near saturation of Zr\(_{6}\)Fe\(_{23}\) films for different thickness X. The solid line presents the experimental data and theoretical simulation obtained using the expression [44,45,46,47,48]:

H is the applied magnetic field. M\(_{s}\) is the saturation magnetization. The a coefficient is related to anisotropy field H\(_{a}\), a = - \(\frac{2}{105}\) H\(_{a}^{2}\). The different magnetic parameters obtained are listed in Table 6. The saturation magnetization M\(_{s}\) value increases from 278 emu/cm\(^{3}\) at X = 18 nm to 312 emu/cm\(^{3}\) at X = 200 nm. Same behavior for anisotropy constant H\(_{a}\) evolution, the H\(_{a}\) value increases from 10100 Oe to a maximum of 11230 Oe for X = 200 nm, then decreases. For X = 500 nm, the Zr\(_{6}\)Fe\(_{23}\)/Si(001) film exhibits significant decrease of M\(_{s}\) and H\(_{a}\), around 81.2 emu/cm\(^{3}\) and 10080 Oe, respectively. The strengthened exchange interaction between adjacent grains contributes to the increased remanence ratio S* = M\(_{r}\)/M\(_{s}\) from 0.51 to 0.74. The remanence ratio S* > 0.5 indicating good magnetic proprieties suggests strong exchange interactions between the adjacent crystallites [49,50,51,52]. The H\(_{c}\) variation as a function of \(\Phi \) is defined by the following relation [53,54,55]: \(\Phi _c\) = 9\(\kappa /2\pi M^2_s\), where \(\kappa \) = (2k\(_{B}\).K.T\(_{C}\)/\(\varrho \))\(^{1/2}\) is the domain wall energy. T\(_{C}\) is Curie temperature, k\(_{B}\) is Boltzmann constant and \(\varrho \) is the lattice coefficient. The critical grain size value (\(\Phi _c\)) from single domain to multi-domain is around 41.5 nm. This result is in good agreement with the experimental value for X = 200 nm. Figure 11 shows MFM images of Zr\(_{6}\)Fe\(_{23}\)/Si(001) films for X = 18 nm, 98 nm, 200 nm and 500 nm. The observed contrasts clearly show the dispersion of the magnetic domains in the analyzed surface. Each domain was separated by well-defined domain walls. A large number of uniform magnetic domains were observed in thickness X between 18 nm and 98 nm (Fig. 11a, b). For X = 18 nm, the image shows a complicated ripple domain pattern, did not evidence a major contribution of magnetic moments on the surface. For X = 200 nm, exhibited the single domains formation ranging in size 5–12 \(\mu \)m (Fig. 11c). For X \(\ge \) 402 nm, the magnetic domains get bigger (Fig. 11d). This implies an increase in the size grains which are in a state with multiple magnetic domains. The magnetic structure change of Zr\(_{6}\)Fe\(_{23}\)/Si(001) film is the reason for the decrease in the magnetic anisotropy H\(_{a}\) and coercivity H\(_{c}\) as a function of X.

4 Conclusion

Nanocrystalline Zr\(_{6}\)Fe\(_{23}\) films of varying thickness X were deposited by RF magnetron sputtering process on Si(001) substrate. Grazing incidence X-ray diffraction (GIXRD) technique, atomic force microscopy (AFM), superconducting quantum interference device (SQUID), vibrating sample magnetometry (VSM) and magnetic force microscopy (MFM) were used to study the microstructural and magnetic properties of these films. The Zr\(_{6}\)Fe\(_{23}\)/Si(001) films show a single phase with a cubic structure of Th\(_{6}\)Mn\(_{23}\) type (Fm-3m space group). We showed the strong preferential orientation for thickness X between 18 and 402 nm. For X above 402 nm, multiple peaks are found indicating the polycrystalline nature of the films and textured along the (4 4 2), (5 3 3) and (6 6 0) orientations. The coercivity H\(_{c}\), the squareness factor S* and the anisotropy field H\(_a\) were investigated as a function of X thickness and grain sizes D. The correlation between the microstructure, magnetic anisotropy parameters and intergrain exchange coupling (IEC) was analyzed. The excellent magnetic properties were found for thickness X = 200 nm: the coercivity H\(_c\) = 3580 Oe, maximum energy product (BH)\(_{max}\) of 2.45 MGOe MGOe, magnetic anisotropy field H\(_a\) = 11230 Oe and Curie temperature T\(_C\) \(\simeq \) 821 K. The found results provide the fundamental reference for adapting the soft magnetic properties of Zr\(_{6}\)Fe\(_{23}\)/Si(001) films for high-density magnetic recording media and spintronic applications.

References

A.P. Dalia, R. Fersi, J. Magn. Magn. Mater. 532, 167874 (2021)

R. Fersi, H. Jabbalah, A. Bezergheanu, D. Patroi, C.B. Cizmas, L. Bessais, N. Mliki, Vacuum 174, 109168 (2020)

R. Fersi, A. Bezergheanu, D. Patroic, C.B. Cizmas, L. Bessais, N. Mliki, J. Magn. Magn. Mater. 494, 165816 (2020)

R. Fersi, N. Mliki, L. Bessais, Magnetochemistry 8(2), 20 (2022)

R. Fersi, W. Bouzidi, A. Bezergheanu, C.B. Cizmas, L. Bessais, N. Mliki, J. Magn. Magn. Mater. 451, 473 (2018)

C. Gao, H. Wan, G.C. Hadjipanayis, J. Appl. Phys. 67, 4960 (1990)

Z. Altounian, E. Batalla, J.O.S. Olsen, J. Appl. Phys. 59, 2364 (1986)

H. Drulis, W. Iwasieczko, V. Zaremba, J. Magn. Magn. Mater. 256, 139 (2003)

A.M. Ghemawat, M. Foldeaki, R.A. Dunlap, R.C. O’Handley, IEEE Trans. Magn. 25, 3312 (1989)

O.I. Bodak, B.V. Padlyaka, Y.V. Stadnyk, J. Pierre, A.V. Tkachuk, L.P. Romaka, Y.K. Gorelenko, J. Alloys Compd. 317, 357 (2001)

A. D. Pelton, L. Leibowitz, R.A. Blomquist, J. Nucl. Mater. 201 218

K. Bhanumurthy, Scr. Metall. Mater. 28, 753 (1993)

N. Mattern, W.X. Zhang, S. Roth, H. Reuther, C. Baehtz, M. Richter, J. Phys.: Condens. Matter 19, 376202 (2007)

P. Warren, J.B. Forsyth, G.J. McIntyre, N. Bernhoeft, J. Phys.: Condens. Matter 4, 5795 (1992)

L. Leibowitz, R.A. Blomquist, J. Nucl. Mater. 201, 218 (1993)

C. Servant, C. Guéneau, I.J. Ansara, Alloys Compd. 220, 19 (1995)

V. N. Svechnikov, V. M. Pan, A. T. Russ Spektor. J. Inorg. Chem. 8, 1106, 963

K. Bakkari, R. Fersi, H. El Kébir, L. Bessais, N. Mliki, J. Phys.: Condens. Matter 9, 30 (2018)

A. R. Chezan, C. B. Craus, N. G. Chechenin, L. Niesen, and D. O. Boerma, phys. stat. sol. (a) 189, No. 3 (2002) 833

A. Chakraborty, K.R. Mountfield, G.H. Bellesis, D.N. Lambeth, M.H. Kryder, J. Appl. Phys. 80, 1012 (1996)

Y. Kitano, H. Horio, A. Ido, T. Watanabe, M. Komai, K. Takagi, Intermetallics 4, S209–S213 (1996)

D. Kaoumi, A. T. Motta, R. C. Birtcher, Nucl. Instr. and Meth. in Phys. Res. B 242 (2006) 490

A. T. Motta, A. Paesano. Jr., R. C. Birtcher, L. Amaral, Nucl. Instr. and Meth. in Phys. Res. B 175-177 (2001) 521

R.A. Dunlap, D.A. Small, G.R. MacKay, J.W. O’Brien, J.R. Dahn, Z.H. Cheng, Can. J. Phys. 78, 211 (2000)

M. Phejar, V. Paul-Boncour, L. Bessais, Intermetallics 18, 2301–2307 (2010)

H. Rietveld, J. Appl. Crystallogr. 2, 65 (1969)

J. Rodrguez-Carvajal, Phys. B 192, 55 (1993)

L. Bessais, C. Djega-Mariadassou, Phys. Rev. B 63, 054412 (2001)

https://www.bruker.com/fr/products-and-solutions/diffractometers-and-scattering-systems/x-ray-diffractometers/diffrac-suite-software/diffrac-leptos.html

A. Ulyanenkov, K. Omote, J. Harada, Physica B Condens. Matter 283, 237 (2000)

R. Fersi, N. Mliki, M. Cabié, L. Bessais, Phys. Status Solidi (a) 211(4), 910 (2014)

R. Fersi, N. Mliki, L. Bessais, R. Guetari, V. Russier, M. Cabié, J. Alloys Compd. 522, 14 (2012)

R. Fersi, N. Mliki, L. Bessais, J. Magn. Magn. Mater. 465, 220 (2018)

R. Fersi, W. Bouzidi, N. Mliki, L. Bessais, Intermetallics 100, 181 (2018)

R. Fersi, M. Cabié, N. Mliki, L. Bessais, Int. J. Hydrog. Energy. 44, Issue 39 (2019) 22011

H. Jaballah, W. Bouzidi, R. Fersi, N. Mliki, L. Bessais, J. Phys. Chem. Solids 161, 110438 (2022)

R. Bez, R. Fersi, K. Zehani, J. Moscovici, L. Bessais, N. Mliki, E. Fonda, A. Michalowicz, J. Alloy. Compd. 666, 317 (2016)

L. Bessais, R. Fersi, M. Cabié, N. Mliki, MRS Online Proceedings Library (OPL) 1471 (2012)

X. Zhang, Y. Lao, J. Sklenar, N.S. Bingham, J.T. Batley, J.D. Watts, C. Nisoli, C. Leighton, P. Schiffer, APL Mater. 7, 111112 (2019)

Y. Li, L. Peng, J. Magn. Magn. Mater. 323(5), 475 (2011)

A. Kaibi, A. Guittoum, R.M. Öksüzogluc, A.M. Yagcic, M. Boudissad, M. Kechouanea, Appl. Surf. Sci. 350, 50 (2015)

T. Stefan, H. Jurgen, J. Magn. Magn. Mater. 154, no.1, 254, 1996

L. Ning, L. Baohe, F. Chun, L. Minghua, Y. Guanghua, J. Rare. Earth, 30, no.5, 446, 2012

Z. Yamkane, R. Fersi, F.Z. Rachid, R. Moubah, H. Lassri, N. Mliki, L. Bessais, J. Magn. Magn. Mater. 449, 461 (2018)

L. Néel, Rep. Prog. Phy. Radium 9, 193 (1948)

Z. Zhang, X. Song, W. Xu, Acta Mater. 59, 1808 (2011)

Z. Yamkane, R. Fersi, F. Z. Rachid, R. Moubah, H. Lassri, N. Mliki, S. Alleg, M. Sajieddine, L. Bessais, SPIN (2020) 2050016

H. Lassri, M. Tlemçani, M. Slimani, S. Sayouri, M. Abid, H. Houmada, A. Mikou, Phys. B 239, 274 (1997)

R. Fersi, N. Mliki, L. Bessais, IOP Conf. Series: Materials Science and Engineering, 28 (2012) 012014

R. Fersi, M. Cabié, N. Mliki, L. Bessais, J. Alloys Compd. 576, 415 (2013)

L. Bessais, R. Fersi, M. Cabié, N. Mliki, TMS2013 Supplemental Proceedings, 2013, 97-104

R. Fersi, N. Mliki, L. Bessais, EPJ Web of Conferences 29, 00018 (2012)

B.D. Cullity, A. Wesley, Reading (Mass, USA, 1974)

M. George, A.M. John, S.S. Nair, P.A. Joy, M.R. Anantharaman, J. Magn. Magn. Mater. 302(1), 190 (2006)

C. Caizer, Mater. Sci. Eng., B, 100, no.1 (2003) 63

Acknowledgements

This work is main supported by the Romanian Ministry of Research and Innovation (Romania) and the “Ministère de l’Enseignement Supérieur et de la Recherche Scientifique ” (20PEJC 01-15) (Tunisia). The authors acknowledge the “ Agence Universitaire de la Francophonie AUF ” for his support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fersi, R., Dalia, A.P. Crystal structure, morphology and magnetic properties of nanocrystalline Zr\(_{6}\)Fe\(_{23}\) thin films grown on Si(001) substrate. Appl. Phys. A 128, 540 (2022). https://doi.org/10.1007/s00339-022-05653-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-022-05653-3