Abstract

Barley α-amylase 1 mutant (AMY) and Lentinula edodes glucoamylase (GLA) were cloned and expressed in Saccharomyces cerevisiae. The purified recombinant AMY hydrolyzed corn and wheat starch granules, respectively, at rates 1.7 and 2.5 times that of GLA under the same reaction conditions. AMY and GLA synergistically enhanced the rate of hydrolysis by ∼3× for corn and wheat starch granules, compared to the sum of the individual activities. The exo-endo synergism did not change by varying the ratio of the two enzymes when the total concentration was kept constant. A yield of 4% conversion was obtained after 25 min 37°C incubation (1 unit total enzyme, 15 mg raw starch granules, pH 5.3). The temperature stability of the enzyme mixtures was ≤50°C, but the initial rate of hydrolysis continued to increase with higher temperatures. Ca++ enhanced the stability of the free enzymes at 50°C incubation. Inhibition was observed with the addition of 10 mM Fe++ or Cu++, while Mg++ and EDTA had lesser effect.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The current production of glucose feedstock from starch is a two-stage enzymatic process. Liquefaction is the first stage where starch is solubilized by steam cooking and treated with thermostable α-amylase at 90–165°C, pH 6–7. This is followed by saccharification performed at 69°C with glucoamylase. The excess energy demand required to heat the starch slurry in the gelatinization step is about 10%–20% of the fuel value of the ethanol produced (Robertson et al., 2006). An energy-conserving alternative is to conduct the enzyme reaction at a temperature below the gelatinization transition to achieve digestion of solid, native, or raw starch as “cold hydrolysis”. In 2005, 93 ethanol plants in 20 states produced 4.2 billion gallons of ethanol per year mostly from cornstarch (http://www.ethanolrfa.org). With added capital and maintenance costs, liquefaction and saccharification constitute a large energy cost in the processing scheme. Lowering the energy use and raising the efficiency of hydrolysis can potentially save millions in production costs. “Cold hydrolysis” of native, uncooked starch, first investigated 60 years ago (Balls and Schwimmer, 1944; Schwimmer, 1945), has been an area of continuous interest, and recently suggested as the next breakthrough for the starch processing industry.

Amylolytic enzymes that hydrolyze insoluble starch are known to contain a starch-binding domain (SBD) attached to the catalytic domain (Janecek and Sevcik, 1999). It has been demonstrated that Aspergillus niger glucoamylase GA-I with its SBD cleaved, hydrolyzed native starch granules 80 times slower than the full-length enzyme (Southall et al., 1999). Recent studies indicate that the SBD not only binds onto starch, but also disrupts the double helical structures and enhances the rate of hydrolysis (Morris et al., 2005; Sorimachi et al., 1997; Southall et al., 1999). Previously, we isolated and identified a starch-binding fragment in barley α-amylase isoform 1 (AMY) following limited proteolytic digestion (Wong et al., 2000). In a later study, a recombinant polypeptide representing the C-terminal domain was expressed in E. coli, and its affinity to cyclodextrin was determined (Tibbot et al., 2000). Recently, we cloned and expressed Lentinula edodes glucoamylase in Saccharomyces cerevisiae, and characterized the enzyme (Wong et al., 2005). In the present study, a barley α-amylase mutant and L. edodes glucoamylase were characterized in combination for the synergistic hydrolysis of native starch granules.

Materials And Methods

Materials

Yeast cloning vector, pYEX-S1, was obtained from Clontech (Palo Alto, CA). E. coli strains and competent cells were purchased from Invitrogen (San Diego, CA), and yeast strains were obtained from ATCC (Lebanon, IN). Restriction enzymes were from New England Biolabs (Beverly, MA). Precast electrophoresis gels, staining kits, and protein standards were obtained from Invitrogen (Carlsbad, CA) and BioRad (Hercules, CA). Sepharose-6B resin was purchased from Amersham Pharmacia Biotech (Piscataway, NJ). Ultracentrifuge filters were obtained from Millipore (Bedford, MA). Soluble starch (S-9765), corn starch (S-4126), wheat starch (S-5127), β-Cyclodextrin, and dinitrosalicyclic acid (DNSA) were purchased from Sigma (St. Louis, MO). All chemicals and reagents were of analytical grade.

Cloning and Expression of AMY and GLA Genes

The barley AMY gene was isolated from the barley cDNA library, constructed into pYEX-S1 vector, and subjected to directed evolution to increase the secretion and the activity as described previously (Wong et al., 2002A,2003). The glucoamylase (GLA) gene isolated from the cDNA library of L. edodes was inserted downstream of the yeast phosphoglycerate kinase gene promoter with the original vector signal sequence eliminated (Wong et al., 2005). The expression of the enzymes in active forms in S. cerevisiae has previously been confirmed.

Protein Purification

AMY or GLA clones were grown in 3 l YEPG (2% yeast extract, 1% bactopeptone, 2% glycerol) for 96 h at 30°C and 225 rpm (Wong et al., 2002A). The culture was centrifuged at 9000× g for 20 min, and the supernatant was saturated with ammonium sulfate at 75%. The precipitated proteins were dialyzed in 50 mM NaOAc buffer, pH 5.3, containing 5 mM NaCl. After buffer exchange, the protein sample was filtered and applied onto a cyclohepta-amylose-Sepharose 6B column (Silvanovich and Hill, 1976). The column (25 ×2.5 cm) was washed with 300 ml of the buffer, followed by 50 ml of the buffer containing 0.3 M NaCl. The adsorbed enzyme was eluted with 400 ml of the buffer containing 8 mg/ml of β-cyclodextrin. Combined active fractions were buffer exchanged into 50 mM NaOAc, pH 5.3, with 1% glycerol, and concentrated by ultrafiltration.

Hydrolysis of Soluble and Raw Starch

Soluble starch was heated at 85°C for 10 min before the addition of the enzyme to the slurry. For native starch granule digestion, the enzyme was added directly to the solid granule. Reactions were performed at 37°C and at various time intervals, stopped by the addition of DNSA. The enzyme activity was assayed by measuring the number of reducing groups using a glucose standard curve (Wong et al., 2003). Enzyme unit was defined as the amount of enzyme producing 1 μmole of reducing groups per min at pH 5.3 and 37°C with soluble starch as the substrate.

Determination of Optimum Conditions for Synergistic Action

AMY and GLA were premixed in various ratios in 25 mM NaOAc buffer, pH 5.3, with combined enzyme concentration of 1 unit. The premix was added directly onto starch granules, followed by incubation at 37°C at time intervals of 5, 10, 15, 20, and 25 min. The amount of reducing groups formed was reported as % conversion (mg of glucose produced from 100 mg starch). Another set of experiments was performed using changing ratios by varying the amount of one enzyme and keeping the other enzyme constant.

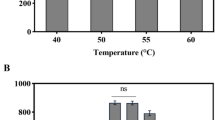

For temperature optimum, an enzyme solution containing AMY and GLA, each at concentrations of 0.25 units, in 25 mM NaOAc buffer, pH 5.3, was added to 15 mg of corn or wheat starch granules. The reaction mixture was incubated at 30, 40, 50, 60, and 70°C for 20 min. The formation of reducing groups was determined using DNSA. For temperature stability, the enzyme solution was incubated at various temperatures for 20 min, before added to the substrate. The hydrolysis reaction was conducted at 37°C for 20 min.

Effect of Metal Ions on Synergistic Action

Enzyme solution was incubated at 20°C for 20 min with 10 mM of MgSO4.7H2O, CuSO4.5H2O, FeSO4.7H2O, CaCl2.2H2O, or NaEDTA in 25 mM NaOAc buffer, pH 5.3. The reaction was conducted at 37°C for 20 min, using 0.1 unit of AMY and 0.1 unit of GLA, with corn starch granules as substrate. To further study the stabilizing effect of Ca++, 0.01, 0.1, and 1 mM of CaCl2.2H2O were used, and the enzyme mixture was incubated at 50°C for 20 min. EDTA at 1 mM was used in a parallel experiment.

Results And Discussion

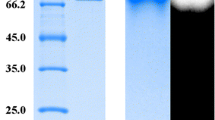

The barley α-amylase 1 mutant (AMY) and L. edodes glucoamylase (GLA) were cloned, expressed, and constitutively secreted in active forms. The purified recombinant AMY and GLA showed the same pH optimum of 4.6, and similar temperature optima of 60°C and 50°C, respectively, as reported previously (Wong et al. 2000B,2005). Both enzymes contain a SBD and are able to digest native starch granules. The enzyme concentration-velocity relationships for AMY and GLA are presented in Fig.1A and 1B. The relationship between enzyme concentration and velocity was non linear. The result is consistent with that representing polymeric hydrolysis and applies to enzyme reactions limited to the surface of the starch particles (Matsumura et al., 1988; McLaren and Packer, 1970). The starch substrate changed in characteristics as hydrolysis proceeded. The relative affinity between the various intermediate polymeric fragments and the enzyme, and the relative rates of hydrolysis of the glucosidic bonds were different.

The combination of AMY and GLA was expected to operate compatibly and synergistically under a single set of reaction conditions, since they both have been shown to contain a SBD, and exhibit very similar optimum pH and temperature. Individually, AMY hydrolyzed wheat and corn starch granules, respectively, at rates 2.5 and 1.7 times faster than GLA, and reflected in part the relative amounts of endo- and exo-cleavage accessible on the surface of the starch substrate. Previous observation with GLA also suggests that wheat starch granules were hydrolyzed faster than corn starch (Wong et al., 2005). AMY mixed with GLA in various ratios with combined enzyme concentrations kept constant were used for the hydrolysis of raw wheat and corn starch granules (Fig.2A and 2B). Exo-endo catalyzed reaction synergistically increased the rate of hydrolysis by ∼3× for wheat and corn granules, compared to the sum of the individual activities, under same reaction conditions (1 unit total enzyme concentration, 15 mg raw starch granules, 37°C, 25 min, pH 5.3).

It was found that varying the ratios (0.75:0.25, 0.5:0.5, and 0.25:0.75) of AMY to GLA did not cause significant variations in the synergistic enhancement, when the total combined enzyme amount was maintained constant for the reactions. The exo-endo synergism yielded about 4% conversion after 30 min, 37°C incubation, using either corn or wheat starch granules.

When the concentration of one enzyme was kept constant while the other enzyme varied, the rate of hydrolysis increased with increasing added amount of the other enzyme (Fig.3A and 3B). This result is essentially similar to that obtained by computer simulation of synergism on the hydrolysis of native potato starch (Fujii et al., 1988). The present result also suggests that it was the change in the total dosage with simultaneous change in the ratio of the two enzymes that affected the synergistic rate of hydrolysis. At constant AMY concentration, the increase in the rate of hydrolysis was proportional to the amount of added GLA. At constant GLA, added AMY increased the rate of hydrolysis proportionally, except that the enhancement was much greater. This was related to the fact that α-amylase-catalyzed internal cleavages liberated multiple non-reducing ends that are available as additional substrates for the GLA. Thus, increasing the concentration of α-amylase significantly enhanced the number of exo-cleavage by GLA. In the case of constant AMY with varying concentrations of GLA, the number of internal cleavages and thus non-reducing ends was not increased, and the enhancement of hydrolysis was not as significant.

The AMY and GLA enzyme mixture exhibited temperature stability of ≤50°C, which was similar to that of the individual enzymes. Increasing temperature of incubation increases the initial rate of hydrolysis up to 70°C (not shown). The unexpected continuous increase above the stability temperature of 50°C was likely due to the compensating thermal effect on the starch substrate by which it is gelatinized and more susceptible to the enzyme action. Similar results on the initial rates (short incubation time) were observed on the conversion of crude corn starch using combinations of α-amylase and glucoamylases of various origins (Liakopoulou-Kyriakides et al., 2001).

The activity of the enzyme combinations was inhibited by 10 mM Fe++, Cu++, Mg++, and NaEDTA (Fig.4A). The addition of Fe++ and Cu++ reduced the yield by 29 and 53%, respectively, while Mg++ and EDTA showed lesser effects.

Effects of (A) metal ions, (B) Ca++ on AMY+GLA activity. Conditions: 0.1 unit AMY and 0.1 unit GLA mixture, 15 mg corn starch granules, 37°C, 20 min, 25 mM NaOAc, pH 5.3. For (A), the enzyme mixtures were incubated with the metal ions at 20°C for 20 min before activity assay. For (B), the enzyme mixtures were incubated with various concentrations of Ca++ at 50°C for 20 min before activity assay to determine the Ca++ effect on stability of the enzyme mixture.

The addition of Ca++ to the reaction mixture did not affect the rate of hydrolysis, however, it increased the enzyme stability at a higher temperature of 50°C incubation (Fig.4B). Increasing concentrations of Ca++ protected the mixed enzymes from thermal inactivation at 50°C in a 20 min incubation. Stability was increased by 27% at 0.1 mM or higher Ca++ concentrations. The addition of EDTA caused a significant decrease in activity at this high temperature. This suggests that the bound Ca++ in the enzyme molecule was essential under these conditions, related to the effect of Ca++ on the thermal stability of the enzyme molecules.

Conclusion

A barley α-amylase 1 mutant and L. edodes glucoamylase constitutively expressed and secreted from S. cerevisiae were purified and combined for use in the hydrolysis of native starch granules. The synergistic hydrolysis achieved a 4% conversion per 1 unit total enzyme combination at 37°C in 30 min incubation. Stability of the enzyme mixture was enhanced by the addition of calcium chloride, and several metal ions are inhibitory to the activity.

Abbreviations

- AMY:

-

barley α-amylase isoform 1

- GLA:

-

Lentinula edodes glucoamylase

- DNSA:

-

dinitrosalicyclic acid

- NaOAc:

-

sodium acetate

- YEPG:

-

2% yeast extract, 1% bactopeptone, 2% glycerol

- SBD:

-

starch-binding domain

References

Balls A. K., Schwimmer S. (1944) J. Biol. Chem. 156:203–211

Fugii M., Homma T., Taniguchi M. (1988) Biotechol. Bioeng. 32:910–915

Janecek S., Sevcik J. (1999) FEBS Lett. 456:119–125

Liakopoulou-Kyriakides, M., Karakatsanis, A., Stamatoudis, M., Psomas, S. (2001). cereal chem. 78: 603–607

Matsumura M., Hirata J., Ishii S., Kobayashi J. (1988) J. Chem. Technol. Biotechnol. 42:51–67

McLaren A. D., Packer L. (1970) Adv. Enzymol. Rel. Sub. Biochem. 33:245

Morris V. J., Gunning A. P., Faulds C. B., Williamson G., Svensson B. (2005) Starch-Starke 57:1–7

Robertson, G. H., Wong, D. W. S., Lee, C. S., Wagschal, K., Smith, M. S., Orts, W. J. (2006) J. Agric. Food Chem. 54: 353–365

Schwimmer S. (1945) J. Biol. Chem. 157:219–234

Silvanovich M. P., Hill R. D. (1976) Anal. Biochem. 73:430–433

Sorimachi K., Le Gal-Coeffet M.-F., Williamson G., Archer D. B., Williamson M. P. (1997) Structure 5:647–661

Southall S. M., Simpson P. J., Gilbert H. J., Williamson G., Williamson M. P. (1999) FEBS Lett. 447:58–60

Tibbot B. K., Wong D. W. S., Robertson G. H. (2000) J. Protein Chem. 19:663–669

Wong D. W. S., Batt S. B., Robertson G. H. (2000) J. Protein Chem. 19:373–377

Wong D. W. S., Batt S. B., Lee C. C., Robertson G. H. (2002A) J. Protein Chem. 21:419–425

Wong D. W. S., Batt S. B., Robertson G. H. (2002B) J. Protein Chem. 20:619–623

Wong D. W. S., Batt S. B., Lee C. C., Robertson G. H. (2003) Protein Peptide Lett. 10:459–468

Wong D. W. S., Batt S. B., Lee C. C., Wagschal K., Robertson G. H. (2005) Protein J. 24:1–9

Author information

Authors and Affiliations

Corresponding author

Additional information

Reference to a company and/or products is only for purposes of information and does not imply approval of recommendation of the product to the exclusion of others that may also be suitable. All programs and services of the U.S. Department of Agriculture are offered on a nondiscriminatory basis without regard to race, color, national origin, religion, sex, age, marital status, or handicap.

Rights and permissions

About this article

Cite this article

Wong, D.W.S., Robertson, G.H., Lee, C.C. et al. Synergistic Action of Recombinant α-Amylase and Glucoamylase on the Hydrolysis of Starch Granules. Protein J 26, 159–164 (2007). https://doi.org/10.1007/s10930-006-9057-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10930-006-9057-9