Abstract

Amorphous flexible (co)polyesters with low glass transition temperature (T g) are very desirable in impact modification of biodegradable brittle polymers and synthesis of biodegradable elastomers. However, most flexible polyesters and binary copolyesters made from linear diacid(s) and diol(s) are crystalline polymers. In order to investigate the effect of monomer structure on the crystallization and T g of such copolyesters, novel ternary or multiple flexible copolyesters containing various structural units were designed and synthesized in this study, and characterized with 1HNMR, GPC, DSC, WAXD, TGA and tensile testing. Introducing aromatic diacid (especially asymmetric one) or short-chain branched diol is favorable to depress copolyester crystallization, and leads to higher T g at the same time. From easily crystallized to fully amorphous copolyesters with low T g were successfully synthesized by adopting different combination of structural units. In addition, the existence of aromatic structural unit in copolyesters is helpful to improve their tensile properties.

Graphical Abstract

Flexible copolyesters containing various structural units were designed and synthesized. Introducing asymmetric, rigid aromatic or short-chain branched unit is favorable to depress copolyester crystallization, and leads to higher T g at the same time. Crystalline to fully amorphous copolyesters with low enough T g have been successfully synthesized by adjusting the structural units.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

It is well-known that using biodegradable polymers instead of non-degradable ones is a promising way to avoid the environmental harm resulted from using the latter. To date, some important biodegradable (co)polyesters including poly(lactic acid) (PLA) [1], poly(butylene succinate) (PBS) [2–5], poly(butylene succinate-co-adipate) (PBSA) [6–8], poly(butylene adipate-co-terephthalate) (PBAT) [9–12] and poly(hydroxyalkanoate)s (PHAs) [13] have been commercialized and applied to a variety of fields in the last decades due to their desirable biodegradability, reasonably good processability and thermo-mechanical properties. Among them, flexible (co)polyesters made from linear diacid(s) and diol(s) like PBS and copolyesters like PBSA and PBAT are often used directly as tough plastics for end uses such as film, bottle and other disposable goods. They are also attempted to be used as impact modifiers of brittle biodegradable polymers like poly(lactic acid) (PLA) [14–19], biodegradable elastomers [20] or components of elastomers [21–25].

For impact modification or elastomer applications, amorphous flexible copolyesters with low glass transition temperature (T g) are often more desired as they can provide better chain flexibility than crystalline counterparts. For an example, ultratough PLA was successfully developed by synergistical introduction of amorphous ε-caprolactone-based copolyester and silica nanoparticles in Odent et al.’s recent report [26]. However, most of linear aliphatic polyesters like PBS [27] and PBA [28] and binary copolyesters like PBSA [6], poly(butylene succinate-co-azelate) (PBSAz) [29], poly(butylene-co-ethylene succinate) (PBES) [30], poly(hexamethylene sebacate-co-suberate) (PHSeSu) [31], poly(hexamethylene suberate-co-adipate) (PHSuA) [31], poly(butylene-co-propylene succinate) (PBPS) [32] and poly(ethylene-trimethylene succinate) (PETS) [33] have excellent to good crystallizability in whole composition range. Aliphatic–aromatic binary copolyesters like PBAT [10], poly(butylene succinate-co-terephthalate) (PBST) [34], poly(butylene succinate-co-furandicarboxylate) (PBSF) [35] and poly(butylene adipate-co-furandicarboxylate) (PBAF) [36] have less crystallizability than the aliphatic counterparts, but still kept certain crystallizability, even at the least crystallizable composition. For an example, typical PBAT (Ecoflex®) has a melting enthalpy over 10 J/g [10]. Few ternary or multiple copolyesters were reported in literature. As an example, poly(butylene succinate-co-ethylene succinate-co-ethylene terephthalate) is also a crystallizable copolyester [37]. But poly(2-methyl-1,3-propylene succinate), a polyester containing side methyl groups [38] was reported to be an amorphous polyester. Recently, some sugar-derived bicyclic diol or diacid compounds were used as comonomers to synthesize novel biobased copolyesters [39–42]. These copolyesters are characterized by high T g and are amorphous at certain composition rage. This implies that monomer structure is another important factor besides composition to affect crystallization and glass transition of flexible (co)polyesters, but relative research is lacked in literature.

In this study, we aim to make clear the effect of monomer structure on crystallization and glass transition of flexible copolyesters and to synthesize from crystalline to amorphous flexible copolyesters with low T g. To this end, ternary and multiple linear copolyesters were designed and synthesized from 1,4-butanediol and 3–4 symmetric and asymmetric linear diacids. Diols with various side groups were further incorporated to synthesize multiple copolyesters with side groups. The copolyesters were characterized with 1HNMR, GPC, DSC, TGA and tensile testing. The effects of structural factors including chain length of aliphatic diacids, symmetry and rigidity of aromatic diacids and short-chain side groups of diols on crystallizability and T g of the copolyesters were discussed. From easily crystallized to fully amorphous copolyesters with low T g were successfully synthesized by adopting different monomer combinations.

Experimental

Materials

Succinic acid (SA or S, Sanxin Chem. Co), adipic acid (AA or A, Aladdin), azelaic acid (AzA or Az, Sinoreagent), sebacic acid (SeA or Se, Sinoreagent), terephthalic acid (TPA or T, Sinoreagent), isophthalic acid (IPA or I, Sinoreagent), 2,5-furandicarboxylic acid (FDCA or F, Ruiyuan Chem. Co), 1,4-butanediol (BDO or B, Wulian Chem. Co), 2-methyl-1,3-propanediol (MPO or M, Aladdin), Neopentyl glycol (NPG or N, Aladdin), 2-ethyl-2-butyl-1,3-propanediol (EBP or E, TCI), tetrabutoxyl titanium (TBT, Aladdin) were all used as received. All other reagents were analytical reagent grade and used as received.

Synthesis of Copolyesters

Copolyesters were synthesized in a 250 mL flask via esterification followed by melt polycondensation. At least three diacids (0.5 mol in total) and BDO (or BDO and a branched diol, 1:1 molar ratio, 1 mol in total) was added in the flask. The diol/diacid molar ratio was fixed at 2:1. More detailed feed ratios of the monomers are shown in Table 1. TBT (0.1 mol% based on diacids) was added as catalyst under stirring and N2 protection. For Runs 1–2, esterification was conducted under atmospheric pressure at 190, 200 and 210 °C for 1, 2 and 1 h respectively. Then, the temperature was raised to 230 °C and the pressure was reduced to 200–400 Pa in about 45 min. Finally, melt polycondensation was carried out at 230 °C for 4 h. For Runs 3–17, the reaction temperatures were 10 °C higher. The resulting product was collected and stored in a dessicator under vacuum before characterization. The copolyesters were named with the acronyms of the monomers used. For an example, PBSeAzST2224 is a copolyester made from sebacic acid (Se), azelaic acid (Az), succinic acid (S) and terephthalic acid (T) in a diacid molar feed ratio of 2:2:2:4.

Characterization

Molecular weight and its distribution of the copolyesters were measured with a Waters 1525/2414 gel permeation chromatography (GPC) at 30 °C. Tetrahydrofuran was used as eluent and polystyrene as standard. The sample concentration was about 4 mg/mL, and the eluent flow rate was 1.0 mL/min.

1H NMR spectra of the copolyesters were recorded with a 400 M BRUKER AC-80 spectroscopy. Deuterated chloroform was used as solvent and tetramethylsilane as internal reference. X-ray diffraction measurements of the samples were performed using a Pert X-ray diffraction system (PANalytical Company) with CuKa radiation (0.154 nm) working at 40 kV and 40 mA. The samples were scanned from 2θ = 5° to 2θ = 60° with a step size of 0.026° and an acquisition time of 30 s per step.

Thermal transition behaviors of the copolyesters were recorded with a TA DSC Q200. A standard heat-cool-heat program was performed between −80 and 200 °C for all samples. The heating and cooling rates were of 10 °C/min. The temperature was hold at 200 °C and −80 °C for 3 min respectively before cooling and second heating. Thermal stability of the copolyesters was assessed with a TA Q500 thermal gravimetric analyzer under nitrogen atmosphere. The samples were measured from 50 to 800 °C at 20 °C/min.

Tensile properties of some copolyesters were measured using dumbbell-shaped specimens (2 mm in thickness and 4 mm in width) with a Zwick/Roell Z020 testing machine at 25 °C according to ASTM D638. The specimens were prepared with different processing methods, namely, injection molding and hot pressing, according to their different thermal transition properties. The details are interpreted in the Mechanical Properties section. All the specimens were conditioned at 25 °C and 50 % relative humidity for over 48 h prior to testing. The crosshead speed was 20 mm/min. For each sample, at least five specimens were tested.

Results and Discussion

Synthesis and Characterization of Chain Structure

The chemical structure of monomers used is illustrated in Scheme 1. The copolyesters were designed using SA, AA and BDO as main monomers. As binary aliphatic copolyester PBSA is crystalline in the whole composition range [6], aliphatic ternary copolyesters (Runs 1–2) were first designed in this study. Long chain diacids, namely, azelaic acid (Az) and sebacic acid (Se) were copolycondensed with succinic acid (S) and adipic acid (A) as their long aliphatic chains can provide better chain mobility [25] and low T g. In addition, they are both biobased monomers. Furthermore, aliphatic–aromatic ternary (Runs 3–9) or quaternary (Runs 10–14) copolyesters were also designed to further depress crystallization. Besides TPA, IPA and biobased FDCA were also introduced considering that their asymmetric structure may favor to further depress crystallization. Besides, short side groups were introduced into copolyesters (Runs 15–17) by using 2- or 2,2-substituted 1,3-propanediol as a diol comonomer in order to study its effect on crystallization and T g.

Diacids and diols used for synthesis of the flexible copolyesters. SA, succinic acid; AA, adipic acid; AzA, azelaic acid; SeA, sebacic acid; TPA, terephthalic acid; IPA, isophthalic acid; FDCA, 2,5-furandicarboxylic acid; BDO, 1,4-butanediol; MPO, 2-methyl-1,3-propanediol; NPG, neopentyl glycol or 2,2-dimethyl-1,3-propanediol; EBP, 2-ethyl-2-butyl-1,3-propanediol

There are lots of possible combinations with these monomers. As the main purpose of this study is to investigate the effect of structural unit on the thermal transition of flexible copolyesters, the effect of copolymer composition was not considered. Copolyesters were designed with some fixed compositions. It is known that binary flexible copolyesters are usually least crystallizable when the content of short chain or aromatic diacid unit is of 20–40 mol% [6, 10, 34, 36]. For binary aliphatic–aromatic copolyesters, 40–50 mol% aromatic diacid unit can assure good balance between thermo-mechanical properties and biodegradability [10, 12]. Therefore, in syntheses of aliphatic copolyesters (Runs 1–2), the molar fraction of SA in total diacids was fixed at 40 mol% and that of other two took the average (30 %). In the syntheses of aliphatic–aromatic copolyesters, the molar ratio of aromatic diacid(s) in total diacids were also fixed at 40 mol%. On the premise of this rule, diacid feed ratios took the averages of aliphatic or aromatic acids. For the synthesis of short-chain branched copolyesters, the molar ratio of substituted 1,3-propanediol to BDO was arbitrarily fixed at 1:1. The detailed feed ratio of monomers are listed in Table 1.

Molecular weight of copolyesters usually affects their glass transition temperature (T g), mechanical properties and end uses. Low molecular weight of thousands gram per mol is suitable for soft segments in multi-block copolymers used for elastomers, however, high molecular weight around 105 g/mol is often required for tough plastics, impact modifiers and elastomers to ensure sufficient thermo-mechanical properties. In this study, we aimed to design and screen flexible amorphous (or nearly amorphous) copolyesters with low T g and acceptable mechanical properties. Therefore, high molecular weight copolyesters were synthesized so that the molecular weight dependence of T g can be avoided and mechanical properties can be assessed.

Most copolyesters are colorless/white or pale yellow. But there is clear discoloration for adipate-containing copolyesters. The GPC results listed in Table 1 indicate that high molecular weight copolyesters were successfully synthesized. The number- and weight-average molecular weights (M n and M w) range in 36,000–75,000 g/mol and 60,000–146,000 g/mol, respectively. And the polydispersity index (Đ) ranges in 1.7–2.0.

Chemical structure of the copolyesters was characterized by 1H-NMR. The spectra and attribution of chemical shifts are shown in Fig. 1 and Scheme 2. The characteristic chemical shifts of succinate, adipate, azelate, sebacate, terephthalate, isophthalate, furandicarboxylate, BDO, MPO, NPG and EBP locate at 2.63 ppm (s), 2.33 ppm (a), 1.32 ppm (z), 1.30 ppm (l), 8.10 ppm (t), 8.22 ppm (i), 7.21 ppm (f), 4.44–4.09 ppm (b), 1.21–0.98 ppm (m), 1.18–0.96 ppm (n) and 0.97–0.80 ppm (v), respectively. For the aliphatic–aromatic copolyesters, the chemical shifts of CH2 in diol unit split into four peaks (b4-1, c4-1, o4-1, q4-1, r4-1), corresponding to different sequence structures as shown in Scheme 2. The attributions of other chemical shifts are also shown in this scheme. From the peak area of characteristic chemical shifts, the copolyester composition and randomness degree were calculated and the results are listed in Table 1. It can be seen that the composition is close to the monomer feed ratio and the randomness degree is close to one. These qualitative and quantitative results indicate that random copolyesters with expected structure and composition were successfully synthesized.

Thermal Transition Behaviors

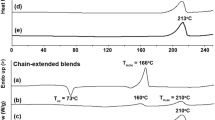

The thermal transition behaviors of the copolyesters were recorded with DSC using a standard heat/cool/heat procedure. The cooling and second heating DSC curves are shown in Fig. 2. The transition temperatures and enthalpies are listed in Table 2.

In the two aliphatic ternary copolyesters PBSeAS334 and PBAzAS334 (Runs 1–2) the long chain diacids, namely sebacic and azelaic acid, were introduced in order to lower down T g. Both copolyesters have only one T g, suggesting random sequence structure. And the T gs (−60, −58 °C) are lower than PBSA46 (−53 °C) [6]. However, both copolyesters exhibit rapid melt crystallization with high crystallization (49.5, 44.3 J/g) and melting enthalpies (50.5, 45.5 J/g). The melting enthalpies are even higher than that of PBSA46 (23.7 J/g [6]), possibly due to the favorable contribution of the long Se or Az alkylene chain to crystallization. The results indicate that the introduction of the third aliphatic long chain diacid monomer does not help to depress the crystallization of the resultant copolyesters.

In the next study, aromatic acid(s) was(were) introduced to synthesize aliphatic–aromatic ternary or quarternary copolyesters. When TPA is used instead of SA, the resultant random copolyesters PBSeAT334 and PBAzAT334 (Runs 3–4) have higher T g, T c and T m, but much slower crystallization and enthalpies (10.4–10.7 vs. 44.3–49.5 J/g). When the adipate is replaced with azelate or sebacate (Run 5 vs. Run 3 or 4), both T c and T m decreased and the crystallization and melting enthalpies kept nearly unchanged. In comparison with PBSeAT334 and PBAzAT334 (Runs 3 and 4), the ternary copolyester (PBSeTI622, Run 6) has slightly higher T g, much lower T c and T m, and higher crystallization and melting enthalpies.

Effect of the structure of aromatic diacid on copolyester crystallization can be seen by comparing the DSC results of PBSeST334, PBSeSI334 and PBSeSF334 (Runs 7–9). Clearly, PBSeST334 has crystallizability nearly equivalent to PBSeAT334, PBAzAT334 and PBSeAzT334 (Runs 3–5). However, PBSeSI334 and PBSeSF334 containing asymmetric isophthalate and furandicarboxylate unit respectively neither crystallize from melt nor from glass state at 10 °C/min. These results indicate that introducing asymmetric structural unit can effectively destroy the structural regularity and therefore depress the crystallization.

In comparison with the ternary copolyesters PBSeAT334, PBAzAT334 (Runs 3–4), the quarternary copolyesters PBSeAzST2224 and PBSeAzAT2224 (Runs 10–11) have comparable T c and T m and crystallization enthalpy. However, when two aromatic units are introduced, amorphous PBSeSTI3322, PBSeATI3322 and PBSeSTF3322 (Runs 12–14) are obtained. Neither melt nor glass crystallization was observed in the DSC thermograms.

In addition to number, chain length, symmetricity of diacid monomers, the effect of short-chain branching on crystallization and T g of copolyesters was further studied. Using BDO, an equimolar short-chain branched 1,3-propanediol (MPO or NPG or BEP) and three diacids (Se, S, T), PBMSeST334, PBNSeST334, PBESeST334 (Runs 15–17), were synthesized. In comparison with the ternary linear counterpart PBSeST334 (Run 7), these copolyesters are all amorphous. This indicates that introducing short-chain branching is also an effective way to depress crystallization of copolyesters. However, it can be seen that they have T g (−25.9 to −19.6 °C) higher than PBSeST334 (−39.2 °C) and the T g increases with the substituted number (1–2) and side group size. This is possibly because the steric hindrance of the substituent group(s) hinders the segment motion, especially for the 2,2-substituted copolyesters.

According to the crystallization and melting enthalpies (ΔH c and ΔH m), all the copolyesters are classified into five classes, as shown in Fig. 3. The aliphatic ternary copolyesters, PBSeAS334 and PBAzAS334 (Runs 1–2) are classified to class A. They can crystallize easily with high ΔH c and ΔH m (ca. 47 J/g) which are equivalent to those of poly(butylene adipate) (ca. 50 J/g) [43]. The aliphatic–aromatic ternary copolyester PBSeTI622 (Run 6) is classified to class B. It crystallizes with moderate ΔH c and ΔH m of about 25 J/g which is equivalent to those reported for PBSA46 (ca. 24 J/g) [6]. This suggests the big contribution of the sebacate unit to crystallizability. Class C includes six aliphatic–aromatic copolyesters, four ternary (Runs 3–5, 7) and two quarternary (Runs 10–11). They weakly crystallize and have ΔH c and ΔH m (ca. 10 J/g) close to those of commercial Ecoflex®. The others neither showed any phase transition in the cooling scan nor in subsequent melting scan both at 10 °C/min. But some of them, namely PBSeSF334, PBSeSTI2224 and PBSeATI2224 did show some melting peak in the first heating scan, especially for PBSeSF334 (Run 9). This phenomenon means that these copolyesters still have certain crystallizability. So, they are classified to “nearly amorphous”. Finally, PBSeSI334, PBSeSTF3322 and the three short chain branched copolyesters are fully amorphous. There is no melting peak observed even in the first heating scan for them. Such order of crystallizability of these copolyesters was also confirmed by WAXD patterns of six representative copolyester samples shown in Fig. 4. Clearly, the intensity of the characteristic peaks decreases from strong (Run 1) and moderate (Run 6) to weak (Run 7), faint (Run 9) and none (Runs 8 and 15). In addition, it can be seen from Table 2 that the crystallizability of the copolyesters was also reflected by their appearance, from opaque, translucent to transparent. From detailed comparison of above results, it can be concluded that the monomer structure contributes to the crystallization of multiple copolyesters in such orders: Se > Az > A > S > T > F > I, B ≫ M ≈ N ≈ E.

Classification of the flexible copolyesters according to their average crystallization and melting enthalpies (ΔH c and ΔH m, in cooling and 2nd heating scanning at 10 °C/min). a Easily crystallized, b moderately crystallized, c weakly crystallized, d nearly amorphous and e fully amorphous. Note Both ΔH c and ΔH m are zero for class D, so the “ΔH m” obtained from the 1st heating scan is shown as a reference

All the copolyesters only exhibit one T g, suggesting that they are all random copolymers. To analyze the effect of structural unit on T g, all the copolyesters are ranked according to T g, as shown in Fig. 5. Clearly, introduction of aliphatic diacid(s) with longer alkylene chain (Az, Se) reduces T g of the copolyesters, but introduction of aromatic diacid(s) or substituted 1,3-propanediol raises T g of the copolyesters. For the three aromatic diacids, the asymmetry and/or rigidity of the aromatic ring also contribute(s) to higher T g. It was reported that FDCA has higher rigidity than TPA and lead to less chain mobility [44]. So, the following order of T g is observed: PBSeST334 (−39.2 °C) < PBSeSI334 (−33.3 °C) ≈ PBSeSTI3322 (−33.2 °C) < PBSeSTF3322 (−31.5 °C) < PBSeSF334 (−28.6 °C). From detailed comparison of T g data, the monomer structure contributes to T g in such orders: Se ≈ Az < A < S < T < I < F, B < N ≈ E < M.

Ranking of the copolyesters according to their T g. The tick lables in the horizontal ordinate are the Run numbers of copolyesters indicated in Table 1

In summary, copolycondensation with shorter chain aliphatic diacid, asymmetric aromatic diacid or short-chain branched diol is helpful to depress copolyester crystallization. On the other hand, these factors lead to higher T g. By compromising these factors, easily crystallized to fully amorphous copolyesters with low enough T g can be synthesized as required. These copolyesters are reasoned to be biodegradable. And the biodegradability of some of them will be reported later.

Thermal Stability

Thermal stability of the copolyesters was further assessed. The TGA curves are shown in Fig. 6, and the characteristic decomposition temperatures, namely T d,5, T d,c, T d,max, are listed in Table 3. Clearly, all the copolyesters present good to excellent thermal stability. Clearly, in comparison with the aliphatic copolyesters, the aliphatic–aromatic copolyesters exhibit better thermal stability, especially in terms of T d,5. Terephthalate- and/or isophthalate-containing aliphatic–aromatic copolyesters have slightly better thermal stability than furandicarboxylate-containing ones. And introduction of short side group(s) does not result in clear change in thermal stability. So, the existence of benzene ring is favorable to improve the thermal stability of the copolyesters. And the thermal stability of the thirteen copolyesters containing only benzene ring as aromatic unit shows little composition and structure dependence (T d,5 387 ± 4 °C, T d,c 401 ± 2 °C, T d,max 429 ± 4 °C).

Mechanical Properties

Finally, the tensile properties of some copolyesters were measured at room temperature. Specimens of Runs 3–5, 7 and 10–11 were prepared with injection molding and those of Runs 1–2, 6 and 9 were prepared with hot pressing. Different processing methods were used because of their different thermal transition properties. The DSC results show that Runs 3–5, 7 and 10–11 can crystallize at 24–56 °C and have high T m (~100 °C), so they crystallized to certain extent during injection molding and could be demolded. The T m of Runs 1–2 and 6 is around room temperature (21–33 °C) and they can only crystallize at lower temperature. Run 9 is a “nearly amorphous” copolyester. Therefore, it is difficult for them to crystallize and demold in injection molding. But with hot pressing followed by long time cooling with water, specimen preparation still succeeded. Other copolyesters are much less crystallizable or fully amorphous. Their soft or even flowable nature at room temperature prevented them from specimen preparation and mechanical testing.

The Young’ modulus, tensile strength and elongation at break are listed in Table 3. Although the two aliphatic copolyesters PBSeAS334 and PBAzAS334 (Runs 1–2) have best crystallizability, their T ms are low and close to testing temperature, so they have lowest tensile modulus (E, 26–36 MPa) and strength (σ b, ca. 2.4–2.7 MPa). In comparison, PBAzAS334 has lower modulus (26 vs. 36 MPa) and higher elongation at break (ε b, 560 vs. 230 %) than PBSeAS334 due to lower T m. In comparison with the aliphatic copolyesters, the six weakly crystallizable aliphatic–aromatic copolyesters (Runs 3–5, 7, 10–11) with higher T m (ca. 100 °C) exhibit higher E (40.7 ± 2.6 MPa), higher σ b (7.0 ± 0.8 MPa) and even higher ε b (590 ± 140 %, except for PBSeAzT334). In comparison with these six copolyesters, PBSeTI622 and PBSeSF334 (Runs 6 and 9) have roughly equivalent σ b and much higher ε b (930–1050 %) because of low T m (32 °C) of Run 6 and nearly amorphous nature of Run 9. The above results suggest that introduction of terephthalate into copolyesters can improve the tensile properties possibly due to higher intermolecular interaction among aromatic units, and introduction of isophthalate or furandicarboxylate can further improve the elongation at break because of less crystallizability.

T d,5 and T d,m are the characteristic decomposition temperatures at 5 % and maximum weight loss respectively, and T d,c is the characteristic decomposition temperature corresponding to the intersection point of the horizontal line of zero decomposition and the tangent line of maximum decomposition. E, σy, σb and ε b are tensile modulus, yielding stress, breaking stress and elongation respectively. For tensile testing, specimens were prepared by injection molding for Runs 3–5, 7, 10–11 and hot pressing for Runs 1, 2, 6, 9.

Conclusions

In this study, novel ternary or multiple random copolyesters containing various structural units were designed, synthesized and characterized, and the effects of chain length, aromaticity, symmetry, rigidity and short-chain branching of the structural units on the crystallization, glass transition temperature and tensile properties of the resultant copolyesters were investigated. Copolyester crystallization can be depressed and glass transition temperature can be raised by incorporating aromatic diacid (especially asymmetric one) or short-chain branched diol. The monomer structure contributes to copolyester crystallization in such an order: Se > Az > A > S > T > F > I, B ≫ M ≈ N ≈ E, but contributes to T g in an almost reverse order: Se ≈ Az < A < S < T< I < F, B < N ≈ E < M. Through adopting suitable monomer combinations, copolyesters with different aggregating structures, from easily crystallized to fully amorphous, can be synthesized. In addition, the existence of aromatic structural units in copolyesters is helpful to improve their tensile properties. These results will be helpful to design and synthesize biodegradable copolyesters with desired properties for use in impact modifiers and elastomeric materials. Further studies are under way and will be reported soon.

References

Drumright RE, Gruber PR, Henton DE (2000) Polylactic acid technology. Adv Mater 12:1841–1846

Xu J, Guo BH (2010) Poly(butylene succinate) and its copolymers: research, development and industrialization. Biotechnol J 5:1149–1163

Fujimaki T (1998) Processability and properties of aliphatic polyesters, ‘BIONOLLE’, synthesized by polycondensation reaction. Polym Degrad Stab 59:209–214

Yang J, Zhang SP, Liu XY, Cao AM (2003) A study on biodegradable aliphatic poly(tetramethylene succinate): the catalyst dependences of polyester syntheses and their thermal stabilities. Polym Degrad Stab 81:1–7

Lim S-K, Jang S-G, Lee S-I, Lee K-H, Chin I-J (2008) Preparation and characterization of biodegradable poly(butylene succinate) (PBS) foams. Macromol Res 16:218–223

Tserki V, Matzinos P, Pavlidou E, Vachliotis D, Panayiotouet C (2006) Biodegradable aliphatic polyesters. Part I. Properties and biodegradation of poly(butylene succinate-co-butylene adipate). Polym Degrad Stab 91(2):367–376

Tserki V, Matzinos P, Pavlidou E, Panayiotouet C (2006) Biodegradable aliphatic polyesters. Part II. Synthesis and characterization of chain extended poly(butylene succinate-co-butylene adipate). Polym Degrad Stab 91:377–384

Nikolic MS, Djonlagic J (2001) Synthesis and characterization of biodegradable poly(butylene succinate-co-butylene adipate)s. Polym Degrad Stab 74:263–270

Yamamoto M, Witt U, Skupin G, Beimborn D, Müller R-J. Biodegradable aliphatic–aromatic polyesters: “Ecoflex®”. Published Online: 15 Jan 2005. http://onlinelibrary.wiley.com/doi/10.1002/3527600035.bpol4011/full

Gan Z, Kuwabara K, Yamamoto M, Abea H, Doiaet Y (2004) Solid-state structures and thermal properties of aliphatic–aromatic poly(butylene adipate-co-butylene terephthalate) copolyesters. Polym Degrad Stab 83(2):289–300

Kuwabara K, Gan Z, Nakamura T et al (2002) Crystalline/amorphous phase structure and molecular mobility of biodegradable poly(butylene adipate-co-butylene terephthalate) and related polyesters. Biomacromolecules 3(2):390–396

Müller R-J, Kleeberg I, Deckwer W-D (2001) Biodegradation of polyesters containing aromatic constituents. J Biotechnol 86:87–95

Chen GQ (2009) A microbial polyhydroxyalkanoates (PHA) based bio-and materials industry. Chem Soc Rev 38:2434–2446

Liu HZ, Zhang JW (2011) Research progress in toughening modification of poly(lactic acid). J Polym Sci, Part B: Polym Phys 49:1051–1083

Harada M, Ohya T, Iida K, Hayashi H, Hirano K, Fukuda H (2007) Increased impact strength of biodegradable poly(lactic acid)/poly(butylene succinate) blend composites by using isocyanate as a reactive processing agent. J Appl Polym Sci 106:1813–1820

Lee S, Wook J (2005) Characterization and processing of Biodegradable polymer blends of poly(lactic acid) with poly(butylene succinate adipate). Korea Aust Rheol J 17:71–77

Jiang L, Wolcott MP, Zhang JW (2006) Study of biodegradable polylactide/poly(butylene adipate-co-terephthalate) blends. Biomacromolecules 7:199–207

Zhang NW, Zeng C, Wang L, Ren J (2013) Preparation and properties of biodegradable poly(lactic acid)/poly(butylene adipate-co-terephthalate) blend with epoxy-functional styrene acrylic copolymer as reactive agent. J Polym Environ 21:286–292

Dong WF, Zou BS, Ma PM, Liu WC, Zhou X, Si DJ, Ni ZB, Chen MQ (2013) Influence of phthalic anhydride and bioxazoline on the mechanical and morphological properties of biodegradable poly(lactic acid)/poly[(butylene adipate)-co-terephthalate] blends. Polym Int 62:1783–1790

Park H-S, Seo J-A, Lee H-Y, Kim H-W, Wall IB, Gong M-S, Knowles JC (2012) Synthesis of elastic biodegradable polyesters of ethylene glycol and butylene glycol from sebacic acid. Acta Biomater 8(8):2911–2918

Zeng XQ, Wu BS, Wu LB, Hu JJ, Bu ZY, Li B-G (2014) Poly(L-lactic acid)-block-poly(butylene succinate-co-butylene adipate) multiblock copolymers: from synthesis to thermo-mechanical properties. Ind Eng Chem Res 53:3550–3558

Ba C, Yang J, Hao Q, Liu X, Cao AM (2003) Syntheses and physical characterization of new aliphatic triblock poly(L-lactide-b-butylene succinate-b-l-lactide)s bearing soft and hard biodegradable building blocks. Biomacromolecules 4:1827–1834

Xu C-L, Zeng J-B, Zhu QY, Wang Y-Z (2013) Poly(ethylene succinate)-b-poly(butylene succinate) multiblock copolyesters: the effects of block length and composition on physical properties. Ind Eng Chem Res 52:13669–13676

Li S-L, Zeng J-B, Wu F, Yang Y, Wang Y-Z (2014) Succinic acid based biodegradable thermoplastic poly(ester urethane) elastomers: effects of segment ratios and lengths on physical properties. Ind Eng Chem Res 53:1404–1414

Li WD, Zeng JB, Li YD, Wang XL, Wang YZ (2009) Synthesis of high-molecular-weight aliphatic-aromatic copolyesters from poly(ethylene-co-1,6-hexene terephthalate) and poly(l-lactic acid) by chain-extension. J Polym Sci, Part A: Polym Chem 47:5898–5907

Odeng J, Habibi Y, Raquez J-M, Dubois P (2013) Ultra-tough polylactide-based materials synergistically designed in the presence of rubbery ε-caprolactone-based copolyester and silica nanoparticles. Comp Sci Technol 84:86–91

Qiu ZB, Fujinam S, Komura M, Nkajima K, Ikehara T, Nishi T (2004) Nonisothermal crystallization kinetics of poly(butylene succinate) and poly(ethylene succinate). Polym J 36:642–646

Kai WH, Zhu B, He Y, Inoue Y (2005) Crystallization of poly(butylene adipate) in the presence of nucleating agents. J Polym Sci, Part B: Polym Phys 43:2340–2351

Mincheva R, Delangre A, Raquez JM, Narayan R, Dubois P (2013) Biobased polyesters with composition-dependent thermomechanical properties: synthesis and characterization of poly(butylene succinate-co-butylene azelate). Biomacromolecules 14:890–899

Cao AM, Okamura T, Nakayama K, Inoue Y, Masuda T (2002) Studies on syntheses and physical properties of biodegradable aliphatic poly(butylene succinate-co-ethylene succinate)s and poly(butylene succinate-co-diethylene glycol succinate)s. Polym Degrad Stab 78:107–117

Liang ZC, Pan PJ, Zhu B, Inoue Y (2011) Isomorphic crystallization of aliphatic copolyesters derived from 1, 6-hexanediol: effect of the chemical structure of comonomer units on the extent of cocrystallization. Polymer 52:2667–2676

Papageorgiou GZ, Bikiaris DN (2007) Synthesis, cocrystallization, and enzymatic degradation of novel poly(butylene-co-propylene succinate) copolymers. Biomacromolecules 8:2437–2449

Tsai C-J, Chang W-C, Chen C-H, Lu H-Y, Chen M (2008) Synthesis and characterization of polyesters derived from succinic acid, ethylene glycol and 1,3-propanediol. European Polym J 44:2339–2347

Nagata M, Goto H, Sakai W, Tsutsumi N (2000) Synthesis and enzymatic degradation of poly(tetramethylene succinate) copolymers with terephthalic acid. Polymer 41:4373–4376

Wu L, Mincheva R, Xu Y, Raquez J-M, Dubois P (2012) High molecular weight poly(butylene succinate-co-butylene furandicarboxylate) copolyesters: from catalyzed polycondensation reaction to thermomechanical properties. Biomacromolecules 13(9):2973–2981

Wu B, Xu Y, Bu Z et al (2014) Biobased poly(butylene 2,5-furandicarboxylate) and poly(butylene adipate-co-butylene 2,5-furandicarboxylate) s: from synthesis using highly purified 2,5-furandicarboxylic acid to thermo-mechanical properties. Polymer 55(16):3648–3655

Deng L-M, Wang Y-Z, Yang K-K, Wang X-L, Zhou Q, Ding S-D (2004) A new biodegradable copolyester poly(butylene succinate-co-ethylene succinate-co-ethylene terephthalate). Acta Mater 52(20):5871–5878

Chen C-H, Yang C-S, Chen M, Shih Y-C, Hsu H-S, Lu S-F (2011) Synthesis and characterization of novel poly(butylene succinate-co-2-methyl-1,3-propylene succinate)s. Express Polym Lett 5:284–294

Japu C, de Ilarduya AM, Alla A, García-Martín MG, Galbis JA, Muñoz-Guerra S (2014) Bio-based PBT copolyesters derived from d-glucose: influence of composition on properties. Polym Chem 5(9):3190–3202

Japu C, de Ilarduya AM, Alla A, García-Martín MG, Galbis JA, Muñoz-Guerra S (2013) d-Glucose-derived PET copolyesters with enhanced T g. Polym Chem 4(12):3524–3536

Japu C, Martínez de Ilarduya A, Alla A, Jiang Y, Loos K, Muñoz-Guerra S (2015) Copolyesters made from 1, 4-butanediol, sebacic acid, and d-glucose by melt and enzymatic polycondensation. Biomacromolecules 16(3):868–879

Japu C, de Ilarduya AM, Alla A, Muñoz-Guerra S (2013) Bio-based poly(hexamethylene terephthalate) copolyesters containing cyclic acetalized tartrate units. Polymer 54(6):1573–1582

Woo EM, Wu MC (2005) Thermal and X-ray analysis of polymorphic crystals, melting, and crystalline transformation in poly(butylene adipate). J Polym Sci, Part B: Polym Phys 43:1662–1672

Burgess SK, Leisen JE, Kraftschik BE, Mubarak CR, Kriegel RM, Koros WJ (2014) Chain mobility, thermal, and mechanical properties of poly(ethylene furanoate) compared to poly(ethylene terephthalate). Macromolecules 47:1383–1391

Acknowledgements

This work was supported by the National Key Research and Development Program (2016YFB0302402), the National Nature Science Foundation of China (51373152), State Key Laboratory of Chemical Engineering (SKL-ChE-15D01), and 151 Talents Project of Zhejiang Province.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pan, C., Lu, J., Wu, B. et al. Effect of Monomer Structure on Crystallization and Glass Transition of Flexible Copolyesters. J Polym Environ 25, 1051–1061 (2017). https://doi.org/10.1007/s10924-016-0881-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-016-0881-5