Abstract

(1 − x)Bi0.5Na0.5TiO3−xBa0.3Sr0.7TiO3 (abbreviated as BNT-BST, x = 0.05 ~ 0.40) was prepared by a conventional ceramic processing method and their structural evolution, dielectric and ferroelectric properties were investigated. The structure of the BNT-BST ceramics changes from phase coexistences of Rhombohedral-Tetragonal (x ≤ 0.10) to Tetragonal-Cubic (x ≥ 0.35), across a dominant Tetragonal phase region (0.15 ≤ x ≤ 0.30). By increasing BST content, the grain size of the BNT-BST ceramics slightly decreases, while the temperature Tm of the maximum dielectric constant gradually goes downward from ~ 250 °C to near room temperature. Meanwhile, with the increase of measuring frequency, the Tm increases for the BNT-BST ceramics with x ≥ 0.15, indicating their relaxor ferroelectric characteristics. Room temperature P-E loop test results show that both coercive field Ec and remnant polarization Pr gradually reduce with the increase of x value for relaxor BNT-BST ceramics. Both high peak dielectric constant (εr > 6000 at Tm) and saturated polarization (Ps ~ 30 µC/cm2), as well as tunable remnant polarization Pr are obtained in relaxor BNT-BST ceramics suitable for capacitor candidate materials.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Ceramic capacitors are indispensable components in modern electronics, which are employed for functions of bypassing, coupling, decoupling, filtering, pulse discharge, power conditioning, and so on [1]. Ferroelectrics used for ceramic capacitors must satisfy many requirements in order to be used reliably in such applications. A high relative dielectric constant εr is essential for large valued capacitors with good volumetric efficiency and thus affords system miniaturization [2]. In general, normal ferroelectrics have very high εr in the vicinity of Curie temperature. However, such high εr in the vicinity of Curie temperature is not suitable for practical usage for capacitors due to its poor temperature dependence [3]. An effective method for improving temperature dependence of dielectric properties is to make the Curie peak diffuse and form so-called relaxor ferroelectrics [4]. During the past decades, lead-based relaxor ferroelectrics, typically represented by Pb(Nb,Mg)O3–PbTiO3 (PMN-PT), have been extensively studied and successfully commercialized [5,6,7]. However, lead-based ceramics will be prohibited in the future with increasing attention to environmental issues and human health. Therefore, it is desirable to develop lead-free ferroelectric ceramics with excellent dielectric properties for replacing the lead-containing ceramics in capacitor applications [8].

Bi0.5Na0.5TiO3 (BNT), which is an environmentally friendly perovskite structural ferroelectric material with rhombohedral symmetry (R3c) at room temperature, has been attracted considerable attention due to its high promising dielectric and piezoelectric properties over a wide temperature range [9,10,11]. BNT exhibits extremely complex crystal structure and is characterized by temperature dependent permittivity with two anomalies at Td ~ 200 °C and Tm ~ 320 °C [12, 13]. Previously, BNT was extensively studied as a promising lead-free piezoelectric candidate, because it can form a morphotropic phase boundary (MPB) with other tetragonal perovskites, such as BaTiO3 (BT) and Bi0.5K0.5TiO3 (BKT), and such MPB composition will show enhanced piezoelectric properties [14, 15]. However, the research of BNT as capacitor ceramic applications is far less extensive than that of BNT as piezoelectric ceramics because of its relatively low permittivity at room temperature (εr ~ 760 at 1 kHz). Recently, with the aim of improving room temperature permittivity and temperature dependent behavior, different compounds such as (Na,Bi)NbO3 and SrTiO3 modified BNT-based ceramics were investigated for energy storage capacitor applications [16, 17]. Moreover, some works about the application of BNT-based ceramics as high temperature capacitors have also been reported, because BNT can actually obtain good temperature dependent dielectric characteristics at elevated temperatures even up to 400 °C by modification [11, 18,19,20].

In our previous work, Ba0.3Sr0.7TiO3 (BST) was found to be more suitable for preparation of pulse power capacitors [21, 22]. However, the room temperature permittivity (εr ~ 650 at 1 kHz) of BST is also relatively low due to its Curie temperature (Tc = − 85 °C) far below room temperature. Consequently, in this work, a (1 − x)Bi0.5Na0.5TiO3−xBa0.3Sr0.7TiO3 (BNT-BST) binary solid solution is developed to improve room temperature dielectric properties by designing to form relaxor ferroelectrics. Accordingly, the influence of BST content on the crystal structure, microstructure, dielectric and ferroelectric properties of the ceramics was comprehensively investigated.

2 Experimental procedures

A conventional processing method was applied to fabricate (1 − x)Bi0.5Na0.5TiO3−xBa0.3Sr0.7TiO3 (BNT-BST) ceramics, in which x equals 0.05, 0.10, 0.15, 0.20, 0.25, 0.30, 0.35, and 0.40 respectively, by using raw materials of bismuth oxide (Bi2O3, 99%), sodium carbonate (Na2CO3, 99.8%), barium carbonate (BaCO3, 99%), strontium carbonate (SrCO3, 99%), and titanium dioxide (TiO2, 98%) from Sinopharm Chemical Reagent Co. Ltd., Shanghai, China. The raw powders were weighed according to the stoichiometric formula of each composition and milled in a polyethylene jar for 24 h in ethanol medium with ZrO2 balls. After separating the balls, the mixed slurry were dried and calcined at 850 °C for 3 h and then milled again for 24 h. The calcined powders were granulated to be pressed into disks of 13 mm diameter and about 1 mm thick under 120 ± 10 MPa by adding polyvinyl alcohol solution (PVA, 5 wt%) as a binder. The disks were first preheated in air at 650 °C for 2 h to remove PVA binders, and then sintered at temperatures ranging from 1140 °C to 1260 °C for 2 h in air with a heating rate of 5 °C/min and finally furnace-cooled to ambient temperature.

An X-ray diffraction (XRD, D8-Advance, Bruker, Germany) technique with CuKα radiation (λ = 0.15406 nm) was used to determine the phase structure of sintered BNT-BST ceramics. Data analysis was carried out by a Rietveld method using the GSAS program suite. The microstructure features of the polished and thermally-etched surfaces of the sintered ceramics were characterized by a scanning electron microscopy (SEM, JSM-6700F, JEOL, Japan). The sintered ceramic samples were polished to about 0.8 mm thick for dielectric measurements. Silver pastes were painted on both sides of the polished ceramic samples, and then fired to electrodes at 800 °C for 20 min. The temperature dependence of the dielectric constant εr and loss tanδ was determined using a precision impedance analyzer (HP4294A, Agilent) over a temperature range from room temperature to 400 °C, being connected to a computer controlled temperature chamber. The data at testing frequencies of 1 kHz, 10 kHz, 100 kHz and 1 MHz are collected. The polarization–electric field (P–E) hysteresis loops were examined at room temperature using a Radiant precision workstation (TRek model 609B) based on a standard Sawyer–Tower circuit at 10 Hz.

3 Results and discussion

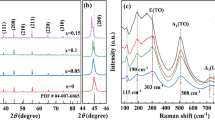

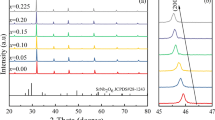

Figure 1a shows the XRD patterns of the BNT-BST ceramics with different x values. It can be seen that all ceramics have a pure perovskite phase, and no secondary phases can be traced within the detection accuracy of XRD technique. The zoomed XRD patterns in the 2θ range of 38° ~ 42° and 45° ~ 48° are given in Fig. 1b, c, respectively. For the BNT-BST ceramics with x ≤ 0.10, two splitting (003)/(021) diffraction peaks around 2θ = 40° and one (202) diffraction peak around 2θ = 46.5° are detected, in accordance with the structural characteristics of rhombohedral BNT phase [23]. When x ≥ 0.15, only one diffraction peak can be detected around 2θ = 40°, but two splitting diffraction peaks appear around 2θ = 46.5°, and these two peaks gradually merge together with the increase of x followed by a basically one peak at x = 0.35. This phenomenon indicates a dominant tetragonal phase for the BNT-BST ceramics with 0.15 ≤ x ≤ 0.30, while the appearance of cubic phase when x ≥ 0.35.

To understand the detailed crystal structure of the BNT-BST ceramics, Rietveld refinement was performed and the results are given in Table 1. The selected Rietveld refinement profiles of the BNT-BST ceramics with x = 0.05, 0.15, and 0.35 are shown in Fig. 2. The profile R-value (Rp), weighted profile R-value (Rwp) and χ2-value of the refined structure parameters indicate that the refinement results are acceptable. As shown in Table 1, the phase structure evolution of the BNT-BST ceramics with increasing BST content can be clearly identified. The BNT-BST ceramics hold a coexistence of Rhombohedral (R3c) and Tetragonal (P4bm) phases when x ≤ 0.10, but a coexistence of Tetragonal (P4bm) and Cubic (Pm\(\stackrel{-}{3}\)m) phases when x ≥ 0.35, passing through a dominant Tetragonal (P4bm) phase region with 0.15 ≤ x ≤ 0.30.

Figure 3 shows the microstructure features of the thermally-etched surfaces of the BNT-BST ceramics with different x values. It can be seen from Fig. 3 that all ceramics achieve high density with clear grains and grain boundaries. Basically, the grain size gradually decreases with the increase of BST content. For the BNT-BST ceramics with x = 0.05 (see Fig. 3a), the gain size is up to 10 µm. However, the grain size can be reduced to ~ 2 µm for BNT-BST ceramics with x = 0.40 (see Fig. 3h).

Figure 4 shows the temperature dependent dielectric constant and loss of the BNT-BST ceramics with different x values. It was reported that the temperature dependence of the dielectric permittivity of undoped BNT shows two anomalies: a broad maximum at Tm ~ 320 °C corresponding to a transition from a paraelectric to a presumed antiferroelectric (AFE) phase, and a shoulder hump at ~ 200 °C attributed to a transition to a ferroelectric state, which is often designated as a depolarization temperature Td accompanied by a decay of spontaneous polarization [13, 24]. For the BNT-BST ceramics with x ≤ 0.10, as shown in Fig. 4a, b, the temperature dependent dielectric constant exhibits similar behavior to that of undoped BNT, but the Tm and Td are all decreased. For example, the Tm and Td are observed to be ~ 230 °C and ~ 120 °C, respectively for the BNT-BST ceramics with x = 0.10. However, only Tm can be observed for the BNT-BST ceramics with x ≥ 0.15, as shown in Fig. 4c–h. Moreover, the temperature dependent dielectric constant behavior is satisfied with a generic feature of relaxor ferroelectrics: the Tm shifts to higher temperature as the frequency of the probing field increases [25]. In general, with the increase of BST content x, the Tm of the BNT-BST ceramics gradually shifts downward to near room temperature. Therefore, the room temperature dielectric constant of the BNT-BST ceramics gradually increases with the BST content due to the relaxor ferroelectric characteristics of the ceramics and high peak dielectric constant (εr > 6000) at Tm. Actually, when BST content x ≥ 0.30, the room temperature dielectric constant of the ceramics at 1 kHz is close to 4000 (see Fig. 4f), and even 4500 (see Fig. 4g, h), showing a very high level.

Figure 5 shows the room temperature P-E hysteresis loops of the BNT-BST ceramics with different x values measured at different applied electric fields until saturation. For BNT-BST ceramics with x = 0.05 (see Fig. 5a), the loop displays a well-saturated ferroelectric behavior with both large remnant polarization (Pr = 31.2 µC/cm2) and coercive field (Ec = 50 kV/cm) under an applied electric field of 70 kV/cm. When BST content is increased to x = 0.10 (see Fig. 5b), a well-saturated loop is obtained under an applied electric field of 60 kV/cm accompanied by a little increased Pr (33.8 µC/cm2) but apparently reduced Ec (35.6 kV/cm). With further increasing BST content (x ≥ 0.15), both the Pr and Ec are gradually decreased, and the P–E loop even becomes slanted slim for BNT-BST ceramics with x = 0.40 (see Fig. 5h), being marked with a low Pr (4.3 µC/cm2) and sustained high Ps (~ 30 µC/cm2). It is supposed that the ferroelectric order is disturbed with the increase of BST, leading to a ferroelectric to relaxor state transformation, as confirmed by the temperature dependent dielectric properties shown in Fig. 4. Therefore, the suppressed ferroelectricity of the BNT-BST ceramics is believed to be induced by an enhanced nonpolar tetragonal (P4bm) and/or Cubic (Pm\(\stackrel{-}{3}\)m) structure with the increase of BST content as analyzed by XRD results (see Fig. 2; Table 1).

4 Conclusions

In summary, the structure of (1 − x)Bi0.5Na0.5TiO3−xBa0.3Sr0.7TiO3 (BNT-BST) ceramics is revealed to be changing from phase coexistences of Rhombohedral-Tetragonal (x ≤ 0.10) to Tetragonal-Cubic (x ≥ 0.35), across a dominant Tetragonal phase region (0.15 ≤ x ≤ 0.30). With increasing BST content, the BNT-BST ceramics undergo a ferroelectric to relaxor state transformation accompanied by a gradually decrease of Tm from ~ 250 °C to near room temperature. For BNT-BST ceramics with relaxor ferroelectric state (x ≥ 0.15), both the Pr and Ec gradually reduce with increasing BST content due to an enhanced nonpolar tetragonal (P4bm) and/or Cubic (Pm\(\stackrel{-}{3}\)m) structure. The relaxor BNT-BST ceramics possess both high peak dielectric constant (εr > 6000 at Tm) and saturated polarization (Ps ~ 30 µC/cm2), in addition to tunable remnant polarization Pr, which is suitable for application of good capacitor candidate materials.

References

W.J. Sarjeant, J. Zirnheld, F.W. MacDougall, J.S. Bowers, N. Clark, I.W. Clelland, R.A. Price, M. Hudis, I. Kohlberg, G. McDuff, I. McNab, S.G. Parler, Jr.J. Prymak, Capacitors—past, present, and future, Handb. Low High Dielectr. Constant. Mater. Appl. 2, 423–491 (1999)

C.A. Randall, H. Ogihara, J.R. Kim, G.Y. Yang, C.S. Stringer, S. Trolier-McKinstry, Proceedings of the IEEE Pulsed Power Conference, p346 (2009)

M.E. Lines, A.M. Glass, Principles and applications of ferroelectrics and related materials (Oxford University Press, New York, 2004), pp. 241–255

L.E. Cross, Ferroelectrics 76, 241–267 (1987)

R.A. Cowley, S.N. Gvasaliya, S.G. Lushnikov, B. Roessli, G.M. Rotaru, Adv. Phys. 60, 229–327 (2011)

K. Uchino, Chap. 3 - Relaxor Ferroelectric-Based Ceramics, Advanced Piezoelectric Materials (2nd edn.) p. 127–153 (2017)

F. Li, S. Zhang, T. Yang, Z. Xu, N. Zhang, G. Liu, J. Wang, J. Wang, Z. Cheng, Z. Ye, J. Luo, T.R. Shrout, L.Q. Chen, Nat. Commun. 7, 13807 (2016)

W. Jia, Y. Hou, M. Zheng, Y. Xu, M. Zhu, K. Yang, H. Cheng, S. Sun, J. Xing, IET Nanodielectr. 1, 3–16 (2018)

J. Hao, W. Li, J. Zhai, H. Chen, Mater. Sci. Eng. R 135, 1–57 (2019)

W.P. Cao, W.L. Li, X.F. Dai, T.D. Zhang, J. Sheng, Y.F. Hou, W.D. Fei, J. Eur. Ceram. Soc. 36, 593–600 (2016)

Q. Xu, Z. Song, W. Tang, H. Hao, L. Zhang, M. Appiah, M. Cao, Z. Yao, Z. He, H. Liu, J. Am. Ceram. Soc. 98, 3119–3126 (2015)

G.A. Smolenskii, V.A. Isupov, A.I. Agranovskaya, N.N. Krainik, Sov. Phys. Solid State 2, 2651–2654 (1961)

C.S. Tu, I.G. Siny, V.H. Schmidt, Phys. Rev. B 49, 11550–11559 (1994)

S.R. Kanuru, K. Baskar, R. Dhanasekaran, Ceram. Int. 42, 6054–6064 (2016)

A. Sasaki, T. Chiba, Y. Mamiya, E. Otsuki, Jpn. J. Appl. Phys. 38, 5564–5567 (1999)

J. Wang, H. Fan, B. Hu, H. Jiang, J. Mater. Sci.: Mater. Electron. (2018). https://doi.org/10.1007/s10854-018-0522-y

W. Ma, Y. Zhu, M.A. Marwat, P. Fan, B. Xie, D. Salamon, Z.G. Ye, H. Zhang, J. Mater. Chem. C 7, 281–288 (2019)

M. Acosta, J. Zang, W. Jo, J. Rödel, J. Eur. Ceram. Soc. 32, 4327–4334 (2012)

R. Dittmer, E.M. Anton, W. Jo, H. Simons, J.E. Daniels, M. Hoffman, J. Pokorny, I.M. Reaney, J. Rödel, J. Am. Ceram. Soc. 95, 3519–3524 (2012)

M. Xiao, H. Sun, Y. Wei, L. Li, P. Zhang, J. Mater. Sci.: Mater. Electron. 29, 17689–17694 (2018)

Y. Wang, Z.Y. Shen, Y.M. Li, Z.M. Wang, W.Q. Luo, Y. Hong, Ceram. Int. 41, 8252–8256 (2015)

Z.Y. Shen, Y.Y. Yu, Y. Wang, L. Zhang, W.Q. Luo, Z.M. Wang, Y.M. Li, J. Mater. Sci.: Mater. Electron. 29, 1093–1097 (2018)

M. Chen, Q. Xu, B.H. Kim, B.K. Ahn, J.H. Ko, W.J. Kang, O.J. Nam, J. Eur. Ceram. Soc. 28, 843–849 (2008)

K. Wang, A. Hussain, W. Jo, J. Rödel, J. Am. Ceram. Soc. 95, 2241–2247 (2012)

V.V. Shvartsman, D.C. Lupascu, J. Am. Ceram. Soc. 95, 1–26 (2012)

Acknowledgements

This work was financially supported by National Natural Science Foundation of China (51767010), Science & Technology Key Research Project of Jiangxi Provincial Education Department (GJJ170760) and Graduate Student Innovation Fund of Jiangxi Province (YC2018-S295).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, D., Shen, ZY., Li, Z. et al. Structural evolution, dielectric and ferroelectric properties of (1-x)Bi0.5Na0.5TiO3-xBa0.3Sr0.7TiO3 ceramics. J Mater Sci: Mater Electron 30, 5917–5922 (2019). https://doi.org/10.1007/s10854-019-00890-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-00890-4