Abstract

Medium-temperature sintering X8R ceramics were fabricated based on BaTiO3-based ceramics with Bi2O3 additives. The effects of sintering aids Bi2O3 on crystalline structure and electrical properties of BaTiO3-based ceramics were investigated. The sinterability of BaTiO3 ceramics was significantly improved by adding Bi2O3, whose densification sintering temperature reduced from 1,260 to 1,130 °C. However, the dielectric constant (ε) of BaTiO3-based ceramics doped with Bi2O3 was decreased dramatically. Both low ε phase Bi4Ti3O12 and the decrease of the tetragonality (c/a ratio), which are demonstrated by XRD pattern, are resulted in the decrease of ε. The ε of samples doped with 5.5 wt% Bi2O3 was higher than the other doped samples. The substitution of Bi3+ for the Ba2+ in BaTiO3 resulted in the increase of electrovalence (from +2 to +3) of A-site ion, so the attractive force between A and B (Ti4+) sites becomes stronger. Thus Ti4+’s polarization enhances, then ε was increased to some extent. The X8R BaTiO3-based ceramics could be sintered at as low as 1,130 °C by doping 5.5 wt% Bi2O3 additives into the BaTiO3-based ceramics, with a ε greater than 2,430 at 25 °C, dielectric loss lower than 1.3 % and temperature coefficient of capacitance <±15 % (−55–150 °C).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Because of temperature-stable dielectric behaviors (temperature coefficient of capacitance TCC less than ±15 % over the temperature range from −55 to 150 °C), X8R multilayer ceramic capacitors have been widely used for harsh conditions, such as the engine electronic control unit (ECU), programmed fuel injection (PGMFI), and anti-lock brake system (ABS) [1]. These modules are subjected to high temperature above 130 °C. TCC equals to (C − C25)/C25, where C and C25 represent the capacitance value at measuring temperature and at 25 °C respectively. Currently, the development of X8R MLCCs has been focused on the BaTiO3-based ceramics.

Barium titanate (BaTiO3) is a well-known material for EIA X8R capacitors. However, dielectric constant ε of pure BaTiO3 ceramics shows noticeable changes as the temperature changes, particularly when approaching the Curie temperature (Tc about 125 °C). Thus, BaTiO3 is modified with different additives to increase the Tc and obtain smooth TCC. Another requirement for X8R MLCCs is the cofiring of dielectric ceramics with low-cost electrode. The sintering temperature of the pure BaTiO3 is as high as 1,300 °C, so expensive electrode slurry of Pd or Pt must be used and the cost of MLCCs were increased dramatically. If the sintering temperature was lower than 1,160 °C, the electrode slurry of Pd30Ag70 can be used and the cost of monolithic capacitors can be greatly reduced. Several approaches have been reported to reduce the sintering temperature of dielectric materials including: (1) adding low melting point compounds such as Li2O3, CuO, B2O3, Bi2O3 and glass [2–5], (2) chemical processing for smaller particle sizes of starting powders [6]. The second method leads to higher cost and longer processing time because of a complicated procedure. In this study, the approach of adding a low-melting oxide was adopted due to the ease in processing and its effectiveness in reducing sintering.

In this paper, low-melting oxide Bi2O3 was chosen as additive doped into BaTiO3 composite. Bi2O3 has been proved to lower the sintering temperature effectively, meanwhile, the dielectric properties of BaTiO3 composite can meet X8R requirement. The effects of Bi2O3 on the dielectric properties of BaTiO3-based ceramics were discussed.

2 Experimental procedures

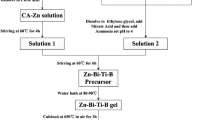

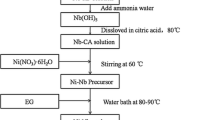

2.1 Preparation of X8R ceramics

Pb (Ti0.55Sn0.45)O3 powders (synthesized according to chemical formula), BaTiO3 (99.9 %, Aoxin, China), Nb2O5(99.5 %, Fengchuan, China), Co2O3(99.5 %, Fengchuan, China) and Bi2O3(99 %, Fengchuan, China) were used as the starting materials. Samples were prepared by a conventional ceramic processing technique with powders of BaTiO3 (calcined at 1,100 °C for 2 h), 2–3 wt% Nb2O5, 0.5 −2 wt% Co2O3, 0.5–7 wt% Pb (Ti0.55Sn0.45)O3 and x wt% Bi2O3 (x = 0, 3.5, 5.5, 7). The mixed powders were ball milled in deionized water for 6 h, and dried, sieved, then pressed into disks with 15 mm diameter. The disks without and with Bi2O3 were sintered at 1,260 and 1,130 °C for 6 h, respectively.

2.2 Measurements

The surface microstructure of sintered samples was observed with Scanning Electron Microscopy (SEM, Philips XL 30). The core–shell structure was observed with Scanning Electron Microscopy (NanoSEM430, FEI). Crystal structure of the samples were identified at room temperature using an X-ray diffractometer (XRD, Rigaku 2038X) with Cu Ka radiation (λ = 0.15406 nm) at a step width of 0.02° and a scan rate of 2°/min. The lattice constants of samples were derived from XRD data by least square fit. In order to measure the sample’s electrical properties, silver electrodes were attached to the surface of the sintered discs and fired at 800 °C for 15 min. ε and dielectric loss (tanδ) were measured by Agilent 4,278 Capacitance Meter at 1 kHz, with temperature range of −55 to 150 °C.

3 Results and discussion

3.1 Crystalline phases and surface microstructure

The X-ray analysis of BaTiO3-based ceramics with and without Bi2O3 was shown in Fig. 1. As shown in Fig. 1, main phase was BaTiO3, and extra phases Ti0.1Sn0.9O2, Ti9O17, TiO and PbTiO3 were formed in both samples. Within the XRD resolution limit, the Nb and Co elements were not detected in the profile. As shown in Fig. 1b, Bi2O3 were also not detected, but new phase Bi4Ti3O12 was appeared in the sample doped with 5.5 wt% Bi2O3. Doped with 5.5 wt% Bi2O3, the content of Bi2O3 exceed the solubility of Bi2O3 in barium titanate (about 3–5 wt% [7]). Surplus Bi2O3 reacted with dissociative TiO2 and the new phase Bi4Ti3O12 was formed. Due to the low solubility of Bi4Ti3O12 in Barium titanate (less than 2.9 wt% [8]), the new phase Bi4Ti3O12 was detected in the Fig. 1b.

As shown in Table 1, the lattice parameters and tetragonality (c/a ratio) were derived from XRD data by least square fit. Doped with 5.5 wt% Bi2O3, the tetragonality (c/a ratio) was decreased.

Figure 2 shows SEM images of samples doped with different content of Bi2O3. As shown in Fig. 2a, the sample doped without Bi2O3 was predominantly composed of fine grains with smooth surface and clear boundaries; although a small amount of strip grains were observed. The strip grains were formed attributed to non-ferroelectric phases, such as Ti0.1Sn0.9O2, Ti9O17 and TiO. As shown in Fig 2b, the Bi2O3 mainly resides in the grain boundaries or covers the grains, so the edges of the grains were not distinct and a lot of air pores existed in the ceramics. Because the amount of Bi2O3 was small, the sintering temperature was too low to research the desired temperature for the growth of grain crystal. As shown in Fig 2c, the grains were well crystallized with smooth surface and clear boundaries. Bi2O3 addition can be dissolved in BaTiO3 matrix, meanwhile, the grain growth was improved and the ceramics were densification; so the ceramics become quite dense and almost no air pore could be found. As shown in Fig 2d, the grain size was smaller as the content of Bi2O3 addition was increased. The reduction in grain size could be explained by the grain-growth-inhibiting phase at the grain boundaries. However, some large grains with a strip shape were also observed, owing to over doping of Bi2O3 (Fig. 2d).

For the sample doped with 5.5 wt% Bi2O3, a fine structure in the core and a coarse structure in the shell were observed in Fig. 3, so this sample was the core–shell type. Jain [9] has reported that an apparent core–shell structure was observed, when BaTiO3-based ceramics was doped with proper amount of Bi4Ti3O12.

3.2 The effect of Bi2O3 additives on dielectric properties of BaTiO3-based X8R ceramics

Calcination is an important section in fabrication process of ceramics, because the solid state reaction occurred mainly in calcination process. Yang et al. [10] found that both densification and grain growth processes rely on mass transport. The melting point of Bi2O3 was as low as 825 °C. During the sintering process, Bi2O3 were formed liquid phase due to the high sintering temperature 1,130 °C. The liquid phase enhances the ion diffusion via dissolution and reprecipitation process, and the small grains grew quickly. The densification of ceramics was accelerated, and the sintering ability of ceramics was enhanced. Hence the sintering temperature of BaTiO3-based ceramics was significantly reduced from 1,260 to 1130 °C.

Figure 4a shows temperature dependence of ε for BaTiO3-based ceramics doped with different content of Bi2O3. The effect of Pb (Ti0.55Sn0.45)O3 on Tc of BaTiO3-based ceramics has been discussed in detail in Ref. [11] and is not of further relevance to the present work.

In an ideal cubic perovskite BaTiO3 structure, the ionic radius of 12-coordinated Bi3+ is 0.145 nm, which is nearly comparable to the value of 0.135 nm for Ba2+. Despite of three electrovalence of Bi3+, Bi3+ substituted for A-site in ABO3 structure. As shown in Eq. (1), solid state reaction might occur during the sintering process:

where \( {\text{Ba}}_{\text{Ba}}^{ \times } \) stands for a neutral barium atom on a barium site, \( V_{\text{Ba}}^{''} \) for a barium vacancy with two negative charges, \( {\text{Bi}}_{\text{Ba}}^{ \bullet } \) for a bismuth atom on barium site with one positive charge, \( {\text{Ti}}_{\text{Ti}}^{ \times } \) for neutral titanium on a titanium site, and \( {\text{O}}_{\text{O}}^{ \times } \) for a neutral oxygen atom on an oxygen site.

As shown in Fig. 4a, ε of the samples was dramatically decreased. According to Eq. 1, the appearance of \( V_{\text{Ba}}^{''} \) and \( {\text{Bi}}_{\text{Ba}}^{ \bullet } \) would result in the shrinkage of crystal lattice in some direction, which is demonstrated by the date in Table 1. Hence, the volume of titanium centered eight oxygen octahedrons was decreased. So the active space for Ti4+ was decreased, and Ti4+ ions were restricted to the center of oxygen octahedrons. Thus Ti4+’s polarization was depressed, then ε was decreased accordingly.

Zhang duanming et al. reported the equation between ε and tetragonality (c/a ratio) in perovskite with ABO3 structure, which can be described in the following equation:

In Eqs. (2) and (3), C is Curie constant, T is measuring temperature, T0 is Curie–Weiss temperature, ε0 is vacuum permittivity, α1 is second order dielectric stiffness, α11 is fourth order dielectric stiffness, α11 is sixth order dielectric stiffness, Q11 and Q12 are electrostrictive coefficient, all the parameters above are constant for specific material.Footnote 1

Form Eqs. (2) and (3), Eq. (4) can be obtain.

The value of Eq. (5) is lower than zero, so ε was decreased with the decrease of c/a. As shown in Table 1, doped with Bi2O3, the tetragonality (c/a ratio) was decreased from 1.008 to 1.004, so ε of the ceramics was decreased accordingly.

Meanwhile, as the amount of Bi2O3 increasing, the new phase was detected in the XRD profile. ε of Bi4Ti3O12 was about 127. According to Lichtenecker formula:

So, why ε was decreased when the content of Bi4Ti3O12 phases was increased was explained well by Eq. (6).

ε of samples doped with 5.5 wt% Bi2O3 was higher than the samples doped with 3.5 and 7 wt% Bi2O3. For the increase of electrovalence (from +2 to +3) of A-site ion, a residual positive charge appears (\( {\text{Bi}}_{\text{Ba}}^{ \bullet } \)) and the attractive force between A and B (Ti4+) sites becomes stronger. Thus Ti4+’s polarization enhances, then ε was increased accordingly. The fine and homogeneous grains were responsible for good dielectric properties. SEM indicated that fine and homogeneous grains were observed at 25 °C with 5.5 wt% Bi2O3 additives, which also gave rise to the increase of ε.

Figure 4b shows the temperature dependence of TCC of the BaTiO3-based ceramics with various Bi2O3 contents. For BaTiO3-based ceramics doped with 5.5 wt% Bi2O3, the change of ε is less than ±9 %. Moreover, tanδ of four samples was lower than 2.0 % at 25 °C, which satisfied X8R specification.

4 Conclusions

Because of low melting point (825 °C), Bi2O3 were formed liquid phase during the sintering process. The ion diffusion was enhanced via dissolution and reprecipitation process, so the densification of ceramics was accelerated, and sintering ability of BaTiO3-based ceramics were enhanced. The sintering temperature is reduced from 1,260 to 1,130 °C, the electrode slurry of Pd30Ag70 can be used and the cost of monolithic capacitors was greatly reduced.

Compared with ceramic without Bi2O3, ε of BaTiO3-based ceramics doped with Bi2O3 was decreased dramatically. Ba2+ was substituted by Bi3+, Ti4+’s polarization was depressed, then ε was decreased accordingly. According to the equation between ε and tetragonality (c/a ratio), ε was decreased with the decrease of c/a ratio. Demonstrated by the XRD pattern, c/a ratio was decreased from 1.008 to 1.004, so ε of the ceramics was decreased accordingly. Meanwhile, new phase Bi4Ti3O12 was detected in XRD pattern. According to Lichtenecker formula, ε of Bi4Ti3O12 was as low as 127, so the ε was decreased. Both enhancement of Ti4+’s polarization and homogeneous microstructure are attributed to the highest ε among Bi2O3 doped samples.

Doped with 5.5 wt% Bi2O3, the sintering temperature of BaTiO3-based can be reduced form 1,260 to 1,130 °C, exhibited dielectric properties: ε25 °C ≈ 2430, tanδ ≈ 1.3 %, TCC < ±15 % (−55–150 °C), which satisfied X8R specification.

Notes

The list of the parameters of G (in SI units, T in kelvin) used in the calculations. For BaTiO3: α1(T) = 4.124 × 105(T − 118)Jm/C2; α11(T) = −2.097 × 108Jm5/C4; α111(T) = 1.294 × 109Jm9/C6; Q12 = −0.043 m4/C2; Q11 = 0.1024 m4/C2.

References

G.-H. Chen, Mater. Sci. Mater. Electron. (2012). doi:10.1007/s10854-012-0710-0

N. Ma, J. Electroceram. 28(4), 275 (2012)

K. Yan, J. Am. Ceram. Soc. 93(11), 3823 (2010)

H. Naghib-zadeh, J. Eur. Ceram. Soc. 3(1), 31 (2010)

L. Zhou, J. Eur. Ceram. Soc. 21(4), 531 (2001)

H. Beltrán, J. Electroceram. 18, 277 (2007)

L. Zhou, J. Am. Ceram. Soc. 82(4), 1064 (1999)

Y. Li, J. Wuhan Univ. Technol. Mater. Sci. Edit. 23, 143 (2008)

T.A. Jain, J. Eur. Ceram. Soc. 29, 2595 (2009)

K.Y.J. Yang, Alloys Compd. 458, 415 (2008)

S. Wang, Mater. Sci. Mater. Electron. 21, 1159 (2010)

Acknowledgments

This work was supported by the Science and Technology Development Foundation Project of Tianjin Higher Education (under Grant 20100712) and the National Natural Science Foundation of China (under Grant 51102076). We also acknowledge the Science and Technology Development Foundation Project of Tianjin Higher Education (under Grant 20110710) and Youth Teacher Plan by CSC.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, S., He, H. & Su, H. Effect of Bi2O3 doping on the dielectric properties of medium-temperature sintering BaTiO3-based X8R ceramics. J Mater Sci: Mater Electron 24, 2385–2389 (2013). https://doi.org/10.1007/s10854-013-1106-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-013-1106-5