Abstract

WO3/Bi2WO6 heterojunctions with flower-like structure were prepared by a facile hydrothermal process without any surfactants or templates. In the heterojunctions, WO3 nanoparticles were incorporated into three-dimensional flower-like hierarchical Bi2WO6. The WO3/Bi2WO6 samples showed much higher photocatalytic activity than pure Bi2WO6 did for rhodamine B degradation under visible light irradiation. This could be ascribed to the formation of n–n type heterojunction, which resulted in the high transfer rate of the photo-generated electron–holes between WO3 and Bi2WO6 and confirmed by photoluminescence and photocurrent measurements.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Semiconductor photocatalysts have received much attention due to their abilities of solar energy conversion and environmental purification [1–3]. The semiconductor TiO2 is considered as one of the best photocatalysts [4, 5]. However, the light response range of TiO2 is limited to ultraviolet because of the wide band gap (3.2 eV) [6], and the ultraviolet accounts for only about 4 % of entire sunlight [7–9]. So it is significant to prepare new photocatalysts, which can response in large range of sunlight including the visible light which accounts for about 46 % of sunlight.

Bi2WO6, an n-type semiconductor [10], is exactly a visible-light-driven photocatalyst with a relatively narrow band gap of 2.7 eV [11] (E CB = 0.24 eV vs NHE), which has attracted a great deal of attention [12–14]. However, as a single-phase photocatalyst, some drawbacks restrict its further practical application, such as high recombination of the photo-generated electron–hole pairs and low photo quantum efficiency. Fortunately, as preparing a heterojunction is a well-known way to suppress the photo-carriers recombination rate and enhance the photocatalytic property, many materials have been coupled with Bi2WO6 to form the heterojunction, such as BiOBr [15], Bi2O2CO3 [16], CdS [17], Co3O4 [18], WO3 [19, 20], or ZnFe2O4 [21]. Among these, WO3 is an inexpensive and promising material reported to have good photocatalytic performance. As an n-type semiconductor with band gap of 2.8 eV (E CB = 0.74 eV vs NHE) [22], WO3 can match well with Bi2WO6 to form an n–n type heterojunction.

Morphology-controlled synthesis of Bi2WO6 has been also considered as an efficient way to enhance photocatalytic activities under visible light. Three-dimensional flower-like Bi2WO6 photocatalysts have large surface areas and plenty of meso-pores which can effectively harvest visible light due to multiple scattering [23], In addition, the flower-like Bi2WO6 structure have been found to increase the active sites and improve the photoenergy conversion efficiency [24]. He et al. [20] have prepared the WO3 (core)/Bi2WO6 (shell) photocatalyst through a hydrothermal reaction and heat treatment. Unfortunately, the preparation process was complex and the advantage of flower-like superstructure Bi2WO6 could not survive.

Therefore, for the first time, we successfully prepared the flower-like WO3/Bi2WO6 heterojunction by one-step hydrothermal method without any surfactants or templates. The experimental results show that the flower-like WO3/Bi2WO6 heterojunction has much greater activities for photocatalytic degradation of rhodamine B under visible light irradiation than pure Bi2WO6 does. Moreover, a possible mechanism of WO3/Bi2WO6 on the degradation of RhB is discussed and confirmed by photoluminescence spectra and photocurrent measurements.

Experimental

Preparation of WO3/Bi2WO6

All chemicals are reagent grade and used without further purification. A typical procedure (molar ratio of WO3/Bi2WO6 samples designed as 0.3:1) is as follows: 2 mmol Bi(NO3)3·5H2O was firstly dissolved in a 30 mL 0.4 mol/L HNO3 solution, and then the solution was stirred for 10 min at 40 °C. 30 mL aqueous solution containing 1.3 mmol Na2WO4·2H2O was added into the above solution drop by drop and then stirred for 24 h at 40 °C. The obtained white suspension was transferred into a 100-mL Teflon-lined autoclave. The autoclave was heated at 160 °C for 20 h and then cooled to room temperature naturally. The light yellow precipitate was collected and washed with distilled water and ethanol for several times. Then the light yellow precipitate was dried at 60 °C in the air for 10 h. According to this method, WO3/Bi2WO6 samples with different molar ratios of 0.15:1, 0.3:1, and 0.6:1 were also obtained and denoted as 5, 10, and 20 % WO3/Bi2WO6 (mass ratio), respectively. The pure Bi2WO6 and WO3 were also synthesized by a similar procedure.

Characterization

The structure and morphology characterization

The crystal structure of the samples were investigated by X-ray diffraction (XRD, Model No: D/max2200pc, Japan) with Cu Kα radiation (λ = 1.54 Å) over the range of 10° ≤ 2θ ≤ 70°. The morphology and microstructure of the samples were obtained by field emission scanning electron microscope (FE-SEM, Model No: Hitachi S-4800) and transmission electron microscope (TEM, Model No: FEI Tecnai G2 F20 S-TWIN).

N2 physisorption analysis

According to the Brunauer–Emmett–Teller analysis (BET, ASAP 2460, Micromeritics, USA), the specific surface areas were determined by nitrogen adsorption–desorption isotherms at 77 K. Prior to measurements, all Bi2WO6-based powders were degassed at 473 K for 24 h under a vacuum to ensure a clean, dry surface, free of any loosely bound adsorbed species. The pore size distributions of all samples were calculated from desorption branches of the corresponding nitrogen isotherm by the Barrett–Joyner–Halenda (BJH) method.

Photoluminescence and photoelectrochemical measurements

The photoluminescence measurements were carried out on a Hitachi F-4600 fluorescence spectrophotometer. The photocurrent was conducted by an electrochemical workstation (Model No: CH1660D instruments, shanghai). A three-electrode system was employed using the Ag/AgCl (3 M KCl) electrode as a reference electrode, a Pt wire as the counter electrode and an indium tin oxide (ITO) conducting glass coated with the WO3/Bi2WO6 film as the working electrodes. The WO3/Bi2WO6 film was deposited on ITO glass by the dip-coating method. Briefly, a piece of ITO glass was washed with distilled water and ethanol in an ultrasonic bath for 30 min, and dried at room temperature. In the meantime, WO3/Bi2WO6 (0.02 g) was dispersed in 1 mL distilled water containing 0.5 mL Nafion and ultrasonically treated for 10 min. The as-resulted WO3/Bi2WO6 suspension was deposited onto the surface of ITO using a microsyringe and dried at room temperature. 1 M Na2SO4 was used as the electrolyte and a 300 W Xe lamp (wavelength range, distance between sample and lamp) was used as light source. All measurements were carried out at room temperature.

Photocatalytic activity

The photocatalytic activities of the samples were evaluated via the degradation of RhB in an aqueous solution under visible light irradiation. A xenon long-arc lamp GXU 500 with a UV 420-nm cutoff filter was used as the light source to simulate visible light irradiation. In every experiment (seven quartz tubes), 5-mg sample was added into 5 mL RhB aqueous solution with a concentration of 10 mg/L in a quartz tube. Before illumination, the suspensions were sonicated for 30 min and magnetically stirred in the dark for 30 min to reach the adsorption–desorption equilibrium between the photocatalyst and RhB solution. Then the mixture was exposed to the stimulated visible light under magnetic stirring. At given time intervals, 5 mL suspension was taken and centrifuged to remove the photocatalyst. Then the RhB concentration was detected by recording the absorbance at the characteristic band of 553 nm using a Shimadzu UV-2550 UV–vis spectrophotometer.

Results and discussion

Crystal structures

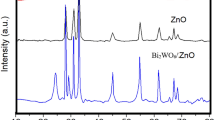

Figure 1 shows XRD patterns of the samples. The pure Bi2WO6 is identified as the orthorhombic Bi2WO6 (JCPDS NO. 39-0256) without any impurity. The pure WO3 is identified as monoclinic WO3 (JCPDS NO. 72-1465) without any impurity. For the WO3/Bi2WO6 samples, XRD patterns consist of Bi2WO6 and WO3 diffraction peaks. As shown in the inserted figure for the 20 % WO3/Bi2WO6 sample, the diffraction peaks of WO3 can be observed. The strongest peak of WO3 is attributed to (002) plane, which is in good agreement with the following HRTEM analyses. No impurity peak is also found in the WO3/Bi2WO6 heterojunction. This suggests that the photocatalyst is only composed of orthorhombic Bi2WO6 and monoclinic WO3.

Figure 1 shows XRD patterns of the samples. The pure Bi2WO6 is identified as orthorhombic Bi2WO6 (JCPDS NO. 39-0256) without any impurity. The pure WO3 is identified as monoclinic WO3 (JCPDS NO. 72-1465) without any impurity. For the WO3/Bi2WO6 samples, XRD patterns consist of Bi2WO6 and WO3 diffraction peaks. As shown in the inserted figure for the 20 % WO3/Bi2WO6 sample, the diffraction peaks of WO3 can be observed. The strongest peak of WO3 is attributed to (002) plane, which is in good agreement with the following HRTEM analyses. No impurity peak is also found in the WO3/Bi2WO6 heterojunction. This suggests that the photocatalyst is only composed of orthorhombic Bi2WO6 and monoclinic WO3.

Morphology characterization

The morphology and microstructure of the 5 % WO3/Bi2WO6 sample were investigated by SEM and TEM. Figure 2a shows that the 5 % WO3/Bi2WO6 sample consists of spherical particles with diameter ranging from 3 to 5 µm. All the spherical particles are well dispersed. Figure 2b is image with high magnification of an individual 5 % WO3/Bi2WO6 spherical particle which reveals more detailed structural characteristics of the heterojunction photocatalysts. We can see that the spherical particle is flower-like and consists of two-dimensional thin nanoplates with many different pores, which can serve as transport paths for small molecules and then improve the photocatalytic property. More in-depth information of the sample can be observed by TEM (Fig. 2c) and HRTEM micrographs (Fig. 2d). There are many nanoparticles with the diameter about 10 nm attached to the nanoplate. By carefully measuring the lattice parameters with Digital Micrograph and comparing with the data in JCPDS, three different kinds of lattice fringes with spacing of 0.273, 0.315, and 0.33 nm are obtained. It can be sure that the lattice fringes with spacing of 0.273 and 0.315 nm belong to the (200) and (113) crystallographic plane of orthorhombic Bi2WO6 (JCPDS NO. 39-0256) and the lattice fringe with spacing of 0.33 nm belongs to (120) plane of monoclinic WO3 (JCPDS NO. 72-1465). So the nanoplates could be Bi2WO6 and the nanoparticles on the surface of the nanoplates could be WO3.

Figure 3 is SEM micrograph of all the samples: (a) pure Bi2WO6; (b) 5 % WO3/Bi2WO6; (c) 10 % WO3/Bi2WO6; and (d) 20 % WO3/Bi2WO6. All the samples exhibit flower-like structure which consists of nanoplates. From the inserted figures, we can see that with increasing WO3 doping content, the nanoplates become denser and thinner, at the same time, the pores among the nanoplates become smaller and smaller. The thickness of the nanoplates is about 27, 20, 17, and 12 nm for the WO3 content of 0, 5, 10, and 20 %, respectively.

N2 physisorption analysis

The analysis of surface area and pore size are carried out to establish correlations, which derived from the nitrogen molecules that are physisorbed by these composite photocatalysts [25]. The nitrogen adsorption/desorption isotherms and the corresponding BJH pore size distribution curves of the pure Bi2WO6 and 5 % WO3/Bi2WO6 composite are shown in Fig. 4. It can be seen that the pure Bi2WO6 and 5 % WO3/Bi2WO6 heterojunction exhibit the typical type-III curves for mesoporous materials according to IUPAC classification (Fig. 4a). The specific surface areas are calculated using the BET method and the pore size distribution of the each sample is calculated from the desorption branch of the isotherms using the BJH algorithm (Fig. 4b). As seen in Table 1, with increasing the content of WO3, the BET specific surface area becomes larger and larger and the BJH pore size becomes smaller and smaller.

Photoluminescence spectra analysis

PL spectrum is useful to reveal the migration, transfer, and recombination process of the photo-generated electron–hole pairs in the semiconductor. In order to demonstrate the separated efficiency of the electron–hole pairs, the room temperature photoluminescence (PL) spectra were examined for Bi2WO6 and all WO3/Bi2WO6 samples with an excitation wavelength of 300 nm. As shown in Fig. 5, all samples show an apparent characteristic emission peak from 400 to 500 nm. The strongest emitting peak at 455 nm can be attributed to the radiative recombination process of self-trapped excitations [26]. Compared with pure Bi2WO6, all WO3/Bi2WO6 samples have a weaker PL intensity and the 5 % WO3/Bi2WO6 sample shows the lowest emission peak. A weaker intensity of the peak represents a lower recombination probability of free charges. So couple WO3 with Bi2WO6 has improved the separated efficiency of the electron–hole pairs and the 5 % WO3/Bi2WO6 sample has the best performance.

Transient photocurrent analysis

We also have measured transient photocurrent to gain an insight into the high separation efficiency of the photo-generated electrons and holes in the Bi2WO6 and WO3/Bi2WO6 samples. Figure 6 displays the photocurrent–time (I–t) curves of the four samples with typical on–off cycles of intermittent visible light irradiation. As shown in Fig. 6, the photocurrent boosts rapidly once the light is turned on and returns quickly to its dark current state when the light is turned off. The initial current is due to the separation of the electron–hole pairs at the semiconductor/electrolyte interface: holes are trapped by the reduced species in the electrolyte, while electrons transport to the back contact substrate [27]. As WO3 concentration increases, the photocurrent increases until WO3 doping content is 5 % and then decreases. This dependence corresponds well to the above PL results.

Photocatalytic activity

Figure 7a shows the photocatalytic degradation efficiency of RhB in the presence of different samples under visible light irradiation. The blank test confirms that the photocatalytic degradation of RhB can be ignored without catalyst. All heterojunctions show higher photocatalytic activity than pure Bi2WO6 dose and the 5 % WO3/Bi2WO6 shows the highest photocatalytic activity. It can be observed that only 48.9 and 32.1 % RhB is photodegraded by pure Bi2WO6 and WO3 under visible light in 100 min, respectively. 5 % WO3/Bi2WO6 can result in 98.5 % degradation rate in the same condition. However, to further increase the amount of WO3, photocatalytic activity of RhB is decreased to 93 % in the same condition. According to the above SEM, BET specific surface areas and BJH pore size distribution results, we think that the suitable amount of WO3 can uniformly distribute on the surface of flower-like Bi2WO6 and make the nanoplates become density and thin which is helpful to improve the photocatalytic activity. However, the excess WO3 makes flower-like Bi2WO6 overlap and agglomerate which prevent the transport paths for organic molecules and then lower photocatalytic property. The results indicate that the suitable content of WO3 plays an important role in the enhancement of photocatalytic performance.

For a better comprehension of the photocatalytic activity of catalysts, the reaction kinetic of the RhB degradation was investigated. The experimental data were fitted by the relevant equation as below: −ln(C/C 0) = kt, where C 0 and C are the concentrations of RhB at adsorption–desorption equilibrium and the reaction time t, respectively, and k is the apparent first-order rate constant. As shown in Fig. 7b, upon varying the WO3 content within 5.0–20 %, the plots of the (C 0/C) versus irradiation time (t) display a nearly straight line. All WO3/Bi2WO6 heterojunctions show higher photodegraded efficiency than pure Bi2WO6 and WO3 do. The 5 % WO3/Bi2WO6 exhibits the highest photodegraded efficiency and is about fivefold compared to that of the pure Bi2WO6 sample (Table 1).

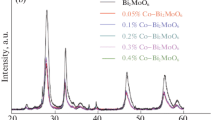

In order to demonstrate the photocatalytic activities of WO3/Bi2WO6 samples with WO3 mass ratio between 0 and 5 %, we do experiment about 3 % WO3/Bi2WO6 sample. As is shown in Fig. 8, all strong peaks can be ascribed to the orthorhombic Bi2WO6 (JCPDS NO. 39-0256). No clear diffraction peak belonging to WO3 is observed, due to the small amount of WO3 and their highly dispersion in WO3/Bi2WO6 sample (Fig. 8a). It can be observed that the flower-like superstructure cannot be destroyed and also consist of two-dimensional nanoplates (Fig. 8b). The specific surface areas and pore size distribution is 23.68 m2/g and 11.37 nm, respectively (Fig. 8c). The photocatalytic activity indicates that the 3 % WO3/Bi2WO6 heterojunction exhibits lower photocatalytic activity (90.2 % RhB be photodegraded) than 5 % WO3/Bi2WO6 does due to the small amount of WO3 loading (Fig. 8d).

Circulation experiment

Figure 9a shows the variations of the UV–vis absorption spectra of RhB solutions in the presence of 5 % WO3/Bi2WO6 heterojunction under visible light irradiation (λ > 420 nm), which shows a maximum absorption band at 553 nm. With the increase of irradiation time, a rapid decrease of RhB absorption band is observed and the color of the suspension gradually changes from pink to light green. In addition, the maximum absorption peak of RhB gradually shifts to blue region, which can be attributed to a successive de-ethylation from the aromatic rings and destruction of the conjugated structure process, according to the formation of the different de-ethylated rhodamine intermediates [28]. To evaluate the stability of 5 % WO3/Bi2WO6, the circulating runs in the photodegradation of RhB under visible light were checked. As shown in Fig. 9b, after every 100 min of photodegradation, the separated photocatalysts were washed with deionized water and dried to remove the ions absorbing on its surface after every reaction. There is no obvious catalyst deactivation after four cycling runs and the flower-like structure do not change. The reasons for this little decrease may be some catalysts washout during the repetitive steps. The results indicate that the n–n type photocatalyst exhibits excellent stability, reusability, and less photocorrosion during the photocatalytic reaction.

The role of WO3

About the influence of WO3 concentration on the photocatalytic activity, two effects should be considered: on one hand, WO3 concentration affects morphology of the sample (as shown in Fig. 3). As WO3 concentration increases, the nanoplates become denser and thinner and the pores among the nanoplates become smaller and smaller. This may be helpful to increase the specific surface area and the active sites in porous microsphere. On the other hand, WO3 concentration affects photo-carriers recombination rate of the sample (as shown in Figs. 5, 6). The addition of WO3 has suppressed photo-carriers recombination due to the formation of n–n type heterojunction, which is helpful to improve the sample photocatalytic activity. However, the suppression effect of heterojunction does not monotonically increase with the WO3 concentration increasing. From Figs. 5 and 6, we can see that 5 % WO3/Bi2WO6 exhibits the highest separated efficiency of the photo-carriers. In above two respects, the latter effect is expected to dominate. So the sample photocatalytic activities show the dependence on WO3 concentration: as WO3 concentration increases, the photocatalytic activities increase until WO3 mass ratio is 5 % and then decreases.

Photocatalytic mechanism

To better understand the photocatalytic mechanism of the n–n type WO3/Bi2WO6 heterojunction, a possible mechanism on the degradation of RhB is shown in Fig. 10. The optical band gap energy of Bi2WO6 and WO3 is 2.7 eV (E CB = 0.24 vs NHE) and 2.8 eV (E CB = 0.74 eV vs NHE), respectively. The band gaps of the two semiconductors match well with each other. Under visible light irradiation, both the Bi2WO6 and WO3 are excited by absorbing photons, and then electron–hole pairs are produced. The WO3 acts as electron-accepting semiconductor. Photo-generated electrons transfer from the conduction band (CB) of Bi2WO6 to that of WO3. Simultaneously, holes shift from the valence band (VB) of WO3 to that of Bi2WO6. The effectively separation of photo-generated electrons and holes can be enhanced, which result in higher photocatalytic performance.

Conclusions

In summary, the flower-like WO3/Bi2WO6 heterojunction with different WO3 concentrations was prepared via the one-step hydrothermal method. The flower-like superstructure is composed of Bi2WO6 nanoplates and WO3 nanoparticles. The WO3 concentration has a great influence on the morphology and photocatalytic activity of WO3/Bi2WO6 heterojunction. As WO3 concentration increases, the nanoplates become denser and thinner, and the photocatalytic activities increase until mass ratio of WO3 is up to 5 % and then decreases. The result indicates that n–n type heterojunction has better photocatalytic activity than pure Bi2WO6 does, because electrons can be injected from the CB of Bi2WO6 to that of WO3 under visible irradiation. Thus, the photo-generated electrons and holes are efficiently separated at the intimate interface of heterojunction in time. Therefore, the flower-like WO3/Bi2WO6 heterojunction has good potential for application to organic pollutants purification.

References

Chen CC, Ma WH, Zhao JC (2010) Semiconductor-mediated photodegradation of pollutants under visible-light irradiation. Chem Soc Rev 39:4206–4219

Hoffmann M, Martin S, Choi WY, Bahnemannt D (1995) Environmental applications of semiconductor photocatalysis. Chem Rev 95:69–96

Hagfeldt A, Gratzel M (1995) Light-induced redox reactions in nanocrystalline systems. Chem Rev 95:49–68

Ge L, Han CC, Liu J (2011) Novel visible light-induced g-C3N4/Bi2WO6 composite photocatalysts for efficient degradation of methyl orange. Appl Catal B 108:100–107

Li JQ, Liu ZX, Wang DF, Zhu ZF (2014) Visible-light responsive carbon-anatase-hematite core-shell microspheres for methylene blue photodegradation. Mater Sci Semicond Process 27:950–957

Wu L, Yu JC, Wang XC, Zhang LZ, Yu JG (2005) Characterization of mesoporous nanocrystalline TiO2 photocatalysts synthesized via a sol-solvothermal process at a low temperature. J Solid State Chem 178:321–328

Zhang L, Zhu YF, He Y, Li W, Sun HB (2003) Preparation and performances of mesoporous TiO2 film photocatalyst supported on stainless steel. Appl Catal B 40:287–292

Ge L, Xu MX, Fang HB (2006) Photo-catalytic degradation of methyl orange and formaldehyde by Ag/InVO4-TiO2 thin films under visible-light irradiation. J Mol Catal A Chem 258:68–76

Li JQ, Wang DF, Guo ZY, Zhu ZF (2012) Preparation, characterization and visible-light-driven photocatalytic activity of Fe-incorporated TiO2 microspheres photocatalysts. Appl Surf Sci 263:382–388

Li ZQ, Chen XT, Xue ZL (2013) Microwave-assisted synthesis and photocatalytic properties of flower-like Bi2WO6 and Bi2O3–Bi2WO6 composite. J Colloid Interface Sci 394:69–77

Ge L, Liu J (2011) Efficient visible light-induced photocatalytic degradation of methyl orange by QDs sensitized CdS-Bi2WO6. Appl Catal B 105:289–297

Zhang ZJ, Wang WZ, Yin WZ, Shang M, Wang L, Sun SM (2010) Inducing photocatalysis by visible light beyond the absorption edge: effect of up conversion agent on the photocatalytic activity of Bi2WO6. Appl Catal B 101:68–73

Wang XJ, Chang LL, Wang JR, Song NN, Liu HL, Wan XL (2013) Facile hydrothermal synthesis of Bi2WO6 microdiscs with enhanced photocatalytic activity. Appl Surf Sci 270:685–689

Zhang N, Ciriminna R, Pagliaro M, Xu YJ (2014) Nanochemistry-derived Bi2WO6 nanostructures: towards production of sustainable chemicals and fuels induced by visible light. Chem Soc Rev 43:5276–5287

Xia JX, Di J, Yin S, Xu H, Zhang J, Xu YG, Xu L, Li HM, Ji MX (2014) Facile fabrication of the visible-light-driven Bi2WO6/BiOBr composite with enhanced photocatalytic activity. RSC Adv 4:82–90

Huang XW, Chen HF (2013) One-pot hydrothermal synthesis of Bi2O2CO3/Bi2WO6 visible light photocatalyst with enhanced photocatalytic activity. Appl Surf Sci 284:843–848

Ge L, Liu J (2011) Synthesis and photocatalytic performance of novel CdS quantum dots sensitized Bi2WO6 photocatalysts. Mater Lett 65:1828–1831

Xiao Q, Zhang J, Xiao C, Tan XK (2008) Photocatalytic degradation of methylene blue over Co3O4/Bi2WO6 composite under visible light irradiation. Catal Commun 9:1247–1253

Gui MS, Zhang WD (2012) One-step hydrothermal preparation strategy for nanostructured WO3/Bi2WO6 heterojunction with high visible light photocatalytic activity. Chem Eng J 197:283–288

He GH, He GL (2014) Synthesis and visible light photocatalytic behavior of WO3 (core)/Bi2WO6 (shell). J Mol Catal A Chem 385:106–111

Li JQ, Liu ZX, Zhu ZF (2014) Magnetically separable ternary hybrid of ZnFe2O4-Fe2O3-Bi2WO6 hollow nanospheres with enhanced visible photocatalytic property. Appl Surf Sci 320:146–153

Chen SF, Hu YF, Meng SG, Fu XL (2014) Study on the separation mechanisms of photogenerated electrons and holes for composite photocatalysts g-C3N4-WO3. Appl Catal B 150–151:564–573

Li XN, Huang RK, Hu YH, Chen YJ, Liu WJ, Yuan RS, Li ZH (2012) A templated method to Bi2WO6 hollow microspheres and their conversion to double-shell Bi2O3/Bi2WO6 hollow microspheres with improved photocatalytic performance. Inorg Chem 51:6245–6250

Li JQ, Guo ZY, Zhu ZF (2012) Ag/Bi2WO6 plasmonic composites with enhanced visible photocatalytic activity. Ceram Int 40:6495–6501

Kibombo HS, Rasalingam S, Koodali RT (2013) Facile template free method for textural property modulation that enhances adsorption and photocatalytic activity of aperiodic titania supported silica materials. Appl Catal B 142–143:119–128

Huang HW, Wang SB, Tian N, Zhang YH (2014) A one-step hydrothermal preparation strategy for layered BiIO4/Bi2WO6 heterojunctions with enhanced visible light photocatalytic activities. RSC Adv 4:5561–5567

Tian BZ, Dong RF, Zhang JM, Bao SY, Yang F, Zhang JL (2014) Sandwich-structured AgCl@Ag@TiO2 with excellent visible-light photocatalytic activity for organic pollutant degradation and E. coli K12 inactivation. Appl Catal B 158–159:76–84

Cruz AM, Ctrica UM, León UAN, Universitaria C (2010) Photocatalytic properties of BiVO4 prepared by the co-precipitation method: degradation of rhodamine B and possible reaction mechanisms under visible irradiation. Mater Res Bull 45:135–141

Acknowledgements

We acknowledge financial support from the National Science Foundation of China (51272147), the Academic Backbone Cultivation Program of Shaanxi University of Science & Technology (XSGP201203), and the Graduate Innovation Fund of Shaanxi University of Science and Technology.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhu, Z., Yan, Y. & Li, J. One-step synthesis of flower-like WO3/Bi2WO6 heterojunction with enhanced visible light photocatalytic activity. J Mater Sci 51, 2112–2120 (2016). https://doi.org/10.1007/s10853-015-9521-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-015-9521-z