Abstract

Co-doped Bi2MoO6 photocatalyst has been synthesized by a simple and facile solvothermal method. It exhibits the flower-like microspheres composed of orthorhombic Bi2MoO6 nanoplates with the increase of the Co doping amount from 0 to 0.4%. Among these Co-doped samples, 0.1% Co–Bi2MoO6 sample shows the degradation efficiency of 99.7% for Rhodamine B under visible-light-irradiation within 120 min, which is higher than pure Bi2MoO6 and other Co-doping Bi2MoO6 flower-like microspheres. The calculated apparent reaction rate constant for the 0.1% Co–Bi2MoO6 of 0.0298 ± 0.0028 min–1 is 4.18 times of pure Bi2MoO6 photocatalyst (0.0071 ± 0.0010 min–1). The flower-like microspheres of 0.1% Co–Bi2MoO6 with high efficient photocatalytic performance is a promising photocatalytic material.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 INTRODUCTION

Semiconductor photocatalysis is a effective, green and potential method for the degradation of many toxic organic pollutants from aqueous systems because of its low cost, simplicity and high efficiency [1–3]. Industrial application of this technology is depended on developing efficient and stable visible-light-driven photocatalysts [4–6]. A significant progress of the photocatalysts has been made, and the photocatalysts have shown the great promise in degradation of organic pollutants from industrial wastewater by utilizing sunlight [7–10]. Many photocatalysts with a wide bandgap limit their availability to irradiation light [11–15]. Consequently, it is necessary to develop the visible light driven semiconductor photocatalysts for effective utilization of the solar spectrum.

Bismuth-base oxide semiconductors, such as Bi2O3, BiOX (X = Cl, Br, I), Bi2WO6, BiVO4, and Bi2MoO6 [16, 17], have been demonstrated to show superior photocatalytic activities under visible-light irradiation because of Bi 6s and O 2p levels forming a preferable hybridized conduction band to exhibit strong oxidative ability for degradation of organic pollutants [18, 19]. Bi2MoO6 with flower-like microspheres consisted of nanosheets has been widely studied due to the excellent electrical property, high light absorption and abundant reactive sites [20]. However, photocatalytic performance of Bi2MoO6 is seriously limited by high recombination efficiency of photogenerated electron-hole pairs [21]. To enhance the photocatalytic performance, many materials [22] have been developed to improve the photocatalytic capability of Bi2MoO6, a large number of studies showed that Bi2MoO6 doped with different element can effectively improve the photocatalytic activity compared to pure nanostructures. For example, Cl-doped Bi2MoO6 as visible light driven photocatalyst was synthesized by hydrothermal method, and showed higher photocatalytic degradation of rhodamine B than pure Bi2MoO6 [23]. W-doped Bi2MoO6 nanoplates photocatalyst [24] with the increase of the W doping amount from 0 to 3% exhibit increased photodegradation efficiency for RhB under visible light irradiation. The property of Ce-doped Bi2MoO6 nanoplates demonstrated that the well-engineered crystal defects could boost electron dynamics by trapping effects and mediate the band structure by introducing new energy levels, leading to an enhanced photocatalytic activity [25].

Inspired by these previous reports, here we have synthesized flower-like Bi2MoO6 doped with Co by a solvothermal method. The photocatalytic activity of Co-doped Bi2MoO6 was investigated under visible light irradiation, and they displayed high performance and stability for the photodecomposition of rhodamine B (RhB).

2 EXPERIMENTAL

2.1 Preparation of Pure-Bi2MoO6 and Co-Doped Bi2MoO6

All reagents were analytically pure and used without further purification. Co-doped Bi2MoO6 with different Co/Bi molar ratios (0.00, 0.05, 0.1, 0.2, 0.3, and 0.4%) were prepared by a one-step solvothermal method. In a typical solvothermal synthesis, firstly, 2 mmol of Bi(NO3)3 · 5H2O (0.97 g) was dissolved in 20 mL of ethylene glycol and magnetically stirred for 30 min, then 1 mmol of Na2MoO4 · 2H2O (0.242 g) was added to the above solution and stirred for 30 min at room temperature. Second, a certain amount of Co(C5H7O2)3 (0.0, 2.57, 5.14, 10.28, 15.42, and 20.56 mg for 0.0, 0.05, 0.1, 0.2, 0.3, and 0.4%, respectively) was dissolved in 20 mL of ethanol and stirred for 20 min. Third, ethanol solution with different amounts of Co(C5H7O2)3 was added to the mixtures of Bi(NO3)3 · 5H2O and Na2MoO4 · 2H2O, and the mixed solution was stirred continuously for 2 h. Subsequently, the mixed solution was transferred into a 50 mL Teflon-lined stainless steel autoclave and heated in an oven at 160°C for 20 h. After the reaction, the autoclave was cooled down to room temperature in air, the sample was then collected by centrifugation and washed with ethanol and deionized water several times, and dried at 70°C for 12 h. Bi2MoO6 with different Co/Bi molar ratios were obtained, and named the sample pure-Bi2MoO6, 0.05% Co–Bi2MoO6, 0.1% Co–Bi2MoO6, 0.2% Co–Bi2MoO6, 0.3% Co–Bi2MoO6, and 0.4% Co–Bi2MoO6, respectively.

2.2 Characterizations

The structures and purity of the as-prepared products were characterized by X-ray diffraction (XRD, Rigaku D/max-2550 PC X-ray powder diffractometer). The morphology and size of the samples were observed using a field emission scanning electron microscope (SEM, S-4800) with an energy dispersive X-ray spectrometer (EDS). Transmission electron microscopy (TEM) and high-resolution TEM (HRTEM) images were acquired on a JEM-2100F high-resolution transmission electron microscope with the acceleration voltage of 200 kV. X-ray photoelectron spectroscopy (ESCALab MKII spectrometer with an excitation source of Mg-Ka radiation) analysis was used to determine the chemical binding states of the constituent elements. UV–Vis diffuse reflectance spectroscopy (DRS) was performed on UV3600 spectrophotometer. The mass of Co(C5H7O2)3 powder were weighed by electronic analytical balance (METTLER TOLEDO XS105DU, max weight = 41 g, d = 0.01 mg).

2.3 Photocatalytic Activity Experiments

Rhodamine B (RhB, the maximum absorption peak 554 nm) is a popular probe molecule in heterogeneous catalytic reactions because of being a typical dye resistant to biodegradation and direct photolysis. For the evaluation of catalytic activity, degradation experiments of the RhB dye were carried out under visible light at ambient temperature. The experimental procedures are as follows, 20 mg of the photocatalyst sample was added into RhB solution (50 mL, 5.0 mg L–1) to form a suspension. Afterwards, the suspension was kept in the dark under magnetic stirring for 60 min to ensure an adsorption/desorption equilibrium. Then, the suspension under magnetic stirring was placed approximately 10 cm below a xenon lamp (500 W, Model PLS-SXE300) with a cut-off filter that only emits visible light (λ > 400 nm). At each sampling time (20 min), the irradiation was switched off and the suspension of about 3.5 mL was taken and centrifuged. The absorbance spectrum of RhB solution was analyzed using a UV-1901 spectrophotometer. After testing, the solution was returned and the irradiation was resumed.

3 RESULTS AND DISCUSSION

3.1 Structure and Morphology

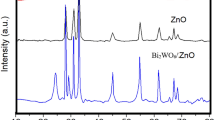

The crystalline structure of the samples was determined by X-ray diffraction (XRD) measurements. Figure 1a shows the XRD patterns of the 0.0–0.4% Co-doped Bi2MoO6. In the XRD pattern of pure Bi2MoO6 sample, all diffraction peaks match well with the standard orthorhombic Bi2MoO6 structure (JCPDS no. 21-0102). No obvious peaks of other impurities were detected, indicating that high quality orthorhombic phase Bi2MoO6 sample was obtained via current synthetic method. In the XRD pattern of Co-doped Bi2MoO6 samples, no new peak is observed in the Co-doped Bi2MoO6 sample. The careful observation from the Fig. 1b indicates that the intensity of the diffraction peaks in all Co-doped Bi2MoO6 samples obviously decreases by comparing with pure Bi2MoO6 sample. Moreover, a minor shift of the (140) and (131) diffraction peaks of Co-doped Bi2MoO6 also takes place in comparing to pure Bi2MoO6 due to the different element Co doping, as shown in Fig. 1c. Therefore, the XRD analysis confirms that the Co was incorporated into the Bi2MoO6 lattices by a simple solvothermal method.

To further understand the function of Co ions doping, X-ray photoelectron spectroscopy (XPS) was performed to investigate the chemical states of doped Co ions and bismuth and molybdenum atoms in the distorted crystal of 0.1% Co–Bi2MoO6, the survey scan of XPS spectra of 0.1% Co-doped Bi2MoO6 is shown in Fig. 2a. It was found that the binding energies peaks of Bi located at 158.9 and 164.2 eV. They are identified to Bi 4f7/2 and Bi 4f5/2, as shown in Fig. 2b. Figure 2c shows the binding energies at 232.2 and 235.4 eV of Mo in 0.1% Co–Bi2MoO6 which are assigned to Mo 3d5/2 and Mo 3d3/2 of Mo6+. The O 1s region can be fitted into two peaks at 529.7 and 531.1 eV, which are attributed to binding energies of Bi–O and Mo–O bonding Fig. 2d [24]. The binding energies values of Co show two binding energies peaks at 805.3 and 781.3 eV in accordance with Co 2p1/2 and Co 2p3/2 in 0.1% Co–Bi2MoO6Fig. 2e [26, 27], indicating the chemical state of Co3+ in Co-doped Bi2MoO6.

The morphology and size of Bi2MoO6 and 0.1% Co–Bi2MoO6 nanostructures were firstly observed by scanning electron microscopy (SEM). Figures 3a and 3b are the images of pure-Bi2MoO6, and the sample is composed of the small assemblies and the big flower-like microspheres. The small assemblies are consisted of several nanosheets, and these microspheres with diameters of ∼2 μm are built from two dimensional (2D) nanosheets with the thickness of 20 nm. The 0.1% Co–Bi2MoO6 nanostructures present microspherical morphology with diameters ranging from 1 to 3.5 μm, as shown in Figs. 3c and 3d. With the Co content increasing, the Co doped Bi2MoO6 nanostructures display the flower-like shape similar to 0.1% Co–Bi2MoO6. The TEM image further verifies that the flower-like microsphere of 0.1% Co–Bi2MoO6 is consisted of 2D nanosheets with the nanoparticles on the surface (Fig. 3e). The high-resolution TEM image (Fig. 3f) clearly displays two types of lattice fringes. The crystal planes with lattice fringe spacing of 0.236 and 0.328 nm correspond to the (221) and (140) crystallographic plane of orthorhombic Bi2MoO6, respectively. Furthermore, the EDS pattern (Fig. 4) further confirms that 0.1% Co–Bi2MoO6 consists of Bi, O, Mo, and Co elements. Based on XRD, XPS, SEM, TEM, and EDS characterizations, one can confirm the well formation of the flower-like Co-doped Bi2MoO6 microsphere.

3.2 UV–Vis Spectra of the Products

The UV–Vis absorption spectra of pure-Bi2MoO6 and Co doped Bi2MoO6 composites are showed in Fig. 5. The absorption edge of pure-Bi2MoO6 is around 501 nm (Eg = 2.48 eV), indicating that Bi2MoO6 possesses strong photo absorption from the UV to visible-light region [28–30]. Co doping slightly affected the light absorption of Bi2MoO6 crystal and led to an obvious red-shift in the absorption threshold except 0.05% Co–Bi2MoO6 sample, indicating a decrease in the band gap. Moreover, 0.1% Co–Bi2MoO6 sample clearly shows the stronger absorption in the visible light range (450–800 nm) in comparison with pure-Bi2MoO6. It suggested that Co doping can obviously enhance the visible light harvesting ability of 0.1% Co–Bi2MoO6 sample, which could benefit an increase in visible light photocatalytic performance.

Fourier transform infrared (FTIR) spectra of pure-Bi2MoO6 and Co-doped Bi2MoO6 over the wave number of 600–2000 cm–1 are presented in Fig. 6. The FITR band at 717 cm–1 corresponds to the asymmetric stretching of Mo–O relating to vibration of the equatorial oxygen atoms in MoO6 octahedrons. The absorption bands at 791 and 842 cm–1 are assigned to the asymmetric and symmetric stretching modes of Mo–O vibration of the apical oxygen atoms, respectively [20, 31]. The intensity of the bands at 717, 791, and 842 cm–1 appears slight decrease with the increase of Co concentration. The variations for the IR peaks further confirmed that Co could be successfully doped into the crystal lattice of Bi2MoO6.

3.3 Photocatalytic Activity of the Products

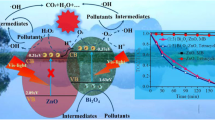

The photocatalytic performances of pure-Bi2MoO6 and Co-doped Bi2MoO6 samples were investigated by a degradation of Rhodamine B (RhB). Prior to the irradiation, the adsorption in the dark for 60 min was conducted so as to establish the adsorption/desorption equilibrium, and the absorbance value of aqueous RhB is 0.814. The corresponding photocatalytic properties have been demonstrated in Fig. 7. Figure 7a presents the temporal evolution of the absorption spectra of RhB solution over 20 mg of 0.1% Co–Bi2MoO6 as a catalyst after exposure to visible light. It could be seen that the characteristic absorption peak of RhB is located at 554 nm. After 60 min, the absorbance value of aqueous RhB reached 0.023, and after 80 min, the absorbance value of aqueous RhB achieved 0.006. The absorbance value of RhB solution decreases rapidly with extension of exposure time, and completely disappears after about 120 min, confirming that the RhB solution can be effectively photodegraded by the 0.1% Co–Bi2MoO6.

(Color online) (a) The absorption spectra of RhB solution versus visible-light irradiation time in the presence of 0.1% Co–Bi2MoO6; (b) the degradation curves of RhB solution over different catalysts; (c) kinetic linear simulation curves of RhB photocatalytic degradation over different samples under visible light; (d) five cycles in the photocatalytic decomposition of RhB over 0.1% Co–Bi2MoO6.

Figure 7b depicts the variation of RhB relative concentration C/C0 with time over pure-Bi2MoO6, P25, 0.05% Co–Bi2MoO6, 0.1% Co–Bi2MoO6, 0.2% Co–Bi2MoO6, 0.3% Co–Bi2MoO6, 0.4% Co–Bi2MoO6, and blank RhB solution under the illumination of visible light. 6.9% of RhB solution is degraded without the photocatalyst after visible light irradiation for 120 min. The 0.1% Co–Bi2MoO6 show much higher photocatalytic performance than other samples, and the degradation percentage of RhB is up to 99.7% after 120 min. When pure-Bi2MoO6, P25, 0.05% Co–Bi2MoO6, 0.2% Co–Bi2MoO6, 0.3% Co–Bi2MoO6, and 0.4% Co–Bi2MoO6 were used as the photocatalyst, the degradation rate of RhB reached to 60.5, 66.9, 93.9, 90.2, 86.7, and 65.6%, respectively. Among them, 0.1% Co–Bi2MoO6 displays the highest activity, indicating the optimal molar ratio of Co/Bi is 0.001/1. In comparison with other Bi2MoO6 morphologies for degradation of RhB [32, 33], the present Co–Bi2MoO6 nanostructures exhibited excellent photocatalytic performance. Moreover, the mineralization ability of Bi2MoO6to RhB dye under visible-light irradiation were proved by different researchers [3, 29, 32], and confirming that Co–Bi2MoO6 can efficiently mineralize organic pollutant (RhB) under visible light.

The photocatalytic degradation kinetics of RhB was investigated in order to better understand the photocatalytic efficiency of our products. The degradation data were fit using a pseudo-first-order model, ln(C/C0) = kt, where k is the reaction rate constant, and t is the light irradiation time. The reaction rate constant k, which is equal to the corresponding slope of the fitting line, is shown in Fig. 7c. The k value of RhB over pure-Bi2MoO6, 0.05% Co–Bi2MoO6, 0.2% Co–Bi2MoO6, 0.3% Co–Bi2MoO6, and 0.4% Co–Bi2MoO6 are lower than that of 0.1% Co–Bi2MoO6. Notably, 0.1% Co–Bi2MoO6 (0.0298 ± 0.0028 min–1) achieves the highest degradation rate among these samples, which is 4.18, 1.44, and 1.74 times higher than that of pure-Bi2MoO6 (0.0071 ± 0.0010 min–1), 0.05% Co–Bi2MoO6 (0.0207 ± 0.0021 min–1), and 0.2% Co–Bi2MoO6 (0.0171 ± 0.0016 min–1), respectively. A five-cycle experiment was conducted for the photocatalytic degradation of RhB over the 0.1% Co–Bi2MoO6 to evaluate their stability, which is an important factor for the practical applications. Figure 7d illustrates the five cycles of variation in RhB relative concentration C/C0 with irradiation time over 0.1% Co–Bi2MoO6 catalysts.

The values of degradation rate are 98.0, 98.7, 95.4, 90.3, and 90.1%, for the first, second, third, fourth, and fifth runs, respectively. After five consecutive runs, there is only a slight loss of the photocatalytic activity, demonstrating the high photocatalytic stability of 0.1% Co–Bi2MoO6 catalysts. Comparing these samples, 0.1% Co–Bi2MoO6 has better degradation activity, which indicates Co doping played key roles in the enhanced photocatalytic performance. The enhancement may be due to the following reasons. Firstly, the higher photocatalysis efficiency of the 0.1% Co–Bi2MoO6 samples could be explained in terms of the enhancement of UV–Vis absorbance spectra due to Co doping. The enhancement of UV–Vis absorbance spectra of the 0.1% Co–Bi2MoO6 samples represents the optimized absorption property, offering the higher photocatalytic activity. Secondly, the results of XRD indicated that the average crystallite size of Bi2MoO6 was slightly decreased by Co doping. The decrease in crystal size lead to the increase of surface area for 0.1% Co–Bi2MoO6, and benefit the light harvesting and dye adsorption. Therefore, 0.1% Co–Bi2MoO6 exhibit higher catalytic activity than other samples.

4 CONCLUSIONS

The flower-like microspheres of pure-Bi2MoO6 and Co-doped Bi2MoO6 as visible-light-driven photocatalysts have been successfully synthesized through a sample and facile solvothermal method. The characterization results of XRD, XPS, SEM, and TEM show that all products were identified to the orthorhombic Bi2MoO6 microspheres composed of nanoplates. The photocatalytic degradation of RhB by pure-Bi2MoO6, P25, 0.05% Co–Bi2MoO6, 0.05% Co–Bi2MoO6, 0.1% Co–Bi2MoO6, 0.2% Co–Bi2MoO6, 0.3% Co–Bi2MoO6, and 0.4% Co–Bi2MoO6 as photocatalysts was investigated under visible-light irradiation. Among them, the 0.1% Co–Bi2MoO6 shows the highest photocatalytic performance for degradation of RhB within 120 min, and the degradation rate of 0.1% Co–Bi2MoO6 is 4.18, 1.44, and 1.74 times higher than that of pure-Bi2MoO6, 0.05% Co–Bi2MoO6, and 0.2% Co–Bi2MoO6, respectively. The facilely prepared 0.1% Co–Bi2MoO6 products are promising materials in fields such as photocatalytic and optoelectronic applications.

REFERENCES

X. Lin, J. Yu, and M. Jaroniec, Chem. Soc. Rev. 45, 2603 (2016).

H. P. Li, T. X. Hu, R. J. Zhang, J. Q. Liu, and W. G. Hou, Appl. Catal., B 188, 313 (2016).

S. Y. Wang, X. L. Yang, X. H. Zhang, X. Ding, Z. X. Yang, K. Dai, and H. Chen, Appl. Surf. Sci. 391, 194 (2017).

Q. Xiang, B. Cheng, and J. Yu, Angew. Chem., Int. Ed. 54, 11350 (2015).

Y. Zhao, G. Chen, T. Bian, C. Zhou, G. I. N. Waterhouse, L. Wu, C. Tung, L. J. Smith, D. O’Hare, and T. Zhang, Adv. Mater. 27, 7824 (2015).

Y. Ma, Y. Jia, L. Wang, M. Yang, Y. Bi, and Y. Qi, Chem. Eur. J 22, 5844 (2016).

H. Wang, L. Zhang, Z. Chen, J. Hu, S. Li, Z. Wang, J. Liu, and X. Wang, Chem. Soc. Rev. 43, 5234 (2014).

M. Wang, J. Ioccozia, L. Sun, C. Lin, and Z. Lin, Energy. Environ. Sci. 7, 2182 (2014).

M. Zhang, J. Xu, R. Zong, and Y. Zhu, Appl. Catal., B 147, 229 (2014).

M. P. Rao, V. P. Nandhini, J. J. Wu, A. Syed, F. Ameen, and S. Anandan, J. Solid State Chem. 258, 647 (2018).

L. Wu, J. Bi, Z. Li, X. Wang, and X. Fu, Catal. Today 131, 15 (2008).

S. Cao, J. Low, J. Yu, and M. Jaroniec, Adv. Mater. 27, 2150 (2015).

H. Li, Y. Zhou, W. Tu, J. Ye, and Z. Zou, Adv. Func. Mater. 25, 998 (2015).

Y. G. Sun, L. Y. Cai, X. J. Liu, Z. Cui, and P. H. Rao, J. Phys Chem. Solids. 111, 75 (2017).

X. D. Zhu, Y. L. Zheng, Y. J. Feng, and K. N. Sun, J. Solid State Chem. 258, 691 (2018).

J. L. Zhang, L. S. Zhang, N. Yu, K. B. Xu, S. J. Li, H. L. Wang, and J. S. Liu, RSC Adv. 5, 75081 (2015).

Z. Zhao, Y. Zhou, F. Wang, K. Zhang, S. Yu, and K. Cao, ACS Appl. Mater. Inter. 7, 730 (2015).

Z. Li, X. Chen, and Z. Xue, CrystEngComm. 15, 498 (2013).

Y. Ma, Y. Jia, Z. Jiao, M. Yang, Y. Qi, and Y. Bi, Chem. Commun. 51, 6655 (2015).

M. Imani, M. Farajnezhad, and A. Tadjarodi, Mater. Res. Bull. 87, 92 (2017).

L. Shi, L. Liang, F. Wang, J. Ma, and J. Sun, Catal. Sci. Technol. 4, 3235 (2014).

M. Y. Zhang, C. L. Shao, P. Zhang, C. Y. Su, X. Zhang, P. P. Liang, Y. Y. Sun, and Y. C. Liu, J. Hazard. Mater. 225, 155 (2012).

A. Phuruangrat, P. Dumrongrojthanath, B. Kuntalue, S. Thongtem, and T. Thongtem, Mater. Lett. 196, 256 (2017).

A. Phuruangrat, P. Dumrongrojthanath, S. Thongtem, and T. Thongtem, Mater. Lett. 194, 114 (2017).

Z. Dai, F. Qin, H. P. Zhao, J. Ding, Y. L. Liu, and R. Chen, ACS Catal. 6, 3180 (2016).

Z. C. Wu, X. Wang, J. S. Huang, and F. Gao, J. Mater. Chem. A 6, 167 (2018).

B. J. Tan, K. J. Klabunde, and P. M. A. Sherwood, J. Am. Chem. Soc. 113, 855 (1991).

Y. S. Xu and W. D. Zhang, Appl. Catal., B 140, 306 (2013).

J. L. Zhang, L. S. Zhang, N. Yu, K. B. Xu, S. J. Li, H. L. Wang, and J. S. Liu, RSC Adv. 5, 75081 (2015).

Y. J. Chen, G. H. Tian, Y. H. Shi, Y. T. Xiao, and H. G. Fu, Appl. Catal. B: Environ. 164, 40 (2015).

J. Zhao, Z. Liu, and Q. Lu, Dyes Pigments 134, 553 (2016).

S. J. Li, S. W. Hu, J. L. Zhang, W. Jiang, and J. S. Liu, J. Colloid Interf. Sci. 497, 93 (2017).

C. L. Yu, Z. Wu, R. Y. Liu, H. B. He, W. H. Fan, and S. S. Xue, J. Phys Chem. Solids 93, 7 (2017).

ACKNOWLEDGMENTS

This research was supported by the Foundation of Shanghai University of Engineering Science (grant no. 2012gp13, E1-0501-15-0105), Innovation Program of Shanghai Municipal Education Commission (grant no. 14ZZ160), Open Fund of State Key Laboratory for Modification of Chemical Fibers and Polymer Materials, Donghua University (grant no. LK1209).

Author information

Authors and Affiliations

Corresponding authors

Additional information

The article is published in the original.

Rights and permissions

About this article

Cite this article

Jie Wang, Sun, Y., Wang, Z. et al. Synthesis and Enhanced Photocatalytic Activity of Visible-Light-Driven Co-Doped Bi2MoO6 Photocatalyst with Flower-Like Nanostructures. Russ. J. Phys. Chem. 93, 736–742 (2019). https://doi.org/10.1134/S0036024419040307

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036024419040307