Abstract

The disappearance of bibliographic heritage is one of the biggest problems facing libraries. One of the most common methods used to restore paper, lining, is to apply a reinforcing layer to the document. This study focuses on lining papers with bacterial cellulose (BC) sheets from Gluconacetobacter sucrofermentans. For this purpose, several model papers have been selected. They have been characterized before and after the lining with this BC and a specific Japanese paper (JP) to compare both materials. Taking into account the differences between bacterial and vegetal cellulose is expected that the results may be similar to other BC and JP. The samples have been characterized before and after an aging process. There are no significant differences in some of the characteristics studied. Nevertheless, BC-lined papers present higher gloss values and b* coordinate. The wettability decreases with both BC and JP. However, in papers lined with BC, the wettability decreases more markedly and independently of the model paper used. This is related to the sealing of the surface structure by BC, which also leads to a reduction of air permeability. When the lined papers go through an aging process, there are no significant changes in any characteristic, except in b* and L* color coordinates. Additionally, the wettability rate decreases in all cases. This study indicates that papers lined with BC are stable over time. Finally, the use of BC as reinforcing material may offer advantages for specific conservation treatments, being more suitable for certain types of paper than JP.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The most abundant polysaccharide produced in nature, cellulose, can be synthesized by plants, some animals, and a large number of microorganisms [1]. Bacterial cellulose (BC) is mainly produced by Gluconacetobacter sucrofermentans, a gram-negative bacterium, strictly aerobic, that produce cellulose as a primary product of its metabolism at temperatures between 25 and 30 °C and pH from 3 to 7 [1, 2], using different carbon sources [3, 4]. BC synthesis begins with the incorporation of monomeric glucose into β-1,4-glucan chains [5] that aggregate into subfibrils, which form crystalline microfibrils, that subsequently are gathered into bundles, which group to form ribbons [6]. These ribbons interact to form a two-dimensional layer. Finally, parallel layers interact by hydrogen bonds and Van der Waals forces, forming a gelatinous suspension in the liquid medium [7]. Although the BC properties depend on the culture parameters (cultivation method, pH, temperature, carbon, and nitrogen sources) and on the producing strain used, it can be assumed that BC is chemically identical to that produced by plants but shows higher crystallinity [8], mechanical strength, and purity [9], because it is free from lignin, hemicellulose, and other biopolymers and extractives.

Thanks to these structural properties, the BC has a wide field of applications including their use as potential biological substrate for cell culture [10, 11] or in biomedical field, as in the case of artificial skin [5], dialysis membranes [12], tissue regeneration [13], controlled drug delivery [14], and artificial blood vessels [15]. BC has been also used as a reinforcing agent for the design of nanocomposites [16]. For example, BC is able to cover natural fibers when cellulose-producing bacteria are cultivated with them, forming a high number of hydrogen bonds between BC and the natural fibers [17]. Surma-Slusarska et al. [18] studied the possibility of modifying the structure and properties of fibrous papermaking pulps with BC, obtaining specific composites by three ways, i.e., (i) making the BC biosynthesis in the presence of fibers of papermaking semi-products, (ii) adding suitable disintegrated BC film to different papermaking pulps, and (iii) joining semi-product paper sheets with BC film. In all cases, the breaking length was improved. According to the results of these studies, BC may be a promising candidate to be used in paper restoration. However, in spite of the numerous studies dealing with the wide field of applications of BC, to the best of our knowledge, there is no study about this potential use.

Until the nineteenth century, paper was produced with rags of linen, hemp, and cotton [19]. These materials, made mostly by crystalline cellulose of high quality, had a remarkable chemical stability and hardly suffered a significant degradation by hydrolysis or oxidation. However, in the mid-nineteenth century, the demand for paper increased considerably, while the rags were scarce. It was thus necessary to search for a new raw material. In 1840, Köller introduced the use of mechanical pulp from wood that began to be massively used for the production of paper from the 1850s [20]. The fundamental characteristic of the papers made from mechanical wood pulp is the presence of lignin [21], which is degraded by the action of the environment (e.g. ultraviolet radiation, heat). The degradation of lignin produces radicals and generates acid groups, which cause an acid hydrolysis of cellulose chains. Additionally, Illig developed in 1806 the sizing with rosin, a process that was generalized in the 1840s, replacing gelatin sizing. This process requires an acidic media to be effective [22], which promotes the degradation of the paper. Most importantly, the acidification leads to the disappearance of bibliographic and documentary heritage, which is one of the biggest problems faced by libraries and archives around the world [23].

Paper conservators have attempted to limit the decomposition of paper by adding alkali to neutralize acids and create an alkaline reserve that can buffer future acid degradations [24]. Deacidification does not, however, regain flexibility and strength of the damaged paper; therefore, it is necessary to perform additional treatments for reinforcing the paper [25]. Applying a reinforcing layer to the damaged document is a common method. This method is named “lining” [26]. The material most used to reinforce degraded paper is called “Japanese papers” (JP), which has a low basis weight. JP may be made of different types of Japanese long paper fibers (kozo, mitsumata, gampi…), providing them different properties. However, these types of papers are not completely satisfactory for all the documents to be restored. BC layers may be a good alternative to the JP in the restoration field due to its unique properties (e.g. high purity and crystallinity, and good mechanical properties).

The aim of this study is to evaluate the feasibility of BC to restore documents. BC and JP are characterized in this first part of this study (Part I), as well as the capacity of both materials to be used as reinforcement agents of model papers. For this purpose, BC layers have been obtained by G. sucrofermentans using the culture media previously optimized for this application [4]. In order to imitate the papers to be restored, three different model papers have been selected. One of them was filter paper made of cotton, which is totally lignin free and simulates the behavior of a high-quality paper. The other two model papers were handsheets made with wood pulps. One of them is made with 100 % chemical pulp with a residual amount of lignin. The other paper has been made with 100 % mechanical pulp and contains most of the original wood lignin. This model paper simulates the low-quality documents made with wood pulp since 1840. Finally, all of these model papers have been artificially aged to simulate old papers. Both types of samples, original model papers and aged model papers, have been lined with BC and JP.

The characterization of the samples has been made in terms of their mechanical properties (tear and burst strength), optical properties (CIELab coordinates, gloss, opacity), surface wettability (static and dynamic contact angles), and laser profilometry (LP). The way in which the model papers and the reinforcing material are joined has been studied by scanning electron microscopy (SEM). The properties were determined before and after aging the samples due to the importance of durability of the proposed treatment.

The use of the lined method with BC and its comparative with JP applied to real samples will be discussed in the forthcoming second part (Part II).

Materials and methods

Microorganism

Gluconacetobacter sucrofermentans CECT 7291 was obtained from the Spanish Type Culture Collection (CECT). For maintenance, it was subcultured periodically in HS medium [27]. Gluconacetobacter sucrofermentans was grown in HS solid medium placed in Petri dishes for 6 days, in order to obtain the suspension of bacterial cells to be used in the further experiments. 500-mL Erlenmeyer flasks containing 100 mL of liquid HS medium were inoculated with these plates and cultivated in static conditions for 4 days. Subsequently, the pellicles formed were cut in small pieces (about 1 cm × 1 cm) in sterile conditions and shaken with the liquid medium at 700 rpm for 30 min. The suspension obtained was filtered through gauze, centrifuged at 4000 rpm for 10 min, and after removing the supernatant, the pellet was washed with Ringer’s solution (NaCl, 2.5 g L−1; KCl, 0.105 g L−1; CaCl2·2H2O, 0.120 g L−1; and NaHCO3, 0.05 g L−1). This solution was centrifuged again in the same conditions, and the pellets were re-suspended in a small volume of Ringer’s solution. The optical density of the solution was adjusted to 0.59–0.64 (McFarland standards 3–4) with a wavelength of 600 nm diluting with Ringer’s solution. 250 µL of this final solution was used to inoculate 100 mL of medium.

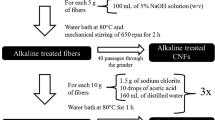

Cellulose layers production and purification

Culture medium used for BC production was a modified HS medium (fructose, 20 g L−1; yeast extract, 5 g L−1; corn steep liquor, 5 g L−1; Na2HPO4, 2.7 g L−1; and citric acid, 1.15 g L−1) with 1 % ethanol. In all cases, 100 mL of liquid medium was added to 150-mm Petri dishes, inoculated with the suspension described above and cultivated at 30 °C under static conditions. Cellulose layers were collected after 7 days of cultivation. The cellulose pellicles were washed with distilled water. To purify the BC, the pellicles were incubated at 90 °C in 1 % NaOH for 60 min. After the treatment, the pellicles were exhaustively washed with continuous distilled water and dried by filtering through a medium porosity filter paper in a Buchner funnel. Subsequently, the cellulose layers were air dried.

Model papers

Filter paper Whatman no 42 (F), made from cotton linters, was selected as free lignin, high-quality, model paper. Handsheets from mechanical (M) and chemical (C) pulps were obtained in a Rapid-Köethen sheet former according to ISO 5269-2:2004. Thirty sheets from each model paper were subjected to an accelerated aging process (filter aged, F A; mechanical aged, M A; chemical aged, C A) according to ISO 5630-3:1996, using 80 °C and 65 % relative humidity during 144 h.

Reinforcement of model papers

Lining is a general term for fusing together thin layers of different materials. In archival contexts, lining refers specifically to the process of layering a sheet of archival paper with stronger materials, in order to strengthen the object. JP and BC were used in this study to evaluate their reinforcing capacity, using native wheat starch as adhesive.

The JP used as reinforcing material, Tengucho (Awagami Papers), was selected because is one of the most common Japanese papers used in restoration (basis weight of 9 g m−2, white, 100 % kozo fibers, unsized).

Lining was performed following the traditional Japanese method. Previously, wheat starch was prepared in a proportion of 1–3 volumes of water, stirred, and cooked in microwave, stirring every 30 s until boiling 3 times. After cooling 24 h, the starch paste is passed three times through a sieve of horsehair, and then diluted in water three times and bat with a brush and water to achieve the right consistence. The first step of the lining process was to spray with water the model paper, and to apply the starch on the reinforcing material (BC or JP) with a brush. The reinforcing material was then placed on the model paper with a palm fibers brush, also used to smooth the surface and to eliminate possible wrinkles. Afterwards, the reinforced paper was hit with an Uchibake brush to remove bubbles. Finally, it was air dried.

Ten sheets of each model paper (F, M, C, F A, M A, C A) were lined with BC (F-BC, M-BC, C-BC, F A-BC, M A-BC, C A-BC) and ten with JP (F-JP, M-JP, C-JP, F A-JP, M A-JP, C A-JP).

Aging process of lined sheets

Ten lined sheets from each model paper, five reinforced with BC and five with JP, were subjected to an accelerated aging process [(F-BC)A, (M-BC)A, (C-BC)A, (F A-BC)A, (M A-BC)A, (C A-BC)A, (F-JP)A, (M-JP)A, (C-JP)A, (F A-JP)A, (M A-JP)A, (C A-JP)A] according to ISO 5630-3:1996 using 80 °C and 65 % relative humidity during 144 h. Totally, 24 different samples were characterized.

Paper characterization

The characterization of the aged and non-aged samples was performed before and after the lining. The lined samples were also characterized after the aging process. In all cases, samples were conditioned under standard conditions (23 °C and 50 % relative humidity) according to ISO 187:1990, prior to their characterization.

The mechanical properties determined were as follows: Grammage (ISO 536:2012), burst strength (ISO 2758:2014), and tear strength (ISO 1974:2012). A reflectometer Elrepho 070 was used to obtain optical properties: opacity (ISO 2471:2008) and CIELab coordinates (ISO 5631-1:2009). Specular gloss was determined using an angle of incidence of 75° (ISO 8254-1:1999). To measure the air permeance of the reinforced model papers, a Gurley porosimeter was used (ISO 5636-5:2013).

Static contact angles (α) and dynamic contact angles (αd) were measured for distilled water with a DataPhysics Instrument OCA 15 plus, running on SCA 20/21 software and using the sessile drop method. For α, the images were taken by a CCD camera immediately after the drop rested on surface. The corresponding contact angle is calculated after fitting the drop contour line numerically, using the Young–Laplace method. In this study, 20 drop tests were conducted, using 2 µL of drop volume. αd was assessed monitoring the change of the contact angle with distilled water as a function of time. For each sample, eight videos recorded the evolution of the drop for 8 s, taking 25 frames per second, applying droplets of 2 µL. To quantify differences in the evolution of α between samples, wettability rate (W) was calculated as follows:

where α 0 is the corresponding values of normalized α at time 0, α t is the respective values at a specific time, t, in seconds. In this study, W was calculated at 5 s, since the rates are less affected by errors and reveal more significant differences among the assessed samples.

The morphology of lined sheets was assessed by SEM using a JEOL JSM 6335 F at 1 kV (at a maximum resolution of 5 nm), to avoid upcharging of the samples by the electron beam during SEM observation. Samples have been previously cryofractured after immersing them into liquid nitrogen and metalized with gold during 3 min and stored for 16–18 h at 50 °C in a vacuum stove (20 mmHg) before proceeding with SEM observations. This latter treatment led to total dryness of the samples.

Samples of 10 mm × 10 mm were coated with a layer of gold for LP analysis (Lehmann, Lehman Mess-Systeme AG, Baden-Dättwil, Germany). Ten LP topography images were acquired from each sample. The lateral and z-resolutions of the LP system were 1 µm and 10 nm, respectively. The size of the local areas was 1 mm × 1 mm. The surfaces were horizontally leveled. The micro-roughness described by the facet orientation was thus quantified [28].

Results and discussion

Reinforcing materials

Several properties of BC have been evaluated in order to test it as a reinforcing material. These properties have been compared with those of the JP, the most used reinforcing material in paper restoration [26]. As can be shown in Table 1, it is noted that the two materials have a similar grammage; however, the BC sheets are thinner. Materials which are relatively thin and strong, are considered advantageous for restoring documents [29]. With regard to mechanical properties, the burst strength is greater in the BC, while tear strength is significantly higher in the JP.

The Gurley porosimeter data reveal the different macrostructure of the reinforcing materials: PJ is formed by the crosslinking of cellulose vegetal fibers, while BC is formed by a network of cellulose nanofibers [30]. The difference with respect to the Gurley air permeability between both materials is remarkably high, since this property is related to the porosity (structure) of the sheets [31]. However, the air permeability was out of the range of the Gurley air permeability tester. The values for the BC sample were above the upper limit (900 s), indicating a structure that prevents air flow. On the other side, the JP sample exhibited values below the lower limit (5 s), indicating an open structure that does not restrict the air flow.

BC and JP wettability were measured through α with water. As can been seen in Table 1, JP shows a higher α than BC. This difference was as expected, since the measurement of contact angle depends on factors related to the paper structure and to the surface chemistry [32, 33]. As also indicated by the air permeability data, both materials have significantly different structure.

The L*a*b* color Space (CIELab) describes all the colors visible to the human eye. L* represents the lightness of the color (L* = 0 yields black and L* = 100 indicates white), a* coordinate gives its position between red/magenta (positive values) and green (negative values), and b* coordinate stands for its position between yellow (positive values) and blue (negative values) [34]. The determined L*a*b* values are similar for BC and JP. Keep in mind that in most printing papers, L* values are close to 90 (high lightness), and a*b* values are around 0 (almost colorless). In addition, the low opacity implies that the color appearance of the restored documents will not be significantly modified.

The gloss values for JP are in the range of those of uncoated printing papers, whereas gloss values for BC are similar to those of non-glossy coated papers. These different ranges could indicate that each material may be useful to restore different types of papers.

After the aging process, all the properties varied in <10 %, except in the case of b*, that presents a higher increase in both materials. This indicates an increment in the yellow color intensity, which is a result to the aging process [35].

In view of all these properties, it can be concluded that BC could be appropriate for lining. Although this characterization is specific to the selected BC and JP, it is expected that the results do not differ by much considering other types of BC and JP.

Lined samples

Most of the papers to be restored come from the 1850 to 1950 period. However, in some cases, it may be useful to restore new papers that have suffered deterioration. To simulate both cases, the selected model papers have been submitted to an accelerated aging process. Lining was performed with BC and JP on the non-aged and aged model papers. In both cases, the lined samples were tested before and after being subjected to an additional aging process, to evaluate their stability over time.

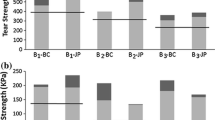

The evaluation of mechanical properties of lined samples is essential to determine the goodness of the lining process. Figure 1 shows the burst strength and tear strength, before and after the aging process. When model papers, represented by horizontal lines, are subjected to an aging process, there is a slight decrease in both mechanical properties. After lining with BC and JP, there is a similar increase in mechanical properties, both in the case of non-aged model papers (Fig. 1a, b) as in aged model papers (Fig. 1c, d). When the lined samples go through an aging process, there is a decrease in the burst strength and tear strength. However, the final values of these properties remain higher than those of the original model papers. Ardelan et al. [25] reported the same behavior with respect to the burst strength after reinforcing aged model papers (105 °C, 72 h) with several additives (e.g. carboxymethylcellulose, methylcellulose, chitosan). The decrease in the mechanical properties is particularly small in the case of samples made from mechanical pulp, M and M A, which are the most similar to the real papers to be restored due to their low original values. This indicates a good stability over time. It is worth noting that the different mechanical properties of the reinforcing materials (JP higher tear strength, BC higher burst strength) were reduced after lining.

Mechanical properties of lined samples. Grey square aged lined samples black square non-aged lined samples. Horizontal lines represent the values of the model papers, non-aged and aged, before lining. a Burst strength of non-aged model papers, b tear strength of non-aged model papers, c burst strength of aged model papers, d tear strength of aged model papers

The gloss values of each sample are shown in Table 2. It should be noted that the applied reinforcing material, regardless of the base paper used, determines the resulting paper gloss. The gloss in samples with BC always reaches values between 15 and 25 %. The samples lined with JP are in the range of 4–6 %. With the aging process, the gloss varies <6 points for all assessed samples.

When the papers to restore are matte, as in this study, restoration with a material that is also matte, as JP, do not modify the gloss range of the corresponding samples before lining. However, if the papers to restore have higher gloss (silk or glossy coated papers), lining with BC would be beneficial and lead to gloss values close to those of the original papers.

Opacity of the model papers and lined samples with BC and JP before and after the aging process is shown in Table 3. As expected, M and M A have higher opacity than the chemical and filter sheets. Neither the lining nor the aging process modifies the opacity of the original M sample. The opacity of chemical and filter sheets, which have lower opacity values before lining, increases slightly with the reinforcing treatment. In these cases, the aging process leads to an additional increment. The same effect has been found by van der Reyden et al. [36] after aging tracing papers. Also Santos et al. [37] described the increase in opacity of BC with aging.

The color coordinates, L*a*b*, were determined. a* values remain in a narrow range close to zero (data not shown). L* and b* values are represented in Fig. 2. As expected, when the model papers are aged, L* decreases and b* increases, although in all cases, the difference is <5 points. This is consistent with the results previously reported by Bansa and Ishii [26], which studied the effect of aging in different types of papers.

When model papers are lined with JP, the modification in both variables, L* and b*, is low (<1 point). Whereas when BC is used as reinforcing material, the modification is a little bit higher, L* decreases in 1 point in mechanical sheets and in 5 points in the other two type of papers. b* increases in 2 points in mechanical sheets and approximately 8 points in the other papers.

When the reinforcing material is JP, and chemical and filter papers are previously aged, the modifications in L* and b* are very low (<1 point). Lining with BC leads to changes close to 5 points. Moreover, when mechanical papers are aged, changes are low for BC (approx. 1 point) and higher with JP (<3 points).

To evaluate the stability of aged and non-aged model papers, they were subjected to an aging process after lining with BC or JP. In all cases, L* decreases 1–4 points and b* increases 2–7 points, although no significant differences are observed neither with the papers to be reinforced nor with the reinforcing materials.

In the light of these results, the optical properties were not noticeably modified by lined process, although when JP is used as reinforcing material, changes are even lower than with BC. With both reinforcing materials, the optical properties of all lined papers are stable over time. All these optical properties have been evaluated using unprinted model papers. Nevertheless, the real documents to restore could be printed papers. Assessing how the reinforcement affects the legibility of the restored document should be of interest in future studies.

SEM has been used to study the mechanism in which the model papers and the reinforcing material are joined. The study reveals that there is no difference neither with the original model papers nor with the aged ones (data not shown). Hence, the differences with respect to the reinforcement with JP and BC are shown using only mechanical sheets. The main difference lies on the structure of the reinforcing materials. While the BC presents a layered structure, the JP shows a typical fibrous paper structure. Figure 3 shows the fibrous structure of JP. It can be observed that the linkage with the model paper is very close.

The assembling between BC and the model paper (Fig. 4) is also very close. The images are acquired at different magnifications showing the layered structure of BC and its linkage with the mechanical sheets. Nanofibrils in the contact area of both materials can be observed. This may indicate the efficiency of the linkage. This point is supported by the internal bond test (TAPPI T569), which determines the strength of paper in its thickness direction. The integrity of the bonding surface of the lined samples was tested, concluding that in all cases the model paper was delaminated in two layers; however, the binding was never broken.

This study was also made after the aging process, and it was observed that there were no significant differences in the structure (data not shown).

The topography of the samples was assessed by LP. The surface morphology of the model papers and the aged ones was similar (data not shown). The main difference is caused by the reinforcement material (Fig. 5). Samples lined with BC have a smoother surface due to the layered structure of this reinforcing material. Nevertheless, the JP fibrous structure is evidenced in samples lined with it.

The micro-roughness described by the facet orientation was quantified using also LP. The results indicate that the BC application reduces the surface roughness significantly in all the model papers (Fig. 6), confirming the previous results. The surface topography is one of the factors affecting the glossy appearance of paper. The facet orientation is relatively high for all the samples, indicating a low gloss level (4–25 %). This is in accordance to previously presented models [28]. BC application reduces the surface roughness significantly (Fig. 6), which is in agreement with an increment of the corresponding gloss levels.

The structural difference between JP and BC is reflected by the Gurley air permeance values of lined samples. Model papers have air permeability values lower than 55 s. When BC is applied, the Gurley air permeance values exceed the upper limit of that considered by the papermaking industry in all cases (>900 s). On the other hand, papers lined with JP exhibit air permeability values <75 s. The aging process does not significantly modify the results. This result indicates that the closed structure of the BC prevents the air flow therethrough, which could be beneficial for protecting papers against atmospheric pollutants. This agrees with Yousefi et al. [38], who found that paper made with BC has no air permeability.

Paper wettability was studied through the measurement of α and αd with distilled water. The α values are shown in Table 4. The lining process causes the increment of α values, which means that the paper resistance to wetting is enhanced. The increment of α is due not only to the reinforcing material (JP or BC), but also to the starch used in the lamination process. Starch is a sizing agent, which is commonly used in the paper industry to reduce the wettability of the paper surface [39, 40].

The BC and the JP laminated samples showed different wettability behaviors. When using BC as the reinforcing material, the obtained α values were independent of the model paper that was restored. The values range from 70° to 87°. The relatively large variation is probably due to irregularities of the surface [32, 33, 41]. The application of starch is done manually and may result in a not completely uniform surface. Although the low porosity of the BC material (Gurley air permeability >900 s, Table 1) probably yields an inhomogeneous layer of starch on the surface, the starch leads to a similar degree of sizing for all the samples. In contrast, for JP-lined samples, the α values vary from 55° to 93°, which is a wider range. This is due not only to the manual starch application, but also to the high porosity of JP (Gurley air permeability <5 s, Table 1). The starch migrates from the surface into the bulk structure, causing these differences.

Taking into account that α values differed between the three model papers, it can be concluded that the resulting α values are not influenced by the properties of the base paper when BC is used as reinforcing material. On the other hand, for the JP-lined samples, the characteristics of the base paper seem have a marked effect on α.

Regarding the effect of the aging on the α values for non-lined samples, the α values increase with aging consequently (Table 4). However, for lined samples, the behavior is irregular, this parameter in some samples increases and in other decreases after the aging process. This could be related to the reaction that suffers the starch at a high temperature. This is in concordance with Andersson et al. [42], which found an α increment in a starch film when the climate conditions change from 23 °C/50 % RH to 80 °C/70 % RH.

The wettability of the samples was also studied by examining how α values change with time (Fig. 7). In order to compare the assessed samples, α values were normalized in relation to the corresponding initial values at 0 s. Figure 7 shows the graphs of the evolution of normalized α in non-aged model papers, before and after the lining with BC and JP. As it can be observed, each model paper has a different dynamic wettability. The water wets and spreads faster in F and M than in C. The dynamic wettability values are reduced when the samples are reinforced with JP, and even more when the paper is treated with BC. In a previous study [37], it was found that BC layers present wettability rates rather low, which confirms that the wettability seems to be independent of the model paper studied. The behavior of the evolution of normalized α in aged model papers, before and after the lining with BC and JP, follows the same pattern.

Figure 8 shows the W values for each lined sample. The samples lined with BC show similar wettability rates from 3.5 to 6.5 % s−1. In contrast, the samples lined with JP show higher and more variables values, from 6 to 14 % s−1. No data could be obtained for F-JP and F A-JP because in these samples the water was absorbed into the paper very quickly and drops rested on it for <0.50 s. For samples lined with BC, the wettability seems to be independent of the base paper properties, while these properties have a noticeable influence on the wettability of the sample reinforced con JP. This is consistent with the results previously discussed for α. Also, Fig. 8 shows that the aging process decreases the wettability rate in all the lined samples. This may be due to the curing of starch, which increases the hydrophobicity of the samples [42].

Conclusions

As has been demonstrated, BC has certain features that could be of interest in preserving cellulosic material. Comparing the two reinforcing materials, BC and JP, the BC thickness is lower with a similar grammage. Additionally, BC layers have higher burst strength and lower opacity. On the other hand, JP has higher tear resistance. Both materials show similar L*a*b* coordinates. Due to the difference of gloss of both materials, each of them may be used to restore different type of documents. The most important difference refers to the air permeance, in which both materials show different behaviors.

Irrespective of the lining material (BC or JP), no important differences are found on the lined papers with respect to the burst and tear strength, opacity, and L*, a* optical coordinates. Nevertheless, BC-lined papers present higher gloss values in all cases than those lined with JP. Hence, BC is suitable for restoring different groups of papers, including tracing paper, coated, parchment, and vellum. In addition, BC leads to an increase of the b* coordinate, which indicates a trend to yellowing. This can be considered an advantage if the paper to restore presents high yellowness, which is common in old papers.

Other important difference between both reinforced materials is the wettability. In papers lined with BC or JP, the wettability decreases, but in papers lined with BC, this effect is much more marked and independent of the paper model. The decrease in wettability caused by BC is related to the reduction in air permeance.

When the lined papers go through an aging process, there are no important changes in any characteristic regarding non-aged lined samples, except in b* and L* color coordinates, as expected. It can also be observed that the accelerated aging process decreases the wettability rate in all the lined samples. Hence, the stability over time of papers lined with BC is proved in this study.

Finally, the use of BC as reinforcing material may offer advantages for specific conservation treatments, being more suitable for certain types of paper than JP, currently used as a restoration material.

References

Bielecki S, Krystynowicz A, Turkiewicz M, Kalinowska H (2005) Bacterial cellulose. In: Steinbuchel A (ed) Biotechnology of polymer: from synthesis to patents. Wiley, Weinheim, pp 381–434

Iguchi M, Yamanaka S, Budhiono A (2000) Bacterial cellulose: a masterpiece of nature’s arts. J Mater Sci 35:261–270

Ramana KV, Tomar A, Singh L (2000) Effect of various carbon and nitrogen sources on cellulose synthesis by Acetobacter xylinum. World J Microbiol Biotechnol 16:245–248

Santos SM, Carbajo JM, Villar JC (2013) The effect of carbon and nitrogen sources on bacterial cellulose production and properties from Gluconacetobacter sucrofermentans CECT 7291 focused on its use in degraded paper restoration. BioResources 8:3630–3645

Jonas R, Farah LF (1998) Production and application of microbial cellulose. Polym Degrad Stab 59:101–106

Yamanaka S, Ishihara M, Sugiyama J (2000) Structural modification of bacterial cellulose. Cellulose 7:213–225

Brett CT (2000) Cellulose microfibrils in plants: biosynthesis, deposition and integration into the cell wall. Int Rev Cytol 199:161–199

Nakagaito AN, Nogi M, Yano H (2010) Displays from transparent films of natural nanofibers. MRS Bull 35:214–218

Castro C, Zuluaga R, Putaux JL, Caro G, Mondragon I, Gañán P (2011) Structural characterization of bacterial cellulose produced by Gluconacetobacter swingsii sp. from Colombian agroindustrial wastes. Carbohydr Polym 84:96–102

Brown RM Jr (1989) Bacterial Cellulose. In: Kennedy JF, Phillips GO, Williams PA (eds) Cellulose: structural and functional aspects. Ellis Horwood Ltd, New York, pp 145–151

Watanabe K, Eto Y, Takano S, Nakamori S, Shibai H, Yoshinaka S (1993) A new bacterial cellulose substrate for mammalian cell culture. Cytotechnology 13:107–114

Sokolnicki AM, Fischer RJ, Harrah TP, Kaplan D (2006) Permeability of bacterial cellulose membranes. J Membr Sci 272:15–27

Czaja WK, Young DJ, Kawecki M, Brown RM (2007) The future prospects of microbial cellulose in biomedical applications. Biomacromolecules 8:1–12

Wan W, Millon L (2005) Poly (vinyl alcohol)-bacterial cellulose nanocomposite, US Patent 2005/0037082 A1

Bäckdahl H, Helenius G, Bodin A, Nannmark U, Johansson BR, Risberg B, Gatenholm P (2006) Mechanical properties of bacterial cellulose and interactions with smooth muscle cells. Biomaterials 27:2141–2149

Yano S, Maeda H, Nakajima M, Hagiwara T, Sawaguchi T (2008) Preparation and mechanical properties of bacterial cellulose nanocomposites loaded with silica nanoparticles. Cellulose 15:111–120

Pommet M, Juntaro J, Heng JYY, Mantalaris A, Lee AF, Wilson K, Kalinka G, Shaffer MSP, Bismarck A (2008) Surface modification of natural fibers using bacteria: depositing bacterial cellulose onto natural fibers to create hierarchical fiber reinforced nanocomposites. Biomacromolecules 9:1643–1651

Surma-Ślusarska B, Danielewicz D, Presler S (2008) Properties of composites of unbeaten birch and pine sulphate pulps with bacterial cellulose. Fibres Text East Eur 16:127–129

Sánchez Hernampérez A (1999) Políticas de conservación en bibliotecas. Arco Libros, Madrid

Smook GA (1990) Handbook for pulp and paper technologists. TAPPI Press, Atlanta

Sjöström E, Westermark U (1999) Chemical composition of wood and pulps: basic constituents and their distribution. In: Sjöström E, Alen R (eds) Analytical methods in wood chemistry, pulping, and papermaking. Springer, New York, pp 1–19

Lindström T (2009) Sizing. In: Ek M, Gellerstedt G, Henriksson G (eds) Pulp and paper chemistry and technology, vol 3., De Gruyter, Stockholm, Sweden, pp 275–318

Baty JW, Maitland CL, Minter W, Hubbe MA, Jordan-Mowery SK (2010) Deacidification for the conservation and preservation of paper-based works: a review. BioResources 5:1955–2033

Ahn K, Rosenau T, Potthast A (2013) The influence of alkaline reserve on the aging behavior of book papers. Cellulose 20:1989–2001

Ardelean E, Bobu E, Niculescu GH, Groza C (2011) Effects of different consolidation additives on ageing behavior of archived document paper. Cellul Chem Technol 45:97–103

Bansa H, Ishii R (1997) The effect of different strengthening methods on different kinds of paper. Restaurator 18:51–72

Hestrin S, Schramm M (1954) Synthesis of cellulose by Acetobacter xylinum. 2. Preparation of freeze-dried cells capable of polymerizing glucose to cellulose. Biochem J 58:345–352

Chinga-Carrasco G, Kauko H, Myllis M, Timonen J, Wang B, Zhou M, Fossum JO (2008) New advances in the 3D characterization of mineral coating layers on paper. J Microsc 232:212–224

Owen A, Fiske B, Barrett T, McClintock TK, Volent P, Nicholson K, Kruth L, Rodger S (1988) Lining. Chap. 29 in paper conservation catalog. American Institute for Conservation Book and Paper Group, Washington D.C. http://cool.conservation-us.org/coolaic/bpg/pcc/17_sizing-resizing.pdf. Accessed 22 Mar 2013

Torres FG, Troncoso OP, Torres C, Grande CJ (2013) Cellulose based blends, composites and nanocomposites. In: Sabu T, Visakh PM, Mathew, Aji P (eds) Advances in natural polymers. Composites and nanocomposites. Springer, New York, pp 21–54

Yamauchi T, Murakami K (2001) Porosity and gas permeability. In: Borch J, Lyne MB, Mark RE (eds) Handbook of physical testing of paper, vol 2. Springer, New York, pp 267–302

Swain PS, Lipowsky R (1998) Contact angle on heterogeneous surfaces: a new look at Cassie’s and Wenzel’s laws. Langmuir 14:6772–6780

Tåg CM, Pykönen M, Rosenholm JB, Backfolk K (2009) Wettability of model fountain solutions: the influence on topo-chemical and physical properties of offset paper. J Colloid Interface Sci 330:428–436

Hubbe MA, Pawlak JJ, Koukoulas AA (2008) Paper’s appearance: a review. BioResources 3:627–665

Karlovits M, Gregor-Svetec D (2011) Comparison of durability between UV inkjet and conventional offset prints exposed to accelerated ageing. JGED 2:10–15

Van der Reyden D, Baker M, Hoffman C (1993) Effects of aging and solvent treatments on some properties of contemporary tracing papers. JAIC 31:177–206

Santos SM, Carbajo JM, Quintana E, Ibarra D, Gómez N, Ladero M, Eugenio ME, Villar JC (2015) Characterization of purified bacterial cellulose focused on its use on paper restoration. Carbohydr Polym 116:173–181

Yousefi H, Faezipour M, Hedjazi S, Mousavi MM, Azusa Y, Heidari AH (2013) Comparative study of paper and nanopaper properties prepared from bacterial cellulose nanofibres and fibres/ground cellulose nanofibres of canola straw. Ind Crop Prod 43:732–737

Moutinho I, Figueiredo M, Ferreira PJ (2004) Influência dos agentes de colagem superficial na estrutura do papel: uma análise química. In: Jiménez L, Villar JC (eds) Proceedings of III CIADICYP. INIA, Madrid, pp 377–383

Etzler FM, Buche M, Bobalek JF, Weiss MA (1995) Surface free energy of paper and inks: printability issues, papermakers conference. TAPPI Press, Chicago, pp 383–394

Ferreira PJT, Moutinho IMT, Figueiredo MML (2008) How paper topography affects contact angle measurement. In: Turrado J (ed) V Congreso Iberoamericano de Investigación en Celulosa y Papel CIADICYP 2008. Grafisma, Guadalajara, pp 66–69

Andersson C, Jonhed A, Järnström L (2008) Composition and film properties of temperature responsive, hydrophobically modified potato starch. Starch 60:539–550

Acknowledgements

The authors wish to thank the Spanish Ministry of Science and Innovation for funding this study via Project CTQ 2010-17702, and the Madrid Regional Government via Project RETO PROSOST P2013-MAE2907.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Santos, S.M., Carbajo, J.M., Gómez, N. et al. Use of bacterial cellulose in degraded paper restoration. Part I: application on model papers. J Mater Sci 51, 1541–1552 (2016). https://doi.org/10.1007/s10853-015-9476-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-015-9476-0