Abstract

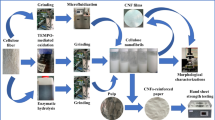

Using nanostructured materials issued from renewable resources could be the key to the development of good-quality low-cost products that help reduce pollution. Cellulose nanofibrils (CNFs) were obtained by alkaline and bleaching treatments of Amazonian Paricá hardwood sawdust, a waste material from the Brazilian forestry industry. This study evaluated a process consisting in alternating layers of Paricá CNFs and cassava starch to coat standard writing and printing (W&P) papers with a skim-coating method, in which one face of each paper sample is passed over the surface of a suspension containing either CNFs or cassava starch, alternatively. The coated samples were then compared to the uncoated paper in terms of mechanical and surface properties. The mechanical properties of the papers coated with alkaline CNFs showed a declining trend as the number of coating layers increased (from 47 to 31 MPa). The papers coated with starch layers showed improved mechanical performance compared to the samples only coated with alkaline and alkaline bleached CNFs. All the coated samples showed excellent resistance to water degradation. The worst degradation (4%) was observed for the samples coated with a single layer of alkaline CNFs. A significant improvement in surface wettability was observed when gelatinized cassava starch was applied to the paper samples, irrespective of the type of CNFs eventually present on the surface. All in all, these results suggest that using gelatinized cassava starch as an alternating layer between successive CNFs layers on the surface of W&P paper samples may be promising for improving their overall properties.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Data availability

All information can be published in the journal.

References

Eslami H, Mekonnen TH (2023) Flexible and green multilayer paper coating for barrier enhancement of paper packaging. Sustain Mater Technol 37:e00694. https://doi.org/10.1016/j.susmat.2023.e00694

Li J, Wang M, She D, Zhao Y (2017) Structural functionalization of industrial softwood kraft lignin for simple dip-coating of urea as highly efficient nitrogen fertilizer. Ind Crop Prod 109:255–265. https://doi.org/10.1016/j.indcrop.2017.08.011

Hult EL, Iotti M, Lenes M (2010) Efficient approach to high barrier packaging using microfibrillar cellulose and shellac. Cellulose 17:575–586. https://doi.org/10.1007/s10570-010-9408-8

dos Santos ADA, Matos LC, Mendonça MC, do Lago RC, Muguet MC, Damásio RAP, Tonoli GHD (2023) Evaluation of paper coated with cationic starch and carnauba wax mixtures regarding barrier properties. Ind Crop Prod 203:117177. https://doi.org/10.1016/j.indcrop.2023.117177

de Oliveira MLC, Mirmehdi S, Scatolino MV, Júnior MG, Sanadi AR, Damasio RAP, Tonoli GHD (2022) Effect of overlapping cellulose nanofibrils and nanoclay layers on mechanical and barrier properties of spray-coated papers. Cellulose. https://doi.org/10.1007/s10570-021-04350-3

Hernández RE, Cool J (2008) Evaluation of three surfacing methods on paper birch wood in relation to water- and solvent-borne coating performance. Wood Fiber Sci 40:459–469

Mirmehdi S, Oliveira MLC, Hein PRG, Dias MV, Sarantópoulos CIGL, Tonoli GHD (2018) Spraying cellulose nanofibrils for improvement of tensile and barrier properties of writing and printing (W&P) paper. J Wood Chem Technol. https://doi.org/10.1080/02773813.2018.1432656

Koivula HM, Jalkanen L, Saukkonen E, Ovaska SS, Lahti J, Christophliemk H, Mikkonen KS (2016) Machine-coated starch-based dispersion coatings prevent mineral oil migration from paperboard. Prog Org Coat 99:173–181. https://doi.org/10.1016/j.porgcoat.2016.05.017

Li Y, Wang F, Xu J, Wang T, Zhan J, Ma R, Tian Y (2023) Improvement in the optical properties of starch coatings via chemical-physical combination strategy for fruits preservation. Food Hydrocoll 137:108405. https://doi.org/10.1016/j.foodhyd.2022.108405

Reis RL, Cunha AM, Allan PS, Bevis MJ (1997) Structure development and control of injection-molded hydroxylapatite-reinforced starch/EVOH composites. Adv Polym Technol 16:263–277. https://doi.org/10.1002/(SICI)1098-2329(199711)16:4%3c263::AID-ADV2%3e3.0.CO;2-T

Chang PR, Jian R, Yu J, Ma X (2010) Starch-based composites reinforced with novel chitin nanoparticles. Carbohydr Polym 80:421–426. https://doi.org/10.1016/j.carbpol.2009.11.041

Bakri MKB, Jayamani E, Hamdan S (2017) Processing and characterization of banana fiber/epoxy composites: effect of alkaline treatment. Mater Today Proc 4:2871–2878. https://doi.org/10.1016/j.matpr.2017.02.167

Viel Q, Esposito A, Saiter JM, Santulli C, Turner JA (2018) Interfacial characterization by pull-out test of bamboo fibers embedded in poly (lactic acid). Fibers 6(1):7–15. https://doi.org/10.3390/fib6010007

Saiter JM, Esposito A, Dobircau L, Turner JA, Adhikari R (2013) Synthetic polymer composites reinforced by bamboo fibers. Macromol Symp 327:114–120. https://doi.org/10.1002/masy.201350514

Scatolino MV, Bufalino L, Dias MC, Mendes LM, da Silva MS, Tonoli GH, de Souza TM, Junior FT (2022) Copaiba oil and vegetal tannin as functionalizing agents for açai nanofibril films: valorization of forest wastes from Amazonia. Environ Sci Pollut Res 29(44):66422–37

Hubbel CA, Ragauskas AJ (2010) Effect of acid-chlorite delignification on cellulose degree of polymerization. Bioresour Technol 101:7410–7415. https://doi.org/10.1016/j.biortech.2010.04.029

Pudjiastuti L, Widjaja T, Altway A, Rohmania I, Rohmah NA (2021) Optimization of lignin removal pre-treatment process in acetone-butanol-ethanol (ABE) production from empty fruit bunches of oil palm. In: AIP conference proceedings 2021, vol 2349. AIP Publishing. https://doi.org/10.1063/5.0052179

Yan Q, Hou H, Guo P, Dong H (2012) Effects of extrusion and glycerol content on properties of oxidized and acetylated corn starch-based films. Carbohydr Polym 87:707–712. https://doi.org/10.1016/j.carbpol.2011.08.048

Otoni CG, Avena-Bustillos RJ, Olsen CW, Bilbao-Sáinz C, McHugh TH (2016) Mechanical and water barrier properties of isolated soy protein composite edible films as affected by carvacrol and cinnamaldehyde micro and nanoemulsions. Food Hydrocol 57:72–79. https://doi.org/10.1016/j.foodhyd.2016.01.012

Li W, Xu Z, Wang Z, Liu X, Li C, Ruan F (2018) Double etherification of corn starch to improve its adhesion to cotton and polyester fibers. Int J Adhes Adhes 84:101–107. https://doi.org/10.1016/j.ijadhadh.2018.03.001

Guimarães Júnior M, Botaro VR, Novack KM, Teixeira FG, Tonoli GHD (2015) Starch/PVA-based nanocomposites reinforced with bamboo nanofibrils. Ind Crop Prod 70:72–83. https://doi.org/10.1016/j.indcrop.2015.03.014

Mohsenabadi N, Rajaei A, Tabatabaei M, Mohsenifar A (2018) Physical and antimicrobial properties of starch-carboxy methyl cellulose film containing rosemary essential oils encapsulated in chitosan nanogel. Int J Biol Macromol 112:148–155. https://doi.org/10.1016/j.ijbiomac.2018.01.034

Luchese CL, Uranga J, Spada JC, Tessaro IC, Caba K (2018) Valorisation of blueberry waste and use of compression to manufacture sustainable starch films with enhanced properties. Int J Biol Macromol 115:955–960. https://doi.org/10.1016/j.ijbiomac.2018.04.162

Ortega F, Giannuzzi L, Arce VB, García MA (2017) Active composite starch films containing green synthetized silver nanoparticles. Food Hydrocol 70:152–162. https://doi.org/10.1016/j.foodhyd.2017.03.036

Monteiro MKS, Oliveira VRL, Santos FKG, Barros Neto EL, Leite RHL, Aroucha EMM, Silva RR, Silva KNO (2018) Incorporation of bentonite clay in cassava starch films for the reduction of water vapor permeability. Food Res Int 105:637–644. https://doi.org/10.1016/j.foodres.2017.11.030

Yue Y, Han J, Han G, Zhang Q, French AD, Wu Q (2015) Characterization of cellulose I/II hybrid fibers isolated from energycane bagasse during the delignification process: morphology, crystallinity and percentage estimation. Carbohydr Polym 133:438–447. https://doi.org/10.1016/j.carbpol.2015.07.058

Wise LE, Murphy M, D’Addieco AA (1946) Chlorite holocellulose, its fractionation and bearing on summative wood analysis and on studies on the hemicelluloses. Pap Trade J 122:35–43

Nasri-Nasrabadi B, Behzad T, Bagheri R (2014) Extraction and characterization of rice straw cellulose nanofibers by an optimized chemomechanical method. J Appl Polym Sci 131:40063. https://doi.org/10.1002/app.40063

Souza RCR, Andrade CT (2000) Investigation of corn starch gelatinization and extrusion processes. Polímeros 10:24–30. https://doi.org/10.1590/S0104-14282000000100006

Brazilian Association of Technical Standards: ABNT (2010b) NBR 14853: determination of soluble matter in ethanol-toluene and in dichloromethane and in acetone. ABNT, Rio de Janeiro

Brazilian Association of Technical Standards-ABNT (2003) NBR 13999: paper, board, pulps and wood—determination of residue (ash) on ignition at 525 °C. ABNT, Rio de Janeiro

Brazilian Association of Technical Standards: ABNT (2010a) NBR 7989: pulp and wood—determination of acid-insoluble lignin. ABNT, Rio de Janeiro

Browning BL (1963) The chemistry of wood. Interscience, Warrenvile, p 689

Kennedy F, Phillips GO, Williams EPA (1987) Wood and cellulosic: industrial utilization, biotechnology, structure and properties. Halsted, New York, p 1130

Zhao J, Zhang W, Zhang X, Zhang X, Lu C, Deng Y (2013) Extraction of cellulose nanofibrils from dry softwood pulp using high shear homogenization. Carbohydr Polym 97:695–702

American Society for Testing Materials (2016) ASTM D828-16 standard test method for tensile properties of paper and paperboard using constant-rate-of-elongation apparatus. In: ASTM, American Society for Testing and Materials, West Conshohocken. p 8

American Society for Testing Materials (2013) ASTM D7490–13 standard test method for measurement of the surface tension of solid coatings, substrates and pigments using contact angle measurements. In: Annual book of ASTM standards, pp 1–5

Qing Y, Sabo R, Zhu JY, Agarwal U, Cai Z, Wu Y (2013) A comparative study of cellulose nanofibrils disintegrated via multiple processing approaches. Carbohydr Polym 97:226–234. https://doi.org/10.1016/j.carbpol.2013.04.086

Wang Q, Zhu JY, Considine JM (2013) Strong and optically transparent films prepared using cellulosic solid residue recovered from cellulose nanocrystals production waste stream. ACS Appl Mater Interface 5:2527–2534. https://doi.org/10.1021/am302967m

Nair SS, Yan N (2015) Effect of high residual lignin on the thermal stability of nanofibrils and its enhanced mechanical performance in aqueous environments. Cellulose 22:3137–3150. https://doi.org/10.1007/s10570-015-0737-5

Spence KL, Venditti RA, Rojas OJ, Habibi Y, Pawlak JJ (2010) The effect of chemical composition on microfibrillar cellulose films from wood pulps: water interactions and physical properties for packaging applications. Cellulose 17:835–848. https://doi.org/10.1007/s10570-010-9424-8

Bian H, Gao Y, Wang R, Liu Z, Wu W, Dai H (2018) Contribution of lignin to the surface structure and physical performance of cellulose nanofibrils film. Cellulose 25:1309–1318. https://doi.org/10.1007/s10570-018-1658-x

Dufresne A, Medeiros ES, Orts WJ (2010) In: Starch: characterization, properties, and applications. Taylor and Francis Group, LLC, Boca Raton, pp 250–252

Zhao R, Torley P, Halley PJ (2008) Emerging biodegradable materials: starch-and protein-based bio-nanocomposites. J Mater Sci 43:3058–3071. https://doi.org/10.1007/s10853-007-2434-8

Li W, Xu WZ, Wei AF, Xu ZZ, Zhang CH (2016) Quaternization/maleation of corn starch to improve its adhesion and film properties for warp sizing. Fiber Polym 17:1589–1597. https://doi.org/10.1007/s12221-016-6360-8

Li W, Zhu ZF (2016) Electroneutral maize starch by quaterization and sulfosuccination for strong adhesion-to-viscose fibers and easy removal. J Adhes 92:257–272. https://doi.org/10.1080/00218464.2015.1025953

Mali S, Karam LBR, Ramos LP, Grossmann MVE (2004) Relationships among the composition and physicochemical properties of starches with the characteristics of their films. J Agric Food Chem 52:7720–7725. https://doi.org/10.1021/jf049225

Feng YH, Cheng TY, Yang WG, Ma PT, He HZ, Yin XC, Yu XX (2018) Characteristics and environmentally friendly extraction of cellulose nanofibrils from sugarcane bagasse. Ind Crop Prod 111:285–291. https://doi.org/10.1016/j.indcrop.2017.10.041

Shahbazi P, Behzad T, Heidarian P (2017) Isolation of cellulose nanofibers from poplar wood and wheat straw: optimization of bleaching step parameters in a chemo-mechanical process by experimental design. Wood Sci Technol 51:1173–1187. https://doi.org/10.1007/s00226-017-0929-2

Dufresne A (2012) Nanocellulose: from nature to high performance tailored materials. Walter de Gruyter, Berlin

Heidarian P, Behzad T, Karimi K (2016) Isolation and characterization of bagasse cellulose nanofibrils by optimized sulfur-free chemical delignification. Wood Sci Technol 50:1071–1088. https://doi.org/10.1007/s00226-016-0820-6

Nogi M, Iwamoto S, Nakagaito AN, Yano H (2009) Optically transparent nanofiber paper. Adv Mater 21:1595–1598. https://doi.org/10.1002/adma.200803174

Kang Y, Ahn Y, Lee SH, Hong JH, Ku MK, Kim H (2013) Lignocellulosic nanofiber prepared by alkali treatment and electrospinning using ionic liquid. Fiber Polym 14:530–536. https://doi.org/10.1007/s12221-013-0530-8

Saelee K, Yingkamhaeng N, Nimchua T, Sukyai P (2016) An environmentally friendly xylanase-assisted pretreatment for cellulose nanofibrils isolation from sugarcane bagasse by high-pressure homogenization. Ind Crop Prod 82:149–160. https://doi.org/10.1016/J.INDCROP.2015.11.064

Nair SS, Kuo PY, Chen H, Yan N (2017) Investigating the effect of lignin on the mechanical, thermal, and barrier properties of cellulose nanofibril reinforced epoxy composite. Ind Crop Prod 100:208–217. https://doi.org/10.1016/j.indcrop.2017.02.032

Jiang F, Hsieh YL (2013) Chemically and mechanically isolated nanocellulose and their self-assembled structures. Carbohydr Polym 95:32–40. https://doi.org/10.1016/j.carbpol.2013.02.022

Fonseca AS, Panthapulakkal S, Konar KS, Sain M, Bufalino L, Raabe J, Miranda IPA, Martins MA, Tonoli GHD (2019) Improving cellulose nanofibrillation of non-wood fiber using alkaline and bleaching pre-treatments. Ind Crop Prod 131:203–212. https://doi.org/10.1016/j.indcrop.2019.01.046

Pääkko M, Ankerfors M, Kosonen H, Nyka¨nen A, Ahola S, Österberg M, Ruokolainen J, Laine J, Larsson PT, Ikkala O, Lindström T (2007) Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromolecules 8:1934–1941. https://doi.org/10.1021/bm061215p

Dias MC et al (2022) Influence of hemicellulose content and cellulose crystal change on cellulose nanofibers properties. Int J Biol Macromol 213:780–790. https://doi.org/10.1016/j.ijbiomac.2022.06.012

Chaker A, Sabrine A, Mutjé P, Vilar MR, Boufi S (2013) Key role of the hemicellulose content and the cell morphology on the nanofibrillation effectiveness of cellulose pulps. Cellulose 20:2863–2875. https://doi.org/10.1007/s10570-013-0036-y

Klemm D, Kramer F, Moritz S, Lindström T, Ankerfors M, Gray D, Dorris A (2011) Nanocelluloses: a new family of nature-based materials. Angew Chem Int Ed 50:5438–5466. https://doi.org/10.1002/anie.201001273

Chen C, Baucher M, Christensen JH, Boerjan W (2001) Biotechnology in trees: towards improved paper pulping in lignin engineering. Euphytica 118:185–195

Pacaphol K, Aht-Ong D (2017) The influences of silanes on interfacial adhesion and surface properties of nanocellulose film coating on glass and aluminum substrates. Surface and Coatings Technology 320:70–81

Jonoobi M, Khazaeian A, Tahir PM, Azry SS, Oksman K (2011) Characteristics of cellulose nanofibers isolated from rubberwood and empty fruit bunches of oil palm using chemo-mechanical process. Cellulose, 18:1085–1095

Tonoli GHD, Holtman KM, Glenn G, Fonseca AS, Wood D, Williams T, Sá VA, Torres L, Klamczynski A, Orts WJ (2016) Properties of cellulose micro/nanofibers obtained from eucalyptus pulp fiber treated with anaerobic digestate and high shear mixing. Cellulose 23:1239–1256

Uetani K, Yano H (2011) Nanofibrillation of wood pulp using a high-speed blender. Biomacromol 12:348–353

Dai L, Li C, Zhang J, Cheng F (2018) Preparation and characterization of starch nanocrystals combining ball milling with acid hydrolysis. Carbohydr Polym 180:122–127. https://doi.org/10.1016/j.carbpol.2017.10.015

Dufresne A (2014) Crystalline starch based nanoparticles. Curr Opin Colloid Interface Sci 19:397–408. https://doi.org/10.1016/j.cocis.2014.06.001

Tabassi N, Moghbeli MR, Ghasemi I (2016) Thermoplastic starch/cellulose nanocrystal green composites prepared in an internal mixer. Iran Polym J 25:45–57. https://doi.org/10.1007/s13726-015-0398-0

Caligiuri V, Tedeschi G, Palei M, Miscuglio M, Martin-Garcia B, Guzman-Puyol S, Hedayati MK, Kristensen A, Athanassiou A, Cingolani R, Sorger VJ, Salerno M, Bonaccorso F, Krahne R, Heredia-Guerrero JA (2020) Biodegradable and insoluble cellulose photonic crystals and metasurfaces. ACS Nano 14:9502–9511. https://doi.org/10.1021/acsnano.0c03224

Scatolino MV, Bufalino L, Mendes LM, Guimarães Júnior M, Tonoli GHD (2017) Impact of nanofibrillation degree of eucalyptus and Amazonian hardwood sawdust on physical properties of cellulose nanofibril films. Wood Sci Technol 51:1095–1115

Fakhouri FM, Fontes LCB, Gonçalves PVM et al (2007) Films and edible coatings based on native starches and gelatin in the conservation and sensory acceptance of Crimson grapes. Ciênc Tecnol Aliment 27:369–375. https://doi.org/10.1590/S0101-20612007000200027

Vicentino SL, Floriano PA, Dragunski DC (2011) Films of starch cassava to coat and conservation of grapes. Quim Nova 34:1309–1314. https://doi.org/10.1590/s0100-40422011000800003

Suhasini MR, Rajeshwari KM, Bindya S, Hemavathi AB, Prashant MV, Asad S, Rajalakshmanan E, Raghavendra GA, Chandan S, Vijay KC, Sanjay SM, Shiva PK (2023) Pectin/PVA and pectin-MgO/PVA films: preparation, characterization and biodegradation studies. Heliyon 9:e15792. https://doi.org/10.1016/j.heliyon.2023.e15792

Guan J, Eskridge KM, Hanna MA (2004) Functional properties of extruded acetylated starch-cellulose foams. J Polym Environ 12:113–121. https://doi.org/10.1023/B:JOOE.0000038542.98493.2c

Guan Y, Qian L, Xiao H, Zheng A (2008) Preparation of novel antimicrobial-modified starch and its adsorption on cellulose fibers: part I. Optimization of synthetic conditions and antimicrobial activities. Cellulose 15:609–618. https://doi.org/10.1007/s10570-008-9208-6

Guan Y, Qian L, Xiao H, Zheng A, He B (2008) Synthesis of a novel antimicrobial-modified starch and its adsorption on cellulose fibers: part II––adsorption behaviors of cationic starch on cellulose fibers. Cellulose 15:619–629. https://doi.org/10.1007/s10570-008-9207-7

Shahbazi M, Rajabzadeh G, Sotoodeh S (2017) Functional characteristics, wettability properties and cytotoxic effect of starch film incorporated with multi-walled and hydroxylated multi-walled carbon nanotubes. Int J Biol Macromol 104:597–605. https://doi.org/10.1016/j.ijbiomac.2017.06.031

Dufresne A, Vignon MR (1998) Improvement of starch film performances using cellulose microfibrils. Macromolecules 31:2693–2696. https://doi.org/10.1021/ma971532b

Li Y, Shoemaker CF, Ma J, Shen X, Zhong F (2008) Paste viscosity of rice starches of different amylose content and carboxymethylcellulose formed by dry heating and the physical properties of their films. Food Chem 109:616–623. https://doi.org/10.1016/j.foodchem.2008.01.023

Pereira GS, Machado FLC, Costa JMC (2014) Application of coating extends postharvest quality in the ‘Valencia Delta’ orange during ambient storage. Rev Ciênc Agron 45:520–527. https://doi.org/10.1590/S1806-66902014000300012

Teisala H, Mikko T, Janne H, Mikko A, Milena S, Jyrki MM, Jarkko JS, Martti T, Jurkka K (2014) Switchable water absorption of paper via liquid flame spray nanoparticle coating. Cellulose 21:2033–2043. https://doi.org/10.1007/s10570-014-0223-5

Acknowledgements

The authors thank Fundação de Amparo à Pesquisa do Estado de Minas Gerais (FAPEMIG), CAPES, Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq), Brazilian Research Network in Lignocellulosic Composites and Nanocomposites (RELIGAR) and Groupe de Physique des Matériaux from Université de Rouen Normandie for welcoming Mário Vanoli Scatolino within the framework of the Erasmus Mundus Program. More particularly, Eric Dontzoff and Marie-Rose Garda are acknowledged for their technical contribution to the experiments performed in Rouen, France (mechanical and wettability tests).

Funding

This work was funded by CAPES, CNPq (finance code 484082/2013–2; 312108/2015–0; 307723/2017–8; 300985/2022–3) and FAPEMIG. The Erasmus Mundus Program from the European Union is acknowledged for Mário Vanoli Scatolino’s mobility abroad.

Author information

Authors and Affiliations

Contributions

M.V. Scatolino was contributed to conceptualization, investigation, writing—original draft. R.R. de Melo and E.A. de O. Paula were contributed to drafting graphs and tables. M.A. Martins and G.H.D. Tonoli were contributed to formal analysis, visualization, writing—review and editing. A. Esposito was contributed to writing—review and editing, validation. L.M. Mendes was contributed to funding acquisition, project administration.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: Stephen Eichhorn.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Scatolino, M.V., de Melo, R.R., de Oliveira Paula, E.A. et al. Mechanical and surface properties of standard writing and printing papers coated with alternating layers of Amazonian Paricá nanofibrils and cassava starch. J Mater Sci 59, 11362–11380 (2024). https://doi.org/10.1007/s10853-024-09827-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-024-09827-7