Abstract

The introduction of highly volatile fragrances within polymeric nano-scaled fibers is a promising route for efficient and simple encapsulation of temperature-sensitive materials. This work describes the investigation of selected parameters influencing the electrospinning of emulsions of poly(vinyl alcohol) (PVA) and (R)-(+) limonene or hexadecane. Thereby the influence of environmental parameters such as temperature and relative humidity on the fiber structure and encapsulation efficiency (EE) of the fragrance is demonstrated. For that purpose, the electrospinning process was carried out in a climatic cabin in which temperature and relative humidity were controlled. Studied temperatures ranged from 8 to 24 °C and relative humidity varied between 55 and 85 %. The influence of temperature was dependent on the PVA concentration in the emulsion. The relative humidity influenced both the obtained fiber morphology and fragrance EE to a higher extent than the temperature due to the hydrophilic nature of the PVA. This study is of importance when considering the use of emulsion electrospinning for encapsulation purposes.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Electrospun membranes can find applications in various areas such as sensors, drug delivery, or tissue engineering [1–6]. However, while producing nanofibers, the environmental conditions (temperature and relative humidity) are strongly influencing the obtained fiber morphology [7–13].

For example, when electrospinning solutions of hydrophilic polymers such as (poly(ethylene oxide) (PEO), poly(vinyl alcohol) PVA or PVA/hyaluronic acid in water [7, 9, 13], poly(vinyl pyrrolidone) (PVP) in ethanol [10], and PEO or PEO/chitosan in acetic acid [13], a decrease in fiber diameter was observed when the relative humidity was increased. A tenfold increase in relative humidity (from 4 to 40 % RH) caused a fiber diameter decrease of at least 50 % [13]. When beaded fibers were formed, the bead diameter increased with increasing relative humidity. These results were the opposite of what was observed with solution electrospinning of hydrophobic polymers such as poly(styrene) (PS), poly(methylmethacrylate) (PMMA), PMMA in toluene, poly(lactide) (PLA) in hexafluoropropanol or trifluoroethanol [9], or cellulose acetate (CA) in an acetone/dimethylformamide (DMF)/ethanol solvent mixture [11]. As such, opposite trends in the fiber diameter variation were observed when spinning hydrophilic (PVA, PEO, and PVP) polymers or hydrophobic polymers (PS, PMMA, and PLA) according to the humidity. Upon electrospinning at high relative humidity, the solvent evaporation rate was expected to be reduced (the atmospheric pressure being closer to water vapor saturation pressure). The decreased solvent evaporation rate would then lead to an enhanced fiber elongation during the flight toward the collector and thus to thinner fibers. In the case of hydrophobic polymers, however, this effect was overcompensated by the rapid precipitation of the polymer, a decrease of the drawing ratio and thus the formation of thicker fibers was observed [11].

Controlling temperature is also critical during electrospinning, as demonstrated for solutions of CA in acetone/DMF (from 10 to 30 °C) [10] or in acetone/DMF/ethanol (from 17.5 to 32.5 °C) [11] or for poly(acrylonitrile) (PAN) in DMF (from 32 to 90 °C) [8]. Overall, a decrease in fiber diameter was observed with increased temperature during electrospinning. Indeed, a higher temperature decreased the solution viscosity which led to a higher drawing during fiber formation [11]. For PAN in DMF solutions, at the highest studied temperature (100 °C) the solution surface tension and viscosity decreased and the polymer solution conductivity was increased [8], which led to a reduced fiber diameter with a low crystalline order, but a higher polymer chain orientation. However, the spinning of CA in acetone/DMF or PVP in ethanol [10] at three different temperatures induced the formation of fibers of increasing diameter between 10 and 20 °C, but decreasing diameter between 20 and 30 °C. First of all, the evaporation rate of the solvent increased exponentially with increasing temperature, thus allowing less elongation of the nascent fiber when temperature was increased. The observed result was an increase in fiber diameter from 10 to 20 °C. However, when temperature was increased from 20 to 30 °C, the solution viscosity decreased, and the number of chain entanglement was reduced. To compensate for the decrease in viscosity as well as for the decreased surface tension, a higher voltage was applied, causing higher drawing rates and thinner fibers.

Regarding the electrospinning set-up itself, the humidity can easily be controlled by placing the equipment into a climatized enclosure. However, different ways for controlling the process temperature were reported. Temperature-controlled electrospinning can thus refer to heating only the syringe/polymer solution dispensing system [8, 12], the collector [14] or the whole enclosure of the device [7, 11, 13]. This last approach is particularly relevant since it avoids the formation of temperature gradients which can interfere with the fiber formation process.

It was thus established that by controlling the temperature and relative humidity while electrospinning polymer solutions one can finely tune the fiber morphology. Important types of feeds for electrospun fiber production are colloidal systems such as dispersions or emulsions. In particular emulsion electrospinning allows the environmentally friendly production of nanofibrous membranes [15] as well as the encapsulation of a wide variety of active ingredients due to its ease of processing [16, 17]. However, for complex systems containing immiscible solvents or temperature-sensitive compounds, the investigation of the influence of the environmental parameters on the electrospinning outcome in terms of fiber morphology as well as on the encapsulation efficiency (EE) is needed.

Here, we show the influence of temperature (ranging from 8 to 24 °C) and of relative humidity (ranging from 55 to 85 %) on the fiber formation by electrospinning of direct emulsions composed of PVA. Limonene, a highly volatile compound was chosen in order to assess the influence of the environmental parameters on the EE of the process. A second model compound, hexadecane (low volatility, high melting point) was also used as dispersed phase, and the evolution of the fiber morphology below and above its melting point was evaluated. This study shows that emulsion electrospinning, like previously reported systems of solution electrospinning, should be performed in environments in which temperature and relative humidity can be measured and/or controlled. Both parameters influence the resulting membrane, either considering EE or fiber morphology.

Experimental

Materials

(R)-(+)-Limonene (97 %, P vap = 400 Pa at 14.4 °C), and PVA (Mowiol 40-88, M w = 205000 g mol−1, T g = 55 °C) were purchased from Sigma (Steinheim, Germany). Tween 20 and ethanol were purchased from Fluka (Steinheim, Germany), hexadecane and anisole from Fluka (Buchs, Switzerland). All chemicals were used as received. For all experiments deionized water was used (2.1 µS cm−1).

Methods

Emulsion preparation

Two PVA stock solutions were prepared (6 and 9 %, w/w) by gradually adding PVA in the required amount of water under stirring and heating (75 °C). Limonene was weighed and added drop-wise in required amounts to the PVA solution in order to reach an emulsion ratio of 1:8 (dispersed phase:continuous phase, w/w) for limonene emulsions. Concerning hexadecane emulsions, Tween 20 was added and dissolved at a concentration of 2 % relative to the polymer solution (w/w). Hexadecane was then dispersed into the polymer phase at a mass equal to that of PVA in the continuous phase. Emulsions were then stirred for 2 h at 1250 rpm and sonicated for 2 min at 70 % amplitude using a Branson Digital Sonifier (400 W, 20 kHz) equipped with a ½ inch tip. To prevent phase separation, emulsions were stirred at 200 rpm until used for electrospinning.

Emulsion rheology

The viscosity measurements were performed on a Physica MCR301 Rheometer (Anton Paar, Graz, Austria) with a plate—cone geometry linked to a temperature control unit (Anton Paar, Viscotherm VT2, Graz, Austria) containing a 50:50 (w/w) % mixture of ethylene glycol and water. To exclude rheological history of the polymer emulsions and thus to obtain high repeatability, the rheometer was programed to perform a pre-shear followed by a hold and finally a stepwise linear shear ramp. The rheometer was set either to 8, 16, or to 24 °C to be comparable to the electrospinning procedures and the shear rates applied ranged from 0.05 to 500 s−1. The pre-shear applied lasted 30 s at a shear rate of 50 s−1, and was followed by 30 s of relaxation of the emulsion.

Electrospinning

A custom-made electrospinning set-up, previously described [16], was used for all experiments. In brief, an infusion pump (KD Scientific, USA) provided a constant emulsion flow through a plastic syringe (1 mL, Henke Sass Wolf, Germany) equipped with a stainless steel needle (0.8 mm inner diameter, Unimed S.A., Switzerland). Positive and negative voltage supply sources (AIP Wild AG, Switzerland) were connected to the needle and the collector, respectively. The device was placed in a Faraday cage. The whole device was then placed into a climatic cabin with controlled environmental conditions (temperature and relative humidity). While electrospinning, the needle to collector distance was kept constant (20 cm), the flow rate was fixed at 5 µL min−1, and the voltage applied was between 0.5 and 0.725 kV cm−1. For each environment, four samples were electrospun, each of them for 1 h. Electrospinning environmental conditions achieved in the climatic cabin are summarized in Table 1. Relative humidity could vary by ±4 % and temperature by ±1 °C.

Fiber morphology

The morphologies of the obtained fibers were analyzed by Scanning Electron Microscopy (SEM, Hitachi S-4800, Hitachi High technologies, Canada). Electrospun fibers were sputtered before imaging with a 5 nm gold/palladium (80/20) coating (Leica EM ACE600, Wien Austria). Bead and fiber diameters were evaluated based on the acquired SEM micrographs, with the Image J software, analyzing at least 75 beads and/or fibers.

Encapsulation efficiency of d-limonene in electrospun samples

The presence of d-limonene in samples electrospun from PVA/limonene emulsions was detected by Gas Chromatography (GC—Trace 2000, Italy), using anisole as internal standard. Each membrane was placed in a closed vial containing 10 mL of ethanol and sonicated in an ultrasound bath for 10 min to ensure full fiber breakage. After sonication, 1 mL of the ethanol dispersion was filtered and mixed with 0.5 mL of a 7.4 × 10−3 mol L−1 ethanolic solution of anisol, and the obtained solution analyzed. As a reference, a solution of 7.4 × 10−3 mol L−1 anisol and 5.9 × 10−3 mol L−1 limonene in ethanol was used. EE was then calculated as the ratio between the amounts of limonene extracted from a given mass of fibers compared to the total amount of limonene that could be encapsulated if the whole emulsion was spun. A two way analysis of variance was performed on the obtained EE with Origins software (p < 0.05).

Results and discussion

Emulsion viscosity

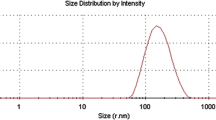

The dynamic viscosity of limonene and hexadecane-containing emulsions was evaluated at the respective electrospinning temperatures (8, 16, and 24 °C). The dynamic viscosities of the limonene-based emulsions increased linearly with increasing polymer concentration (6 and 9 %, respectively) and decreasing temperature (Fig. 1). The low-shear rate viscosities for the investigated formulations are shown in Fig. 1 and Table 2. The hexadecane emulsion was only prepared using a continuous phase with a concentration of 6 % PVA, since at higher concentrations the emulsion was too viscous to be processed by electrospinning. The viscosity of the hexadecane-containing emulsions at temperatures close to and above its melting point (16 and 24 °C) was comparable to the one of the limonene-containing formulations. At 8 °C, when the hexadecane is expected to solidify and thus the formulation to behave like a suspension, a significant increase of its viscosity at low-shear rates was observed.

Table 2 and Fig. 1, show that the decrease in viscosity with increasing temperature is more important, when the polymer concentration in the continuous phase is increased (from 6 to 9 %) rather than when the dispersed phase is changed (from limonene to hexadecane). With 9 % PVA concentration, the increase in temperature caused an increase in polymer chain mobility as well as a decrease in water viscosity. The viscosity increased tenfold when the polymer concentration in the continuous phase was increased from 6 to 9 %. As a comparison, the values for viscosity of pure 6 and 9 % PVA solutions in water were added in Table 2 and Fig. 1 The same evolution as for emulsions is visible (decreasing viscosity with increasing temperature). Also, when comparing PVA solution viscosity to emulsion viscosity, it appears that the viscosity is on average higher for the emulsion of same polymer concentration, the increase in viscosity being due to the presence of the dispersed phase.

Influence of temperature and relative humidity on the fiber morphology

Different factors may induce a fiber morphology change while electrospinning emulsions at selected temperature and relative humidity. First, a temperature change influences the viscosity of the formulated emulsion, which would in turn influence the morphology of the formed fibers (the more viscous the emulsion, the least beads are expected [18]) and also the tendency of the fragrance to evaporate (the higher the temperature, the faster the fragrance evaporation). Also, a relative humidity change at a chosen temperature would influence the solvent vapor pressure of the continuous polymer phase (water was used as a solvent). By changing this parameter, we hypothesized that the speed of the solvent evaporation would be modified, and therefore, the polymer chains would organize at different speeds, which would in turn influence the fiber forming process and thus the fiber morphology. We expected as well that the relative humidity would influence the permeability of the PVA shell as was demonstrated by Zhang et al. [19] when using ethylene vinyl alcohol (EVOH) copolymer films and limonene in various environments. At high relative humidity, the presence of moisture in the EVOH films decreased cohesive forces among polymer chains which increased the chain mobility, and so the diffusion of the limonene through the EVOH film was eased.

PVA/limonene emulsion electrospinning

For a given temperature, the fiber morphology was constant, though impossible to measure for some samples due to fiber re-dissolution at high relative humidity (Figs. 2, 3). The PVA-based emulsion yielded beaded fibers in all investigated conditions. The diameters of the relatively large beads showed broad distributions for all investigated conditions. The bead morphology was spindle-like in the case of the emulsions spun at lower humidity (55 %), and a spherical morphology was observed in all other investigated conditions. This suggested a slight increase in the jet stability at low humidity, due to an increased solvent evaporation rate. It then increased when RH was raised to 75 %, and reached a maximum when RH was 85 %. At 85 % RH, independent of the temperature, the fibers appeared strongly deformed. As expected at 85 % RH the beads had the highest average diameter (for example, for 6 % PVA emulsions, (1607 ± 453) nm at 8 °C, (1721 ± 621) nm at 16 °C, and (1216 ± 437) nm at 24 °C)). With increasing PVA content (9 %), fibers were of larger diameter and presented more elongated spindle-like beads, as compared to the fibers obtained from the emulsions with a less concentrated continuous phase. Indeed, the viscosity of the 9 % PVA-based emulsions was one order of magnitude higher, and thus this formulation allowed a higher stability of the electrospinning jet.

No important difference between the bead diameters was observed at 55, 65, and 75 % humidity, respectively (Fig. 4). A clear change was, however, visible at 85 % RH. The bead morphology was more spherical, and the average bead diameter increased (around 1 µm) as compared to the diameters observed at lower humidity (Fig. 3). A clear decrease in fiber diameter was observed, when the relative humidity changed from 65 to 75 % at 8 and 16 °C. Moreover, the nanofibers connecting the beads appeared to be partially re-dissolved, similarly to the situation observed in the case of fibers produced from 6 % PVA emulsions. The temperature had no clear influence on the fiber morphology and on the bead or fiber diameter.

As a preliminary conclusion, the morphology of emulsion electrospun fibers was influenced primarily by the concentration of the continuous phase. Emulsions with a higher concentration of polymer in the continuous phase were more viscous and increased molecular chain entanglement occurred. The enhanced entanglement led to a more stable electrospinning jet. Also, the fiber morphology evolved toward a more cylindrical shape. Relative humidity was the major environmental parameter influencing the bead and fiber diameters. For oil in water emulsions, the evolution of the fiber morphology with the humidity was similar to the one previously reported for the solution spinning of water soluble polymers [7, 9, 10, 13].

PVA/hexadecane emulsion electrospinning

The electrospinning of hexadecane-containing emulsions (and 6 % PVA) led in all conditions to a characteristic-beaded fiber morphology, and only at the highest investigated temperature (24 °C) and the lowest relative humidity (55 %) the bead shape appeared spindle like (Fig. 5). Additionally, as compared to the limonene-containing emulsion, the hexadecane system appeared to be more sensitive to humidity. As such, for temperatures below the melting point of hexadecane (8 and 16 °C) the bead diameter increased with the relative humidity (Fig. 6).

Bead diameters evolved from (963 ± 342) nm to (1574 ± 280) nm at 8 °C, and from (711 ± 350) nm up to (1087 ± 352) nm at 16 °C. At 24 °C, the bead diameter almost doubled when comparing diameters obtained at 55 % RH ((672 ± 298) nm) and at 85 % RH ((1372 ± 328) nm). The decrease in the evaporation rate of the solvent with humidity led to a greater number of instabilities in the electrospinning jet. Larger structures were formed. Moreover, for a specific humidity value, a slight decrease in the average bead diameter was observed when increasing the temperature. This was expected, due to a large volume contraction of hexadecane above its melting point. Indeed, at 24 °C the smallest average bead diameters were observed. The viscosity of the PVA/hexadecane emulsions was also the lowest measured at 24 °C. The PVA polymer chain mobility was high, thus allowing a proper organization and shell formation around the hexadecane droplets.

Encapsulation efficiency (EE)

The EE of the volatile limonene was assessed by GC, and a first observation concerned the influence of the concentration of PVA in continuous phase concentration. Indeed, as was previously reported [16], the fibers from emulsions of 6 % PVA/limonene (Fig. 7) showed lower EE than the ones obtained from 9 % PVA/limonene emulsions (Fig. 8). This was comparable to results obtained when using classical microencapsulation approaches [20]. It was expected that the EE of the highly volatile limonene fragrance would be dependent on the temperature (which increases its evaporation rate), and humidity (which influences the permeability properties of the polymer fibers).

However, when analyzing the EE of 6 % PVA/limonene as a function of the environmental parameters no significant effect of the relative humidity could be identified below 75 % RH (p < 0.05). At constant RH (below 75 % RH), a lower temperature induced a decrease in EE (e.g., at 55 % RH from 26 % EE at 8 °C to 40 % EE at 24 °C). At 85 % RH, the EE remained similar at 8 °C (from 27 to 23 %), decreased slightly at 16 °C (from 36 to 28 %) and dramatically at 24 °C (from 36 to 8 %) when compared to EE at 75 % RH. For 9 % PVA emulsions, the global EE was higher than for the electrospinning feeds based on 6 % PVA. For 9 % PVA emulsions, at low temperature (8 and 16 °C) and low humidity (55 and 65 %) no significant difference between the encapsulation efficiencies was observed. The highest EE was of (67 ± 6) % at 16 °C and 55 % RH. At 75 % RH, the EE decreased with the temperature from (57 ± 7) % at 8 °C, down to (46 ± 7) % at 16 °C and finally to (26 ± 10) % at 24 °C. At 85 % RH, the EE also decreased with increasing temperature, the lowest one being 2 % at 24 °C.

Temperature, when decreased, was expected to decrease the limonene vapor pressure which would lead to higher EE. However, for 6 % PVA/limonene emulsions in most of the conditions investigated, this effect was overcompensated by the reduced solvent evaporation rate of the continuous phase. The PVA remained hydrated for longer time during fiber formation, which led to a higher drawing of the polymer jet as well as an increase in the PVA matrix permeability, thus increasing the evaporation rate of the fragrance. Indeed, EVOH copolymers permeability to limonene is increased, when relative humidity is increased from 75 to 100 % RH [19]. These results were also supported by the observations of the effect of the relative humidity on the fiber morphologies (Figs. 2, 9) and on the EE (Fig. 7). Low relative humidity allowed the rapid drying of the polymer jet by enhancing the solvent evaporation and led to better encapsulation efficiencies.

For 9 % PVA emulsions spun at 75 and 85 % RH, an opposing trend was observed. The EE decreased dramatically with increasing temperature. As we pointed out previously, at high relative humidity the instabilities in the jet prevailed, and some fibers were re-dissolved in the residual solvent still present upon arriving on the collector. The fibers contained a similar amount of solvent and thus the decreased volatility of limonene led to a more efficient encapsulation at low temperatures.

To this end, both temperature and relative humidity are influencing factors when looking at morphological properties and EE of fibers derived from emulsion electrospinning.

Conclusion

The electrospinning of emulsions of PVA in water and limonene or hexadecane allowed the formation of bi-component nanofibers and beads encapsulating hydrophobic liquids. When the polymer content of the emulsion was increased, the fibers spun became more cylindrical and the fragrance EE increased. However, switching from limonene to hexadecane in the dispersed phase did not substantially modify the fiber morphology. Relative humidity while electrospinning was the most influencing parameter on both fiber morphology and EE. Indeed, the PVA shell was permeable to limonene since it remained hydrated at high relative humidity. When the polymer concentration was relatively high (9 %), higher electrospinning temperature led to lower encapsulation efficiencies. The contrary was observed when using 6 % polymer at a relative humidity of 55 or 65 % RH. This information is particularly relevant for further work on emulsion electrospinning. Specifically, it should be mentioned that the polymer permeability to the encapsulated compound according to relative humidity should be studied before starting emulsion electrospinning for encapsulation purposes, especially if the component encapsulated is itself influenced by either temperature or humidity. We show, that by use of emulsion electrospinning procedures, both additives with high and low volatility can be embedded within electrospun beaded fibers.

References

Sill TJ, von Recum HA (2008) Electrospinning: applications in drug delivery and tissue engineering. Biomaterials 29(13):1989–2006. doi:10.1016/j.biomaterials.2008.01.011

Zhang L, Aboagye A, Kelkar A, Lai C, Fong H (2014) A review: carbon nanofibers from electrospun polyacrylonitrile and their applications. J Mater Sci 49(2):463–480. doi:10.1007/s10853-013-7705-y

Guex AG, Birrer DL, Fortunato G, Tevaearai HT, Giraud MN (2013) Anisotropically oriented electrospun matrices with an imprinted periodic micropattern: a new scaffold for engineered muscle constructs. Biomed Mater 8(2):021001. doi:10.1088/1748-6041/8/2/021001

Guex AG, Kocher FM, Fortunato G, Korner E, Hegemann D, Carrel TP, Tevaearai HT, Giraud MN (2012) Fine-tuning of substrate architecture and surface chemistry promotes muscle tissue development. Acta Biomater 8(4):1481–1489. doi:10.1016/j.actbio.2011.12.033

Gautam S, Chou C-F, Dinda A, Potdar P, Mishra N (2014) Fabrication and characterization of PCL/gelatin/chitosan ternary nanofibrous composite scaffold for tissue engineering applications. J Mater Sci 49(3):1076–1089. doi:10.1007/s10853-013-7785-8

Yan J, White K, Yu D-G, Zhao X-Y (2014) Sustained-release multiple-component cellulose acetate nanofibers fabricated using a modified coaxial electrospinning process. J Mater Sci 49(2):538–547. doi:10.1007/s10853-013-7733-7

Tripatanasuwan S, Zhong Z, Reneker DH (2007) Effect of evaporation and solidification of the charged jet in electrospinning of poly(ethylene oxide) aqueous solution. Polymer 48(19):5742–5746. doi:10.1016/j.polymer.2007.07.045

Wang C, Chien HS, Hsu CH, Wang YC, Wang CT, Lu HA (2007) Electrospinning of polyacrylonitrile solutions at elevated temperatures. Macromolecules 40(22):7973–7983. doi:10.1021/ma070508n

Mattoso LHC, Offeman RD, Wood DF, Orts WJ, Medeiros ES (2008) Effect of relative humidity on the morphology of electrospun polymer fibers. Can J Chem 86(6):590–599. doi:10.1139/v08-029

De Vrieze S, Van Camp T, Nelvig A, Hagstrom B, Westbroek P, De Clerck K (2009) The effect of temperature and humidity on electrospinning. J Mater Sci 44(5):1357–1362. doi:10.1007/s10853-008-3010-6

Hardick O, Stevens B, Bracewell DG (2011) Nanofibre fabrication in a temperature and humidity controlled environment for improved fibre consistency. J Mater Sci 46(11):3890–3898. doi:10.1007/s10853-011-5310-5

Rodoplu D, Mutlu M (2012) Effects of electrospinning setup and process parameters on nanofiber morphology intended for the modification of quartz crystal microbalance surfaces. J Eng Fibers Fabr 7(2):118–123

Pelipenko J, Kristl J, Jankovic B, Baumgartner S, Kocbek P (2013) The impact of relative humidity during electrospinning on the morphology and mechanical properties of nanofibers. Int J Pharm 456(1):125–134. doi:10.1016/j.ijpharm.2013.07.078

Kim CH, Jung YH, Kim HY, Lee DR, Dharmaraj N, Choi KE (2006) Effect of collector temperature on the porous structure of electrospun fibers. Macromol Res 14(1):59–65

Agarwal S, Greiner A (2011) On the way to clean and safe electrospinning-green electrospinning: emulsion and suspension electrospinning. Polym Adv Technol 22(3):372–378. doi:10.1002/pat.1883

Camerlo A, Vebert-Nardin C, Rossi RM, Popa AM (2013) Fragrance encapsulation in polymeric matrices by emulsion electrospinning. Eur Polym J 49(12):3806–3813. doi:10.1016/j.eurpolymj.2013.08.028

Crespy D, Friedemann K, Popa AM (2012) Colloid-electrospinning: fabrication of multicompartment nanofibers by the electrospinning of organic or/and inorganic dispersions and emulsions. Macromol Rapid Commun. doi:10.1002/marc.201200549

Fong H, Chun I, Reneker DH (1999) Beaded nanofibers formed during electrospinning. Polymer 40(16):4585–4592. doi:10.1016/s0032-3861(99)00068-3

Zhang Z, Lim L-T, Tung MA (2001) Limonene transport and mechanical properties of EVOH and nylon 6,6 films as influenced by RH. J Appl Polym Sci 79(11):1949–1957. doi:10.1002/1097-4628(20010314)79:11<1949:aid-app1002>3.0.co;2-f

Jyothi NVN, Prasanna PM, Sakarkar SN, Prabha KS, Ramaiah PS, Srawan GY (2010) Microencapsulation techniques, factors influencing encapsulation efficiency. J Microencapsul 27(3):187–197

Acknowledgements

The authors would like to thank Karl Kehl and Elisabeth Michel for their help during GC measurements and Dr Patrick Rupper for his advices concerning SEM analysis.

Conflict of interest

The authors declare no competing financial interest. This work was not financially supported.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Camerlo, A., Bühlmann-Popa, AM., Vebert-Nardin, C. et al. Environmentally controlled emulsion electrospinning for the encapsulation of temperature-sensitive compounds. J Mater Sci 49, 8154–8162 (2014). https://doi.org/10.1007/s10853-014-8524-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-014-8524-5