Abstract

In the present study, we have fabricated a ternary composite nanofibrous scaffold from PCL/gelatin/chitosan, by electrospinning technique, using a solvent system—chloroform/methanol for polycaprolactone (PCL) and acetic acid for gelatin and chitosan, for tissue engineering applications. Field emission scanning electron microscopy (FE-SEM) was used to investigate the fiber morphology of the scaffold and it was found that the fiber morphology was influenced by the concentrations of PCL, gelatin, and chitosan in polymer solution during electrospinning. X-ray diffraction, Fourier transform infrared, and thermogravimetric (TG) analysis results showed some interactions among the molecules of PCL, gelatin, and chitosan within the scaffold. In-vitro cell culture studies were done by seeding L929 mouse fibroblasts on fabricated composite scaffold, which confirmed the cell viability, high cell proliferation rate, and cell adhesion on composite scaffold as indicated by MTT assay, DNA quantification, and FE-SEM analysis of cell-scaffold construct. Thus, the ternary composite scaffold made from the combination of PCL (synthetic polymer), gelatin, and chitosan (natural polymer) may find potential application in tissue engineering.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Tissue engineering, an application of biological science and engineering to regenerate biological substitutes for repairing/replacing damage organ or tissue [1–4] involves three important components: cells, scaffold (3D polymeric matrix), and growth factors. Among these three components, scaffold is one of the most important factors which interact with the cells and growth factors to regenerate a specific tissue [5, 6]. For successful application, the scaffold should have some desired characteristics, e.g., it should be biocompatible, biodegradable, and the degradation rate of scaffold should be closely similar to the rate of native tissue regeneration to promote proper tissue growth [7]. Further, it should mimic the morphological structure and chemical composition of extra cellular matrix (ECM), so that cells can adhere to the scaffold surface, proliferate, and differentiate into new tissue [4]. A scaffold, if prepared from a single polymer, cannot impart all these desired properties, but by taking two or more polymers in combination, it is possible to tailor a scaffold with the desired characteristics [8, 9]. Various polymers have been employed for scaffold fabrication [8, 10–21]. Among these, Polycaprolactone (PCL), a linear, hydrophobic, synthetic polymer, has been widely used in tissue engineering for its good mechanical properties [8, 22]. Though PCL has good mechanical strength it, however, shows poor cell adhesion [22–24] and slow biodegradation rate [24, 25]. Another widely used polymer is gelatin, which is a biocompatible, biodegradable, natural polymer derived from collagen by hydrolysis, and it has almost identical composition of collagen, [26, 27] a major component of native ECM. Gelatin has excellent cell adhesion, proliferation, and differentiation properties [28], but it shows low mechanical strength [29–31] and high degradation rate [32], which is not suitable for tissue engineering application. Chitosan, another polymer, is a biocompatible and biodegradable natural polysaccharide derived from chitin which contains glucosamine and N-acetylglucosamine that is structurally similar to glycosaminoglycans—a major component of native ECM [33–35]. Chitosan shows good cell adhesion, proliferation, and antimicrobial properties [12], but, similar to gelatin, it also shows low mechanical strength [29, 30] and high degradation rate [12].

To combine the beneficial properties of PCL and gelatin, PCL/gelatin composite scaffold had been fabricated by several scientists [8, 36–38], which showed good mechanical properties as well as good cell adhesion and proliferation. Similarly, to combine the advantageous properties of PCL and chitosan, PCL/chitosan composite scaffold had been fabricated by Cooper et al. [39] and Prabhakaran and coworkers [36] which also showed high mechanical strength and good cell adhesion properties. Though PCL/gelatin and PCL/chitosan composite scaffold had been fabricated, however, to the best of our knowledge, there is no work on fabrication of ternary PCL/gelatin/chitosan electrospun composite scaffold, which might give good cell adhesion and proliferation properties along with high mechanical strength and controllable degradation rate: in addition, this scaffold, due to the synergetic effect of these three polymers, might give various chemical cues which may trigger the cells to regenerate in various kind of tissues.

Tissue engineering scaffold can be fabricated by various methods, e.g., “foaming” [22, 40, 41], “solvent casting and particulate leaching” [42], “phase separation” [43], “solid free form fabrication technique” [44], and “electrospinning” [45]. Electrospinning is one of the simplest technique which produces nanofibers continuously [46, 47]. Native ECM in our body is mainly composed of polymeric nanofibers: thus nanofibrous scaffold fabricated by electrospinning would mimic morphological structure of ECM [48].

In this study, we aim to fabricate a ternary PCL/gelatin/chitosan nanofibrous composite scaffold by electrospinning, which might be used as one of the ideal scaffold for tissue engineering applications.

Materials and methods

Materials

PCL pellets (M w = 80000), gelatin (type B, from bovine skin), and Chitosan (degree of deacetylation ≥75 %) powder were purchased from Sigma-Aldrich (St. Louis, MO). Chloroform and methanol were procured from Fisher Scientific, Mumbai, India. Glacial acetic acid was purchased from Qualigens Fine Chemical, Mumbai, India. 3-(4,5-dimethylthiazol-2-yl-2, 5-diphenyltetrazolium bromide) (MTT), phosphate buffer saline (PBS) and Dulbecco’s modified eagle medium (DMEM) were procured from Hi-media (Mumbai, India). Fetal bovine serum was obtained from Hyclone, USA L929 mouse fibroblast cell line was procured from NCCS, Pune, India.

Preparation of PCL/gelatin/chitosan solutions

PCL (20 wt%) solution was prepared in chloroform/methanol (3:1, v/v) solvent mixture by agitating at 600 rpm for 2 h, and gelatin (8 wt%) was dissolved in acetic acid (80 % v/v) by stirring the mixture at 500 rpm for 3 h. Similarly, chitosan solution (1 wt%) was prepared in acetic acid (2 % v/v) at 500 rpm for 2 h. All the polymeric solutions have been prepared at room temperature (26 ± 1 °C). After the preparation of all polymeric solutions, PCL, gelatin, and chitosan were mixed in volume ratio of (PCL/gelatin/chitosan) 0:50:50, 20:40:40, 40:30:30, 60:20:20, 80:10:10, and 100:0:0, respectively and incubated for 72 h. After 72 h of incubation, gelatin and chitosan solutions were uniformly dispersed in PCL solution whereby an immiscible polymer blend of PCL/gelatin/chitosan was obtained, which was used for electrospinning.

Electrospinning of PCL/gelatin/chitosan composite scaffold

Nanofibrous scaffold from PCL/gelatin/chitosan were fabricated by using electrospinning technique, the technical details of which are discussed in the previous literature [49]. For electrospinning process, polymer blend of PCL/gelatin/chitosan solution was filled in a 3 mL plastic syringe which is fitted with a needle with tip diameter of 0.56 mm. The flow rate of polymer solution was controlled at 0.1 mL/h by a syringe pump (Model 11 Plus, Harvard Apparatus). A high voltage of 22 kV was applied at the tip of the needle, and a distance of 10 cm between needle and collector was maintained throughout the electrospinning process. Nanofibers were collected on a flat aluminum plate with the dimension of 1.5 cm × 1.5 cm × 1 mm. The electrospinning process was carried out at 25 ± 1 °C (room temperature), and humidity was maintained at 45 % throughout the process.

Characterization of PCL/gelatin/chitosan composite scaffold

The morphology of PCL/gelatin/chitosan composite scaffold was determined by FE-SEM (Quanta 200F Model, FEI, Netherland) which is equipped with field-gun at an accelerating voltage of 15 kV. Before imaging, PCL/gelatin/chitosan scaffolds were coated with gold for 30 min using a sputter coater (Biotech SC005, Switzerland). Fiber diameters of ternary composite scaffold were studied on the basis of FE-SEM images at 5000× magnification. Five images were used for each sample and form each image, ~10 different fibers at 100 different locations were randomly selected, and then average fiber diameter was calculated by following the protocol of Yang et al. [50] using image analysis software (Image J, NIH, USA). The pore size of fabricated ternary composite scaffold was determined by Image J, and furthermore, the cell morphology of L929 mouse fibroblasts on ternary composite scaffold was also quantified by Image J.

XRD, TGA, derivative TG (DTG), and FT-IR analysis were performed for characterization of ternary composite scaffold. The experiments were also performed simultaneously by taking components of scaffold i.e., PCL pellets, gelatin, and chitosan powder to observe any possible interaction among the molecules of PCL, gelatin, and chitosan in fabricated composite scaffold. XRD patterns were determined by X-ray diffractometer (Bucker, AXS D8 Advance diffractometer), using Cu at 40 kV anode and 30 mA with 2θ values ranging from 5 to 40°. Thermogravimetric (TG) analysis was recorded by TGA (EXSTAR, TG/DTA 6300) to determine the thermal degradation of composite scaffold and its components. For TGA, each sample (4.0 mg) was run at the temperature ranging from 22 to 700 °C at a scanning rate of 30 °C/min under a nitrogen atmosphere. Chemical analysis of all components were performed by using thermo nicolet FT-IR (Nexus, USA) spectroscopy over a range between 4000 and 500 cm−1.

In-vitro degradation of composite scaffold

Nanofibrous PCL/gelatin/chitosan composite scaffolds were cut into 1 cm × 1 cm × 1 mm pieces and then weighed for degradation study. Each scaffold (25 mg) was incubated with 2 ml PBS (pH 7.4) containing 0.2 % sodium azide as a bacteriostatic agent in 12-well tissue culture plate at 37 °C for 8 weeks. The scaffolds have been taken in triplicates for study. At different time intervals, scaffolds were removed from culture plate and then rinsed three times with distilled water and dried at room temperature for 24 h. The PBS was changed every week, and weight loss (%) of each scaffold was determined as follow:

where W 0 denotes the initial weight of scaffold in its dry state before immerse in PBS and W t denotes the weight of the degraded scaffold at different time intervals.

In-vitro cell culture studies of L929 mouse fibroblasts on PCL/gelatin/chitosan composite scaffold

Cell viability assay

MTT was performed to study the cell viability of L929 mouse fibroblast cells on PCL, PCL/gelatin, and PCL/gelatin/chitosan composite scaffold for 1, 3, and 5 days of cell culture. MTT assay determines the ability of mitochondrial dehydrogenases enzymes of living cells to oxidize a tetrazolium salt (3-[4,5-dimethylthiazolyl-2-y]-2,5-diphenyltetrazolium bromide) into an insoluble purple formazan product. The concentration of the purple formazan product is directly proportional to the number of metabolically active cells [38]. L929 mouse fibroblast cell line was maintained in DMEM with 10 % FBS, penicillin (100 U/mL) and streptomycin (100 μg/mL) at 37 °C in a 5 % CO2 incubator (BINDER, Germany). All scaffolds were cut into 5 × 5 × 1 mm3 dimension and then sterilized with UV light for 30 min both side each. Sterilized scaffolds were placed in the 96-well plate in triplicate and incubated with DMEM overnight to make scaffold surface more efficient for cell adhesion. The next day, L929 cell suspension (in DMEM media) at a density of 5 × 103 cells/well (200-μL volume) was added in each well and incubated for 1, 3, and 5 days time period along with control i.e., cells (L929) were incubated in DMEM media without scaffold. After incubation period, the media was removed from the wells and then freshly prepared 90 μL of complete DMEM media was added in each well. Then 10 μL of MTT solution (5 mg/mL stock in 1 × PBS) was added in each well to make final volume 100 μL. The plate was placed in 5 % CO2 incubator at 37 °C for 4 h until purple color formazan crystals were formed in the culture media due to reduction of MTT salt by viable cells. The media was discarded and 200 μL of dimethyl sulphoxide (DMSO) was added to each well, and mixed properly to dissolve the formazan crystals. After removing the scaffolds from each well, the absorbance was taken using Microplate Reader Model Sunrise (TECAN, India) at 490 nm with the subtraction for plate absorbance at 650 nm.

Cell proliferation study on composite scaffold

DNA quantification was performed to study the cell proliferation on PCL, PCL/gelatin, and PCL/gelatin/chitosan composite scaffold. After sterilization, the composite scaffolds (5 × 5 × 1 mm3) were placed in 96-wells plate and soaked with 100 μL DMEM media overnight at 37 °C to make scaffolds surface more efficient for cell attachment before cell seeding. The next day, scaffolds were incubated with L929 mouse fibroblast cells (5 × 103 cells/well) in DMEM for 1, 3, and 5 days at 37 °C in 5 % CO2 incubator. After the incubation period, all scaffolds were rinsed with PBS, and then the total DNA from the cells was isolated by alkaline lysis method [51]. NanoDrop 1000, spectrophotometer (Thermofisher, USA) was used to calculate the total DNA amount at the absorbance 260 nm.

Cell morphology studies on composite nanofibrous scaffolds

Morphological characteristics and cell adhesion of L929 mouse fibroblasts on PCL/gelatin/chitosan ternary composite scaffolds were determined by FE-SEM analysis. Sterilized PCL/gelatin/chitosan composite scaffolds (5 × 5 × 1 mm3) were placed in 96-wells plate and soaked with 100 μL DMEM media overnight at 37 °C in CO2 incubator. The next day, after PBS washing, ternary composite scaffolds were incubated with L929 mouse fibroblasts at a density of 5 × 103 cells/well for 1, 3, and 5 days. Following incubation period, PCL/gelatin/chitosan scaffolds were rinsed three times with PBS and fixed with 2.5 % glutaraldehyde for 6 h at 4 °C. Next, scaffolds were dehydrated with gradient concentration of ethanol (50, 70, 95, and 100 %) for 30 min each at 4 °C. Finally, the PCL/gelatin/chitosan scaffolds were air-dried overnight and analyzed by FE-SEM to study the morphology of attached cell on PCL/gelatin/chitosan composite scaffold.

Statistical analysis

The experimental results were represented as mean values with ±standard deviations. The two-way analysis of variation was also employed to determine the difference between the various scaffolds in cell proliferation assay. A p value of <0.05 (p < 0.05) was considered to be of significant difference and a p value of >0.05 (p > 0.05) is considered for insignificant difference between the scaffolds.

Results and discussion

Morphology of PCL/gelatin/chitosan composite nanofibrous scaffold

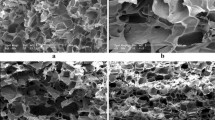

Composite PCL/gelatin/chitosan nanofibrous scaffold was fabricated by electrospinning method. To produce bead-free smooth fibers, it was varied different parameters such as applied voltage, distance between needle (spinneret) and collector, flow rate of polymer solution, and PCL/gelatin/chitosan ratio in the solution. It has been observed that the morphology of the electrospun nanofiber depends on the above-mentioned parameters. These parameters were optimized to get bead-free smooth fibers, and the optimized values of these parameters were used to fabricate the nanofibrous scaffold that had been characterized for cell viability, degradation, etc. Here, we will discuss only the influence of the weight ratio of PCL/gelatin/chitosan on fiber morphology, as it has provided the interesting results. Different fiber morphology and fiber diameter obtained at different ratio of PCL, gelatin, and chitosan, have been described in Table 1. FE-SEM images (Fig. 1) showed different fiber morphology of PCL/gelatin/chitosan composite scaffold at different ratio of PCL, gelatin, and chitosan. It has been observed (from FE-SEM images) that fiber morphology changed gradually from beaded structure to smooth fiber on increasing the concentration of PCL in solution and on decreasing the concentrations of gelatin and chitosan. For PCL/gelatin/chitosan ratio 0:50:50 (v/v) in solution [PCL (20 wt% solution)/gelatin (8 wt% solution)/chitosan (1 wt% solution)], only beads were formed without any fiber structure (Fig. 1a); whereas bead-free smooth nanofibers were formed at 80:10:10 ratio of PCL/gelatin/chitosan (in solution) (Fig. 1e).

Fiber morphology of electrospun PCL/gelatin/chitosan composite nanofibrous scaffold with different PCL (20 wt%)/gelatin (8 wt%)/chitosan (1 wt%) ratio (v/v): a 0:50:50, b 20:40:40, c 40:30:30, d 60:20:20, e 80:10:10, f 100:0:0. Beaded structure was converted into fiber morphology by increasing the concentration of PCL in electrospinning solution

Smooth nanofibers were also formed when gelatin and chitosan were totally removed from the solution, and only PCL (20 wt%) solution (PCL/gelatin/chitosan in 100:0:0 ratio) was used for electrospinning, but in this condition, larger fiber diameter was obtained. Thus, the concentration of PCL, gelatin, and chitosan, is one of the factors to control the fiber morphology and fiber diameter (Fig. 1).

In this study, fiber morphology was gradually converted from beaded structure to the smooth fiber morphology by decreasing the concentrations of ionic polymers (gelatin and chitosan). The reason for changes in fiber morphology is discussed in the following. PCL is a nonionic synthetic polymer and it does not produce any ions in the solution when it is dissolved in chloroform/methanol (3:1 v/v) solvent mixture, but gelatin and chitosan are ionic polymers having different ionizable groups [23]. Gelatin possesses amino and carboxylic (–NH2 and –COOH) groups, and chitosan possesses amino and hydroxyl (–NH2 and –OH) groups. Ionic groups are generally ionized under acidic condition or at neutral pH [8]. So when these polymers are dissolved in acetic acid, they are ionized and produces charge in the solution. Initially, PCL/gelatin/chitosan was used in ratio 0:50:50 for electrospinning. In this condition, only ionic polymers, gelatin, and chitosan were present at high concentrations [4 % gelatin and 0.5 % chitosan (w/v)] in the electrospinning solution, and on application of high electric field, a high charge density is produced on the surface of the polymer-jet ejected from the tip of the syringe-needle during electrospinning [23, 52]. High charge density generates a very high repulsive force between the ionic groups within the polymer backbone and it is expected that this high repulsive force favor to explode the polymer jet into small droplets on the collection target (Fig. 1a). On decreasing the concentrations of gelatin and chitosan in PCL/gelatin/chitosan solution, the repulsive force will also be decreased, which subsequently will prevent the drop formation and will favor fiber formation. And, when the concentrations of PCL/gelatin/chitosan (ratio 80:10:10) fixed at 16, 0.8, and 0.1 % in solution, respectively, there is no bead formation, but smooth fiber was formed (Fig. 1e). Therefore, this scaffold has been used for further characterization (Fig. 1e). Besides fiber morphology, fiber diameter is also influenced by the concentrations of PCL, gelatin and chitosan in the solution. The fiber diameter increased gradually from 230 ± 171 to 1403 ± 660 nm by decreasing the concentrations of gelatin and chitosan or increasing the concentration of PCL in the solution as shown in Fig. 1 and Table 1. In earlier studies also, it has been reported that the addition of ionic polymers would increase the conductivity of polymer solution which favors the formation of lower diameter fiber [23, 53]. Here, gelatin and chitosan are ionic polymers, and the presence of high concentrations of gelatin and chitosan would increase charge density inside the solution which consecutively will increase the charge–charge repulsion: this charge–charge repulsion will act in the direction opposite to the surface tension force and thereby influence the formation of low diameter fibers.

The fiber diameter and pore size of the composite scaffold [PCL (20 wt%)/gelatin (8 wt%)/chitosan (1 wt%) mixed at 80:10:10 (v/v) ratio] were found to be 663 ± 151 nm and 6.6 ± 1.9 μm, respectively (Fig. 1e). Fiber diameter [54] and pore size [55] both are important factors for the growth of fibroblast cells over the scaffold. In 2008, Kumbar et al. [54] observed that the proliferation of human skin fibroblasts was influenced by the fiber diameter, and found well spread morphology of fibroblasts on the nanofibrous scaffold within the fiber diameter range of 250–1,200 nm. Pore size is another important factor for cell proliferation as it influences cell migration inside the scaffold and also aids in efficient exchange of nutrients and metabolic waste between the scaffold and its environment [50]. PCL/gelatin/chitosan showed an average pore size of 6.6 ± 1.9 μm (ranging from 3.6 to 10.6 μm), which is larger than the lower cutoff limit (<5 μm) described for fibroblast penetration and migration [56–58]. Thus our fabricated scaffold is suitable for fibroblast growth and proliferation.

X-ray diffraction

Figure 2 represents X-ray diffraction of PCL, gelatin, chitosan, and PCL/gelatin/chitosan composite scaffolds. PCL demonstrated two sharp peaks at 2θ = 21.3° and 23.6° position which confirmed the crystalline nature of PCL [59]. Gelatin demonstrated a broader peak at 2θ = 20° which indicated amorphous nature of gelatin [60]. Chitosan exhibited two diffraction peaks at 2θ = 10.1° and 20.1° with low intensity—suggesting the semi-crystalline nature of chitosan [61]. PCL/gelatin/chitosan composite scaffold shows only the characteristic peaks of PCL with low intensity (Fig. 2) that proposed the crystalline nature of the composite scaffold. The decreased intensity of PCL peaks indicated reduction in the degree of crystallinity of the composite scaffold due to the incorporation of amorphous gelatin and semi-crystalline chitosan in PCL solution, which implies some interactions among the molecules of PCL, gelatin, and chitosan. These results indicated that there might be some interactions among the molecules of PCL, gelatin, and chitosan in PCL/gelatin/chitosan scaffold.

XRD patterns of a PCL, b gelatin, c chitosan, and d PCL/gelatin/chitosan composite scaffold [PCL (20 wt% in chloroform/methanol; 3:1 v/v)/gelatin (8 wt% in 80 % acetic acid)/chitosan (1 wt% in 2 % acetic acid) mixed at 80:10:10 (v/v) ratio]. PCL/gelatin/chitosan composite scaffold showed crystalline nature due to the presence of high proportion of crystalline PCL

Thermogravimetric (TG) analysis

TG analysis (Fig. 3) was performed to analyze the thermal degradation of PCL, gelatin, chitosan, and PCL/gelatin/chitosan composite scaffold. PCL showed a single stage thermal degradation which started at 376 °C and completed at around 460 °C which is comparable to other studies [62]. The weight loss of PCL was found to be around 88 % between 376 and 480 °C. Gelatin decomposition was recorded in two stages. The first stage has been found in between 50 and 220 °C, which is related to the loss of absorbed and bound water. The second stage was found in between 250 and 680 °C, which is associated with protein chain breakage and peptide bond rupture, [63–65]. Approximately 77 % of gelatin was degraded between these two stages. Similarly, chitosan also showed thermal degradation in two stages. The first stage was found in between 30 and 110 °C, which is related with initial weight loss due to moisture vapourization. The second stage of thermal degradation of chitosan found in the range of 280–650 °C is the main thermal degradation region which comprises dehydration of the saccharide rings of chitosan—leading to decomposition of chitosan backbone [66]. Chitosan was decomposed at around 98 % between these two stages. PCL/gelatin/chitosan composite scaffold showed a single stage thermal degradation (Fig. 3a), started at 350 °C and almost completed at 500 °C—showing 92 % degradation.

The derivatives of weight loss for PCL, gelatin, chitosan, and PCL/gelatin/chitosan composite scaffold are shown in Fig. 3(b). Each peak in Fig. 3(b) represents the T max which corresponds to the maximum degradation rate at that particular temperature. In derivative thermo-gravimetric (DTG) analysis, gelatin and chitosan both exhibit two peaks: gelatin shows the maximum degradation rate at 194 and 331 °C, while chitosan at 69 °C and 300 °C. PCL and PCL/gelatin/chitosan composite scaffold reveal only single peak of fast thermal degradation at 432 °C in PCL, whereas this peak is found at 413 °C at PCL/gelatin/chitosan composite scaffold. T max and maximum degradation rate of PCL, gelatin, chitosan, and PCL/gelatin/chitosan composite scaffold have been shown in Table 2.

The PCL/gelatin/chitosan composite scaffold showed higher T max compared with gelatin and chitosan. According to Lewandowska [67], if the measured lower T max of one component shifts toward the higher T max of another component then it shows various interactions between these two components. In PCL/gelatin/chitosan composite scaffold, lower T max values of gelatin and chitosan have shifted toward the higher T max of PCL that indicates some interactions among the molecules of PCL, gelatin, and chitosan. Thus, TGA and DTG supported the results of XRD which indicated the interactions among PCL, gelatin, and chitosan in PCL/gelatin/chitosan composite scaffold.

Fourier transform infrared (FT-IR) analysis

FT-IR spectroscopy was performed to characterize the functional groups of PCL, gelatin, chitosan, and PCL/gelatin/chitosan composite scaffold (Fig. 4). Several characteristic bands of PCL were found at 2949 cm−1 (asymmetric –CH2 stretching), 2865 cm−1 (symmetric –CH2 stretching), 1726 cm−1 (carbonyl stretching), 1293 cm−1 (C–O and C–C stretching), 1240 cm−1 (asymmetric C–O–C stretching), and 1170 cm−1 (symmetric C–O–C stretching): similar results were obtained by other researchers also [37, 68]. The IR spectrum of gelatin exhibited the characteristic bands at 3443 cm−1 due to N–H stretching of amide bond, C=O stretching at 1640 cm−1 (amide I), N–H bending at 1543 cm−1 (amide II), and N–H out-of-plane wagging at 670 cm−1. Lim et al. [37] and Meskinfam et al. [69] also found the similar results in IR spectrum of gelatin. The IR spectrum of chitosan confirms the presence of –OH and –NH stretching vibration at 3442 cm−1, in which the –OH stretching vibration is overlapped by –NH stretching. The absorption of C–H stretching of methylene group of chitosan is at 2921 cm−1. The peak at 1641 cm−1 corresponds to C=O stretching of primary amide. The C–O–C, C–O, and C–OH bending were visible at 1156 cm−1. The C–H bending was seen at 1378 cm−1: similar results were obtained in our earlier study [5]. In PCL/gelatin/chitosan composite scaffold, all the characteristic bands of PCL, gelatin, and chitosan are observed, but shifted toward the lower wave numbers. IR spectrum of PCL/gelatin/chitosan composite scaffold showed two absorption bands at 1723 and 1245 cm−1 corresponding to the characteristic peak of PCL originally situated at 1727 and 1291 cm−1: thus there is a measurable shift of the peaks toward relatively lower wave numbers. Besides this, the C=O stretching of primary amide in gelatin at 1640 cm−1 and in chitosan at 1641 cm−1 also shifted toward the lower wave number in PCL/gelatin/chitosan scaffold and became visible at 1632 cm−1. A characteristic band of –OH stretching is seen at 3439 cm−1 in the IR spectrum of PCL/gelatin/chitosan scaffold. Thus, shifting of original absorption bands toward the lower wave numbers and the appearance of –OH band in composite scaffold indicates that there are some interactions among the amino, carbonyl, and hydroxyl groups of these components. These interactions may arise from hydrogen bonding which possibly formed among amino groups of gelatin, hydroxyl groups of chitosan, and carbonyl groups of PCL in PCL/gelatin/chitosan composite scaffold: it was not found any new bond formation in the IR spectrum of composite scaffold. The possible chemical reaction among PCL, chitosan, and gelatin [23, 70] in composite scaffold has been shown in Fig. 5.

In-vitro degradation of composite scaffold

The fiber morphologies of degraded PCL/gelatin/chitosan composite scaffold at different time intervals have been shown in Fig. 6. After 1 week of incubation in PBS, most of the fibers of PCL/gelatin/chitosan composite scaffold were swollen (Fig. 6a) compared with the original fiber morphology shown in Fig. 1e. This might be owing to chain relaxation of polymer matrix after incubation in PBS solution [71]. After 2 weeks of incubation period, fibers of PCL/gelatin/chitosan scaffold started to degrade and collapse to each other which increased by increasing the incubation period. After 8 weeks of incubation period, almost all the fibers of composite scaffold were found to be collapsed with each other compared with original PCL/gelatin/chitosan composite scaffold (Fig. 6h).

Morphology of degraded PCL/gelatin/chitosan composite scaffold at different time intervals; a after 1 week, b after 2 weeks, c after 3 weeks, d after 4 weeks, e after 5 weeks, f after 6 weeks, g after 7 weeks, h after 8 weeks at 20000× magnification. Gelatin and chitosan (fast degrading as compare to PCL) were released from the fibrous structure after incubation in PBS, which developed collapse morphology

Gravimetric analysis of weight loss of degraded PCL/gelatin/chitosan composite scaffold along with PCL/gelatin and PCL scaffold is depicted in Fig. 7. After 1 week of incubation period, all the scaffolds showed negligible weight loss. After 2 weeks of incubation, PCL/gelatin/chitosan and PCL/gelatin scaffold exhibited slightly fast degradation compared with PCL scaffold, and the same pattern is continued up to 5 weeks. The weight losses were found to be 3.1, 4.8, and 2.2 % for PCL/gelatin/chitosan, PCL/gelatin, and PCL scaffold, respectively, after 5 weeks of incubation. The fast degradation of PCL/gelatin/chitosan and PCL/gelatin scaffold compared with the PCL scaffold might be owing to the presence of hydrophilic gelatin and chitosan in PCL/gelatin/chitosan scaffold, and gelatin in PCL/gelatin scaffold. After 5 weeks of incubation period, PCL/gelatin/chitosan scaffold revealed a slightly decrease in weight degradation compared with the PCL/gelatin scaffold which showed a continuous decrease in weight loss up to 8 weeks. After 8 weeks, the weight losses of PCL/gelatin/chitosan scaffold, PCL/gelatin, and PCL scaffold were found to be 4, 5.7, and 3.4 %, respectively. The higher degradation rate of PCL/gelatin scaffold compared with PCL/gelatin/chitosan composite scaffold may be explained as follows. In PCL/gelatin scaffold, PCL is a crystalline polymer and gelatin is an amorphous polymer, but in PCL/gelatin/chitosan composite scaffold, chitosan is also present, which has semicrystalline nature. It is well known that during hydrolytic degradation of a scaffold, amorphous region degrades more rapidly than the crystalline region [72, 73]. Thus, because of this semicrystalline nature of chitosan, PCL/gelatin/chitosan composite scaffold exhibits slow degradation rate compared with PCL/gelatin scaffold.

The presence of hydrophilic gelatin and chitosan will increase the adhesion of cells [28] and fast degradation [74, 75] of these polymers will provide the more space for cell migration which ultimately initiates the cell proliferation, and the presence of PCL which show slow degradation rate [25], will provide an intact and rigid shape to the scaffold for cell growth.

In-vitro culture studies of L929 fibroblast on PCL/gelatin/chitosan composite scaffold

Cell viability and proliferation studies

MTT assay was performed to evaluate the viability of L929 mouse fibroblast cells on PCL/gelatin/chitosan composite scaffold for 1, 3, and 5 days as shown in Fig. 8a. MTT assay showed that cells were not only viable on PCL/gelatin/chitosan composite scaffold but also proliferated during cell culturing period. Although, PCL/gelatin scaffold also showed the cell viability and increased cell proliferation rate of L929 mouse fibroblasts during the cell culture period, but PCL/gelatin/chitosan composite scaffold showed the higher cell viability and proliferation rate compared with other substrates (Tissue culture plate, PCL scaffold, and PCL/gelatin scaffold). The high cell viability and proliferation rate of L929 mouse fibroblasts on PCL/gelatin/chitosan composite scaffold might be due to the synergistic effects of the properties of all the three polymers, and this effect may be generated during the scaffold fabrication and through the interactions among the carboxyl group of PCL, amino group of gelatin and hydroxyl group of chitosan. Total DNA content in cell-scaffold construct was estimated by DNA quantification assay after 1, 3 and 5 days and was shown in Fig. 8b. DNA content was increased on PCL/gelatin/chitosan composite scaffold compared with control (Tissue culture plate), PCL, and PCL/gelatin scaffold throughout the culture period. Thus, DNA quantification results confirmed the highest proliferation rate of L929 mouse fibroblast cells on ternary composite scaffold compared with other scaffolds in this experiment: this indicated the suitability of this scaffold for tissue engineering applications.

a MTT assay; b DNA quantification assay of L929 mouse fibroblast cells on tissue culture plate (control), PCL, PCL/gelatin, and PCL/gelatin/chitosan composite scaffold [PCL (20 wt% in chloroform/methanol; 3:1 v/v)/gelatin (8 wt% in 80 % acetic acid)/chitosan (1 wt% in 2 % acetic acid) mixed at 80:10:10 (v/v) ratio] after 1, 3 and 5 days of cell seeding. Here, absorbance is directly proportional to the viability of L929 mouse fibroblasts. Cell proliferation was found the highest on PCL/gelatin/chitosan composite scaffold after 5 days of cell culture. Significant difference between different scaffolds were denoted as * (p < 0.05). (*) unmarked bars show insignificant difference between the scaffolds (p > 0.05)

Cell adhesion and cell morphology on composite scaffold

Cell morphology of L929 mouse fibroblasts on PCL/gelatin/chitosan composite scaffold, after 1, 3, and 5 days, was studied by FE-SEM analysis as shown in Fig. 9. After 1 day of cell seeding (Fig. 9a–c), cells were found in round morphology mostly, but some cells started stretching and spreading over the scaffold. After 3 days of cell seeding (Fig. 9d–f), cell density on the composite scaffold had been increased and the cells had taken its characteristics spindle shape morphology. A similar type of morphology of L929 cells on naofibrous composite scaffold was reported in previous study [23, 76]. After 5 days of cell culturing (Fig. 9g–i), maximum surface of the scaffold was covered by cells which confirmed good cell adhesion and proliferation over the ternary composite scaffold.

Morphology of L929 mouse fibroblast cells on PCL/gelatin/chitosan composite scaffold [PCL (20 wt% in chloroform/methanol; 3:1 v/v)/gelatin (8 wt% in 80 % acetic acid)/chitosan (1 wt% in 2 % acetic acid) mixed at 80:10:10 (v/v) ratio]: a, b, and c after 1 day, d, e, and f after 3 days; g, h, and i after 5 days of cell seeding at 500×, 1000×, and 2000× magnification. L929 mouse fibroblasts covered maximum surface of PCL/gelatin/chitosan composite scaffold after 5 days of incubation

Quantitative analysis, after 1, 3, and 5 days of cell culturing of L929 mouse fibroblasts on ternary composite scaffold, was determined with different parameters such as aspect ratio, circularity, cell area, cell size, and area fraction. Initially, when the cell is circular, magnitude of aspect ratio and circularity is 1, and increase in aspect ratio and decrease in circularity from value 1 represents the elongation of cells [77, 78]. Aspect ratio and circularity have been shown in Fig. 10. After 1 day of cell culturing, aspect ratio had been increased, while circularity had been decreased. After 3 days of cell culturing, further increase in aspect ratio and decrease in circularity have been observed: this exhibited the elongation of fibroblasts, and conversion of these cells into spindle shape morphology from round (circular) shape during this time period. After 5 days of cell culturing, there is only a small change in aspect ratio as well as in circularity: this indicates that L929 mouse fibroblast cells, mostly, gained their characteristic spindle-shaped morphology after 3 days of cell culturing on ternary PCL/gelatin/chitosan composite scaffold and that is why there is almost no variation in aspect ratio and in circularity. Cell area, cell size, and area fraction have been shown in Fig. 11. Cell size (cell length) of L929 mouse fibroblasts was measured as the length of a direct line between two points at the maximal distance on a cell outline [79]. Cell area and cell size both were increased, whereas area fraction was decreased during the cell culture period, which confirmed the proliferation of L929 mouse fibroblast on ternary composite scaffold.

Effect of culturing time period on L929 mouse fibroblast morphology quantified by a aspect ratio and b circularity. FE-SEM images (Fig. 9a, d and g) at 100-μm scale bar are used to quantify the morphology of L929 mouse fibroblasts at 1, 3, and 5 days respectively. (Initially, when the cell is circular, magnitude of aspect ratio and circularity is 1)

Effect of culturing time period on L929 mouse fibroblast morphology quantified by a cell area, b cell size, and c area fraction. FE-SEM images (Fig. 9a, d and g) at 100-μm scale bar are used to quantify the morphology of L929 mouse fibroblasts at 1, 3, and 5 days respectively.

Thus, MTT assay, DNA quantification, and FE-SEM analysis of cell-scaffold construct revealed high cell proliferation, efficient cell adhesion, and well-maintained characteristic cell morphology of L929 on PCL/gelatin/chitosan ternary composite scaffold that confirmed the applicability of this scaffold toward tissue engineering applications.

Conclusions

A ternary composite tissue engineering scaffold has been successfully fabricated by electrospinning method using a new polymer combination of PCL, gelatin, and chitosan. Here, PCL in chloroform/methanol, gelatin, and chitosan in acetic acid, was found to be an excellent and economic polymer–solvent system for tissue engineering applications. PCL, gelatin, and chitosan concentrations in the polymer solution influenced the fiber morphology of the composite scaffold, and bead-free fiber morphology was obtained only when nonionic polymer concentration (PCL) was increased up to 16 %. Chemical interaction among the molecules of PCL, gelatin and chitosan in composite scaffold was indicated by XRD, FT-IR, and TGA. High proliferation rate, excellent cell adhesion, and characteristic fibroblast cell morphology over the scaffold confirmed that the ternary PCL/gelatin/chitosan composite scaffold might be a potential candidate for skin and other tissue engineering applications. The synergistic effects of all the characteristics of the three polymers combined may be the reason to enhance the cell adhesion and proliferation.

References

Parveen S, Krishnakumar K, Sahoo SK (2006) J Stem Cell Regen Med 1:8

Sharma C, Gautam S, Dinda AK, Mishra NC (2011) Adv Mater Lett 2:90

Ikada Y (2006) J R Soc Interface 3:589

Langer R, Vacanti JP (1993) Science 260:920

Sharma C, Dinda AK, Mishra NC (2012) J Appl Polym Sci 127:3228

Ott HC, Matthiesen TS, Goh S-K, Black LD, Kren SM, Netoff TI, Taylor DA (2008) Nat Med 14:213

Sell SA, Wolfe PS, Garg K, McCool JM, Rodriguez IA, Bowlin GL (2010) Polymer 2:522

Zhang Y, Ouyang H, Lim CT, Ramakrishna S, Huang ZM (2005) J Biomed Mater Res B 72:156

Sharma C, Dinda AK, Mishra NC (2012) J Biomater Tissue Eng 2:133

Geng X, Kwon O-H, Jang J (2005) Biomaterials 26:5427

Ohgo K, Zhao C, Kobayashi M, Asakura T (2003) Polymer 44:841

Kong M, Chen XG, Xing K, Park HJ (2010) Inter J Food Microbol 144:51

Kim K, Yu M, Zong X, Chiu J, Fang D, Seo Y-S, Hsiao BS, Chu B, Hadjiargyrou M (2003) Biomaterials 24:4977

Yang F, Murugan R, Wang S, Ramakrishna S (2005) Biomaterials 26:2603

Boland ED, Wnek GE, Simpson DG, Pawlowski KJ, Bowlin GL (2001) J Macromol Sci-Pure Appl Chem A 38:1231

Katti DS, Robinson KW, Ko FK, Laurencin CT (2004) J Biomed Mater Res B 70:286

Tan EPS, Ng SY, Lim CT (2005) Biomaterials 26:1453

Li W-J, Tuli R, Okafor C, Derfoul A, Danielson KG, Hall DJ, Tuan RS (2005) Biomaterials 26:599

Matthews JA, Wnek GE, Simpson DG, Bowlin GL (2002) Biomacromolecules 3:232

Min B-M, Lee G, Kim SH, Nam YS, Lee TS, Park WH (2004) Biomaterials 25:1289

Ohkawa K, Cha D, Kim H, Nishida A, Yamamoto H (2004) Macromol Rapid Commun 25:1600

Kim TK, Yoon JJ, Lee DS, Park TG (2006) Biomaterials 27:152

Gautam S, Dinda AK, Mishra NC (2013) Mater Sci Eng C 33:1228

Li WJ, Cooper JA, Mauck RL, Tuan RS (2006) Acta Biomater 2:377

Jeong SI, Kim B-S, Kang SW, Kwon JH, Lee YM, Kim SH, Kim YH (2004) Biomaterials 25:5939

Harrington WF, Vonhippel PH (1961) Adv Protein Chem 16:1

Boedtker H, Doty P (1954) J Phys Chem 58:968

Jiankang H, Dichen L, Yaxiong L, Bo Y, Hanxiang Z, Qin L, Bingheng L, Yi L (2009) Acta Biomater 5:453

Yang S, Leong K-F, Du Z, Chua C-K (2001) Tissue Eng 7:679

Ko H-F, Sfeir C, Kumta PN (2010) Philos Trans R Soc Ser A 368:1981

Fadel SM, Hassan ML, Oksman K (2012) J Compos Mater 1

Porto de Moraes ICC (2012) Polymer Biocompatibility. http://www.intechopen.com/books/polymerization/polymer-biocompatibility. Accessed 6 Sept 2013

Ramya R, Venkatesan J, Kim SK, Sudha PN (2012) J Biomater Tissue Eng 2:111

Mourya VK, Inamdar NN, Tiwari A (2010) Adv Mater Lett 1:11

Chen ZG, Wang PW, Wei B, Mo XM, Cui FZ (2010) Acta Biomater 6:372

Ghasemi-Mobarakeh L, Prabhakaran MP, Morshed M, Nasr-Esfahani MH, Ramakrishna S (2008) Biomaterials 29:4532

Lim YC, Johnson J, Fei Z, Wu Y, Farson DF, Lannutti JJ, Choi HW, Lee LJ (2011) Biotechnol Bioeng 108:116

Alvarez-Perez MA, Guarino V, Cirillo V, Ambrosio L (2010) Biomacromolecules 11:2238

Cooper A, Bhattarai N, Zhang M (2011) Carbohydr Polym 85:149

Eiselt P, Yeh J, Latvala RK, Shea LD, Mooney DJ (2000) Biomaterials 21:1921

Martins AM, Santos MI, Azevedo HS, Malafaya PB, Reis RL (2008) Acta Biomater 4:1637

Mikos AG, Thorsen AJ, Czerwonka LA, Bao Y, Langer R, Winslow DN, Vacanti JP (1994) Polymer 35:1068

Schugens C, Maquet V, Grandfils C, Jérôme R, Teyssie P (1996) J Biomed Mater Res B 30:449

Sachlos E, Czernuszka JT (2003) Eur Cell Mater 5:39

Ma Z, Kotaki M, Inai R, Ramakrishna S (2005) Tissue Eng 11:101

Jang J-H, Castano O, Kim H-W (2009) Adv Drug Deliver Rev 61:1065

Liang D, Hsiao BS, Chu B (2007) Adv Drug Deliver Rev 59:1392

Lim SH, Mao HQ (2009) Adv Drug Deliver Rev 61:1084

Greiner A, Wendorff JH (2007) Angew Chem Int Edit 46:5670

Yang Y, Zhu X, Cui W, Li X, Jin Y (2009) Macromol Mater Eng 249:611

Sambrook J, Fritsch EF, Maniatis T (1989) Molecular cloning: a laboratory manual, vol 2. Cold Spring Harbor Laboratory Press, New York

Park WH, Jeong L, Yoo DI, Hudson S (2004) Polymer 45:7151

Son WK, Youk JH, Lee TS, Park WH (2004) Polymer 45:2959

Kumbar SG, Nukavarapu SP, James R, Nair LS, Laurencin CT (2008) Biomaterials 29:4100

Li W-J, Laurencin CT, Tuan RS, Ko FK (2002) J Biomed Mater Res 60:613

Powell HM, Boyce ST (2008) J Biomed Mater Res A 84:1078

Kempf M, Miyamura Y, Liu P-Y, Chen AC-H, Nakamura H, Shimizu H, Tabata Y, Kimble RM, McMillan JR (2011) Biomaterials 32:4782

McMillan JR, Akiyama M, Tanaka M, Yamamoto S, Goto M, Abe R, Sawamura D, Shimomura M, Shimizu H (2007) Tissue Eng 13:789

Martins-Franchetti SM, Egerton TA, White JR (2010) J Polym Environ 18:79

Kim HW, Knowles CJ, Kim H-E (2005) J Biomed Mater Res B 74:686

Martel-Estrada SA, Martínez-Pérez CA, Chacón-Nava JG, García-Casillas PE, Olivas-Armendariz I (2010) Carbohydr Polym 81:775

Mohamed A, Finkenstadt VL, Gordon SH, Biresaw G, PD E, Rayas-Duarte P (2008) J Appl Polym Sci 110:3256

Barreto PLM, Pires ATN, Soldi V (2003) Polym Degrade Stab 79:147

Peña C, Kdl Caba, Eceiz A, Ruseckait R, Mondragon I (2010) Bioresour Technol 101:6836

Mano V, Silva MESRe (2007) Mater Res 10:165

Wan Y, Lu X, Dalai S, Zhang J (2009) Thermochim Acta 487:33

Lewandowska K (2009) Thermochim Acta 493:42

Ghasemi-Mobarakeh L, Prabhakaran MP, Morshed M, Nasr-Esfahani MH, Ramakrishna S (2010) Mater Sci Eng, C 30:1129

Meskinfam M, Sadjadi MS, Jazdarreh H (2011) World Acad Sci, Eng Technol 52:395

Cruz DMG, Coutinho DF, Mano JF, Ribelles JLG, Sánchez MS (2009) Polymer 50:2058

Peng H, Zhou S, Guo T, Li Y, Li X, JianxinWang JieWeng (2008) Colloids Surf B 66:206

Zong X, Ran S, Kim K-S, Fang D, Hsiao BS, Chu B (2003) Biomacromolecules 4:416

Cho K, Lee J, Kwo K (2001) J Appl Poly Sci 79:1025

Tan H, Wu J, Lao L, Gao C (2009) Acta Biomater 5:328

Huang Y, Onyeri S, Siewe M, Moshfeghian A, Madihally SV (2005) Biomaterials 26:7616

Jia J, Liu G, Guo Z-X, Yu J, Duan Y (2012) J Nanomater 2012:1

Crouch AS, Miller D, Luebke KJ, Hu W (2009) Biomaterials 30:1560

Liu X, Zhang X, Lee I (2010) Acta Bioch Biophy Sin 42:195

Levina EM, Kharitonova MA, Rovensky YA, Vasiliev JM (2001) J Cell Sci 114:4335

Acknowledgements

Chia-Fu Chou and Narayan C. Mishra acknowledge support from the Academia Sinica Nano Program and National Science Council, Taiwan, ROC. (99-2112-M-001-027-MY3) to carry out this research. The authors are thankful to the technical support from Jaslok Hospital and Research Centre, Mumbai, and particularly to Mr. Sachin Ramdas Chaugule for his assistance to carry out biocompatibility study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gautam, S., Chou, CF., Dinda, A.K. et al. Fabrication and characterization of PCL/gelatin/chitosan ternary nanofibrous composite scaffold for tissue engineering applications. J Mater Sci 49, 1076–1089 (2014). https://doi.org/10.1007/s10853-013-7785-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-013-7785-8