Abstract

BiFeO3-modified lead-free piezoceramics Li0.05(Na0.515K0.485)0.95Nb0.8Ta0.2O3 (LKNNT) were successfully fabricated by conventional method to investigate its influences on phase structure and electricity as well as mechanical properties. A tiny amount of BiFeO3 (BF) changes the phase structure of LKNNT to tetragonal and further to pseudocubic, and also effectively improves the sintering ability and densification of LKNNT which enhances the mechanical property. The LKNNT piezoceramics with the addition of 1 mol% BF has the bulk density of 5.02 g/cm3 and an enhanced fracture strength of 142 MPa which is even higher than that of the sample of similar composition prepared by spark plasma sintering, also possesses room temperature electric properties of d 33* ~ 225 pm/V, k p ~ 36.3%, ε r ~ 1140, tgδ ~ 0.018, T c ~ 305 °C and Q m ~ 80. The d 33* remains constant up to 150 °C and the change ratio of dielectric property largely decreases over the temperature range of −50–150 °C, which can be attributed to the temperature-independent phase structure of LKNNT piezoceramics, making the ceramics as a promising candidate for actual applications.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Lead-free piezoceramics has became a hot topic worldwide, and among them (K,Na)NbO3 (KNN)-based ceramics are considered as one of the promising lead-free candidates for its high Curie point and good piezoelectric properties [1–5]. High piezoelectric properties with d 33 constants up to 400 pC/N can be achieved in the KNN-based ceramics modified with Li, Ta, and Sb dopants even without textured microstructure [6–11]. Pure KNN shows perovskite structure with an orthorhombic symmetry at room temperature, which changes to tetragonal symmetry around 200 °C then to cubic phase above 400 °C. Doping Li, Ta, and/or Sb can significantly shift downward the tetragonal to orthorhombic transition point (T T–O) from above 200 °C to room temperature, resulting in a state of two-phase coexistence in the Li, Ta, and/or Sb-doped KNN ceramics [11]. Nowadays, it is generally accepted that the piezoelectricity enhancement in the KNN system by doping Li, Ta, and/or Sb is mainly due to the shifting of T T–O, which is called the polymorphism phase transition (PPT) effect; a state of two-phase coexistence at room temperature provides more polarization directions in the polycrystalline materials and thus enhances the piezoelectric response [12]. However, for such a modified KNN composition with enhanced electrical properties due to PPT effect, its electrical properties will decrease drastically even a small temperature deviation from T T–O occurs [13].

This study was conducted under a motivation to improve the temperature stability of piezoelectricity in KNN-based ceramics. BiFeO3 is a multiferroic material of rhombohedral phase at room temperature with a melting point of ~960 °C [14]. A small amount of BiFeO3 was incorporated into Li/Ta-modified KNN with an optimized composition whose T T–O is shifted closely to room temperature because of the following considerations. First, BiFeO3 is also a lead-free ferroelectric compound with large spontaneous polarization, whose addition to KNN may favor the piezoelectricity enhancement by ferroelectric effect. Second, it was reported that a tiny amount of BiFeO3 (BF) addition can change the phase structure of KNN [15], which may create a new phase boundary in the KNN–BF system to enhancement piezoelectricity. Last, previous studies revealed that BiFeO3 is also an effective sintering aid for KNN ceramics [16]; reducing sintering temperature and hence suppressing the volatilization of alkali elements is technologically important for realizing the industrial applications of KNN-based ceramics.

This study shows that the temperature stability of piezoelectric properties can be greatly improved by adding only 1 mol% BiFeO3 into Li/Ta-doped KNN ceramics (LKNNT) with an optimized composition of Li0.05(Na0.515K0.485)0.95Nb0.8Ta0.2O3, in which no phase transition existed from room temperature to Curie point. In addition, as a consequence of refined and dense microstructure the BiFeO3-added LKNNT ceramics show higher mechanically properties than that without BiFeO3 addition.

Experimental

(K,Na)NbO3-based piezoceramics with compositions of (1 − x) Li0.05(Na0.515K0.485)0.95Nb0.8Ta0.2O3-xBiFeO3 (abbreviated as LKNNT–BF x , 0.0 ≤ x≤0.03) were prepared by conventional process [15, 16]. Oxides and carbonates, Li2CO3 (97 wt%), K2CO3 (99 wt%), Na2CO3 (99.8 wt%), Nb2O5 (99.95 wt%), Ta2O5 (99 wt%), Fe2O3 (99 wt%), and Bi2O3 (99 wt%) were used as raw materials. The mixed powders after being weighed were milled for 24 h in ethanol using ZrO2 balls, and then the slurry was dried and calcined at 850 °C for 5 h. The synthesized powder were ball milled again for 24 h also in ethanol and dried, after that the powders were pressed into small disks with of 10 mm in diameter, followed by cold isostatic pressing under 200 MPa. Finally, these pellets were sintered in air at an optimized temperature of 1120 °C for 2 h. After being painted with sliver electrodes, the samples were poled at 120 °C for 20 min under an electric field of 4 kV/mm in silicone oil.

Bulk densities of the samples were measured by the Archimedes method. The crystal structure of the sintered ceramics was determined by X-ray diffraction (XRD) characterization with Cu K a radiation (Rigaku, D/Max 2500, Tokyo, Japan). The cross-sectional microstructures and thermally etched surfaces of the ceramics were observed by scanning electron microscopy (SEM, JSM6460, Tokyo, Japan). Energy dispersive X-ray spectroscopy (EDS) was also carried out to analyze the concentration of the involved elements qualitatively and quantitatively. OK, NaK, KK, NbL, TaM, FeK, and BiM lines were counted for the quantitation. The dielectric properties and loss at room temperature were measured using an Agilent 4194A precision impedance analyzer (Hewlett-Packard, Palo Alto, CA) at 1 kHz. The electric field-induced strains were measured by using an attachment onto the TF ANALYZER 1000 (aixACCT Systems GmbH, Germany) where the ferroelectricity was also measured. These measurements all involved the application of a triangular voltage waveform with a frequency of 10 Hz. Evaluation of dielectric temperature stability was carried out in a temperature-regulated chamber which was connected with Agilent 4294(Hewlett-Packard, Palo Alto, CA) at 1 kHz. Mechanical strength was evaluated using a modified small punch (MSP) method after the ceramic disks were polished to 0.50 mm thickness. More details of the MSP method can be found elsewhere [17].

Results and Discussion

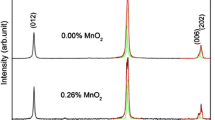

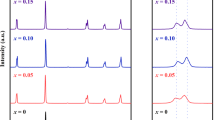

Figure 1 shows the XRD patterns of the LKNNT–BF x ceramic samples with 0.0 ≤ x ≤ 0.03 in the ranges of 2θ from 20° to 60°. The XRD pattern differs with the variation of x. All the compositions have the dominant perovskite structure and the samples show the existence of impurities at the low addition of BiFeO3. Relatively more impurities were observed in the LKNNT–BF0.005 sample, which may be identified to be close to K4Nb6O17 (PDF #76-0977) and Li4.07K5.70Nb10.23O30 (PDF #73-1229), as shown in Fig. 1a. It have been also reported that the second phases like K4Nb6O17 and Li2K3Nb5O15 appear in Li-doped KNN ceramics [18]. When the addition of BiFeO3 reaches 0.03, the second phase nearly disappears. A large amount of BiFeO3 doping into KNN-based ceramics may influence the distribution of alkali elements which leads to the disappearance of the second phase, but the mechanism needs to be further investigated. In KNN-based ceramics, the analysis of the relative intensity of two peaks around 2θ = 45° in XRD patterns is an effective method to distinguish the phase structure of ceramics that show orthorhombic and/or tetragonal symmetry at room temperature [19]. When the ceramics are of orthorhombic phase with a = c > b, I (002)/I (020) equals 2 and the (002) line has a smaller Bragg angle [20]. But the I (002)/I (020) equals 0.5 and the (002) line is also located at a smaller Bragg angle for KNN-based ceramics of tetragonal phase with a = b < c. An estimation of the tetragonal and orthorhombic phase ratio in KNN-based ceramics can be done by the following equation:

where m t denotes the ratio of tetragonal phase and m o denotes the ratio of orthorhombic phase. The tetragonal phase ratio was 32, 58, 88% in LKNNT–BF x piezoceramics for x = 0.0, x = 0.005, x = 0.01, respectively. The pure LKNNT ceramics shows the predominant orthorhombic phase and with increasing addition of BF, the phase structure of the ceramics changes from orthorhombic to tetragonal and then to pseudocubic being analogous to a previous report [15]. When x equals 0.01, the sample shows the dominant existence of tetragonal phase at room temperature. The lattice parameters of the LKNNT–BF x piezoceramics were calculated according to the method presented by Wang and Li [21], and the results are shown in Fig. 2. For pure LKNNT ceramics of orthorhombic phase, it has the lattice parameters of a = c>b and angle β > 90°. When doped by 0.5 mol% BiFeO3, the LKNNT ceramics shows the dominant existence of tetragonal phases, the lattice parameters changes to a = b<c and β = 90°. When the addition of BiFeO3 increases from 1 mol% to 2 mol%, the lattice parameters a and b increase, but c decreases. For LKNNT–BF0.03 ceramics of pseducubic phase, its lattice parameters are a = b = c = 3.96 Å and β = 90o.

Table 1 shows the physical properties of the LKNNT–BF x piezoceramics with 0.0 ≤ x ≤ 0.02 at room temperature. The electrical properties of LKNNT piezoceramics could be enhanced by a proper addition of BF, which may be related to the enhanced densification behavior. When doped by 1 mol% BF, the LKNNT possess the best room-temperature electrical properties of k p ~ 36.3%, ε r ~ 1140, tgδ ~ 0.018 and Q m ~ 80. The mechanical quality factor Q m increases with the addition of BF, which is a combined result of the substitution of A+ (Na+, K+ or Li+) by Bi3+ and B5+ (Nb5+ or Ta5+) by Fe3+ where the latter plays a more important role. Previous works have shown that Fe3+ was an acceptor to replace B-site ions and Bi3+ was a donor to replace A-site ions in KNN-based piezoceramics [22, 23]. When the addition of BF exceeds 1 mol%, the electrical properties of LKNNT piezoceramics deteriorate greatly. At the same time, the poling of samples became hard because of the inherently large leakage current of BF. The density of LKNNT–BF x ceramics increases with the contents of BF primarily and reaches the maximum of 5.02 g/cm3 with x = 0.01, then decreases to 4.85 g/cm3 for LKNNT–BF0.02 ceramics. The variation in density is closely related to the microstructure, as shown in Fig. 3. No distinct pores are observed in LKNNT–BF0.01 piezoceramics. The LKNNT piezoceramics possess a bimodel distribution of grain sizes which is broadened by the addition of BF. For LKNNT–BF0.02 with excessive BF, the grains were greatly reduced to ~ 500 nm. A proper addition of BF can greatly improve the sintering ability of LKNNT piezoceramics. At the same time, the elemental concentrations of all compositions were analyzed by EDS. Although EDS is not a very precise method for quantitative analysis at low concentration, the contents of Bi and Fe increase and the peaks of Fe and Bi in EDS spectrum show more and more obviously with the increase of x. Figure 4 shows the representative results of the EDS analysis for the LKNNT–BF x piezoceramics with x = 0.0 and x = 0.02. The region enclosed by the line in the inset of the figure was analyzed, which confirmed the existence of Bi and Fe elements in the sintered samples.

Figure 5 shows the temperature dependence of the relative dielectric constant of LKNNT–BF x ceramics which were measured at 1 kHz during the heating process, and shows that the LKNNT–BF0.01 piezoceramics have a Curie point of 305 °C. It is hard to determine the Curie point of the pure LKNNT and LKNNT–BF0.005 piezoceramics by the temperature dependence of dielectric constant because the relative dielectric constant will reach an abnormal value (>140000, not shown) at about 400 °C, and the mechanism need to be further investigated. The relative dielectric constant of pure LKNNT ceramics shows a peak around 30 °C (see the inset) where the polymorphism phases transition occurs. The addition of BF can decrease the T T–O of LKNNT ceramics, which is similar with the addition of Bi3+ into KNN-based ceramics [23]; this is because the doping of Fe3+ to B-site of KNN has less influence on the phase structure of KNN-based ceramics as discussed in previous study [22]. At the same time, the proper addition of BF can not only increase the relative dielectric constant, but also largely decrease the change ratio of the relative dielectric constant over the temperature range from −60 to 150 °C. When the addition of BF is 1 mol%, the LKNNT piezoceramics have the most temperature stability of dielectric property.

Figure 6 displays the curves of electric-field-induced strains of LKNNT and LKNNT–BF0.01 piezoceramics at different temperature. Although, the LKNNT–BF0.01 piezoceramics shows a slightly lower converse piezoelectric constant d 33* at room temperature than LKNNT ceramics because of the shift of T T–O to lower temperature by the addition of BF, but the temperature stability of the piezoelectric constant of the LKNNT–BF0.01 is much better than the pure LKNNT ceramics. The d 33* of pure LKNNT piezoceramics decreases from 243 to 166 pm/V as the temperature increases from 34 to 150 °C, while that of LKNNT–BF0.01 piezoceramics nearly remain a constant value of 225 pm/V in the same temperature range. The hysteresis in the strain versus E-field behavior conducted at 34 °C is a result of domain wall movement and decreases as the temperature increases because the increased temperature could facilitate the domain wall movement. The thermal stability of piezoelectricity of LKNNT piezoceramics can be greatly improved by the doping of 1 mol% BF, which can attributed to the thermal stability of phase structure with the proper content of BF.

Figure 7 displays the P–E loops of LKNNT and LKNNT–BF0.01 piezoceramics measured at a frequency of 10 Hz at different temperatures. At room temperature, the LKNNT piezoceramics demonstrate a better ferroelectric property than LKNNT–BF0.01 with a larger remnant polarization P r of 14.3 μC/cm2 and the lower coercive field E c of 13.2 kV/cm, owing to the PPT effect. However, because of disappearance of the coexistence of two phases in addition to the temperature effect, the ferroelectric property of LKNNT decreases drastically with a P r of 9.3 μC/cm2 and 5.3 μC/cm2 for 100 and 150 °C, respectively. Because the oxygen vacancies caused by the substitutions of Nb5+ by Fe3+ block the movement of domain wall, the LKNNT–BF0.01 ceramics become “harder” and possess a larger coercive field E c of 20.3 kV/cm at 34 °C. Owing to the temperature independence of phase structure of the ceramics, the P r and E c of LKNNT–BF0.01 piezoceramics decrease slightly from 12.4 μC/cm2 and 20.3 kV/cm to 9.6 μC/cm2 and 11.5 kV/cm, respectively, as the temperature increases from 34 to 150 °C.

As shown in the Fig. 3, a proper addition of BF can decrease the grain size and improve the densification of LKNNT ceramics, which suggests the possibility to enhance the mechanical property of LKNNT piezoceramics. The measured results are shown in Fig. 8 by comparing the MSP load–displacement curves for LKNNT and LKNNT–BF0.01 piezoceramics, which both show brittle fracture behavior. The load increases with increasing displacement and abruptly drops at a critical displacement value, which corresponds to the initiation of crack in the sample. Then with further larger displacement, the load increases to a maximum where the ultimate fracture occurs. The load when the crack initially occurs was identified as fracture load. Three samples for each composition were measured to obtain its average value. The fracture strength was calculated by the following equation:

where 2a is the diameter of the load-supporting hole of the lower die here (a = 2 mm), 2b is the head diameter of the cylinder-shaped pressuring bar (here b = 1 mm), γ is the Poisson ratio of the tested materials (0.32), and t is the thickness of the sample (t = 0.50 mm), respectively. The LKNNT ceramics doped by 1 mol% BF has large average fracture strength of 142.4 MPa which is even higher than the similar composition prepared by spark plasma sintering (SPS) [17]. Although the mechanical strength of piezoelectric ceramics is often ignored, a balanced combination of mechanical and piezoelectric properties is actually important, especially for some applications where strength is important, such as bending actuators and ceramic micro-rod arrays [24]. The present LKNNT–BF0.01 piezoceramics may be particularly suitable for such applications.

Conclusions

LKNNT–BF x lead-free piezoceramics were prepared by conventional method to investigate the sintering behavior and temperature dependence of electric properties of the ceramics with an emphasis on the effect of BiFeO3 addition. Doping 1 mol% BiFeO3 can not only improve the sintering ability of LKNNT ceramics, but also shift the T T–O of the ceramics to lower temperature which endows the sample with great temperature stability of electrical properties. The LKNNT–BF0.01 piezoceramics shows much temperature-stable electric properties of d 33* ~ 225 pm/V, k p ~ 36.3%, ε r ~ 1110, tgδ ~ 0.018 and Q m ~ 80, and excellent mechanical property, which may meet some special requirements for practical applications.

References

Cross E (2004) Nature 432:24

Saito Y, Takao H, Tani T, Nonoyama T, Takatori K, Homma T, Nagaya T, Nakamura M (2004) Nature 432:84

Rodel J, Jo W, Seifert TPK, Anton EM, Granzow T, Damjanovic D (2009) J Am Ceram Soc 92:1153

Panda PK (2009) J Mater Sci 44:5049. doi:10.1007/s10853-009-3643-0

Shrout TR, Zhang SJ (2007) J Electroceram 19:111

Hollenstein E, Davis M, Damjanovic D, Setter N (2005) Appl Phys Lett 87:182905

Wang K, Li JF (2010) Adv Funct Mater 20:1924

Lin D, Kwok KW, Chan HLW (2008) Appl Phys A 91:167

Song HC, Cho KH, Park HY, Ahn CW, Nahm S, Uchino K, Park SH, Lee HG (2007) J Am Ceram Soc 90:1812

Xiao DQ, Wu JG, Wu L, Zhu JG, Yu P, Lin DM, Liao YW, Sun Y (2009) J Mater Sci 44:5408. doi:10.1007/s10853-009-3543-3

Gao Y, Zhang J, Qing Y, Tan Y, Zhang Z, Hao X (2011) J Am Ceram Soc. doi:10.1111/j.1551-2916.2011.04468.x

Dai Y, Zhang X, Zhou G (2007) Appl Phys Lett 90:262903

Hao J, Xu Z, Chu R, Zhang Y, Chen Q, Li G, Yin Q (2009) J Mater Sci 44:6162. doi:10.1007/s10853-009-3852-6

Palai R, Katiyar RS, Schmid H, Tissot P, Clark SJ, Robertson J, Redfern SAT, Catalan G, Scott JF (2008) Phys Rev B 77:014110

Li X, Wu L, Xiao D, Zhu J, Yu P, Jiang Y, Wu J (2008) Phys Stat Sol A 205:1211

Zuo R, Ye C, Fang X (2008) J Phys Chem Solids 69:230

Shen ZY, Zhen Y, Wang K, Li JF (2009) J Am Ceram Soc 92:1748

Tanaka K, Kakimoto K, Ohsato H, Iijima T (2007) Ferroelectrics 358:175

Guo Y, Kakimoto K, Ohsato H (2004) Appl Phys Lett 85:4121

Dai YJ, Zhang XW, Chen KP (2009) Appl Phys Lett 94:042905

Wang K, Li JF (2007) Appl Phys Lett 91:262902

Zuo R, Xu Z, Li L (2008) J Phys Chem Solids 69:1728

Du H, Liu D, Tang F, Zhu D, Zhou W, Qu S (2007) J Am Ceram Soc 90:2824

Shen ZY, Li JF, Chen R, Zhou Q, Shung KK (2011) J Am Ceram Soc 94:1346

Acknowledgements

This work was supported by the Tsinghua University Initiative Scientific Research Program and the Ministry of Science and Technology of China under the Grant 2009CB623304, as well as by National Nature Science Foundation of China (Grant Nos. 50921061 and 51028202).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, JJ., Li, JF. & Zhang, XW. BiFeO3-modified (Li, K, Na)(Nb, Ta)O3 lead-free piezoelectric ceramics with temperature-stable piezoelectric property and enhanced mechanical strength. J Mater Sci 47, 1767–1773 (2012). https://doi.org/10.1007/s10853-011-5957-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-011-5957-y