Abstract

To improve both the temperature stability and the mechanical quality factor of (K0.5Na0.5)0.94Li0.06NbO3 (KNLN6) ceramics, dense (K4CuNb8O23, Bi2O3)-modified KNLN6 lead-free ceramics were prepared. Results showed that the (K4CuNb8O23, Bi2O3)-modified ceramics exhibited a flat, temperature-stable behavior over the range of 20–120 °C. K4CuNb8O23 (KCN) and Bi2O3-codoping changed the KNLN6 to “hard” ceramics with a significant improvement of mechanical quality factor, Qm, from 82 to 756. Meanwhile, the piezoelectric constant, d33, and the planar electromechanical coefficient, kp, still maintained relatively high levels (d33 ~118 pC/N, kp ~35.6%). These results indicate that the modified KNLN6 ceramics are promising lead-free piezoelectric candidates for practical applications.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In the search for lead-free piezoceramics candidates, alkali niobate ceramics based on (K0.5Na0.5)NbO3 (KNN) have received more attention since Saito et al. [1] made a breakthrough in the textured KNN ceramics with codopants of Li, Ta, and Sb, which shows comparable piezoelectric properties to a hard Pb(Zr,Ti)O3 (PZT). However, because of the high volatility of alkaline elements at high temperatures, it is very difficult to obtain dense and well-sintered KNN ceramics using ordinary sintering processes.

Various approaches such as introducing modifying elements [2–7] and adopting advanced sintering techniques [8–10] have been attempted in order to improve the sinterability and electrical properties of KNN ceramics. Recently, many efforts have been made to find new systems based on KNN that can be sintered in a standard way and with improved properties. Among them, the KNN–LiNbO3 (abbreviated as KNLN) system seems more interesting as it reveals excellent piezoelectric properties and high Curie temperature [4]. However, two drawbacks may limit its practical application greatly: first, due to the polymorphic phase transition (PPT) near room temperature, the temperature stability of the electrical properties is relatively poor if without special repeated thermal cycling [11]. Second, the mechanical quality factor, Qm, of the ceramics is fairly low (less than 120 [12]), and low mechanical quality factor, Qm, is not suitable for practical piezoelectric application particularly for ultrasonic application. Therefore, special attention should be paid to obtain KNLN-based ceramics with good temperature stability along with high mechanical quality factor for their applications.

K4CuNb8O23 (KCN) has been used as a novel sintering aid to improve the sintering ability of KNN-based ceramics [13–15]. It is also found that the Qm factor of the KNN-based ceramics was improved significantly by KCN addition. Bi2O3 has been selected to modify KNN system [16, 17] due to its low melt point, and the Bi2O3-modified ceramics also exhibit enhanced piezoelectric properties. However, research on both the KCN and Bi2O3 doping of the KNN-based ceramics has not been reported so far. Therefore, in this work, sintering acids KCN and Bi2O3 were introduced into (K0.5Na0.5)0.94Li0.06NbO3 to improve the mechanical quality factor. The temperature stability and electrical properties of the ceramics were studied.

Experimental

(K0.5Na0.5)0.94Li0.06NbO3 (KNLN6) + x mol% K4CuNb8O23 (KCN) + y mol% Bi2O3 (abbreviated as: KNLN6–x–y. x = 0, y = 0 [sample a]; x = 0.5, y = 0 [sample b]; x = 0.5, y = 0.3 [sample c]) ceramics were prepared by an ordinary sintering technique using analytical-grade metal oxides or carbonate powders: Na2CO3 (99.8%), K2CO3 (99.0%), Li2CO3 (99.0%), Nb2O5 (99.96%), Bi2O3 (99.64%), and CuO (99.0%) (All raw materials were made by Sinopharm Chemical Reagent Co., LtdS, China). First, Na2CO3, K2CO3, Li2CO3, and Nb2O5 powders were weighed and milled in polyethylene jar with ZrO2 balls for 12 h using anhydrous ethanol as the medium. The same procedure was applied to ball-mill K2CO3, Nb2O5, and CuO powders. Then, these dried slurries were calcined at 850 °C for 4 h and 900 °C for 5 h, respectively, to synthesize KNLN6 and KCN powders. After the calcinations, KNLN6, KCN, and Bi2O3 powders were weighed according to the formulas and then ball-milled for 8 h. The resulting powders were sieved through 80 meshes and granulated by adding polyvinyl butyral (PVB) as a binder. The granulated powders were pressed into 12-mm diameter disks with 1.0 mm thickness at 200 MPa. After burning off PVB, these compacts were finally sintered in air at 1080–1120 °C for 2 h. The sintered KNLN6–x–y ceramics at different temperatures had a diameter of 10.5–10.8 mm and thickness of 0.80–0.83 mm. After polishing, silver paste was coated on both sides of the sintered samples and fired at 740 °C for 20 min to form electrodes. The ceramics were poled under a dc field of 5–7 kV/mm at room temperature in a silicone oil bath for 30 min.

The crystal structures of the sintered ceramics were determined by X-ray powder diffraction analysis (XRD) (D8 Advance, Bruker Inc., Germany). The surface morphology of the ceramics was studied by scanning electron microscope (SEM) (JSM-5900, Japan). The temperature dependences of the dielectric properties were measured using an HP 4294A precision impedance analyzer (Agilent Inc., America). P–E hysteresis loops were recorded using an aix-ACCT TF2000FE-HV ferroelectric test unit (aix-ACCT Inc., Germany). The piezoelectric constant, d33, was measured using a quasi-static d33 meter (YE2730 SINOCERA, China). The mechanical quality factor, Qm, and the planar electromechanical coupling factor, kp, were calculated following IEEE standards by using an impedance analyzer (HP 4294A).

Results and discussion

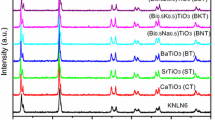

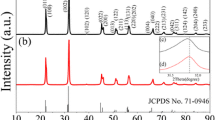

Figure 1 shows X-ray diffraction (XRD) patterns of the KNLN6–x–y ceramics. The XRD patterns are indexed according to the literatures [1, 18]. All samples show a pure perovskite structure, which indicates that a solid solution between KNLN6 and the added (KCN, Bi2O3) has been formed. For pure KNLN6 ceramic, the orthorhombic and tetragonal phases coexist, and tetragonal phase is dominant as characterized by the (001)/(100) peak splitting about 22° and (002)/(200) peak splitting about 45° [4, 12]. However, after adding KCN and Bi2O3 to KNLN6, orthorhombic phase begins to be dominant as evidenced by the change of the characteristic peaks at around 22° and 45°. These results suggest that the phase structure of KNLN6–x ceramics shift from the coexistence of two phases to orthorhombic phase due to the addition of KCN and Bi2O3.

Figure 2 shows the SEM images of KNLN6–x–y ceramics sintered at 1100 °C. For the pure KNLN6 ceramic, the grain sizes are not very homogeneous. However, the modified ceramics exhibit relatively uniform microstructures with the reduced grain sizes. The densities of the KNLN6–x–y ceramics sintered at 1100 °C are found to be 4.29, 4.29, 4.32 g/cm3, corresponding to 95, 95, and 96% of theoretical value, respectively. This result suggests that all the ceramics are well sintered in this work.

Figure 3 shows the temperature dependence of dielectric constant and loss for KNLN6–x–y ceramics at 10 kHz. Two phase transitions are observed in the dielectric permittivity curves, one corresponds to the orthorhombic to tetragonal phase transition at low temperature (TO–T); the other represents the tetragonal to the cubic phase transition at high temperature (Tc) [4, 19]. The εr peaks corresponding to the PPT (at TO–T) of the modified ceramics become much broader and the variations of εr values around PPT become much slighter compare with pure KNLN6. The dielectric loss tangent (tanδ) of all samples is lower than 5% without significant conductivity appearing even at temperature as high as 300 °C. Moreover, it can be clearly seen that the loss tangent of the modified ceramics is much lower than that of pure KNLN6 in the whole measured temperature range of 20–550 °C, confirming the significantly improved insulation.

Figure 4 shows the P–E hysteresis loops of KNLN6–x–y ceramics at different temperatures. The insets present the remnant polarization (Pr) and coercive field (Ec) of KNLN6–x–y ceramics as a function of temperature. It can be observed that well-saturated hysteresis loops are obtained in all samples at 20 °C, which confirms the good ferroelectric nature of the ceramics at room temperature. For KNLN6, the remnant polarization, Pr, and coercive field, Ec, are 20.8 μC/cm2 and 18.9 kV/cm, respectively, which are both a little bit larger than the previous report results [12]. With elevating measuring temperature, P–E loops of pure KNLN6 change notably and both Pr and Ec values vary obviously, suggesting relatively poor temperature stability of the KNLN6 ceramics. However, for KNLN6–0.5 mol% KCN sample, the P–E loops become a little bit narrower but almost keep a typical ferroelectric shape with elevating measuring temperature, Pr decreases gradually from 19.8 to 16.1 μC/cm2 while Ec increases gently from 21.7 to 23.3 kV/cm. For KNLN6–0.5 mol% KCN–0.3 mol% Bi2O3 sample, no significant deformation of the loops is observed in the whole measured temperature range. Meanwhile, both Pr and Ec have very slight changes. These results indicate that the ferroelectric properties of the (KCN, Bi2O3)-modified ceramics possess relatively good temperature stability in the measured temperature range [20]. In the present work, it is anticipated that the improved polarization stability upon KCN-doping is directly related to the “hardening” effect of KCN in KNLN6 ceramics, which has been reported in the literature about Cu2+-doped alkali niobates [21]. On the other hand, because the radius of the Cu2+ ion (0.73 Å) in KCN is similar to that of the Nb5+ ion (0.64 Å), it is easy for Cu2+ ion to enter the B site of the perovskite unit cell and replace the Nb5+ ions [22]. As a result, the improved polarization stability could also be due to the substitution of Cu2+ in B-site which largely affected the domain wall stabilization through the oxygen vacancy increase and manifested in the form of improved the mechanical quality factor [21]. For the Bi2O3-modified mechanism, Wang et al. [16] have studied the effects of Bi3+ ion on electrical properties of KNN, and suggested that Bi3+ ion could easily enter the A site of KNN and substitute K+ cations, which can increase the stability of perovskite structure determined by the tolerance factor, t, \( \left[ {t = {{\left( {r_{\rm A} + r_{\rm O} } \right)} /{{\sqrt{2}}{\left( {r_{\rm B} + r_{\rm O} } \right)} }}} \right]\) [23]. Based on the above, it is reasonable to think the enhanced ferroelectric stability at high temperature may be attributed to the stabilization of orthorhombic phase at room temperature. The exact origin of improved polarization stability caused by Bi2O3, however, is still unclear and needs our further studies.

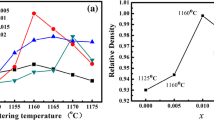

In order to further confirm the temperature stability of the KNLN6–x–y system, temperature dependence of planar electromechanical coefficient, kp, as described in the following has been done. Figure 5 shows the temperature dependence of the planar electromechanical coefficient, kp, from 20 to 120 °C for the KNLN6–x–y ceramics. For the unmodified ceramics, the kp value is found to be 41.6% at 20 °C, remaining nearly unchanged at 60 °C, and then decreasing rapidly to 31.3% at 120 °C. While the modified ceramics show the significantly improved temperature stability with a slight decease kp as temperature increases from 20 to 120 °C. These results confirm the enhanced temperature stability of the modified KNLN6 ceramics.

In this study, we also obtained the piezoelectric constant, d33, and the mechanical quality factor, Qm, values of the three samples. For pure KNLN6 ceramic, d33 and Qm are found to be 212 pC/N, 82, respectively. After KCN and Bi2O3 modified, Qm is greatly improved up to 704 and 756 for KNLN6–0.5 mol% KCN and KNLN6–0.5 mol% KCN–0.3 mol% Bi2O3 samples, respectively. Meanwhile, the piezoelectric constant still maintains relatively high levels for the two samples, d33 ~126 pC/N, 118 pC/N. In this work, although the piezoelectric properties of the modified ceramics are lower than the unmodified ceramics, the sample possesses better temperature stability in the temperature range of 20–120 °C. These results suggest that this material is a more promising candidate for high temperature lead-free piezoelectric ceramics.

Conclusions

Dense (KCN, Bi2O3)-modified KNLN6 lead-free ceramics were prepared in order to improve both the temperature stability and the mechanical quality factor of KNLN6 ceramics. The results showed that the (KCN, Bi2O3)-modified ceramics possessed good temperature stability in the temperature range of room temperature to 120 °C, as well as excellent electrical properties (Qm ~756, d33 ~118 pC/N, kp ~35.6%), suggesting that this material should be an attractive lead-free material for piezoelectric applications.

References

Saito Y, Takao H, Tani T, Nonoyama T, Takatori K, Homma T, Nagaya T, Nakamura M (2004) Nature 432:84

Kim MS, Lee DS, Park EC, Jeong SJ, Song JS (2007) J Eur Ceram Soc 27:4121

Zang GZ, Wang JF, Chen HC, Su WB, Wang CM, Qi P, Ming BQ, Du J, Zheng LM (2006) Appl Phys Lett 88:212908

Guo Y, Kakimoto K, Ohsato H (2004) Appl Phys Lett 85:4121

Guo MS, Lam KH, Lin DM, Wang S, Kwok KW, Helen L, Chan W, Zhao XZ (2008) J Mater Sci 43:709. doi:https://doi.org/10.1007/s10853-007-2199-0

Wang K, Li JF, Liu N (2008) Appl Phys Lett 93:092904

Xu CG, Lin DM, Kwok KW (2008) J Mater Sci Mater Electron 19:1054

Jaeger RE, Egerton L (1962) J Am Ceram Soc 45:209

Wang R, Xie R, Sekiya T, Shimojo Y (2004) Mater Res Bull 39:1709

Li JF, Wang K, Zhang BP, Zhang LM (2006) J Am Ceram Soc 89:706

Hollenstein E, Damjanovic D, Setter N (2007) J Eur Ceram Soc 27:4093

Du HL, Tang FS, Liu DJ, Zhu DM, Zhou WC, Qu SB (2007) Mater Sci Eng B 136:165

Matsubara M, Yamaguchi T, Kikuta K, Hirano S (2004) Jpn J Appl Phys 43:7159

Chen Q, Chen L, Li QS, Yue X, Xiao DQ, Zhu JG (2007) J Appl Phys 102:104109

Matsubara M, Yamaguchi T, Sakamoto W (2005) J Am Ceram Soc 88:1190

Wang Y, Li YX, Kalantar-zadeh K, Wang TB, Wang D, Yin QR (2008) J Electroceram 21:629

Liu DJ, Du HL, Tang FS, Luo F, Zhou WC (2007) J Chin Ceram Soc 35:1141

Wang K, Li JF (2007) Appl Phys Lett 91:262902

Hollenstein E, Davis M, Damjanovic D, Setter N (2005) Appl Phys Lett 87:182905

Wu L, Xiao DQ, Wu JG, Sun Y, Lin DM, Zhu JG (2008) J Eur Ceram Soc 28:2963

Marandian Hagh N, Kerman K, Jadidian B, Safari A (2009) J Eur Ceram Soc 29:2325

Park HY, Choi JY, Choi MK, Cho KH, Nahm S (2008) J Am Ceram Soc 91:2374

Guo Y, Kakimoto K, Ohsato H (2004) J Phys Chem Solids 65:1831

Acknowledgement

This work is financially supported by National Natural Science Foundation of China (No. 50602021).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hao, J., Xu, Z., Chu, R. et al. Enhanced temperature stability of modified (K0.5Na0.5)0.94Li0.06NbO3 lead-free piezoelectric ceramics. J Mater Sci 44, 6162–6166 (2009). https://doi.org/10.1007/s10853-009-3852-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-009-3852-6