Abstract

This work focuses on the effects of Bi compensation on the phase structure, microstructure, ferroelectric, and piezoelectric performances of new 0.69Bi1 + xFeO3-0.31BaTiO3 (x, 0–0.08) piezoceramics fabricated by traditional sintering techniques. X-ray diffraction (XRD) results indicated that Bi compensation has slight influences on the phase structure and all the ceramics locate near the morphotropic phase boundary of rhombehedral–pseudocubic phase coexistence. The rhombehedral phase fraction of all the ceramics fluctuates slightly in the range of 41.7–49.1 %. X-ray photoelectron spectroscopy (XPS) results confirmed that Bi compensation favors the decrease in the percentage of oxygen vacancy in the ceramics. An appropriate content of Bi compensation facilitates the densification, grain growth as well as enhancement of piezoelectric property of the materials. In addition, Bi compensation makes the materials “soft” along with the lower EC compared with the no compensation ceramics. Significantly, the excellent piezoelectric performance (d33 = 207 pC/N) was achieved in the 0.69Bi1.04FeO3-0.31BaTiO3 ceramics, which is higher than the results obtained in the previously reported BiFeO3-BaTiO3-based ceramics. This work would trigger further study on the BiFeO3-BaTiO3-based piezoceramics for practical application.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Piezoceramics with the ability to convert mechanical energy to electrical energy and vice versa have been used as core materials to manufacture actuators, transducers, and sensors [1]. However, according to the Restriction of Hazardous Substances legislation, the conventional Pb(Zr, Ti)O3 (PZT)-based piezoceramics which dominate the market have faced serious challenges due to the toxicity of lead element to the human health and natural environment, promoting extensive studies on perovskite lead-free piezoceramics [1, 2].

Recently, lead-free BiFeO3-BaTiO3 (BF–BT) system piezoceramics, as a promising substitute for PZT-based ceramics, have received much attention due to its high Curie temperature TC and good piezoelectric performance [1,2,3,4]. In general, three approaches such as the chemical doping or composition design [4,5,6,7], processing optimization (quenching or sintering in special atmosphere) [2, 8,9,10,11], and using novel starting materials (nano-BaTiO3 powder) [3, 12,13,14] were used to enhance the piezoelectric performance of BF–BT ceramics. To be specific, the value of piezoelectric coefficient d33 for the most BF–BT ceramics with only chemical doping or composition design is below 195 pC/N [1, 15, 16]. Significantly, the outstanding d33 of 402 pC/N was achieved in the 0.67Bi1.05Fe0.97Ga0.03O3-0.33BaTiO3 ceramics [2] via water quenching following sintering, which gave rise to a rapid surge of studies [1, 12,13,14, 17, 18] on the BF–BT-based ceramics. However, the quenching process may lead to much microcracks in the ceramics due to the extremely fast cooling rate following sintering [12], which might be unsuitable for mass production. Besides, it was reported that the improved d33 up to 191–214 pC/N [3, 12,13,14] was obtained in BF–BT ceramics using nano-BaTiO3 powder as starting materials. But, the cost of nano-BaTiO3 powders is much higher compared with the total cost of ordinary TiO2 and BaCO3 powders.

On the other hand, Bi3+ and Pb2+ cations have the same valence shell electron configuration 6s26p0. It is believed that the strong ferroelectricity and piezoelectricity of BiScO3-PbTiO3 are mainly ascribed to the onset of hybridization between Bi/Pb-6p and O-2p orbitals [19]. Similarly, super high ferroelectric polarization (90–100 µC/cm2) was predicted in BF owing to the hybridization between Bi-6p and O-2p orbitals [14, 20]. However, it is known that Bi is prone to volatilize during sintering at high temperatures, which may cause the deviation from the stoichiometric composition for BF-based ceramics [21]. As reported, appropriately excess Bi2O3 has positive effects on the piezoelectric property of BF–BT materials. It was also confirmed that the enhanced d33 was achieved in the other Bi-based piezoceramics (e.g., Bi0.5Na0.5TiO3) [22, 23] by means of excess Bi2O3. Unfortunately, the improved d33 of 114 pC/N [24] and 142 pC/N [21] of BF–BT with excess Bi2O3 are not very excellent. Therefore, it is necessary to further study the influences of Bi compensation on the electrical property of BF–BT system piezoceramics.

In our previous investigation of undoped BF–BT series solid solution piezoceramics, it was found that the optimal piezoelectric activity was obtained in the ceramics with BF/BT molar ratio of 0.69/0.31 [25]. In this work, Bi-compensated 0.69Bi1 + xFeO3-0.31BaTiO3 (B1 + xF-0.31BT) ceramics, using ordinary BaCO3, TiO2, Bi2O3, and Fe2O3 powder as raw materials, were fabricated by conventional sintering techniques without quenching. The effects of Bi compensation on the phase structure, ferroelectric, and piezoelectric performances of B1 + xF-0.31BT ceramics near morphotropic phase boundary (MPB) were systematically investigated. As expected, excellent piezoelectric property (d33 = 207 pC/N) was achieved in the ceramics with an appropriate content (x = 0.04) of Bi compensation, which is superior to the results obtained in the previously reported BF–BT-based piezoceramics.

2 Experimental procedure

B1 + xF-0.31BT (x, 0-0.08) ceramics were synthesized via conventional sintering techniques. The starting materials with high purity (> 99 %) including Fe2O3, Bi2O3, TiO2, and BaCO3 were weighed and milled in an alcohol with ZrO2 balls for 12 h. After drying to remove alcohol, the mixtures were calcined at 800 °C for 3 h followed by second ball milling for 12 h. The powders were dried and pressed with 1 % PVA under 100 MPa into pellets with 14 mm diameter and ~ 1.30 mm thickness. After burning off the binder at 600 °C for 2 h, the pellets were sintered in a sealed crucible at 1020 °C for 3 h. Silver slurry was pasted on both faces of the sintered pellets and then fired at 580 °C for 20 min. The samples were poled under a dc field of 5 kV/mm in a silicone oil bath at 90 °C for 30 min and approximately 24 h after poling, piezoelectric parameters were measured.

X-ray diffraction (XRD, X’ Pert Pro, PANalytical, the Netherlands) was used to characterize the phase structure. The scanning electron microscopy (SEM, NOVA NANOSEM 430, the Netherlands) was used to observe the microstructure of the ceramics. The bulk density of B1 + xF-0.31BT ceramics was evaluated by the Archimedes method. X-ray photoelectron spectroscopy (XPS, Axis Ultra DLD, Kratos, UK) with Al Kα radiation was used to analyze the state of oxygen in the ceramics. A ferroelectric analyzer (Radiant Technologies, USA) was used to measure the room-temperature polarization–electric (P–E) hysteresis loops at 1 Hz. The piezoelectric coefficient d33 was measured by a piezo-d33 meter (ZJ-3 A, China). The dielectric permittivity εr and dielectric loss tanδ, mechanical quality factors Qm, and planar mechanical coupling coefficient kp were measured using an impedance analyzer 4294 A (Agilent Technologies, America).

3 Results and discussion

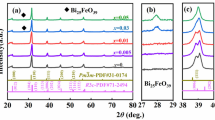

Figure 1 presents the room-temperature XRD patterns of B1 + xF-0.31BT ceramics. It can be seen that the ceramics with x = 0 and x = 0.02 possess pure perovskite structure, while the impurity phase peak of Bi25FeO40 can be observed for the ceramics with x ≥ 0.04. This indicates that excess Bi compensation could give rise to the impurities phase in B1 + xF-0.31BT ceramics, which is consistent with the observation of the impurity phase Bi25FeO40 in the 0.70BF-0.30BT ceramics with 0.03–0.05 Bi compensation [14]. In order to further analyze the influences of Bi compensation on the phase structure of B1 + xF-0.31BT materials, a general diffraction/reflectivity analysis program MAUD [26] was used to perform full-pattern matching with the Rietveld method. The values of the goodness-of-fit indicator S (1.53–1.70) and reliability Rwp (12.2–13.7 %), as shown in Table 1, are less than 2 and 15 %, respectively, suggesting that the calculated and observed XRD patterns are matched well [26]. All the B1+xF-0.31BT samples locate near MPB of rhombohedral (R)–pseudocubic (pC) phase coexistence, and R phase fraction fluctuates in the range of 41.7–49.1 % as shown in Table 1. The similar MPB of R-pC coexistence was also reported in 0.70BF-0.30BT ceramics [3, 27]. In addition, the differences in crystal lattice a and α of the B1 + xF-0.31BT ceramics are insignificant. These results indicate that no remarkable variation in main phase structure is caused by Bi compensation in the B1 + xF-0.31BT ceramics, namely, Bi compensation has ignorable effects on the main phase structure of BF–BT materials [14, 21, 24].

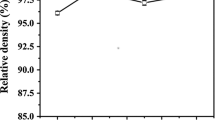

The surface microstructure of B1+xF-0.31BT ceramics is given in Fig. 2. The B1 + xF-0.31BT ceramics with Bi compensation of x = 0.02 and x = 0.04 exhibit dense microstructure and clear grain boundaries, while the ceramics with Bi compensation of x = 0.06 and x = 0.08 present looser grain boundaries. The improved relative density, as shown in Table 1, of 96.8 and 96.5 % is obtained for x = 0.02 and x = 0.04 ceramics, respectively. These results imply that an appropriate concentration of Bi compensation is beneficial to densification of the ceramics, which facilitates the electrical property enhancement for the ceramics. The grain size of B1 + xF-0.31BT increases firstly and then decreases slightly, for example, 5.8, 7.5, 7.7, 9.8, and 9.0 μm for x of 0, 0.02, 0.04, 0.06, and 0.08, respectively. This could be ascribed to the low melting point (830 °C) of Bi2O3. Thus, an appropriate amount of liquid phase can be formed during sintering for the ceramics with Bi compensation of x ≤ 0.06, which favors the diffusion of elements in the B1 + xF-0.31BT solid solutions, resulting in the larger grain size. However, too much liquid phase caused by excess Bi compensation could assemble at grain boundaries, which may suppress the grain growth during sintering [4, 24].

Figure 3 displays the temperature dependence of dielectric permittivity εr and dielectric loss tanδ of B1 + xF-0.31BT ceramics at 100 kHz. A typical dielectric anomaly, corresponding to the Curie peak, is observed for all the B1 + xF-0.31BT samples from room temperature to 550 °C. The Curie temperature TC of all the B1 + xF-0.31BT samples lies in the range of 439–454 °C. Besides, the tanδ of all the B1 + xF-0.31BT ceramics almost remain stable till 370 °C and then increases dramatically near 450 °C due to high-temperature leakage conduction. Note that the TC of the conventional PZT ceramics is in the range of 190–370 °C [1], severely limiting its application at high temperature. According to the above results, B1 + xF-0.31BT ceramics would have promising potential application at high temperature.

The P–E hysteresis loops of B1 + xF-0.31BT ceramics at 1 Hz and room temperature are presented in Fig. 4a. All the ceramics exhibit typical P–E loops, and Bi compensation plays an important role in both the Pr and EC of B1 + xF-0.31BT samples. With increasing the content of Bi compensation, the Pr decreases gradually from 24.09 µC/cm2 for x = 0 to 18.55 µC/cm2 for x = 0.08 as shown in Fig. 4b, and EC decreases firstly from 24.98 kV/cm for x = 0 to 22.63 kV/cm for x = 0.06 and then slightly increases to 23.28 kV/cm for x = 0.08. It is known that the Bi evaporation could lead to the formation of A-site and oxygen vacancies in the ABO3-type perovskite solid solutions; and through pinning at ferroelectric domain walls, the oxygen vacancy could inhibit the reorientation of domains during electric poling [12, 28]. Figure 5 shows XPS spectra of O 1 s of the ceramics. The three-fitted sub-peaks at ~ 529 eV, ~ 531 eV, and ~ 532 eV correspond to the lattice oxygen, absorbed H2O, and oxygen vacancy, respectively [29]. As shown in Table 2, the oxygen vacancy percentage is 63.3 and 51.1 % for BF-0.31BT and B1.04 F-0.31BT, respectively. This confirms that Bi compensation favors the decrease of oxygen vacancy in the ceramics, which facilitates the reorientation of the ferroelectric domains of B1 + xF-0.31BT ceramics. Similar phenomenon of the decreased percentage of oxygen vacancy in BF–BT ceramics via adding excess Bi2O3 was also reported by Zheng et al. [29]. Moreover, the improved relative density and the larger grain size as mentioned in Fig. 2 are also in favor of the domain reorientation [12]. Therefore, the lower EC is observed for the ceramics with Bi compensation compared with the no compensation ceramics. In other words, Bi compensation could make the B1 + xF-0.31BT ceramics “soft” to some extent.

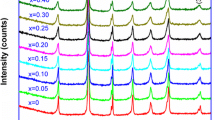

Figure 6a presents the piezoelectric coefficient d33 and planar electromechanical coupling factor kp of B1 + xF-0.31BT ceramics. Both the d33 and kp of the samples increase firstly and then decrease as x increases. For example, the d33 value increases from 190 pC/N for x = 0 to 207 pC/N for x = 0.04 and then decreases to 182 pC/N for x = 0.08, and the value of kp increases from 0.359 for x = 0 to 0.362 for x = 0.02 and then decreases to 0.331 for x = 0.08. These results reveal that a proper content of Bi compensation is beneficial for the improvement of piezoelectric performances. The reason for the enhancement of d33 may be mainly contributed to the decreased EC as shown in Fig. 4b of B1 + xF-0.31BT with an appropriate concentration of Bi compensation. However, the ceramics with excess Bi compensation (x = 0.08) show inferior d33, although the EC of B1.08 F-BT is lower than that of the ceramics without Bi compensation. This should be owing to the severe deteriorated Pr for the B1.08 F-0.31BT ceramics. Nevertheless, it is necessary to note that all the samples possess the relatively high piezoelectric properties (d33, 182-207pC/N, kp, 0.33–0.36), which should be attributed to the formed MPB in the experimental range as above XRD results. The dielectric loss tanδ and mechanical quality factors Qm of B1 + xF-0.31BT samples are displayed in Fig. 6b. Generally, Bi compensation has slight effects on both the tanδ and Qm of B1 + xF-0.31BT ceramics. Specifically, the tanδ and Qm of the samples fluctuate in the range of 0.068–0.074 and 27–32, respectively.

The piezoelectric property of recently reported non-quenched BF–BT system piezoceramics are listed in Table 3. Significantly, the excellent piezoelectric property (d33 = 207 pC/N) is obtained in the B1.04 F-0.31BT ceramics in this work, which is higher than those of 0.75BiFeO3-0.25BaTiO3-0.1 wt% MnO2 (116 pC/N) [9], 0.7BiFeO3-0.3BaTiO3-1 mol% MnO2 (177 pC/N) [10], 0.7Bi(Fe0.991Zn0.009)O3-0.3BaTiO3-0.3 wt% MnO2 (192 pC/N) [15], and 0.7BiFeO3-0.3BaTiO3- 0.025BiZn0.5Ti0.5O3-0.003Li2CO3-0.0035MnO2 (184 pC/N) [16] and even higher or comparable with the results (d33 = 191 ~ 214 pC/N) obtained in 0.70BF-0.30BT ceramics [3, 12,13,14] using costly nano-BaTiO3 powder as starting materials. Considering positive effects of chemical doping or composition design on piezoelectric property of BF–BT materials, further enhanced piezoelectric performance could be obtained in the ceramics based on B1.04 F-0.31BT through composition optimization or adding optimal dopants.

4 Conclusion

The B1 + xF-0.31BT (x, 0–0.08) piezoceramics were prepared via ordinary sintering techniques. All the ceramics with different concentrations of Bi compensation locate near MPB of R-pC phase coexistence. A trace amount of impurity phase was detected for the materials, when x ≥ 0.04. The R/pC phase ratio fluctuates slightly in the range of 41.7/58.3–49.1/50.9 % for all the ceramics. An appropriate content of Bi compensation could facilitate the densification and grain growth of the samples. Decreased percentage of oxygen vacancy was observed for x = 0.04 compared with the no compensation ceramics as confirmed by XPS results. The TC fluctuates in the range of 439 to 454 °C for the ceramics with increasing x to 0.08. Bi compensation, exhibiting “soft” doping effects, favors the decrease of EC of the ceramics. Owing to the increased relative density, larger grain size, and decreased EC, the excellent piezoelectric performance (d33 = 207 pC/N) was obtained for the B1.04 F-0.31BT ceramics, which would inspire further investigation on BF–BT system piezoceramics for practical application.

Data availability

The data and material will be provided under reasonable request.

References

T. Zheng, J. Wu, D. Xiao, J. Zhu, Prog. Mater Sci. 98, 552–624 (2018)

M.H. Lee, D.J. Kim, J.S. Park, S.W. Kim, T.K. Song, M.H. Kim, W.J. Kim, D. Do, I.K. Jeong, Adv. Mater. 27, 6976–6982 (2015)

S. Cheng, L. Zhao, B.P. Zhang, K.K. Wang, Ceram. Int. 45, 10438–10447 (2019)

D. Lin, Q. Zheng, Y. Li, Y. Wan, Q. Li, W. Zhou, J. Eur. Ceram. Soc. 33, 3023–3036 (2013)

H. Yang, C. Zhou, X. Liu, Q. Zhou, G. Chen, W. Li, H. Wang, J. Eur. Ceram. Soc. 33, 1177–1183 (2013)

C. Zhou, A. Feteira, X. Shan, H. Yang, Q. Zhou, J. Cheng, W. Li, H. Wang, Appl. Phys. Lett. 101, 032901 (2012)

S. Murakami, N.T.A.F. Ahmed, D. Wang, A. Feteira, D.C. Sinclair, I.M. Reaney, J. Eur. Ceram. Soc. 38, 4220–4231 (2018)

T. Zheng, J. Wu, J. Alloy. Compd. 676, 505–512 (2016)

S.O. Leontsev, R.E. Eitel, J. Am. Ceram. Soc. 92, 2957–2961 (2009)

J. Wei, D. Fu, J. Cheng, J. Chen, J. Mater. Sci. 52, 10726–10737 (2017)

Q. Li, J. Cheng, J. Chen, J. Mater. Sci. Mater. Electron. 28, 1370–1377 (2016)

L.F. Zhu, B.P. Zhang, J.Q. Duan, B.W. Xun, N. Wang, Y.C. Tang, G.L. Zhao, J. Eur. Ceram. Soc. 38, 3463–3471 (2018)

L.F. Zhu, B.P. Zhang, Z.C. Zhang, S. Li, L.J. Wang, L.J. Zheng, J. Mater. Sci.: Mater. Electron. 29, 2307–2315 (2018)

B.W. Xun, N. Wang, B.P. Zhang, X.Y. Chen, Y.Q. Zheng, W.S. Jin, R. Mao, K. Liang, Ceram. Int. 45, 24382–24391 (2019)

K. Tong, C. Zhou, Q. Li, J. Wang, L. Yang, J. Xu, G. Chen, C. Yuan, G. Rao, J. Eur. Ceram. Soc. 38, 1356–1366 (2018)

Y. Sun, H. Yang, S. Guan, Y. Cao, M. Jiang, X. Liu, Q. Chen, M. Li, J. Xu, J. Alloy. Compd. 819, 153058 (2020)

T. Zheng, Y. Ding, J. Wu, J. Mater. Sci. Mater. Electron. 28, 11534–11542 (2017)

Q. Li, J. Wei, T. Tu, J. Cheng, J. Chen, J. Am. Ceram. Soc. 100, 5573–5583 (2017)

J. Íñiguez, D. Vanderbilt, L. Bellaiche, Phys. Rev. B 67, 224107 (2003)

J.B. Neaton, C. Ederer, U.V. Waghmare, N.A. Spaldin, K.M. Rabe, Phys. Rev. B 71, 014113 (2005)

C. Zhou, H. Yang, Q. Zhou, G. Chen, W. Li, H. Wang, J. Mater. Sci. Mater. Electron. 24, 1685–1689 (2012)

Y.S. Sung, J.M. Kim, J.H. Cho, T.K. Song, M.H. Kim, T.G. Park, Appl. Phys. Lett. 98, 012902 (2011)

R. Zuo, S. Su, Y. Wu, J. Fu, M. Wang, L. Li, Mater. Chem. Phys. 110, 311–315 (2008)

J. Chen, J. Cheng, J. Alloy. Compd. 589, 115–119 (2014)

W. Yi, Z. Lu, X. Liu, D. Huang, Z. Jia, Z. Chen, X. Wang, H. Zhu, J. Mater. Sci. Mater. Electron. (2021). https://doi.org/10.1007/s10854-021-05490-9

L. Lutterotti, MAUD, Material Analysis Using Diffraction (2019). http://www.ing.unitn.it/~maud/index.html. Accessed 20 July 2019

Y. Wei, X. Wang, J. Zhu, X. Wang, J. Jia, J. Am. Ceram. Soc. 96, 3163–3168 (2013)

T. Rojac, M. Kosec, B. Budic, N. Setter, D. Damjanovic, J. Appl. Phys. 108, 74107 (2010)

T. Zheng, Y. Ding, J. Wu, RSC Adv. 6, 90831–90839 (2016)

Acknowledgements

This work was supported by the R & D Projects in Key Fields of Guangdong Province (2020B0109380001; 2019B040403004; 2019B040403006); Science and Technology Planning Project of Guangxi Zhuang Autonomous Region (No. AA18118034); National Natural Science Foundation of China (Grant No.51577070 and U1601208); Science and Technology Program of Guangzhou (No. 201704030095).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yi, W., Lu, Z., Liu, X. et al. Excellent piezoelectric performance of Bi-compensated 0.69BiFeO3-0.31BaTiO3 lead-free piezoceramics. J Mater Sci: Mater Electron 32, 22637–22644 (2021). https://doi.org/10.1007/s10854-021-06748-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-06748-y