Abstract

Sustainability has become a necessity, partly due to the threats created by traditional manufacturing practices, and due to regulations imposed by stakeholders. Performance evaluation is an important component of sustainability initiatives in manufacturing organizations. This study proposes a sustainability evaluation method for manufacturing SMEs using integrated fuzzy analytical hierarchal process (FAHP) and fuzzy inference system (FIS) approach. The performance indicators are identified from literature considering the characteristics of SMEs. Balanced scorecard framework is used to categorize the indicators among its four aspects. The linguistic variables are used to collect the opinions of decision makers about the performance ratings and importance of the aspects and corresponding indicators. The FAHP method is applied to determine the relative weights of measures and indicators. The performance ratings of the organization with respect to indicators and relative weights of indicators are combined to obtain the weighted performance ratings. The weighted performance ratings are considered as inputs to FIS. The hierarchal FIS is applied to derive the overall sustainability performance. Using a case study of manufacturing SME, the sustainability score of the organization was elicited in accordance with this procedure. Consequently, a sensitivity analysis of the proposed method reveals the most important basic indicators affecting overall sustainability, identifying areas which decision makers should place special attention. This method can also assist managers of larger enterprises to assess the effectiveness of their sustainability strategies, especially when dealing with suppliers from the SMEs.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Now-a-days, sustainable development has become an important concern for all aspects of our daily activities. The main objective of sustainable development is to ensure that the needs of the present generation are met without compromising the ability of future generations to meet theirs (Brundtland 1987) . It is a well-established fact that our ecosystem is witnessing a difficult challenge due to the limited resources, energy capacity and waste disposal capability (Solvang et al. 2006). Many studies have attributed that the imbalance in the ecosystem is mainly due to manufacturing operations (Chouikhi et al. 2014). In addition, Manufacturing operations are also accompanied by various social concerns at different stages of the production processes (Kemp 1994; Seuring and Muller 2008). Various laws and rules have been enforced on manufacturing operations and their resultant products across various countries to address these concerns (Olugu et al. 2011). Therefore, it is important for manufacturing organizations to incorporate the philosophy of sustainability into their manufacturing operations. The perspective of sustainability is often referred as idea of Triple Bottom Line (TBL), which has three dimensions; environmental, social and economic (Seuring and Muller 2008). Sustainable manufacturing strives to minimize negative environmental effect and conserve natural resources. It also focuses on the products and processes which are economically sound and safe for employees and communities (ITA 2007).

The success of sustainable manufacturing strategies depends on: (1) selection of an appropriate set of indicators, (2) performance evaluation method and (3) adjustment within the system (Reich-Weiser et al. 2009). Most of the strategies for sustainable manufacturing are based on the indicators and performance evaluation methods, which are designed and tested in larger manufacturing companies. To achieve better sustainability performance of supply chain, larger enterprises extend these practices to their suppliers. Most of these suppliers are small-and medium-scale enterprises (SMEs). Thus, sustainability performance evaluation of SMEs plays an important role in their survival. The performance evaluation of manufacturing SMEs differs significantly from those for large corporations due to characteristics of SMEs, e.g., personalized management, lack of finances, resource limitations, more flexibility, horizontal structure, small number of customers, limited access to market and lack of knowledge about new technologies (Alshawi et al. 2011; Ciliberti et al. 2008). Based on these characteristics, sustainable manufacturing in SMEs cannot be considered as a miniaturized version of larger organizations (Alshawi et al. 2011).

In the case of sustainability performance evaluation of manufacturing organizations, major challenges are to determine the relative importance of each performance indicator and to evaluate the performance of the organization with respect to various indicators that are usually incommensurable and fuzzy in nature (Vinodh et al. 2013; Azadegan et al. 2011). Furthermore, in a group decision making such as sustainability performance evaluation, each decision maker has different knowledge and opinion regarding the importance of indicators and performance rating of the organization. Therefore, sustainability evaluation for manufacturing SMEs involves uncertainties such as fuzziness and interval data. Due to the nature of such problems, fuzzy logic based methods have been reasonably derived to suit the specific needs of sustainability evaluation. The fuzzy analytic hierarchy process (FAHP) method provides a basis to obtain the relative weights of performance indicators. The Fuzzy inference system (FIS) developed by Mamdani and Assilian (1975) provides a basis for sustainability evaluation methods that can effectively deal with the problems of this nature.

In this study, an integrated fuzzy AHP–FIS method is proposed to deal with sustainability evaluation of manufacturing SMEs. The balanced scorecard (BSC) framework is used to consider the financial and non-financial indicators in order to reflect the operational and strategic performances of SMEs. Performance indicators are identified from the literature and categorized into four measures of BSC for sustainability evaluation of SMEs. This model is implemented in an Indian manufacturing SME to evaluate the effectiveness of its sustainability initiative. The sensitivity analysis of this method provides a list of the most important indicators affecting sustainability performance. The results obtained from the case company show the applicability of the proposed method.

The remainder of this study is structured as follows: next section presents a detailed review of literature related to this study. “Sustainability evaluation indicators for manufacturing SMEs” section presents an illustrative list of indicators using BSC framework. “Sustainability evaluation framework and proposed method” section presents the proposed method. Using a case study, the applicability of this method is illustrated in “Illustrative example” section. In the final section, some conclusions are drawn from this study.

Literature review

This section is aimed at reviewing literature to provide a view of sustainable manufacturing practices from SMEs perspectives. As the research aim is to develop a sustainability evaluation method for manufacturing SMEs using BSC framework, the literature review also focuses upon the sustainability evaluation methods and metrics, and use of BSC in SMEs. Finally, research gaps are presented.

Sustainable manufacturing and SMEs

Although widely accepted, the Brundtland Commission definition of sustainable development, presented above, is not an operational one for business and engineering decision makers in manufacturing (Haapala et al. 2013). Sustainable manufacturing is defined by US department of commerce as “the creation of manufactured products that use processes that minimize negative environmental impacts, conserve energy and natural resources, as well as being safe for employees, communities, and consumers and economically sound” (ITA 2007). The sustainable manufacturing concept built upon the TBL concept of sustainability attempts to incorporate economic, environmental and social aspects of manufacturing that can help companies to assess current operations for further improvement, innovate and identify the new source of revenue and cost reduction.

Global or larger companies have been developing the capability required to achieve the sustainable manufacturing over the recent decade. Focusing on the environmental impact in 2005, General Electric announced ‘Eco imagination’ program resulting in the dramatic growth of the company’s business. Returning from the verge of bankruptcy in 2008, General Motors adopted sustainability as an important principle in its business practices. The success of sustainability initiatives of larger companies such as BMW, Dalmer, Coca-Cola and many more are well reported and recognized. However, focusing on sustainability reporting, it is found that percentage of large companies publishing corporate sustainability responsibility (CSR) report is around 95 %, whereas only around 48 % SMEs publish their CSR (KPMG 2013).

The lack of sustainability effort in SMEs is attributed to their characteristics. SMEs often lack the awareness, expertise, skills, finance, and human resources to build the required changes for sustainability within the organization (Lee 2009; Fatimah et al. 2013). Hillary (2004) identified barriers and drivers for environmental management system for SMEs using an empirical study. These barriers include lack of knowledge and training, implementation cost and transient cost. The drivers for sustainability in SMEs as identified by Hillary (2004) are customers, government, local community, employees, insurers, banks and larger companies. This study concluded that despite these barriers, SMEs do achieve benefits from the Environmental Management System (EMS). Lepoutre and Heene (2006) reported that firm size and characteristics of SMEs are also recognized as barriers for sustainable practices. However, the effect of these barriers can be nullified by critical analysis and strategy to overcome the constraining barriers.

The SMEs are adopting the green initiatives to enhance their competitiveness to survive in the market (Lee 2009). For instance, European Union (EU) directives on Waste Electrical and Electronic Equipment (WEEE), Restriction of Hazardous Substances (RoHS), and Eco-design for Energy-using products (EuP) have forced larger organizations to adopt the sustainable practices in their operations (Huang 2015). The ripple effects of these directives extend to suppliers in order to enhance the sustainability performance of these larger manufacturing organizations. Many of these suppliers are SMEs that represent approximately 80 % of global enterprises (Moore and Manring 2009). Furthermore, SMEs are also under pressure to improve their sustainability performance due to government regulations, local community groups, environmental groups and investors from financial institutions (Biondi et al. 2000; Hillary 2004; Lepoutre and Heene 2006). Using an empirical study, Williamson et al. (2006) reported that business performance and regulations are drivers for environmental practices of SMEs. They also emphasized that manufacturing SMEs try to improve business performances because of the pressures placed on them by market-dominated decision-making frames. Using an empirical study in Turkish SMEs, Agan et al. (2013) concluded that most influential drivers for sustainability of SMEs are expected benefits such as cost savings, increased customer satisfaction, new market opportunities, improved corporate image and higher profits.

Sustainability evaluation methods and indicators

Till recent decades, sustainability of manufacturing organizations has been evaluated in terms of financial performances only. The definition of sustainability has been expanded to include non- financial performance measures such as environmental and social. The sustainable manufacturing performance evaluation involves quantifying the efficiency and effectiveness of all the activities and processes related to manufacturing operations of the organization. It reflects the need for improvement in areas with unsatisfactory performance, thus efficiency and quality can be improved (Chan and Qi 2002). The purposes of performance evaluation are: external reporting (CSR), internal control (managing the activities and processes) and internal analysis (understanding the activities and process better and continuous improvement) (Hervani et al. 2005). The performance measurement metrics of traditional manufacturing have been expanded to incorporate sustainability (Carter and Rogers 2008). Following paragraphs present the review of literature on sustainability evaluation methods and metrics.

Researchers have applied various tools and techniques for sustainability evaluation. The life cycle analysis (LCA), which is a tool for measuring environmental and economic effect, along with social life cycle assessment model have been proposed by Schau and Fet (2011). Jaffar et al. (2007) presented a model based on the weighted sum of the product sustainability components, such as, economic, environmental and social, to assess the sustainability of products. Egilmez et al. (2013) presented an economic input-output LCA and data envelopment analysis (DEA) model for sustainability assessment of manufacturing units in the United States of America. Sustainability evaluation model of a desalination plant based on resources, ecological and environment factors have been proposed by Afghan et al. (1999). Vinodh et al. (2012) presented a model for environmental impact assessment of an automotive ancillary using the eco-indicator. Bayesian network approach for calculating sustainability of coastal lakes in New South Wales (Australia) has been presented by Ticehurst et al. (2007).

In manufacturing, the evaluation models require inputs based on decision makers’ perception towards indicators and measures, which are generally fuzzy. Fuzzy logic based models have proved very useful for decision making based on human reasoning (Ayağ et al. 2013). The fuzzy logic based methods have been used for the sustainability evaluation in the various areas such as petroleum corporation sustainability (Zhang 2007), land management unit (Baja et al. 2002) sustainability assessment of nations (Kouloumpis et al. 2008), sustainability of a chemical industry (Conner et al. 2009) and sustainability of mining and mineral sectors (Kommadath et al. 2012). Phillis and Davis (2009) presented a fuzzy logic model for assessment of corporate sustainability using multi stage fuzzy reasoning model. Using, sensitivity analysis in their model, the authors demonstrated that important indicators affecting corporate sustainability can be identified. Based on the fuzzy logic, the Fuzzy Inference System (FIS) methods have also been applied in manufacturing organizations. For example, modeling of surface roughness in face milling by Kovac et al. (2013), prediction of remaining useful life of cutting tools by Gokulachandran and Mohandas (2015), modeling and analysis of packing properties through FIS by Erginel (2010), intelligent robotic assembly by Jakovljevic et al. (2014), optimization of machining process by Iqbal et al. (2013) and suppliers’ performance evaluation by Ordoobadi (2009), Carrera and Mayorga (2008). Amindoust et al. (2012) proposed a FIS method for supplier selection based on the sustainability performance evaluation. They implemented a three-stage FIS model. However, the limitation of the method is that it did not consider the relative importance of indicators. Another limitation of most of these studies is that fuzzy methods have been designed without considering the monotonic behavior of system. Further, there was no investigation on integrating FAHP method with FIS to solve the sustainability evaluation problems.

The success of evaluation method also depends on the selection of appropriate set of indicators. The indicator should be simple and robust, reproducible and consistent, cost-effective in data collection, complement regulatory requirements and coherence with the organization’s vision. Different sets of indicators have been developed to measure sustainability at the organizational level such as ISO 14000 (including ISO 14020, ISO 14040 and ISO 14064), Dow Jones Sustainability Indexes (DJSI), Global Reporting Initiative (GRI) and sustainable manufacturing Toolkit by Organization for Economic Cooperation and Development (OECD) (Rachuri et al. 2009). Except OECD toolkit, all organizational level set of indicators are general in nature and suitable for larger organizations (Singh et al. 2014a). Based on the characteristics of SMEs, OECD toolkit provides 18 indicators which address only the environmental dimension of sustainability. Considering economic, environmental and social dimensions, sustainability evaluation methods and frameworks are still evolving.

Balanced scorecard (BSC) and SMEs

The BSC Scorecard conceived by Kaplan and Norton (1992) provides a comprehensive framework for performance evaluation by including four different perspectives, viz. financial, customer, internal business process and learning and growth. These four perspectives focus on the various stakeholders’ interests as shown in Table 1. BSC aims to maintain balance “between short-term and long-term objectives, between financial and non-financial measures, between lagging and leading indicators, and between internal and external performance perspectives” (Bhagwat and Sharma 2007). The BSC is a performance assessment tool used in various areas such as supply chain performance management (Varma et al. 2008; Bullinger et al. 2002; Bhagwat and Sharma 2007), customer relationship management (Kim et al. 2003), textile industry (Cebeci 2009), higher education (Tseng 2010), information technology (Asosheh et al. 2010), banking (Wu et al. 2009) and manufacturing (Fernandes et al. 2006). Although BSC has been used widely for performance evaluation but it has some deficiencies in implementation. These deficiencies include methods to combine the indicators’ scores to obtain overall performance rating; computation of relative importance weightage of indicators (Abran and Buglione 2003; Lee et al. 2008; Leung et al. 2005). Ravi et al. (2005) applied ANP with BSC to overcome these deficiencies in the reverse logistic problems of computer hardware industry. Leung et al. (2005) suggested the use of AHP to overcome deficiencies of BSC. Lee et al. (2008) presented a combination of FAHP and BSC model as a solution to these problems.

Application of BSC as a performance evaluation framework has increased in recent decades, but literature related to the application of BSC in SMEs are limited. The SMEs are more focused on the financial and operational performance and there is lack of measures dealing with other aspects of sustainability (Addy et al. 1994). The BSC can be used for performance assessment of SMEs considering the characteristics of SMEs (Hudson et al. 2001). Kaplan and Norton (1992) reported successful application of BSC in SMEs. Manville (2007) developed and implemented the BSC for not-to-profit SMEs. Bhagwat and Sharma (2007) applied BSC to study the day-to-day performance of a supply chain in an Indian SME. Fernandes et al. (2006) demonstrated that the BSC can be implemented successfully in SMEs using systematic and structured methodology. There are three methods to include sustainability in BSC such as the addition of fifth perspective, developing a separate sustainability balanced scorecard or integrating the indicators throughout the four perspectives (Butler et al. 2011). In this study, the indicators are integrated throughout the four perspectives of the BSC to achieve the advantages of allowing the indicators from operational and strategic perspectives.

Research gaps

The literature on sustainable manufacturing focuses primarily on large enterprises rather than SMEs. Even those studies that have discussed sustainable manufacturing from SMEs perspective are still limited and more focused on economic and/or environmental aspects. The limitation of fuzzy based sustainability evaluation methods is that most methods have been designed without considering the monotonic behavior of the system. Furthermore, it is also seen that the relative weights of sustainability indicators are not considered in most of the methods. Although, BSC is a simple and robust framework for performance evaluation, it has not been used for sustainability evaluation in manufacturing SMEs.

In order to fulfill these research gaps, the aim of this paper is to determine the relative weights of the performance indicators under uncertainty and then applies the monotonic FIS for sustainability assessment of manufacturing SMEs using an integrated FAHP–FIS method, which can mimic the real-life decision-making process. The BSC framework is used to include indicators for operational as well as for strategic performance assessment of manufacturing SMEs. The deficiencies in BSC implementation are resolved by using FAHP method to obtain the relative weights of indicators and measures that are used as inputs to the FIS.

Sustainability evaluation indicators for manufacturing SMEs

The BSC evaluates the firm’s performance from four aspects and helps managers to consider both operational and strategic indicators to achieve future competitive advantages (Kaplan and Norton 1992, 2001). The suitability of indicators for sustainability evaluation of manufacturing SME also depends on how these indicators include the characteristics of SMEs (Hudson et al. 2001). Sustainability initiatives are exclusively related to the cost reduction practices in SMEs (Williamson et al. 2006). The financial aspect of the BSC consists of indicators reflecting the cost-related performance of organizations. Cost reduction can be achieved by reducing the manufacturing cost, minimizing waste, increasing resource efficiency and manpower productivity. Waste minimization and increase in resource efficiency also address the problem of resource limitations of SMEs. The major resources used in manufacturing are materials, energy, water and land. Thus, indicators related to usage of these resources become indispensable for sustainability evaluation of manufacturing SMEs. These indicators are included in the internal business process aspect of the BSC. Due to horizontal structure, SME employees have a relatively greater number of responsibilities at a time. The problem of manpower productivity is further augmented due to lack of knowledge towards advanced technologies and sustainability. Specialized training and high motivations are required to enhance or maintain the productivity of employees to remain competitive. Community involvement is also crucial to enhance the competitiveness by improving organizational image. Thus, the learning and growth aspect of the BSC consists of these indicators. A small number of customers and access to limited market suggest that SMEs should focus on customers’ expectation and services. Thus, indicators related to customers are important for sustainability evaluation, which are included in the customer aspect of the BSC. Customers’ satisfaction can be evaluated in terms of flexibility, responsiveness and complaints. For SMEs, sustainable manufacturing indicators should be able to evaluate the performance of organizations with respect to cost, flexibility, responsiveness, resources’ usage, waste minimization, employees productivity, customers’ and employees’ satisfaction and community involvement. The Illustrative list of indicators presented in Table 2 is adopted from an empirical study on the identification of key performance measures for sustainable manufacturing in SMEs (Singh et al. 2014b) and categorized among the four aspects of the BSC .

Sustainability evaluation framework and proposed method

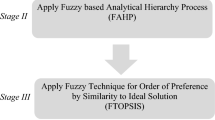

The proposed framework for sustainability evaluation of manufacturing SME is based on performance ratings of the organization with respect to various indicators and relative importance weightages of indicators (Fig. 1). The FAHP approach is used to obtain the relative importance weightage of indicators (see sub-section on importance weightage of indicators and measures). The Mamdani FIS is applied in this study due to its comparatively simpler structure, which predicts reasonable results and also includes the intuitive and interpretable nature of the rule base (Jassbi et al. 2006). The FIS consist of four components, namely; fuzzification interface, knowledge base, inference system and defuzzification interface. The fuzzification interface implements the mapping of the crisp value of inputs to fuzzy inputs, which are represented by membership functions. The knowledge base is a repository of database and rules specific to the system under consideration, which establishes the relationship between input and output. The database consists of linguistic variables used for linguistic rules and membership function defining semantics of linguistic variables. Inference system infers fuzzy inputs into resulting fuzzy output considering the information stored in the knowledge base. The defuzzification interface converts the fuzzy output into crisp output. The number of rules in a FIS depends on two factors: (1) number of inputs to FIS and (2) number of membership functions. In order to avoid the rule explosion, it is proposed that each FIS should have only two inputs with five membership functions. Then, a hierarchal FIS structure with three levels (3-stages) has been obtained as shown in Fig. 2. The weighted performance ratings with respect to indicators are used as inputs in stage-1 of the hierarchal Mamdani FIS. There are four outputs at stage-1, which are considered as inputs at stage-2. At stage-3, there will be two inputs, which are the outputs of stage-2 of FIS used to obtain the sustainability score of organization.

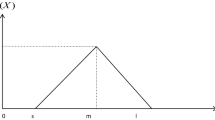

Integrated FAHP–FIS method

The proposed method requires performance ratings of organizations with respect to the indicators pertinent to sustainability evaluation and also importance weights of these indicators. Due to the vagueness in manufacturing decision making, it is recommended that the performance ratings of organization and importance weights of indicators to be gathered in terms of linguistic variables which should be represented by fuzzy numbers. The use of triangular or trapezoidal fuzzy numbers have been recommended to overcome the vagueness (Vinodh and Balaji 2011). The relative importance of indicators is computed based on FAHP as discussed in subsequent subsection. In this study, we have applied triangular fuzzy number (TFN) which can be represented as \(\tilde{A}=(a_l ,a_m ,a_u )\) and shown in Fig. 3.

Five fuzzy sets of membership functions are applied to inputs and outputs of each FIS at all three stages. The fuzzy sets in terms of linguistic variables include ‘Very Poor’, ‘Poor’, ‘Moderate’, ‘Good’ and ‘Very Good’. These variables are equivalent to TFN on a numerical range of 0–100 as shown in Fig. 4.

The following fuzzy operations are applied to compute the fuzzy weights of the indicators and sustainability score (SS) of the manufacturing SMEs. For example, let’s say \(\tilde{A}\) and \(\tilde{B}\) are two TFNs.

Then,

Importance weightage of indicators and measures

Analytic hierarchy process (AHP) is an extensively used MCDM approach to compute the relative weights of the criteria (Saaty 1980; Saaty and Vargas 2001). In the AHP method, the problem structure is generally a multilevel hierarchy. Each criterion on a given level is of some importance and believed to influence the importance of the criterion at the next higher levels. This method is focused on obtaining the importance weights of set of criteria at one level of hierarchy to the level just above (Liberatore 1987) and the same process is being repeated. Weight matrices are multiplied to obtain the importance weightages of criteria at the lowest level to ascertain their impact on the overall goal. Although AHP is a very popular method, it is not able to handle the uncertainties associated with decision making problems (Cheng 1997). Buckely (1985) proposed FAHP method, a systemic approach based on the AHP, which is capable to handle imprecise information in form of fuzzy numbers (Ayağ and Özdemir 2006). The FAHP requires a decision makers’ opinion in the form of a comparison matrix of importance between each criterion to obtain the fuzzy weights. The calculation process of FAHP is explained as follows:

-

(i)

Define hierarchal structure of Problem. Define the hierarchal structure of the sustainability evaluation problem based on the BSC framework.

-

(ii)

Construct the fuzzy positive reciprocal matrix. Decision makers are asked to represent the pairwise comparisons among measures and indicators using linguistic value. The TFN equivalent to linguistic values are shown in Table 3. These collected data are used to form pairwise comparison matrices.

-

(iii)

Examine Consistency of comparison matrixes. If \(C=[c_{ij} ]\) is a positive reciprocal matrix then \(\tilde{C}=[\tilde{c}_{ij} ]\) is a fuzzy positive reciprocal matrix. Buckley (1985) has shown that if the comparison matrix \(C=[c_{ij} ]\) is consistent, then fuzzy comparison matrix \(\tilde{C}=[\tilde{c}_{ij} ]\) is also consistent. In the study, we applied this method to validate the responses of decision makers.

-

(iv)

Compute the fuzzy weights of BSC measures and corresponding indicators.

The Lambda-Max method is used to calculate the fuzzy weights of measures and indicators, which was proposed by Csutora and Buckley (2001). A sequence of positive reciprocal matrices is applied to determine the relative weights. To facilitate the weight computations, apply \(\alpha \)-cut to decompose the fuzzy reciprocal matrix into crisp matrices. The \(\alpha \)-cut of a fuzzy set is a crisp set comprising elements for which the membership function of fuzzy set is greater or equal to\(\alpha \). The calculation steps are as follows:

-

(A)

Apply \(\alpha \)-cut.

-

(a)

Let \(\alpha =1\), to construct \(\tilde{C}_m^k =[C_{ijm}^k ]_{n\times n} \), This represents opinion of decision maker ‘\(k\)’ in the form of the crisp reciprocal matrix \(\tilde{C}\), and obtain the fuzzy weight \(W_m^k =[w_{im}^k ]\) for \(i=1,2,\ldots ,n\) .

-

(b)

Let \(\alpha =0\), using \(\alpha \)-cut to construct \(\tilde{C}_l^k =[C_{ijl}^k ]_{n\times n} \) and \(\tilde{C}_u^k =[C_{iju}^k ]_{n\times n} \) in accordance with fuzzy reciprocal numbers. Determine the weight matrices \(W_l^k =[w_{il}^k ]\) and \(W_u^k =[w_{iu}^k ]\) for \(i=1,2,\ldots ,n\) .

-

(a)

-

(B)

Normalization of the fuzzy weights (Csutora and Buckley 2001). According to this method, lower and upper bounds of the triangular fuzzy weight can be computed as:

$$\begin{aligned} Q_l^k= & {} \min \left\{ {\frac{w_{im}^k }{w_{il}^k }|1\le i\le n} \right\} \end{aligned}$$(4)$$\begin{aligned} Q_u^k= & {} \max \left\{ {\frac{w_{im}^k }{w_{iu}^k }|1\le i\le n} \right\} \end{aligned}$$(5)After computing the values of \(Q_l^k \) and \(Q_u^k \); the adjusted weights can be calculated as:

$$\begin{aligned} \tilde{W}_l^{k{*}}= & {} [w_{il}^{k*}] \hbox { where } w_{il}^{k*} =Q_l^k \times w_{il}^k \end{aligned}$$(6)$$\begin{aligned} \tilde{W}_u^{k{*}}= & {} [w_{iu}^{k*} ], \hbox { where }\; w_{iu}^{k*} =Q_u^k \times w_{iu}^k \end{aligned}$$(7)

After obtaining the new fuzzy weights as \(\tilde{W}_l^{k{*}} =[w_{il}^{k{*}} ],W_m^k =[w_{im}^k ]\) and \(W_u^{k{*}} =[w_{iu}^{k{*}} ]\), these weights are combined to obtain the triangular fuzzy weight of \(i\)th indicator as \(\tilde{w}_i^k =\left( {w_{il}^k ,w_{im}^k ,w_{iu}^k } \right) \) The\(\tilde{w}_i^k \) is local relative fuzzy weight of \(i\)th indicator by decision maker ‘\(k\)’. In a similar way, the relative fuzzy weights of aspects are determined. To compute the global relative weights of indicators, the local relative fuzzy weights of indicators are to be multiplied with the local relative weights of corresponding aspects.

Fuzzy rules in the proposed method

The fuzzy rule base for this method is based on expert knowledge. Sustainability score depends on performance ratings of organization with respect to indicators. Indicators used in BSC are identified as ‘Smaller is better’ and ‘Larger is better’ types. We applied the method suggested by Singh et al. (2014a) to assign the appropriate fuzzy numbers to accommodate both types of indicators. If an indicator is of ‘larger is better’ type, then, higher value of an indicator is preferred and this indicator is assigned a higher fuzzy number for higher value of indicator and vice versa. For other type of indicator which is ‘smaller is better’, lower value of indicator is preferred and this indicator is assigned a higher fuzzy number for lower value of indicator and vice versa. Rules for this FIS model have been developed on the basis of averaging concept as shown in Table 4.

Aggregation and defuzzification

In the case of group decision making, the performance ratings and importance weights are required to aggregate to obtain a single fuzzy number for each rating and weight. In this study, the fuzzy numbers are aggregated by using the arithmetic mean operator (Detyniecki et al. 2000). Aggregated relative weight of \(i\)th criteria can be represented as \(\tilde{w}_i =[(w{_{il}}, w{_{im}}, w{_{iu}})]\) and computed as follows:

where \(p\) is the number of decision makers and \(\tilde{w}_{i}^{k} =[(w_{il}^k ,w_{im}^k ,w_{iu}^k )]\) is the opinion of \(k\)th decision maker about relative weight of \(i\)th indicator.

Aggregated performance rating of organization with respect to \(i\)th indicator can be represented by \(\tilde{x}_i =[(x_{il} ,x_{im} ,x_{iu} )\) and computed as

where \(p\) is the number of decision makers and \(\tilde{x}_{i}^{k} =[(x_{il}^k ,x_{im}^k ,x_{iu}^k )]\) is the opinion of \(k\)th decision maker about the performance rating of organization with respect to \(i\)th indicator.

It is required to defuzzify the fuzzy number into a real number at each level of hierarchy. We applied centre of area (COA) method for defuzzification as represented by Eq. (10)

Explanation of the proposed method

The sustainability score (SS) for manufacturing SME depends on the various performance indicators’ values and their relative importance weights. Decision makers should be asked to identify the relevant indicators from each aspect of the BSC.

This hierarchal FIS structure has three stages as shown in Fig. 2. Each FIS is assigned two inputs and one output with five fuzzy membership functions to avoid rule explosion and to accommodate a large number of indicators. If the numbers of decision makers are more than one and there is no consensus about the importance weights of indicators or performance ratings, then aggregation method as proposed in “Aggregation and defuzzification” section can be used. The fuzzy performance ratings and fuzzy importance weights of indicators as well as the corresponding aspects are defuzzified to obtain the crisp values using Eq. (10). At first stage, crisp performance rating is multiplied by a corresponding crisp relative importance weightage of the indicator to obtain the weighted performance ratings to be used as input. In the process of selecting two by two inputs, if any remains, it would be treated as output in that particular category. This stage is continued until all selected indicators as inputs are accommodated in hierarchal FIS and output for each aspect reduced to one. There are four outputs from stage one, which are considered as performance ratings of the organization with respect to four aspects of BSC. The performance rating of each aspect is considered as inputs at stage 2. Stage 2 consists of two FIS with two inputs and one output to each FIS. Stage 3 consists of two inputs (outputs from stage 2) and one output. The output of stage 3 represents the overall sustainable performance of manufacturing SMEs as a sustainability score (SS).

Monotonic behavior of hierarchal FIS model

For hierarchal FIS, monotonicity of outputs with respect to its inputs is an indispensable requirement (Kouikoglou and Phillis 2009). The conditions for non-decreasing output of the single-stage fuzzy system are given by Won et al. (2002) as follows:

-

Condition 1. The rule bases should be non-decreasing.

-

Condition 2. The weights used in the defuzzification should be piecewise differentiable and non-decreasing.

-

Condition 3. The membership functions assigned to the inputs should be piece-wise differentiable, in the sense that they should be continuous on the corresponding domains and differentiable at all but a finite number of points. Moreover, for any pair of fuzzy sets A and B, if \(A < {B}\) then \([{d}\upmu _{A} (x)/dx]/ \upmu _{A} (x) \le [{d} \upmu _{B} (x)/dx]/ \upmu _{B} (x)\), for all x where \(\upmu _{A} (x)\) and \(\upmu _{B}\) (x) should be differentiable.

Kouikoglou and Phillis (2009) have expanded the applicability of these conditions by proving that these are also sufficient for the monotonicity of multi-stage, hierarchical fuzzy systems if each inference stage satisfies conditions 1 and 2, and the basic inputs satisfy condition 3.

To satisfy condition 1, non-decreasing rule base is developed. The highest value of fuzzy sets applied in this model as shown in Fig. 4 satisfies condition 2. (Won et al. (2002)) explained the condition 3 for triangular membership function as follows:

Fuzzy systems assigned triangular membership functions \(\tilde{A}=(a_l ,a_m ,a_u )\) are piece-wise differential, if \(a_l^p \le a_l^q ,a_m^p \le a_m^q \) and \(a_u^p \le a_u^q \) for all membership functions (\(1,\ldots ,p, q,\ldots ,m\)), where \(1\le \,{p}\le \,{q}\le \,m\).

In this study, each input is assigned the membership functions based on condition 3 for triangular membership function.

Illustrative example

In this section, applicability of the proposed model is illustrated by a case study. The case company (hereafter known as ABC) is located in Manesar, Gurgaon, India. ABC manufactures auto electrical components for various vehicle segments, gensets and home-appliances. ABC is an original equipment manufacturer (OEM) and supplier to more than 20 vehicles and genset manufacturers. ABC is an ISO 9001 certified company and striving to obtain ISO 14001 certification due to pressure from customers and also to achieve a competitive edge. ABC has been using traditional BSC as a performance evaluation framework for the last three years. After deliberations with decision makers, the BSC is identified as a holistic and comprehensive approach to be used as a framework for sustainability evaluation. The decision makers also felt that a fuzzy based model, which can accommodate relative importance of indicators and measures, could be used to deal with uncertainties associated with manufacturing decisions. Three decision makers from ABC are manager (quality assurance), who is also responsible for sustainability initiatives in the company, senior manager (finance) and manager (production).

Data collection

The decision makers were asked to select the indicators pertinent to ABC. Based on decision makers’ opinion, the hierarchy of the performance evaluation using BSC was defined as shown in Fig. 5. Decision makers’ opinion towards the importance of measures and indicators at respective levels were collected in the form of pair-wise comparison matrices as shown in Table 5. Decision makers were also asked to assess the performances rating of their organization with respect to selected indicators as shown in Table 6. It should be noted that decision makers’ opinions towards performance of ABC with respect to indicators are based on mutual agreement.

Implementation and result extraction

The data were gathered from decision makers of ABC in terms of linguistic variables. For further analysis, linguistic variables were replaced by corresponding TFN (see Fig. 4; Table 3). During the implementation and result extraction process, importance weightage of aspects and indicators were computed using FAHP [Eqs. (4)–(7)] for each decision maker. All fuzzy positive reciprocal matrices were examined for consistency by obtaining the consistency index of corresponding positive reciprocal matrices. In the case of inconsistency, decision makers were asked to re-evaluate their opinions. This process was continued until the consistency ratio for all comparison matrices became less than or equal to 0.10. After obtaining the importance weightage of each indicator, aggregation method (as discussed in “Aggregation and defuzzification” section) was applied to combine the weightages obtained from three decision makers as shown in Table 7 under the heading of local TFN weights. In order to compute the global relative weights, local fuzzy weights of indicators were multiplied with the local fuzzy weights of corresponding aspects. These global fuzzy weights were converted to crisp values using the center of area (COA) defuzzification method using Eq. (10) as shown in Table 7. Similarly, the performances rating of ABC with respect to indicators were also defuzzified to obtain real numbers (Table 8). Crisp values of importance weight and performance rating for corresponding indicator were multiplied to obtain weighted performance ratings as input values for stage 1. It is seen that values obtained after the multiplication process were reduced in proposed scale. To eradicate this problem, these values were normalized at stage one. The fuzzy logic toolbox of MATLAB program was used to design and implement the hierarchal FIS model. There were four outputs from stage one that were considered as performance ratings of the organization with respect to four aspects of the BSC. The performance rating of each aspect is considered as inputs at the stage 2. Stage 2 consists of two FIS with four inputs and two outputs. Stage 3 consists of two inputs (outputs from stage 2) and one output with one FIS. The output of stage three represents the overall sustainable performance of manufacturing SMEs as a sustainability score (SS).

The working of FIS models is represented by the rule viewers. To demonstrate the structure of rule viewer, one FIS at second stage is chosen as shown in Fig. 6. In this rule viewer, each input variable is plotted along column and each rule along a row. Input variable values can be changed by moving the red line, and output can be observed from output column. For all FIS in the proposed model, there are two input variables and five membership functions resulting into 25 \((5^{2})\) rules. The monotonic behavior of proposed hierarchal FIS is verified by varying the input values and observing the output values. In addition, this behavior was also verified from the output surface of a FIS as shown in Fig. 7. It is seen that increasing the input values results in non-decreasing value of outputs for each FIS. The robustness of the results obtained from FIS models is generally validated by applying different defuzzification methods (Ordoobadi 2009; Amindoust et al. 2012; Singh et al. 2014a). As can be seen from Table 9, the evaluation results are robust to alternative defuzzification modes which show the validity of this model.

Sensitivity analysis

Sensitivity analysis plays an important role in the decision making process by determining the effects of change in a decision parameter on overall performance. This section attempts to help decision-makers to select the appropriate strategy by sustainability evaluation in the given scenario. A scenario is defined by the available set of sustainability indicators. The change in the values of indicators and resulting change in the sustainability scores observed, the decision makers could identify the most important indicators to improve the sustainability performance.

Sensitivity analysis requires the computation of the gradient of sustainability score with respect to each indicator. A gradient gives the increase of sustainability score per unit increase of an indicator. To perform sensitivity analysis, we followed method suggested by Phillis and Davis (2009). The steps of the sensitivity analysis are as follows:

-

1.

Calculation of the sustainability score: For a given organization, obtain the performance values with respect to each indicator using the proposed method. Start from stage 1 of the hierarchal FIS and proceed successively to obtain the sustainability score.

-

2.

Introduction of perturbation: For an indicator, say, \(i\), increase its weighted performance value \((x_{i})\) by some fixed amount (\(\delta \)), for example, 10 %. If the result is greater than 100, then truncate it to 100 to avoid overshooting the permissible region of the indicators.

-

3.

Sensitivity analysis: evaluate the sustainability score with the same set of data in step 1 except for indicator ‘\(i\)’ whose value is now \(x_{i}+\delta \). Denote the new evaluation as SS \(_{(xi+\delta )}\). The gradient of SS with respect to \(i\)th indicator is defined by forward difference

$$\begin{aligned} \varDelta _i =\,SS_{(xi+\delta )} -SS \end{aligned}$$Reset the value of indicator to \(x_{i}\).

-

4.

Loop: repeat step 2 and 3 for all indicators.

-

5.

Ranking: identify the gradient with the largest values, which corresponds to the indicators which affects most in given scenario.

During the sensitivity analysis, biasness towards indicators which belongs to small groups was observed. For example, financial aspect depends on only two indicators. Therefore, an increase in the debt ratio has nearly direct effect on SS. Internal business process has three indicators, an improvement in one of these indicators results in small improvement of SS. To avoid this bias, the indicator ‘\(i\)’ is ranked according to scaled gradient \((\hbox {D}_{i})\).

where \((100- x_{i})\) is the distance of the \(i\)th indicator from sustainable value and \(\varDelta _{i}\) is gradient of sustainability score with respect to \(i\)th indicator. Therefore, indicators which affect the SS most and are farther from sustainable region are identified and ranked to improve the sustainability performance. The results of sensitivity analysis for ABC are shown in Table 10.

The overall sustainability performance of ABC was found to be moderate. At present scenario, as can be seen from Table 10, the order of importance of indicators is \(\hbox {C1}>\hbox {L1}>\hbox {F2}>\hbox {P1}>\hbox {P3}>\hbox {C2}>\hbox {L2}\). As manufacturing cost (F1) and hazardous material ratio (P2) are already within sustainable region (i.e., distance from sustainable value is zero or near zero), these indicators are not identified as the important indicators. Based on this analysis, decision makers can devise the strategy to improve its sustainability performance.

Conclusions

This study presented an integrated FAHP–FIS method for sustainability evaluation of manufacturing SMEs. The main contributions of this work are summarized as follows:

-

(1)

Sustainability evaluation of manufacturing SMEs: to date, there are very few studies on sustainability evaluation of manufacturing SMEs. Considering the characteristics of SMEs, the indicators for sustainability performance evaluations are identified from literature and classified in four perspectives of BSC framework.

-

(2)

The proposed method can be used for any scenario (i.e. any number of input indicators can be used). The varied importance of indicators and measures are considered to be relative that is very often in the decision making in manufacturing organization. The relative importance of indicators and measures obtained by FAHP method are considered more reliable than absolute weights directly obtained from decision makers.

-

(3)

Due to the vagueness in manufacturing decision making, the decision makers express their opinions into linguistic terms instead of crisp values. Therefore, FIS based method was proposed to deal with subjectivity involved in performance evaluation of manufacturing SMEs.

-

(4)

Using sensitivity analysis, this study identified the most important indicators for sustainability performance. Future research can be focused on the interaction effects (i.e. increasing two or more inputs’ values simultaneously) on sustainability performance to identify most important set of indicators.

References

Abran, A., & Buglione, L. (2003). A multidimensional performance model for consolidating balanced scorecards. Advances in Engineering Software, 34(6), 339–349.

Addy, C., Pearce, J., & Bennet, J. (1994). Performance measures in small manufacturing enterprises; Are firms measuring what matters? In 10th National conference on manufacturing research (proceedings), 1994. Taylor & Francis, pp. 110–114.

Afghan, N. H., Darwish, M., & Carvalho, M. (1999). Sustainability assessment of desalination plants for water production. Desalination, 124, 19–31.

Agan, Y., Acar, M. F., & Borodin, A. (2013). Drivers of environmental processes and their impact on performance: A study of Turkish SMEs. Journal of Cleaner Production, 51, 23–33.

Alshawi, S., Missi, F., & Irani, Z. (2011). Organisational, technical and data quality factors in CRM adoption—SMEs perspective. Industrial Marketing Management, 40(3), 376–383. doi:10.1016/j.indmarman.2010.08.006.

Amindoust, A., Ahmed, S., Saghafinia, A., & Bahreininejad, A. (2012). Sustainable supplier selection: A ranking model based on fuzzy inference system. Applied Soft Computing, 12(6), 1668–1677. doi:10.1016/j.asoc.2012.01.023.

Asosheh, A., Nalchigar, S., & Jamporazmey, M. (2010). Information technology project evaluation: An integrated data envelopment analysis and balanced scorecard approach. Expert Systems with Applications, 37(8), 5931–5938.

Ayağ, Z., & Özdemir, R. (2006). A fuzzy AHP approach to evaluating machine tool alternatives. Journal of Intelligent Manufacturing, 17(2), 179–190.

Ayağ, Z., Samanlioglu, F., & Büyüközkan, G. (2013). A fuzzy QFD approach to determine supply chain management strategies in the dairy industry. Journal of Intelligent Manufacturing, 24(6), 1111–1122. doi:10.1007/s10845-012-0639-4.

Azadegan, A., Porobic, L., Ghazinoory, S., Samouei, P., & Saman Kheirkhah, A. (2011). Fuzzy logic in manufacturing: A review of literature and a specialized application. International Journal of Production Economics, 132(2), 258–270.

Baja, S., Chapman, D. M., & Dragovich, D. (2002). A conceptual model for defining and assessing land management units using a fuzzy modeling approach in GIS environment. Environmental Management, 29(5), 647–661. doi:10.1007/s00267-001-0053-8.

Bhagwat, R., & Sharma, M. K. (2007). Performance measurement of supply chain management: A balanced scorecard approach. Computers & Industrial Engineering, 53(1), 43–62.

Biondi, Vittorio, Frey, Marco, & Iraldo, Fabio. (2000). Environmental management systems and SMEs. Greener Management International, 2000(29), 55–69.

Boër, C. R., Sorlini, M., Bettoni, A., & Pedrazzoli, P. (2013). Mass customization and sustainability. New York: Springer.

Brundtland, G. (1987). Our common future: Report of the 1987 World Commission on Environment and Development. Oxford: Oxford University Press.

Buckley, J. J. (1985). Fuzzy hierarchical analysis. Fuzzy Sets and Systems, 17(3), 233–247.

Bullinger, H.-J., Kühner, M., & Van Hoof, A. (2002). Analysing supply chain performance using a balanced measurement method. International Journal of Production Research, 40(15), 3533–3543.

Butler, J. B., Henderson, S. C., & Raiborn, C. (2011). Sustainability and the balanced scorecard: Integrating green measures into business reporting. Management Accounting Quarterly, 12(2), 1–10.

Carrera, D. A., & Mayorga, R. V. (2008). Supply chain management: A modular fuzzy inference system approach in supplier selection for new product development. Journal of Intelligent Manufacturing, 19(1), 1–12.

Carter, C. R., & Rogers, D. S. (2008). A framework of sustainable supply chain management: Moving toward new theory. International Journal of Physical Distribution & Logistics Management, 38(5), 360–387. doi:10.1108/09600030810882816.

Cebeci, U. (2009). Fuzzy AHP-based decision support system for selecting ERP systems in textile industry by using balanced scorecard. Expert Systems with Applications, 36(5), 8900–8909.

Chan, F. T. S., & Qi, H. J. (2002). A fuzzy basis channel-spanning performance measurement method for supply chain management. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 216(8), 1155–1167. doi:10.1243/095440502760272421.

Cheng, C.-H. (1997). Evaluating naval tactical missile systems by fuzzy AHP based on the grade value of membership function. European Journal of Operational Research, 96(2), 343–350.

Chouikhi, H., Khatab, A., & Rezg, N. (2014). A condition-based maintenance policy for a production system under excessive environmental degradation. Journal of Intelligent Manufacturing, 25(4), 727–737. doi:10.1007/s10845-012-0715-9.

Ciliberti, F., Pontrandolfo, P., & Scozzi, B. (2008). Investigating corporate social responsibility in supply chains: A SME perspective. Journal of Cleaner Production, 16(15), 1579–1588. doi:10.1016/j.jclepro.2008.04.016.

Conner, J., Phillis, Y., & Manousiouthakis, V. (2009). A fuzzy logic global optimization approach to sustainability assessment. Paper presented at the AIChE Annual Meeting, Nashville, 8–13 November.

Csutora, R., & Buckley, J. J. (2001). Fuzzy hierarchical analysis: The Lambda–Max method. Fuzzy Sets and Systems, 120(2), 181–195.

Detyniecki, M., Bouchon-meunier, D. B., Yager, D. R., & Prade, R. H. (2000). Mathematical aggregation operators and their application to video querying. Doctoral Thesis-Research Report, Laboratoire d’Informatique de Paris.

Egilmez, G., Kucukvar, M., & Tatari, O. (2013). Sustainability assessment of U.S. manufacturing sectors: An economic input output-based frontier approach. Journal of Cleaner Production, 53, 91–102.

Epstein, M. J., & Wisner, P. S. (2001). Using a balanced scorecard to implement sustainability. Environmental Quality Management, 11(2), 1–10.

Erginel, N. (2010). Modeling and analysis of packing properties through a fuzzy inference system. Journal of Intelligent Manufacturing, 21(6), 869–874.

Fatimah, Y. A., Biswas, W., Mazhar, I., & Islam, M. N. (2013). Sustainable manufacturing for Indonesian small-and medium-sized enterprises (SMEs): The case of remanufactured alternators. Journal of Remanufacturing, 3(1), 1–11.

Fernandes, K. J., Raja, V., & Whalley, A. (2006). Lessons from implementing the balanced scorecard in a small and medium size manufacturing organization. Technovation, 26(5), 623–634.

Gokulachandran, J., & Mohandas, K. (2015). Comparative study of two soft computing techniques for the prediction of remaining useful life of cutting tools. Journal of Intelligent Manufacturing, 26(2), 255–268. doi:10.1007/s10845-013-0778-2.

Haapala, K. R., Zhao, F., Camelio, J., Sutherland, J. W., Skerlos, S. J., Dornfeld, D. A., et al. (2013). A review of engineering research in sustainable manufacturing. Journal of Manufacturing Science and Engineering, 135(4), 041013.

Hervani, A. A., Helms, M. M., & Sarkis, J. (2005). Performance measurement for green supply chain management. Benchmarking: An International Journal, 12(4), 330–353. doi:10.1108/14635770510609015.

Hillary, R. (2004). Environmental management systems and the smaller enterprise. Journal of Cleaner Production, 12(6), 561–569.

Hsieh, T.-Y., Lu, S.-T., & Tzeng, G.-H. (2004). Fuzzy MCDM approach for planning and design tenders selection in public office buildings. International Journal of Project Management, 22(7), 573–584.

Huang, C.-Y. (2015). Innovative parametric design for environmentally conscious adhesive dispensing process. Journal of Intelligent Manufacturing, 26(1), 1–12. doi:10.1007/s10845-013-0755-9.

Hudson, M., Lean, J., & Smart, P. (2001). Improving control through effective performance measurement in SMEs. Production Planning & Control, 12(8), 804–813.

Iqbal, A., Zhang, H.-C., Kong, L. L., & Hussain, G. (2013). A rule-based system for trade-off among energy consumption, tool life, and productivity in machining process. Journal of Intelligent Manufacturing, 1–16. doi:10.1007/s10845-013-0851-x.

ITA, D. o. C., United State. (2007). How does commerce define sustainable manufacturing? In D. o. Commerce (Ed.).

Jaffar, H., Venkatachalam, A., Joshi, K., Ungureanu, A., De Silva, N., Dillon, O, Jr, et al. (2007). Product design for sustainability: A new assessment methodology and case studies. In M. Kutz (Ed.), Handbook of environmentally conscious mechanical design (pp. 25–65). New York: Wiley.

Jakovljevic, Z., Petrovic, P. B., Mikovic, V. D., & Pajic, M. (2014). Fuzzy inference mechanism for recognition of contact states in intelligent robotic assembly. Journal of Intelligent Manufacturing, 25(3), 571–587.

Jassbi, J., Serra, P., Ribeiro, R., & Donati, A. (2006). A comparison of mandani and sugeno inference systems for a space fault detection application. In Automation congress, 2006. WAC’06. World, 2006. IEEE, pp. 1–8.

Joung, C. B., Carrell, J., Sarkar, P., & Feng, S. C. (2013). Categorization of indicators for sustainable manufacturing. Ecological Indicators, 24, 148–157. doi:10.1016/j.ecolind.2012.05.030.

Kaplan, R. S., & Norton, D. P. (1992). The balanced scorecard-measures that drive performance. Harvard Business Review, 70(1), 71–79.

Kaplan, R. S., & Norton, D. P. (2001). Transforming the balanced scorecard from performance measurement to strategic management: Part I. Accounting Horizons, 15(1), 87–104.

Kemp, R. (1994). Technology and the transition to environmental sustainability—The problem of technological regime shifts. Futures, 26(10), 1023–1046. doi:10.1016/0016-3287(94)90071-X.

Kim, J., Suh, E., & Hwang, H. (2003). A model for evaluating the effectiveness of CRM using the balanced scorecard. Journal of Interactive Marketing, 17(2), 5–19.

Kommadath, B., Sarkar, R., & Rath, B. (2012). A fuzzy logic based approach to assess sustainable development of the mining and minerals sector. Sustainable Development, 20(6), 386–399. doi:10.1002/Sd.503.

Kouikoglou, V. S., & Phillis, Y. A. (2009). On the monotonicity of hierarchical sum-product fuzzy systems. Fuzzy Sets and Systems, 160(24), 3530–3538. doi:10.1016/j.fss.2009.02.001.

Kouloumpis, V., Kouikoglou, V., & Phillis, Y. (2008). Sustainability assessment of nations and related decision making using fuzzy logic. IEEE Systems Journal, 2(2), 224–236.

Kovac, P., Rodic, D., Pucovsky, V., Savkovic, B., & Gostimirovic, M. (2013). Application of fuzzy logic and regression analysis for modeling surface roughness in face milliing. Journal of Intelligent Manufacturing, 24(4), 755–762. doi:10.1007/s10845-012-0623-z.

KPMG international survey of corporate responsibility reporting (2013). http://www.kpmg.com/Global/en/IssuesAndInsights/ArticlesPublications/corporate-responsibility/Pages/default.aspx. Accessed November 05, 2014.

Labuschagne, C., Brent, A. C., & van Erck, R. P. G. (2005). Assessing the sustainability performances of industries. Journal of Cleaner Production, 13(4), 373–385. doi:10.1016/j.jclepro.2003.10.007.

Lee, A. H., Chen, W.-C., & Chang, C.-J. (2008). A fuzzy AHP and BSC approach for evaluating performance of IT department in the manufacturing industry in Taiwan. Expert Systems with Applications, 34(1), 96–107.

Lee, K.-H. (2009). Why and how to adopt green management into business organizations? The case study of Korean SMEs in manufacturing industry. Management Decision, 47(7), 1101–1121.

Lepoutre, J., & Heene, A. (2006). Investigating the impact of firm size on small business social responsibility: A critical review. Journal of Business Ethics, 67(3), 257–273.

Leung, L., Lam, K., & Cao, D. (2005). Implementing the balanced scorecard using the analytic hierarchy process & the analytic network process. Journal of the Operational Research Society, 57(6), 682–691.

Liberatore, M. J. (1987). An extension of the analytic hierarchy process for industrial R&D project selection and resource allocation. IEEE Transactions on Engineering Management, 1, 12–18.

Mamdani, E. H., & Assilian, S. (1975). An experiment in linguistic synthesis with a fuzzy logic controller. International Journal of Man-Machine Studies, 7(1), 1–13.

Manville, G. (2007). Implementing a balanced scorecard framework in a not for profit SME. International Journal of Productivity and Performance Management, 56(2), 162–169.

Mon, D.-L., Cheng, C.-H., & Lin, J.-C. (1994). Evaluating weapon system using fuzzy analytic hierarchy process based on entropy weight. Fuzzy Sets and Systems, 62(2), 127–134.

Moore, S. B., & Manring, S. L. (2009). Strategy development in small and medium sized enterprises for sustainability and increased value creation. Journal of Cleaner Production, 17(2), 276–282. doi:10.1016/j.jclepro.2008.06.004.

OECD. (2011). OECD Sustainable Manufacturing Toolkit. http://www.oecd.org/innovation/green/toolkit/

Olugu, E. U., Wong, K. Y., & Shaharoun, A. M. (2011). Development of key performance measures for the automobile green supply chain. Resources Conservation and Recycling, 55(6), 567–579. doi:10.1016/j.resconrec.2010.06.003.

Ordoobadi, S. M. (2009). Development of a supplier selection model using fuzzy logic. Supply Chain Management: An International Journal, 14(4), 314–327.

Phillis, Y. A., & Davis, B. J. (2009). Assessment of corporate sustainability via fuzzy logic. Journal of Intelligent & Robotic Systems, 55(1), 3–20. doi:10.1007/s10846-008-9289-3.

Rachuri, S., Sriram, R. D., & Sarkar, P. (2009). Metrics, standards and industry best practices for sustainable manufacturing systems. IEEE International Conference on Automation Science and Engineering, 2009, 472–477. doi:10.1109/Coase.2009.5234090.

Ravi, V., Shankar, R., & Tiwari, M. (2005). Analyzing alternatives in reverse logistics for end-of-life computers: ANP and balanced scorecard approach. Computers & Industrial Engineering, 48(2), 327–356.

Reich-Weiser, C., Vijayaraghavan, A., & Dornfeld, D. A. (2009). Metrics for sustainable manufacturing. In Msec 2008: Proceedings of the ASME international manufacturing science and engineering conference 2008, Vol. 1, pp. 327–335.

Saaty, T., & Vargas, L. L. G. (2001). Models, methods, concepts, and applications of the analytic hierarchy process (Vol. 34). New York: Springer.

Saaty, T. L. (1980). The analytical hierarchical process. New York: Wiley.

Schau, E. M., & Fet, A. M. (2011). Assessing the ecological soundness of organic and conventional agriculture by means of life cycle assessment (LCA) - a case study of leek production (vol 111, pg 1028, 2009). British Food Journal, 113(6–7), 809–809.

Seuring, S., & Muller, M. (2008). From a literature review to a conceptual framework for sustainable supply chain management. Journal of Cleaner Production, 16(15), 1699–1710. doi:10.1016/j.jclepro.2008.04.020.

Singh, S., Olugu, E. U., & Fallahpour, A. (2014). Fuzzy-based sustainable manufacturing assessment model for SMEs. Clean Technologies and Environmental Policy, 16(5), 847–860.

Singh, S., Olugu, E. U., Musa, S. N., & Mahat, A. B. (2014). Proposition of key performance measures for sustainable manufacturing in SMEs. Paper presented at the MSME conclave cum conference on sustainable supply chain capabilities of micro, small and medium enterprises: Influences, practices, training needs and employment opportunities, Doon University, Dehradun, 10th May 2014.

Solvang, W. D., Romàn, E., Deng, Z., & Solvang, B. (2006). A framework for holistic greening of value chains. In Knowledge enterprise: Intelligent strategies in product design, manufacturing, and management. Springer, pp. 350–355

Tanzil, D., & Beloff, B. R. (2006). Assessing impacts: Overview on sustainability indicators and metrics. Environmental Quality Management, 15(4), 41–56. doi:10.1002/tqem.20101.

Ticehurst, J. L., Newham, L. T. H., Rissik, D., Letcher, R. A., & Jakeman, A. J. (2007). A Bayesian network approach for assessing the sustainability of coastal lakes in New South Wales. Australia. Environmental Modelling & Software, 22(8), 1129–1139. doi:10.1016/j.envsoft.2006.03.003.

Tseng, M.-L. (2010). Implementation and performance evaluation using the fuzzy network balanced scorecard. Computers & Education, 55(1), 188–201.

Varma, S., Wadhwa, S., & Deshmukh, S. (2008). Evaluating petroleum supply chain performance: Application of analytical hierarchy process to balanced scorecard. Asia Pacific Journal of Marketing and Logistics, 20(3), 343–356.

Vinodh, S., & Balaji, S. (2011). Fuzzy logic based leanness assessment and its decision support system. International Journal of Production Research, 49(13), 4027–4041.

Vinodh, S., Jayakrishna, K., & Joy, D. (2012). Environmental impact assessment of an automotive component using eco-indicator and CML methodologies. Clean Technologies and Environmental Policy, 14(2), 333–344. doi:10.1007/s10098-011-0405-x.

Vinodh, S., Varadharajan, A. R., & Subramanian, A. (2013). Application of fuzzy VIKOR for concept selection in an agile environment. International Journal of Advanced Manufacturing Technology, 65(5–8), 825–832.

Williamson, D., Lynch-Wood, G., & Ramsay, J. (2006). Drivers of environmental behaviour in manufacturing SMEs and the implications for CSR. Journal of Business Ethics, 67(3), 317–330.

Won, J. M., Park, S. Y., & Lee, J. S. (2002). Parameter conditions for monotonic Takagi–Sugeno–Kang fuzzy system. Fuzzy Sets and Systems, 132(2), 135–146. doi:10.1016/S0165-0114(02)00121-5.

Wu, H.-Y., Tzeng, G.-H., & Chen, Y.-H. (2009). A fuzzy MCDM approach for evaluating banking performance based on Balanced Scorecard. Expert Systems with Applications, 36(6), 10135–10147.

Zhang, L. F. (2007). On the assessment of petroleum corporation’s sustainability based on linguistic fuzzy method. In Computational science—ICCS 2007, Pt 1, proceedings, Vol. 4487, pp. 562–566.

Acknowledgments

This study is supported by University of Malaya Research Grant (RG138-12AET). We thank reviewers for their comments which have helped to improve the quality of our manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, S., Olugu, E.U., Musa, S.N. et al. Fuzzy-based sustainability evaluation method for manufacturing SMEs using balanced scorecard framework. J Intell Manuf 29, 1–18 (2018). https://doi.org/10.1007/s10845-015-1081-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-015-1081-1