Abstract

This paper presents a new robust optimization method for supply chain network design problem by employing variable possibility distributions. Due to the variability of market conditions and demands, there exist some impreciseness and ambiguousness in developing procurement and distribution plans. The proposed optimization method incorporates the uncertainties encountered in the manufacturing industry. The main motivation for building this optimization model is to make tools available for producers to develop robust supply chain network design. The modeling approach selected is a fuzzy value-at-risk (VaR) optimization model, in which the uncertain demands and transportation costs are characterized by variable possibility distributions. The variable possibility distributions are obtained by using the method of possibility critical value reduction to the secondary possibility distributions of uncertain demands and costs. We also discuss the equivalent parametric representation of credibility constraints and VaR objective function. Furthermore, we take the advantage of structural characteristics of the equivalent optimization model to design a parameter-based domain decomposition method. Using the proposed method, the original optimization problem is decomposed to two equivalent mixed-integer parametric programming sub-models so that we can solve the original optimization problem indirectly by solving its sub-models. Finally, we present an application example about a food processing company with four suppliers, five plants, five distribution centers and five customer zones. We formulate our application example as parametric optimization models and conduct our numerical experiments in the cases when the input data (demands and costs) are deterministic, have fixed possibility distributions and have variable possibility distributions. Experimental results show that our parametric optimization method can provide an effective and flexible way for decision makers to design a supply chain network.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

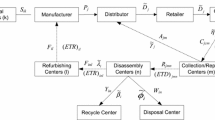

The supply chain is composed of some business entities, mainly including suppliers, plants, distribution centers and customers, whose functions are to acquire raw materials, convert them to finished products, and distribute these products to customers. The supply chain network design seeks to determine the configuration of supply chain network with the objective of minimizing the total costs while satisfying service levels. As an overall research issue, supply chain plan usually involves several levels of hierarchical decisions to improve its performance. The strategic level supply chain plan involves deciding the configuration of the network, i.e., the number, location, capacity and technology of the facilities. The tactical level supply chain plan consists of deciding the aggregate quantities and material flows for purchasing, processing, and distribution of products. The operational level supply chain plan includes fulfilling the demands of the customers.

The supply chain network design problem can be thought as an extension of facility location problem. The facility location problem is composed of a set of potential facility sites where a facility can be opened and a set of demand points that must be serviced, and its goal is to determine which subset of facilities to open so as to minimize the total costs of delivery of goods to the customers plus the opening costs of facilities (Gülpınar et al. 2013). This statement establishes clearly a link between facility location and strategic supply chain network design, though typically no location decisions are made on the tactical or even operational level supply chain plan. Melo et al. (2009) gave a literature review of facility location models in the context of supply chain management. Different from core facility location models, there exist several different types of facilities in supply chain network, and each type plays a specific role, such as production and warehousing, and a natural product flow among them. Each set of facilities with the same type function is usually denoted by a layer or an echelon, i.e., the supply chain network includes some hierarchies of facilities. Therefore, the facility location model has been very helpful as a basis for building a comprehensive supply chain design model.

The supply chain network design problem has been addressed by different methods in the literature. The effect of strategic decisions has lasted for several years, during which the parameters of the business environment (e.g. demands and transportation costs) may change. As shown in the related literature (Efendigil and Önüt 2012; Taleizadeh et al. 2013), all the strategic, tactical and operational decisions should be made under uncertainty, which will result in more realistic supply chain network design models. So far, stochastic approach, fuzzy technique, and robust optimization have been developed for supply chain network design problems under uncertainty. However, there is little research for modeling and designing fuzzy supply chain network problem by parametric optimization method, which provides us a strong motivation to study in this active research area. On the basis of fuzzy possibility theory (Liu and Liu 2010), we develop a fuzzy VaR optimization model that combines facility location and decisions on distribution of those products to multiple customer zones, in which the uncertain demands and transportation costs are characterized by variable possibility distributions. An application example about a food processing company is provided to illustrate our parametric optimization method.

The remainder of this paper is organized as follows. “Literature review” section gives an overview of related works. “Proposed approach” section states our new robust optimization method and major contributions. “Formulation of supply chain network design problem” section develops a new risk-averse fuzzy optimization model for the supply chain network design problem. “Parameter-based domain decomposition method” section deals with the equivalent parametric programming models of the original supply chain optimization model, and designs the parameter-based domain decomposition method by the structural characteristics of the parametric programming models. “An application example and comparison study” section provides one application example to illustrate our new robust parametric optimization ideas. Some managerial implications are also derived from the experimental results in this section. The conclusions are summarized in the last section.

Literature review

Deterministic supply chain network design

Since Geoffrion and Graves (1974) proposed the seminal work on designing single period multi-commodity distribution system, some interesting optimization-based approaches have been developed for the design of supply chain networks. Bachlaus et al. (2008) presented a multi-objective optimization model that aimed to minimize the cost and maximize the plant flexibility and volume flexibility for a five-echelon supply chains. Srivastava (2008) combined descriptive modeling with optimization techniques to provide an integrated holistic conceptual framework and detailed solutions for network configuration and design. Zhang and Zhou (2011) established nonlinear complementarity formulations for the supply chain network equilibrium models and solved them by the smoothing Newton algorithm. Cheshmehgaz et al. (2013) formulated a three-level logistic networks as the multiple criteria decision making problem, and designed a Pareto-based multi-objective evolutionary algorithm to find the compromise solutions. For the recent development of supply chain network problem, the interested reader may refer to (Chandra and Grabis 2007; Dong et al. 2012; Fujita et al. 2013; Li and Womer 2012).

Uncertain supply chain network design

Supply chain network design problems have found a breadth of application areas while maintaining a basic assumption of deterministic conditions, i.e., the critical parameters like demands and transportation costs are assumed to be known in advance. However, for these application-oriented problems, the validity of this assumption may be questionable. In many real-life applications, one or more of the problem parameters are usually not known for certain. In some cases, these uncertain parameters in supply chain network design are modeled as random variables with known probability distributions. Cohen and Lee (1988) presented a comprehensive supply chain model by four stochastic sub-models, and a heuristic procedure was introduced for the optimal solution when these sub-models were integrated. Georgiadis and Athanasiou (2013) employed a simulation-based system dynamics optimization approach to studying the system’s response in terms of transient flows, actual/desired capacity level, capacity expansions/contractions and total supply chain profit in a closed-loop supply chains with two sequential product-types. Kristianto et al. (2014) designed a reconfigurable supply chain network by optimizing inventory allocation and transportation routing, in which the transportation routing was assumed to be stochastic in nature. Zhou and Min (2011) proposed a non-linear mixed-integer programming model and used the genetic algorithm to solve the stochastic network design problem in a closed-loop supply chain. Some drawbacks in using the stochastic approach to designing supply chain networks have been analyzed in (Pishvaee et al. 2011).

With the development of fuzzy theory (Zadeh 1965, 1975, 1978), more and more scholars realized the existence of fuzzy uncertainty in decision systems (Petrovic et al. 2008; Tsao and Lu 2012; Jolai et al. 2011; Wong 2012; Kubat and Yuce 2012). The inclusion of fuzzy uncertainty in the supply chain network is a challenge issue in terms of modeling and solution, and there is a growing interest in building models and algorithms in the literature. Gumus et al. (2009) considered a three echelon supply chain network under demand uncertainty, and applied the proposed integrated neuro-fuzzy and mixed integer linear programming approach to the proposed network design. Miller and John (2010) built a multiple echelon supply chain model based on interval type-2 fuzzy logic, and used the genetic algorithm to search for a near-optimal plan for the model. Paksoy et al. (2012) built a fuzzy multi-objective linear programming model to integrate the supply chain network of an edible vegetable oils manufacturer, and converted the original model into an ordinary linear programming. Pishvaee and Razmi (2012) employed multi-objective optimization method with the emphasis on supply chain social responsibility and environmental consciousness under uncertainty, and developed an interactive fuzzy solution method. Fazlollahtabar et al. (2013) proposed a fuzzy mathematical programming model for a supply chain, and applied two ranking functions to their solution method. Yang and Liu (2013) developed a mean-risk fuzzy supply chain network design model, and solved it by hybrid memetic algorithm incorporating the reduced variable neighborhood search and approximation scheme. In the present paper, we propose a fuzzy VaR optimization model for a supply chain with multiple products, single period and four echelons: suppliers, plants, distribution centers and customer zones. We characterize the uncertain demands and transportation costs by variable possibility distributions, which lead to a new parametric optimization method for supply chain network design problems.

Robust supply chain network design

Robust optimization was first proposed by Soyster (1973) for inexact linear programming problems. Ben-Tal and Nemirovski (1998) and El-Ghaoui et al. (1998) extended the work of Soyster (1973) for uncertain linear problems with different convex uncertain sets, which put a significant step forward in robust optimization theory. In the area of soft worst case robust optimization, Inuiguchi and Sakawa (1998) used the min-max regret approach for fuzzy mathematical programming, whose work was later followed by Kasperski and Kulej (2009) and Nie et al. (2007). Bertsimas and Sim (2004) proposed a less conservative worse case method based on Soyster’s work. Mulvey et al. (1995) presented a more flexible robust optimization method for scenario-based stochastic programming models, which is usually categorised into realistic robust optimization.

In recent years, many authors applied the robust optimization to real world problems, including inventory management (Ben-Tal et al. 2009), capacity expansion plans (Chien and Zheng 2012), portfolio selection (El-Ghaoui et al. 2003), facility location (Gülpınar et al. 2013) and the supply chain network design problems. Pan and Nagi (2010) formulated a robust optimization model for an agile manufacturing supply chain under demand uncertainty, and designed a heuristic to solve it based on the k-shortest path algorithm. In order to handle the inherent uncertainty of input data, Pishvaee et al. (2011) gave a robust optimization model in a closed-loop supply chain network design problem, and assessed the robustness of the solutions obtained by the proposed model under different test problems. Hasani et al. (2012) presented a general comprehensive model of strategic closed-loop supply chain network design based on an interval robust optimisation technique. Baghalian et al. (2013) constructed a stochastic formulation for designing a network of multi-product supply chains based on reliability theory and robust optimization concept, and created a transformation based on the piecewise linear method to solve the model to attain global optimality. Baud-Lavigne et al. (2014) considered the problem of finding the robust solutions for the joint product family and supply chain design problem. Our work in the present paper differs from the above mentioned robust studies because it emphasizes the uncertain demands and transportation costs have variable possibility distributions instead of fixed possibility distributions. The robustness in our paper refers to the variable possibility distributions of uncertain demands (costs). There are two types of parameters to describe our variable possibility distributions. The first type parameters \(\theta \) describe the degrees of uncertainty that demands (costs) take their values, while the second type parameters \(\alpha \) represent the possibility levels in the supports of uncertain demands (costs). Given the first type parameters \(\theta \), the possibility distributions run over the supports of uncertain demands (costs) as the parameters \(\alpha \) vary in the unit interval \([0, 1]\).

Proposed approach

In the present paper, we propose a new fuzzy optimization model for supply chain network design problem, in which the demands and transportation costs are characterized by variable possibility distributions. Based on risk-averse criterion, we construct the objective function by using the value-at-risk of the total costs. In addition, we model the requirements of customers demands as credibility constraints to reflect the service levels of supply chain. We obtain the parametric possibility distributions of uncertain demands and costs via the method of possibility critical value (PCV) reduction, and convert the original credibility-constrained optimization problem into its equivalent parametric programming models. The major new contributions are offered as follows.

-

(i)

We propose a new robust method to characterize uncertain demands and costs included in the supply chain network design problems by using variable possibility distributions instead of fixed possibility distributions. The variable possibility distributions are obtained by using the method of PCV reduction to the secondary possibility distributions of uncertain demands and costs, and characterized by two types of parameters.

-

(ii)

On the basis of risk-averse criterion, we develop a new fuzzy supply chain network design model with VaR objective, in which the service quality of supply chain is described by credibility levels. When the uncertain demands and costs are mutually independent (i.e., the joint possibility distribution of uncertain demands and costs can be represented as the minimum of their marginal possibility distributions), we discuss the equivalent representations of credibility constraints, and turn the original supply chain optimization problem to its equivalent parametric programming models, which can be solved by the designed parameter-based domain decomposition method.

-

(iii)

We provide a practice-oriented case about a food processing company to demonstrate the effectiveness of the proposed optimization method. Compared to several related studies on this topic, the computational results reported in the numerical experiments show the credibility and superiority of the proposed parametric optimization method. In our optimization method, decision makers can select various values of parameters depending on their preference or attitude towards risk. What’s more, some managerial insights are derived from the experimental results.

Formulation of supply chain network design problem

Problem description and notations

The supply chain network design is the most basic decision of supply chain management, and it influences all other decisions concerning a supply chain and has the most extensive effect on the return and service levels of supply chain (Baghalian et al. 2013). In a realistic supply chain, there are various sources and types of uncertainty along the supply chain network. For example, we usually cannot foretell precisely the demands of customers and transportation costs. In such cases, the domain experts’ subjective opinions are helpful to describe these uncertain parameters. As a consequence, fuzzy supply chain design models have been developed in the literature, in which uncertain parameters are often characterized by fixed possibility distributions or membership functions. In this paper, we further address this issue by robust parametric optimization approach. In our method, we will characterize the uncertain demands and costs by variable possibility distributions instead of fixed possibility distributions. The variable possibility distributions are obtained by using the method of PCV reduction to the secondary possibility distributions of uncertain demands and costs. The reduced fuzzy demands and costs have variable possibility distributions with two types of parameters \(\theta \) and \(\alpha \). When the parameter \(\alpha \) varies in the unit interval \([0,1]\), the variable distribution distributions run over the supports of demands and costs, so that the important information about demands and costs cannot be lost. In the following, we will adopt this robust modeling idea to characterize the uncertain parameters included in fuzzy supply chain network design problems. In “Appendix” of the paper, we provide detailed discussion about the method of PCV reduction, parametric possibility distributions of reduced fuzzy variables as well as their properties.

Let \(S,V,I,J,K\) and \(M\) be the sets of suppliers, raw materials, products, plants, distribution centers and customers, respectively. In order to describe conveniently the supply chain network design model, we collect the required parameters in Table 1.

According to the secondary possibility distributions of uncertain coefficients \(\tilde{d}_{im},\tilde{\xi }_{vsj},\tilde{\zeta }_{ijk},\tilde{\eta }_{ikm}\), we employ the method of upper PCV reduction to obtain the upper reduced fuzzy variables \(\xi _{vsj}^U\), \(\zeta _{ijk}^U\) and \(\eta _{ikm}^U\), and use the method of lower PCV reduction to get the lower reduced fuzzy variable \(d_{im}^L\). For the sake of presentation, we denote \({\varvec{x}}=\{x_{vsj},y_{ijk},z_{ikm},u_j,w_k\}\) and \(\varvec{\xi }=\{\xi _{vsj}^U,\zeta _{ijk}^U,\eta _{ikm}^U\}\).

The total costs of supply chain

The supply chain network design problem determines where the facilities (e.g. plants, distribution centers) should be located for the least total costs. The total costs usually include the following four parts: fixed cost, procurement cost, production cost and transhipment cost.

Fixed cost arises when a plant or a distribution center at the potential location is opened, which is independent of the production or distribution activities. The fixed cost of the whole supply chain is represented as \(\sum _jf_ju_j+\sum _kg_kw_k\).

Procurement cost and production cost are paid for purchasing the raw materials from the suppliers and manufacturing the final product at the plants. They can be expressed as \(\sum _{v,s}(q_{vs}\sum _jx_{vsj})+\sum _{i,j}(p_{ij}\sum _ky_{ijk})\).

Transhipment cost is incurred for transporting raw materials from suppliers to plants, and transporting final products from the plants to distribution centers as well as from distribution centers to customers. The total transhipment cost is written as \(\sum _{v,s,j}\xi _{vsj}^Ux_{vsj}+\sum _{i,j,k}\zeta _{ijk}^Uy_{ijk} +\sum _{i,k,m}\eta _{ikm}^Uz_{ikm}\).

Therefore, the total cost function \(C({\varvec{x}},\varvec{\xi })\) of our supply chain network is represented as

which is the function of reduced fuzzy variables \(\varvec{\xi }=\{\xi _{vsj}^U,\zeta _{ijk}^U,\eta _{ikm}^U\}\).

We interpret the value of \(C({\varvec{x}},\varvec{\xi })\) as loss. If we denote \(\Psi ({\varvec{x}}, \bar{C})=\mathrm{Cr}\{C({\varvec{x}},\varvec{\xi })\le \bar{C}\}\) as the credibility distribution function of \(C({\varvec{x}},\varvec{\xi })\), then for any given \(0<\beta <1\), the VaR function \(\nu ({\varvec{x}},\beta )\) is defined as

where \(\beta \) will typically have a large value, for instance, \(\beta =0.95\). In this case, the interpretation of \(\nu ({\varvec{x}},\beta )\) is a minimal loss level, corresponding to the decision vector \({\varvec{x}}\), with the following property: the credibility of the event that loss will not exceed \(\nu ({\varvec{x}},\beta )\) is at least \(\beta \).

In our supply chain network design model, we consider minimizing the VaR of the total cost function \(C({\varvec{x}},\varvec{\xi })\), i.e.,

where \(D\) is the feasible region of decision vectors. By the definition of \(\nu ({\varvec{x}},\beta )\) and introducing an additional variable \(\bar{C}\), model (2) is equivalent to the following formulation results:

where \(\Psi ({\varvec{x}}, \bar{C})\) is the credibility distribution function \(\mathrm{Cr}\{C({\varvec{x}},\varvec{\xi })\le \bar{C}\}\).

The service levels of supply chain

In addition to cost-effective operations, a successful supply chain should react in respond to the demands of customers. Since the exact demands are not known in advance, we describe them by variable possibility distributions with two types of parameters. In this case, the demands of customers may be satisfied partly. We have two methods to measure the the service levels of our supply chain network.

Joint credibility constraint: Given the service level \(\beta \in (0,1)\), the amount of product from the distribution center to customer should meet the demands of customers as much as possible, which can be models as

Separate credibility constraints: Given the service levels \(\beta _{im}\in (0,1)\), the amount of product \(i\) from the distribution center \(k\) to customer \(m\) should meet the demand of customer \(m\) as much as possible, which can be written as

From the computational viewpoint, joint credibility constraint is more difficult to check than separate credibility constraints. However, in the case that demands \(d_{im}^L\) are mutually independent in the sense of Liu and Gao (2007), we have

In this case, joint credibility constraint (4) is equivalent to

which is special case of separate credibility constraints (5) with \(\beta _{im}=\beta \) for all \(i\) and \(m\).

In our supply chain network design problem, we assume the demands are mutually independent in the sense of Liu and Gao (2007). Therefore, it suffices to consider separate credibility constraints (5) in our optimization model formulated in the next section.

Supply chain network design model

Using the notations above, we can build the following fuzzy supply chain network design model subject to the separate credibility constraints:

From the equivalent formulation between problems (2) and (3), we know that the objective of model (7) is to minimize the VaR of the total cost function \(C({\varvec{x}},\varvec{\xi })\) at given confidence level \(\beta \). Constraints (C-2), (C-4) and (C-6) are the raw materials capacity limits of suppliers, the production capacity limits of plants and the distribution capacity limits of distribution centers. Constrains (C-3) and (C-5) are the raw materials and products balance constraints. Constraints (C-7) and (C-8) are the number limits of opened plants and distribution centers. Constraint (C-9) guarantees the product \(i\) allocated from distribution centers to customer \(m\) to satisfy the demands of customers under a prescribed service level \(\beta _{im}\). Constraint (C-10) is the non-negativity limits for all variables, and constraint (C-11) is the binary limits of variables.

Model (7) is a mixed-integer programming problem subject to credibility constraints. Its general solution methods require the conversion of credibility constraints (C-1) and (C-9) to their deterministic equivalents. However, this conversion is usually hard to perform and only successfully in some special cases. In the subsequent section we will discuss the equivalent programming problem of model (7).

Parameter-based domain decomposition method

The equivalent parametric programming models

To solve model (7), it is required to check the credibility constraints (C-1) and (C-9). For this purpose, this section will discuss the equivalent programming problem of model (7) in some special cases.

Assume \(\tilde{\xi }_{vsj},\tilde{\zeta }_{ijk},\tilde{\eta }_{ikm}\) and \(\tilde{d}_{im}\) are mutually independent type-2 triangular fuzzy variables such that their elements are defined by

and

Suppose \(\xi _{vsj}^U,\zeta _{ijk}^U,\eta _{ikm}^U\) are the upper reduced fuzzy variables of \(\tilde{\xi }_{vsj},\tilde{\zeta }_{ijk},\tilde{\eta }_{ikm}\), respectively, and \(d^L_{im}\) is the lower fuzzy variable of \(\tilde{d}_{im}\). Then \(\xi _{vsj}^U,\zeta _{ijk}^U,\eta _{ikm}^U\) and \(d^L_{im}\) are mutually independent fuzzy variables in the sense of Liu and Gao (2007).

If \(\beta >0.5\), then credibility constraint (C-1) has the following equivalent expression

If we denote \(A=\{(v,s,j)\mid 0.5<\beta \le (3-(1-\alpha _{vsj}^\xi )\theta _{r,vsj}^\xi )/4\}\), \(B=\{(i,j,k)\mid 0.5<\beta \le (3-(1-\alpha _{ijk}^\zeta )\theta _{r,ijk}^\zeta )/4\}\) and \(C=\{(i,k,m)\mid 0.5<\beta \le (3-(1-\alpha _{ikm}^\eta )\theta _{r,ikm}^\eta )/4\}\), then it follows from Theorem 3 that Eq. (8) is equivalent to

For convenience, we write the function in the left-hand side of the above inequality as \(F({\varvec{x}};\theta ,\alpha ,\beta )\) with \(\theta =(\theta _l,\theta _r)\).

On the other hand, if \(\beta _{im}>0.5\), then credibility constraint (C-9) is equivalent to

Let \(D=\{(i,m)\mid 0.5<\beta _{im} \le (3+(1-\alpha _{im})\theta _{l,im}^d)/4\}\). Then, by Theorem 2, Eq. (9) is equivalent to the following constraints

or

Using the equivalent representations of credibility constraint (C-9), model (7) can be divided into two sub-models determined by the domain of parameter \(\beta _{i,m}\). Hence, we can solve model (7) indirectly by solving its sub-models.

If the parameter \(\beta _{im}\) satisfies \(0.5<\beta _{im}\le (3+(1-\alpha _{im})\theta _{l,im}^d)/4\), then we solve the following parametric programming sub-model

If the parameter \(\beta _{im}\) meets the constraint \((3+(1-\alpha _{im})\theta _{l,im}^d)/4<\beta _{im}\le 1\), then we solve the following parametric programming sub-model

Domain decomposition method

Just as discussed in the above section, a decision maker may prefer setting a predetermined confidence levels \(\beta \) and \(\beta _{im}\) and expect to minimize the total costs. According to the structural characteristics of model (7), we employ a parameter-based domain decomposition method to solve its equivalent sub-models (10) and (11).

For a given confidence level \(\beta \) and service levels \(\beta _{im}\), the solution process of model (7) by the proposed decomposition method is summariazed as follows.

- Step 1 :

-

Solve the mixed-integer programming sub-models (10) and (11) to find local optimal solutions.

- Step 2 :

-

Compute the objective values \(F({\varvec{x}};\theta ,\alpha ,\beta )\) corresponding to the local optimal solutions.

- Step 3 :

-

Chose the minimum as the global optimal solution to model (7) by comparing the obtained objective values.

The feasible region of model (7) is decomposed into two disjoint subregions according to the values of parameters \(\beta _{im}\). The solution process is implemented at most two times by solving two different sub-models and followed by comparing the optimal solutions to the two sub-models. We refer to this solution procedure as the parameter-based domain decomposition method.

Sub-models (10) and (11) are mixed-integer parametric programs. We can solve them by using conventional optimization algorithms when the parameters vary in their domains. For example, given the parameters \(\alpha ,\beta ,\theta _l\) and \(\theta _r\), we can make use of the branch-and-bound method to solve it. It is known that the LINGO software is a state-of-the-art optimization tool including the branch-and-bound IP code. In the next section, we will demonstrate the effectiveness of the parameter-based domain decomposition method via numerical experiments.

An application example and comparison study

Problem statement

In this subsection, we consider a practical supply chain network design problem about a food processing company. The company boasts advanced equipments, first class technology and reliable quality. The products in the company include stripped chickens, broilers, pig trotters, irascible donkey meat, chicken wings, chicken claws and chicken necks. In recent years, product sales nationwide coverage, a strong potential for growth. Therefore, the company is planning to produce a new cooked food, roast chickens, which can be produced with lower cost as a result of sufficient raw material, chickens, and advanced slaughter processing facilities. The manager of the company wishes to design a supply chain network for the new product to determine the number of plants and distribution centers to be opened, and the distribution strategy so that the demands of customers can be satisfied under all capacities constraints.

For convenience, we assume that there are 4 subcompanies to supply the raw chickens, 5 plants with the high technology of cooked food processing, advanced facilities and rigorous hygienic index, 5 distribution centers to process quick-freeze storage and cold-storage and 5 customer zones in the supply chain network. We assume that one roast chicken requires one unit raw material chicken. Considering the market and other factors, we assume that the number of opened plants and distribution centers are no more than four in the whole region, and unit producing cost of product is 1. In addition, the costs of purchasing unit raw chicken, the costs of opening the plants and distribution centers, and the capacities of the suppliers, plants and distribution centers are provided in Table 2.

To design an efficient supply chain network, our model requires two kinds of key input data: the transportation costs and demands of customers. Since we have not enough data to analyze the parameters in advance, it is difficult for a new product to obtain perfect information about the parameters in our supply chain network problem. In this situation, we adopt type-2 fuzzy variables to represent the uncertain demands and costs. By analyzing the sales volume of the similar product like Dawu roast chicken, Dezhou braised chicken, the manager can estimate the amount of demand is between 100 and 500. Without loss of generality, the demands of customer zone \(C_m,m=1,2,3,4,5\), are randomly generated from the interval [100,500], and represented by \((455,460,490;\overline{\theta }_l,\overline{\theta }_r)\), \((120,160,180;\overline{\theta }_l,\overline{\theta }_r)\), \((280,330,360;\overline{\theta }_l,\overline{\theta }_r)\), \((280,315,360;\overline{\theta }_l,\overline{\theta }_r)\), and \((200, 235,250;\overline{\theta }_l,\overline{\theta }_r)\) respectively. Using the similar method, we generate the transportation costs from the suppliers to plants, plants to distribution centers, distribution centers to customers, and provide the generated data in Table 3.

Computational results with deterministic input data

First, we solve our supply chain network design problem with deterministic input data. For the sake of comparison, the deterministic input data in Table 4 are the mean values of fuzzy transportation costs and demands collected in Table 5.

In this situation, we employ LINGO software to solve our supply chain network design model and obtain the following optimal solution with objective value 35955.03.

We plot the obtained optimal solution in Fig. 1, from which we observe that the food processing company needs to open 4 plants located in \(P_1,P_2,P_3\) and \(P_5\); 3 distribution centers lied in \(D_1,D_2\) and \(D_4\), and assign 466.25 unit products to \(C_1\) supplied by \(D_2\), 155 unit products to \(C_2\) supplied 72.5 units by \(D_2\) and 82.5 units by \(D_4\), 325 unit products to \(C_3\) supplied by \(D_1\), 317.5 unit products to \(C_4\) supplied by \(D_4\), and 230 unit products to \(C_5\) supplied 178.75 units by \(D_1\) and 51.25 units by \(D_2\).

Computational results with fixed possibility distributions

In this subsection, we use LINGO software to solve our supply chain network design model when the input data have fixed possibility distributions collected in Table 5.

For simplicity, we set the parameters \(\beta _{im}=\overline{\beta }\) for each pair \((i,m)\) in model (7). Given \(\beta =\overline{\beta }=0.95\), we have the following optimal solution with objective value 44,995.16,

The optimal solution is shown in Fig. 2, which implies that the food processing company needs to open 4 plants located in \(P_2,P_3,P_4\) and \(P_5\); 4 distribution centers lied in \(D_1,D_2,D_3\) and \(D_4\), and assign 487 unit products to \(C_1\) supplied by \(D_1,D_2\) and \(D_3\), 178 unit products to \(C_2\) supplied by \(D_2\), 357 unit products to \(C_3\) supplied by \(D_2\) and \(D_4\), 355.5 and 248.5 unit products to \(C_4\) and \(C_5\) supplied by \(D_4\) and \(D_1\).

Compared with the computational results under deterministic input data, we find that the network structure changes greatly. In deterministic case, it is required to construct three distribution centers \(D_1,D_2\) and \(D_4\), while in the case of fixed possibility distributions, there are four distribution centers \(D_1,D_2,D_3\) and \(D_4\). In addition, it is easy to check that the optimal solution in deterministic case is not a feasible solution in the second case.

In order to identify parameters’ influence on solution quality, we compute the optimal values by adjusting the values of parameters \(\beta \) and \(\overline{\beta }\), and report the computational results in Table 6.

The parameter \(\beta \) in the objective function represents a decision maker’s attitude towards risk, while the parameter \(\overline{\beta }\) in the credibility constraint reflects the service level of a supply chain network. Table 6 tells us that the total costs will increase when the service level increases. Thus, a decision maker can find a suitable solution according to his risk preference level \(\beta \).

Computational results with variable possibility distributions

Now, we adopt variable possibility distributions to characterize the uncertain demands and transportation costs in our supply chain network design model. For the sake of presentation, we set the parameters \(\theta _{l,vsj}^\xi =\theta _{l,ijk}^\zeta =\theta _{l,ikm}^\eta =\theta _l\), \(\theta _{r,vsj}^\xi =\theta _{r,ijk}^\zeta =\theta _{r,ikm}^\eta =\theta _r\), \(\theta _{l,im}^d=\overline{\theta }_l\), \(\theta _{r,im}^d=\overline{\theta }_r\), \(\alpha _{vsj}^\xi =\alpha _{ijk}^\zeta =\alpha _{ikm}^\eta =\alpha \), and \(\alpha _{im}=\overline{\alpha }\) for each \(v,s,i,j,k,m\) in model (7). To identify the influence of model parameters on solutions, we perform our numerical experiments according to the following three cases.

Case I: The influence of parameter \(\theta \)

With various values of parameter \((\theta _l,\theta _r)\) in the objective and parameter \((\overline{\theta }_l,\overline{\theta }_r)\) in the service level constraints, we report the computational results in Tables 7 and 8, respectively. From Table 7, we observe that the optimal value is a monotone increasing function with respect to \(\theta _r\in (0,1]\). From Table 8, we find that the optimal value is a monotone decreasing function with respect to \(\overline{\theta }_l\in (0,1]\).

Case II: The influence of parameter \(\alpha \)

With various values of parameter \(\alpha \) in the objective function and parameter \(\overline{\alpha }\) in the credibility constraints, we report the computational results in Tables 9 and 10, respectively. Table 9 shows that the optimal value decreases with respect to \(\alpha \in (0,1]\), and Table 10 implies that the optimal value increases with respect to \(\overline{\alpha }\).

Case III: The influence of all model parameters

With various values of all model parameters in the objective function and credibility constraints, we report the computational results in Table 11, where we denote \((\overline{\theta }_l,\overline{\theta }_r)=(\theta _l,\theta _r)\) and \(\overline{\alpha }=\alpha \) for convenience.

From Table 11, we observe that the optimal cost varies while the parameters \((\theta _l,\theta _r),\alpha ,\beta \) and \(\bar{\beta }\) change their values between 0 and 1. From the computational results, we conclude that variable possibility distributions have some advantages over fixed possibility distributions when we employ them to design supply chain network problem.

Managerial implications

Using the proposed parametric optimization method to our application example, we derive the following managerial implications from the experimental results.

-

(I)

In our application example, we first consider the deterministic supply chain network design model, where the input data is obtained by replacing all fuzzy demands and costs by their mean values. The experimental results show that we cannot do in this way. Since the optimal solution under deterministic input data is not a feasible solution to the model with fixed possibility distributions, we cannot adopt such a solution to design our supply chain network problem.

-

(II)

We also formulate our application example as a fuzzy supply chain network design model, where the demands and costs have fixed possibility distributions. Compared with the computational results under deterministic input data, we observe that the network structure in this case changes greatly. That is, the network structure for our application example strongly depends on the demands and costs. If a decision maker cannot obtain their exact possibility distributions in the modeling process, then we advise not to adopt the obtained solution to design our supply chain network problem.

-

(III)

We finally formulate our application example as a robust supply chain network design model, where the uncertain demands and costs are characterized by variable possibility distributions. In our application example, since we have not enough data to analyze the demands and costs in advance, it is difficult for a new product to obtain perfect information about the two parameters. In this case, the developed parametric optimization method would provide an effective way for decision makers to design supply chain network. The computational results support our arguments. There are two types of parameters for decision makers to manage our optimization model. The parameters \(\theta _l\) and \(\theta _r\) describe the degrees of uncertainty that demands and costs take their values, while the parameter \(\alpha \) represents the possibility level in the supports of uncertain demands and costs. The decision makers can adjust the values of model parameters according to their attitude towards risk. Tables 7 and 8 summarize the influence of parameters \(\theta _l\) and \(\theta _r\) on the network design; Tables 9 and 10 summarize the influence of parameter \(\alpha \) on the network design, and Table 11 demonstrates the influence of all model parameters on the network design. The computational results demonstrate the advantages of parametric possibility distributions over fixed possibility distributions when we employ them to design supply chain networks.

Conclusions

The supply chain network design problem is one of the most comprehensive strategic decision issues that need to be optimized for the long-term efficient operation of a company. The purpose of this paper is to develop a new robust optimization method for supply chain network design problem under fuzzy uncertainty. The objective function was constructed based on risk-averse criterion, and the service levels of supply chain were measured by credibility constraints. More importantly, we characterized uncertain demands and costs by variable possibility distributions instead of fixed ones. The variable possibility distributions were obtained by using the method of PCV reduction to secondary possibility distributions of uncertain demands and costs. Based on the equivalent representations of credibility constraints, we transformed the original supply chain network design model to its equivalent parametric programming models. Furthermore, according to the structural characteristics of parameter programming model, we designed a parameter-based domain decomposition method to decompose the equivalent parametric programming model to two mixed-integer programming sub-models. At the end of this paper, we presented one application example about a food processing company to demonstrate our parametric optimization idea and the effectiveness of solution method.

According to the computational results, we synthesize the following main managerial implications. The network structure for our application example strongly depends on the input data (demands and costs). The optimal solution under deterministic input data is not a feasible solution to the model with fixed possibility distributions, we cannot adopt such a solution to design our supply chain network problem. In addition, if a decision maker cannot obtain the exact possibility distributions of demands and costs in the modeling process, then we advise not to adopt the obtained solution to design our supply chain network problem. Since there are two types of parameters for decision makers to manage our optimization model, the developed parametric optimization method would provide an effective way for the decision makers to design supply chain networks.

Future research might address the following topics. First, as far as the total costs incurred from supply chain network design are concerned, our current model assumes a risk-averse decision maker. An extension of the model to the case of risk-neural decision maker is possible. Secondly, the current model considers the total costs as a single objective function, a multi-objective optimization model that accounts for both economical and environmental objectives may be helpful in practice. Third, the present model assumes the productive and transportation capacities are fixed quantities, the case with uncertain capacities is an important issue for future research.

References

Bachlaus, M., Pandey, M. K., Mahajan, C., Shankar, R., & Tiwari, M. K. (2008). Designing an integrated multi-echelon agile supply chain network: A hybrid taguchi-particle swarm optimization approach. Journal of Intelligent Manufacturing, 19(6), 747–761.

Baghalian, A., Rezapour, S., & Farahani, R. Z. (2013). Robust supply chain network design with service level against disruptions and demand uncertainties: A real-life case. European Journal of Operational Research, 227, 199–215.

Bai, X. J., & Liu, Y. K. (2014). Semideviations of reduced fuzzy variables: A possibility approach. Fuzzy Optimization and Decision Making, 13(2), 173–196.

Baud-Lavigne, B., Bassetto, S., & Agard, B. (2014). A method for a robust optimization of joint product and supply chain design. Journal of Intelligent Manufacturing, 1–9, doi:10.1007/s10845-014-0908-5.

Ben-Tal, A., Golany, B., & Shtern, S. (2009). Robust multi-echelon multi-period inventory control. European Journal of Operational Research, 199(3), 922–935.

Ben-Tal, A., & Nemirovski, A. (1998). Robust convex optimization. Mathematics of Operations Research, 23(4), 769–805.

Bertsimas, D., & Sim, M. (2004). The price of robustness. Operations Research, 52(1), 35–53.

Chandra, C., & Grabis, J. (2007). Supply chain configuration: Concepts, solutions and applications. New York: Springer.

Cheshmehgaz, H. R., Desa, M. I., & Wibowo, A. (2013). A flexible three-level logistic network design considering cost and time criteria with a multi-objective evolutionary algorithm. Journal of Intelligent Manufacturing, 24(2), 277–293.

Chien, C. F., & Zheng, J. N. (2012). Mini-max regret strategy for robust capacity expansion decisions in semiconductor manufacturing. Journal of Intelligent Manufacturing, 23(6), 2151–2159.

Cohen, M. A., & Lee, H. L. (1988). Strategic analysis of integrated production-distribution systems: Models and methods. Operations Research, 36, 216–228.

Dong, M., He, F., & Wei, H. (2012). Energy supply network design optimization for distributed energy systems. Computers & Industrial Engineering, 63, 546–552.

Efendigil, T., & Önüt, S. (2012). An integration methodology based on fuzzy inference systems and neural approaches for multi-stage supply-chains. Computers & Industrial Engineering, 62, 554–569.

El-Ghaoui, L., Oks, M., & Oustry, F. (2003). Worst-case value-at-risk and robust portfolio optimization: A conic programming approach. Operations Research, 51(4), 543–556.

El-Ghaoui, L., Oustry, F., & Lebret, H. (1998). Robust solutions to uncertain semidefinite programs. SIAM Journal on Optimization, 9(1), 33–52.

Fazlollahtabar, H., Mahdavi, I., & Mohajeri, A. (2013). Applying fuzzy mathematical programming approach to optimize a multiple supply network in uncertain condition with comparative analysis. Applied Soft Computing, 13, 550–562.

Fujita, K., Amaya, H., & Akai, R. (2013). Mathematical model for simultaneous design of module commonalization and supply chain configuration toward global product family. Journal of Intelligent Manufacturing, 24(5), 991–1004.

Geoffrion, A. M., & Graves, G. W. (1974). Multicommodity distribution system design by Benders decomposition. Management Science, 20, 822–844.

Georgiadis, P., & Athanasiou, E. (2013). Flexible long-term capacity planning in closed-loop supply chains with remanufacturing. European Journal of Operational Research, 225, 44–58.

Gumus, A. T., Guneri, A. F., & Keles, S. (2009). Supply chain network design using an integrated neuro-fuzzy and MILP approach: A comparative design study. Expert Systems with Applications, 36, 12570–12577.

Gülpınar, N., Pachamanova, D., & Çanakoğlu, E. (2013). Robust strategies for facility location under uncertainty. European Journal of Operational Research, 225(1), 21–35.

Hasani, A., Zegordi, S. H., & Nikbakhsh, E. (2012). Robust closed-loop supply chain network design for perishable goods in agile manufacturing under uncertainty. International Journal of Production Research, 50(16), 4649–4669.

Inuiguchi, M., & Sakawa, M. (1998). Robust optimization under softness in a fuzzy linear programming problem. International Journal of Approximate Reasoning, 18(1), 21–34.

Kasperski, A., & Kulej, M. (2009). Choosing robust solutions in discrete optimization problems with fuzzy costs. Fuzzy Sets and Systems, 160(5), 667–682.

Kristianto, Y., Gunasekaran, A., Heloa, P., & Hao, Y. (2014). A model of resilient supply chain network design: A two-stage programming with fuzzy shortest path. Expert Systems with Applications, 41, 39–49.

Kubat, C., & Yuce, B. (2012). A hybrid intelligent approach for supply chain management system. Journal of Intelligent Manufacturing, 23(4), 1237–1244.

Jolai, F., Amalnick, M. S., Alinaghian, M., Shakhsi-Niaei, M., & Omrani, H. (2011). A hybrid memetic algorithm for maximizing the weighted number of just-in-time jobs on unrelated parallel machines. Journal of Intelligent Manufacturing, 22(2), 247–261.

Li, H., & Womer, K. (2012). Optimizing the supply chain configuration for make-to-order manufacturing. European Journal of Operational Research, 221, 118–128.

Liu, B., & Liu, Y. (2002). Expected value of fuzzy variable and fuzzy expected value models. IEEE Transactions on Fuzzy Systems, 10(4), 445–450.

Liu, Y., & Gao, J. (2007). The independent of fuzzy variables with applications to fuzzy random optimization. International Journal of Uncertainty, Fuzziness and Knowledge-Based Systems, 15, 1–20.

Liu, Z., & Liu, Y. (2010). Type-2 fuzzy variables and their arithmetic. Soft Computing, 14(7), 729–747.

Melo, M. T., Nickel, S., & Saldanha-da-Gama, F. (2009). Facility location and supply chain management-A review. European Journal of Operational Research, 196(2), 401–412.

Miller, S., & John, R. (2010). An interval type-2 fuzzy multiple echelon supply chain model. Knowledge-Based Systems, 23, 363–368.

Mulvey, J. M., Vanderbei, R. J., & Zenios, S. A. (1995). Robust optimization of large-scale systems. Operations Research, 43(2), 264–281.

Nie, X. H., Huang, G. H., Li, Y. P., & Li, L. (2007). IFRP: A hybrid interval-parameter fuzzy robust programming approach for waste management planning under uncertainty. Journal of Environmental Management, 84, 1–11.

Paksoy, T., Pehlivan, N. Y., & Özceylan, E. (2012). Application of fuzzy optimization to a supply chain network design: A case study of an edible vegetable oils manufacturer. Applied Mathematical Modelling, 36, 2762–2776.

Pan, F., & Nagi, R. (2010). Robust supply chain design under uncertain demand in agile manufacturing. Computers & Operations Research, 37(4), 668–683.

Petrovic, D., Xie, Y., Burnham, K., & Petrovic, R. (2008). Coordinated control of distribution supply chains in the presence of fuzzy customer demand. European Journal of Operational Research, 185, 146–158.

Pishvaee, M. S., Rabbani, M., & Torabi, S. A. (2011). A robust optimization approach to closed-loop supply chain network design under uncertainty. Applied Mathematical Modelling, 35, 637–649.

Pishvaee, M. S., & Razmi, J. (2012). Environmental supply chain network design using multi-objective fuzzy mathematical programming. Applied Mathematical Modelling, 36, 3433–3446.

Srivastava, S. K. (2008). Network design for reverse logistics. Omega, 36, 535–548.

Soyster, A. L. (1973). Convex programming with set-inclusive constraints and applications to inexact linear programming. Operations Research, 21(5), 1154–1157.

Taleizadeh, A. A., Niaki, S. T. A., & Naini, G. J. (2013). Optimizing multiproduct multiconstraint inventory control systems with stochastic period length and emergency order. Journal of Uncertain Systems, 7(1), 58–71.

Tsao, Y. C., & Lu, J. C. (2012). A supply chain network design considering transportation cost discounts. Transportation Research Part E, 48, 401–414.

Wong, J. T. (2012). DSS for 3PL provider selection in global supply chain: Combining the multi-objective optimization model with experts’ opinions. Journal of Intelligent Manufacturing, 23(3), 599–614.

Yang, G., & Liu, Y. (2013). Designing fuzzy supply chain network problem by mean-risk optimization method. Journal of Intelligent Manufacturing, 1–12, doi:10.1007/s10845-013-0801-7.

Zadeh, L. A. (1965). Fuzzy sets. Information and Control, 8, 338–353.

Zadeh, L. A. (1975). The concept of a linguistic variable and its application to approximate reasoning-I, Information Sciences, 8, 199–249.

Zadeh, L. A. (1978). Fuzzy sets as a basis for a theory of possibility. Fuzzy Sets and Systems, 1, 3–28.

Zhang, L., & Zhou, Y. (2011). A new approach to supply chain network equilibrium models. Computers & Industrial Engineering, 63, 82–88.

Zhou, G., & Min, H. (2011). Designing a closed-loop supply chain with stochastic product returns: A genetic algorithm approach. International Journal of Logistics Systems and Management, 9, 397–418.

Acknowledgments

The authors wish to thank Editors and anonymous reviewers, whose valuable comments led to an improved version of the paper. This work was supported by the National Natural Science Foundation of China (No. 61374184), and the Training Foundation of Hebei Province Talent Engineering.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

In this appendix, we deal with the method of PCV reduction, parametric possibility distributions of the reduced fuzzy variables and their properties.

Let \((\Gamma , \mathcal {A}, \tilde{\mathrm{P}}\mathrm{os})\) be a fuzzy possibility space (Liu and Liu 2010), where \(\Gamma \) is an abstract space of generic elements \(\gamma \) and \(\mathcal {A}\) is a class of subsets of \(\Gamma \) that is closed under arbitrary unions, intersections and complement in \(\Gamma \). Assume that \(\tilde{\xi }\) is a type-2 fuzzy variable with secondary possibility distribution \(\tilde{\mu }_{\tilde{\xi }}(x)\). To reduce the uncertainty in \(\tilde{\mu }_{\tilde{\xi }}(x)\), we employ the lower and upper possibility critical values (PCVs) of \(\tilde{\mu }_{\tilde{\xi }}(x)\) as the representing values of the regular fuzzy variable (RFV) \(\tilde{\mu }_{\tilde{\xi }}(x)\). According to Bai and Liu (2014), the lower PCV of \(\tilde{\mu }_{\tilde{\xi }}(x)\) with respect to possibility, denoted by \(\mathrm{VaR}^L_\alpha (\tilde{\mu }_{\tilde{\xi }}(x))\), is defined as

while the upper PCV of \(\tilde{\mu }_{\tilde{\xi }}(x)\) with respect to possibility, denoted by \(\mathrm{VaR}^U_\alpha (\tilde{\mu }_{\tilde{\xi }}(x))\), is defined as

The method is referred to as the PCV reduction. The variables obtained by the methods of lower and upper PCV reduction are called the lower and upper reduced fuzzy variables, and denoted by \(\xi ^L\) and \(\xi ^U\), respectively.

We call \(\tilde{\xi }\) a type-2 triangular fuzzy variable if its secondary possibility distribution \(\tilde{\mu }_{\tilde{\xi }}(x)\) is the following RFV

for any \(x\in [r_1,r_2]\), and the next RFV

for any \(x\in [r_2,r_3]\), where \(\theta _l,\theta _r\in [0,1]\) are two parameters characterizing the degree of uncertainty that \(\tilde{\xi }\) takes the value \(x\). For convenience, we denote a type-2 triangular fuzzy variable \(\tilde{\xi }\) with the above secondary possibility distribution by \((\tilde{r}_1,\tilde{r}_2,\tilde{r}_3;\theta _l,\theta _r)\).

Theorem 1

Let \(\tilde{\xi }=(\tilde{r}_1,\tilde{r}_2,\tilde{r}_3;\theta _l,\theta _r)\) be a type-2 triangular fuzzy variable. If we denote \(\theta =(\theta _l,\theta _r)\), then the reduced fuzzy variables \(\xi ^L\) and \(\xi ^U\) have the following parametric possibility distributions

Proof

We only prove Eq. (12), and Eq. (13) can be proved similarly.

Note that the secondary possibility distribution \(\tilde{\mu }_{\tilde{\xi }}(x)\) of \(\tilde{\xi }\) is the following triangular RFV

for any \(x\in [r_1,r_2]\), and

for any \(x\in [r_2,r_3]\). Since \(\xi ^L\) is the lower PCV reduction of \(\tilde{\xi }\), we have

which completes the proof of Eq. (12). \(\square \)

Theorem 2

Let \(\tilde{\xi }=(\tilde{r}_1,\tilde{r}_2,\tilde{r}_3;\theta _l,\theta _r)\) be a type-2 triangular fuzzy variable, and \(\xi ^L\) its lower PCV reduced fuzzy variable.

-

(i)

If \(\beta \in (0,(1-(1-\alpha )\theta _l)/4]\), then \(\mathrm{Cr}\{\xi ^L\le r\}\ge \beta \) is equivalent to

$$\begin{aligned} \frac{(1-2\beta -(1-\alpha )\theta _l)r_1+2\beta r_2}{1-\theta _l+\alpha \theta _l}\le r. \end{aligned}$$ -

(ii)

If \(\beta \in ((1-(1-\alpha )\theta _l)/4,0.5]\), then \(\mathrm{Cr}\{\xi ^L\le r\}\ge \beta \) is equivalent to

$$\begin{aligned} \frac{(1-2\beta )r_1+(2\beta +(1-\alpha )\theta _l)r_2}{1+\theta _l-\alpha \theta _l}\le r. \end{aligned}$$ -

(iii)

If \(\beta \in (0.5,(3+(1-\alpha )\theta _l)/4]\), then \(\mathrm{Cr}\{\xi ^L\le r\}\ge \beta \) is equivalent to

$$\begin{aligned} \frac{(2-2\beta +(1-\alpha )\theta _l)r_2+(2\beta -1)r_3}{1+\theta _l-\alpha \theta _l}\le r. \end{aligned}$$ -

(iv)

If \(\beta \in ((3+(1-\alpha )\theta _l)/4,1]\), then \(\mathrm{Cr}\{\xi ^L\le r\}\ge \beta \) is equivalent to

$$\begin{aligned} \frac{(2-2\beta )r_2+(2\beta -1-(1-\alpha )\theta _l)r_3}{1-\theta _l+\alpha \theta _l}\le r. \end{aligned}$$

Proof

We only prove assertions \((i)\)-\((ii)\), and assertions \((iii)\)-\((iv)\) can be proved similarly.

Since \(\xi ^L\) is the lower reduced fuzzy variable of \(\tilde{\xi }\), its parametric possibility distribution \(\mu _{\xi ^L}(x)\) is given by Eq. (12).

If \(\beta \le 0.5\), then by the definition of credibility measure (Liu and Liu 2002), we have

Thus \(\mathrm{Cr}\{\xi ^L\le r\}\ge \beta \) is equivalent to \(\sup _{x\le r}\mu _{\xi ^L}(x;\theta ,\alpha )\ge 2\beta \). If we denote

for \(\beta \in (0,1]\), then we have \(\xi ^L_{\inf ,\mathrm{Pos}}(2\beta )\le r\).

Note that \(\mu _{\xi ^L}((r_1+r_2)/2)=(1-(1-\alpha )\theta _l)/2\). If \(0<2\beta \le (1-(1-\alpha )\theta _l)/2\), i.e., \(\beta \in (0,(1-(1-\alpha )\theta _l)/4]\), then \(\xi ^L_{\inf ,\mathrm{Pos}}(2\beta )\) is the solution of the following equation

Solving the above equation, we have

On the other hand, if \(1\ge 2\beta >(1-(1-\alpha )\theta _l)/2\), i.e., \(\beta \in ((1-(1-\alpha )\theta _l)/4,0.5]\), then \(\xi ^L_{\inf ,\mathrm{Pos}}(2\beta )\) is the solution of the following equation

Solving the above equation, we have

The proof of theorem is complete. \(\square \)

Theorem 3

Let \(\tilde{\xi }_i=(\tilde{r}_1^i,\tilde{r}_2^i,\tilde{r}_3^i;\theta _{l,i},\theta _{r,i})\) be a type-2 triangular fuzzy variable, and \(\xi _i^U\) its upper PCV reduced fuzzy variable for \(i=1,2,\ldots ,n\). Suppose \(\tilde{\xi }_1,\tilde{\xi }_2,\ldots ,\tilde{\xi }_n\) are mutually independent, \((1-\alpha _1)\theta _{r,1}\le (1-\alpha _2)\theta _{r,2}\le \cdots \le (1-\alpha _n)\theta _{r,n}\) and \(k_i\ge 0\) for \(i=1,2,\ldots ,n\).

-

(i)

If \(\beta \in (0,(1+(1-\alpha _1)\theta _{r,1})/4]\), then \(\mathrm{Cr}\{\sum _{i=1}^nk_i\xi ^U_i\le r\}\ge \beta \) is equivalent to

$$\begin{aligned} \sum _{i=1}^nk_i\frac{(1-2\beta +(1-\alpha _i)\theta _{r,i})r^i_1+2\beta r^i_2}{1+\theta _{r,i}-\alpha _i\theta _{r,i}}\le r. \end{aligned}$$ -

(ii)

If there exists an \(i_0\), \(1\le i_0<n\) such that \(\beta \in ((1+(1-\alpha _{i_0})\theta _{r,i_0})/4,(1+(1-\alpha _{i_0+1})\theta _{r,i_0+1})/4]\), then \(\mathrm{Cr}\{\sum _{i=1}^nk_i\xi ^U_i\le r\}\ge \beta \) is equivalent to

$$\begin{aligned}&\sum _{i=1}^{i_0}k_i\frac{(1-2\beta )r^i_1+(2\beta -(1-\alpha _i) \theta _{r,i})r^i_2}{1-\theta _{r,i}+\alpha _i\theta _{r,i}}\\&\quad + \sum _{i=i_0+1}^nk_i\frac{(1-2\beta +(1-\alpha _i)\theta _{r,i})r^i_1+2\beta r^i_2}{1+\theta _{r,i}-\alpha _i\theta _{r,i}}\le r. \end{aligned}$$ -

(iii)

If \(\beta \in ((1+(1-\alpha _n)\theta _{r,n})/4,0.5]\), then \(\mathrm{Cr}\{\sum _{i=1}^nk_i\xi ^U_i\le r\}\ge \beta \) is equivalent to

$$\begin{aligned} \sum _{i=1}^nk_i\frac{(1-2\beta )r^i_1+(2\beta -(1-\alpha _i) \theta _{r,i})r^i_2}{1-\theta _{r,i}+\alpha _i\theta _{r,i}}\le r. \end{aligned}$$ -

(iv)

If \(\beta \in (0.5,(3-(1-\alpha _n)\theta _{r,n})/4]\), then \(\mathrm{Cr}\{\sum _{i=1}^nk_i\xi ^U_i\le r\}\ge \beta \) is equivalent to

$$\begin{aligned} \sum _{i=1}^nk_i\frac{(2-2\beta -(1-\alpha _i)\theta _{r,i})r^i_2 +(2\beta -1)r^i_3}{1-\theta _{r,i}+\alpha _i\theta _{r,i}}\le r. \end{aligned}$$ -

(v)

If there exists an \(i_0\), \(1\le i_0<n\) such that \(\beta \in ((3-(1-\alpha _{i_0+1})\theta _{r,i_0+1})/4,(3-(1-\alpha _{i_0})\theta _{r,i_0})/4]\), then \(\mathrm{Cr}\{\sum _{i=1}^nk_i\xi ^U_i\le r\}\ge \beta \) is equivalent to

$$\begin{aligned}&\sum _{i=1}^{i_0}k_i\frac{(2-2\beta -(1-\alpha _i)\theta _{r,i})r^i_2 +(2\beta -1)r^i_3}{1-\theta _{r,i}+\alpha _i\theta _{r,i}}\\&\qquad + \sum _{i=i_0+1}^nk_i\frac{2(1-\beta )r^i_2+(2\beta -1+(1-\alpha _i)\theta _{r,i}) r^i_3}{1+\theta _{r,i}-\alpha _i\theta _{r,i}}\\&\quad \le r. \end{aligned}$$ -

(vi)

If \(\beta \in ((3-(1-\alpha _1)\theta _{r,1})/4,1]\), then \(\mathrm{Cr}\{\sum _{i=1}^nk_i\xi ^U_i\le r\}\ge \beta \) is equivalent to

$$\begin{aligned} \sum _{i=1}^nk_i\frac{2(1-\beta )r^i_2+(2\beta -1+(1-\alpha _i)\theta _{r,i}) r^i_3}{1+\theta _{r,i}-\alpha _i\theta _{r,i}}\le r. \end{aligned}$$

Proof

We only prove assertions \((i)\)-\((iii)\), and assertions \((iv)\)-\((vi)\) can be proved similarly.

Since \(\xi ^U_i\) is the upper reduced fuzzy variable of \(\tilde{\xi }_i\), its parametric possibility distribution is as follows

Denote \(\xi =\sum _{i=1}^nk_i\xi ^U_i\). If \(\beta \le 0.5\), then we have

Thus \(\mathrm{Cr}\{\xi \le r\}\ge \beta \) is equivalent to \(\sup _{x\le r}\mu _{\xi }(x;\theta ,\alpha )\ge 2\beta \). If we denote

for \(\beta \in (0,1]\), then we have \(\xi _{\inf ,\mathrm{Pos}}(2\beta )\le r\).

Since \(\xi ^U_1,\xi ^U_2,\ldots ,\xi ^U_n\) are mutually independent fuzzy variables, by Liu and Gao (2007), we have

Note that \(\mu _{\xi _i^U}((r^i_1+r^i_2)/2)=(1+(1-\alpha _i)\theta _{r,i})/2\). If \(0<2\beta \le (1+(1-\alpha _i)\theta _{r,i})/2\), i.e., \(\beta \in (0,(1+(1-\alpha _i)\theta _{r,i})/4]\), then for each \(i\), \(\xi ^U_{i,\inf ,\mathrm{Pos}}(2\beta )\) is the solution of the following equation

Solving the above equation, we have

On the other hand, if \(1\ge 2\beta >(1+(1-\alpha _i)\theta _{r,i})/2\), i.e., \(\beta \in ((1+(1-\alpha _i)\theta _{r,i})/4,0.5]\), then for each \(i\), \(\xi ^U_{i,\inf ,\mathrm{Pos}}(2\beta )\) is the solution of the following equation

Solving the above equation, we have

According to the inequalities \((1-\alpha _1)\theta _{r,1}\le (1-\alpha _2)\theta _{r,2}\le \cdots \le (1-\alpha _n)\theta _{r,n}\), we have the following results.

If \(0<2\beta \le (1+(1-\alpha _1)\theta _{r,1})/2\), then \(\beta \le (1+(1-\alpha _i)\theta _{r,i})/4\) for \(i=1,2,\ldots ,n\). Therefore, if \(\beta \in (0,(1+(1-\alpha _1)\theta _{r,1})/4]\), then \(\mathrm{Cr}\{\sum _{i=1}^nk_i\xi ^U_i\le r\}\ge \beta \) is equivalent to

If there exists an \(i_0\), \(1\le i_0<n\) such that \((1+(1-\alpha _{i_0})\theta _{r,i_0})/2<2\beta \le (1+(1-\alpha _{i_0+1})\theta _{r,i_0+1})/2\), i.e., \(\beta \in ((1+(1-\alpha _{i_0})\theta _{r,i_0})/4,(1+(1-\alpha _{i_0+1})\theta _{r,i_0+1})/4]\), then \(\mathrm{Cr}\{\sum _{i=1}^nk_i\xi ^U_i\le r\}\ge \beta \) is equivalent to

If \(1\ge 2\beta >(1+(1-\alpha _n)\theta _{r,n})/2\), then \(\beta \ge (1+(1-\alpha _i)\theta _{r,i})/4\) for \(i=1,2,\ldots ,n\). Therefore, if \(\beta \in ((1+(1-\alpha _n)\theta _{r,n})/4,0.5]\), then \(\mathrm{Cr}\{\sum _{i=1}^nk_i\xi ^U_i\le r\}\ge \beta \) is equivalent to

The proof of theorem is complete. \(\square \)

Rights and permissions

About this article

Cite this article

Bai, X., Liu, Y. Robust optimization of supply chain network design in fuzzy decision system. J Intell Manuf 27, 1131–1149 (2016). https://doi.org/10.1007/s10845-014-0939-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-014-0939-y