Abstract

The experimental nonlinear time series of welding current contain the arc feature information related to welding quality. The local mean decomposition (LMD) combining with the support vector machine (SVM) is put forward to quantitatively estimate the rationality of welding parameters and welding formation quality. The LMD is used to investigate the time–frequency distribution of arc energy, and the energy entropy is employed to quantitatively judge the welding arc characteristics related to welding quality. The collected current signal is decomposed into a number of product functions (PFs) by LMD. The energy entropy of each PF is calculated to establish the welding arc energy feature vectors, which are inputted into support vector machine classifier. The LMD combining with SVM can quantitatively estimate the time–frequency energy distribution characteristics of the arc current signal at different welding parameters and welding formation quality. Experimental results are provided to confirm the effectiveness of this approach to estimate the rationality of welding parameters and welding formation quality.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The use of modern signal processing methods to extract arc feature information for analysis and evaluation of the welding technology, process stability and welding quality is one of the important way to estimate welding quality (Wu and Tung 2008; He et al. 2011; Huang and Kovacevic 2011; Chokkalingham et al. 2012; He et al. 2013). Because the process parameters such as welding current, voltage and welding speed depend on arc energy characteristics in the welding process, which directly affect the stability of the welding process and welding formation quality. As early as in 1980, characterization of spot welding behaviour by dynamic electrical parameter monitoring was researched by Dickinson et al. Dickinson et al. (1980). Based on dynamic resistance signal together with the electrode displacement signal, Yong proposed a new technology for measuring dynamic resistance and estimating strength in resistance spot welding (Cho and Rhee 2000). A real-time imaging and detecting system was introduced to detect weld defects in steel tube, which could automatically alarm if the defect exceeds the national standard (Sun et al. 2005). In recent years, the introduction of advanced technology to monitoring and evaluation of welding process has become research focus, the theory of stochastic processes was applied to the analysis of gas metal arc welding data (Absi Alfaro et al. 2006). Weld joint strength prediction was implemented by neurowavelet packet analysis based on arc current (Pal et al. 2008). In nonlinear feature extraction, Sudhanya adopted the adaptive chirplet transform to detect the weld joint strength using current as a sensor output during the welding, it provided better time–frequency resolution, has much more accurate, high sensitivity with respect to faults, and also has better diagnostic resolution (Chatterjee et al. 2012). In order to obtain more welding information, the multi-parameter test system was also appeared in welding monitoring and evaluation (Cullen et al. 2008; Li 2012). At the same time, nonlinear time series processing methods have also become an important mean for analysis of arc stability characteristics in welding process monitoring and evaluation. This effect was also well studied and a lot of practical applications could be found (He et al. 2013; Zhiyong et al. 2013). Based on the experimental non-linear time series of welding current at different frequency and duty cycle, He numerically evaluated the arc stability of Square Wave Alternating Current Submerged Arc Welding (SW AC SAW) by the largest Lyapunov exponents (He et al. 2013). Li accurately calculated the maximum Lyapunov exponent of the welding processes for different parameters to evaluate stability of the welding process in gas metal arc welding (GMAW) (Zhiyong et al. 2013).

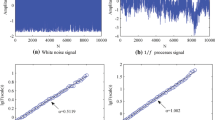

Because of the uncertainty and nonlinear coupled affecting factors to the welding quality, the collected welding arc data is the non-stationary arc signal. The time–frequency analysis method is most powerful tool for non-stationary signals presently. There are some time–frequency analysis methods such as window flourier transformation, continuous wavelet transformation, Wigner–Ville distribution, Hilbert–Huang transformation and local mean decomposition (LMD) (Zhang et al. 2013; Flandrin et al. 2013; Hsu et al. 2013; Smith 2005). Where, LMD is a new self-adapting time–frequency analysis method, and first proposed by Jonathan S. Smith, which get better results by applling to the EEG signal processing and Smith (2005). LMD method cana adaptively decompose a complex multi-component signal into a number of instantaneous frequency and a physical meaning Product Function (PF) components, each of the PF component is multiplied by an envelope signal and a pure frequency modulation signal. It has higher time–frequency resolution and concentration, which is especially suitable to the analysis of arc electric signal.

In this paper, a method based on the PF component energy entropy and support vector machine (SVM) is presented to estimate welding quality (the rationality of welding parameters, the recognition of welding formation quality). The collected current signal is adaptively decomposed into physical meaning PF components. The energy entropy of PFs are calculated to be the arc feature vectors that are inputted into support vector machine classifier to evaluate the rationality of welding parameters and welding formation quality. Experimental results show that the PF component energy entropy of arc current signal can characterize quantitatively the energy variation of arc welding process, and the support vector machine classifier can effectively achieve recognition for the rationality of welding parameters and welding formation quality.

In “Quantitative estimation principle and methods” section, we discuss the theory and algorithm for the LMD, and how the collected current signal decomposed into physical meaning PF components, the quantitative estimation method based on the PF component energy entropy and SVM is put forward. In “Experiment and results” section, the experimental condition and scheme are designed, and the proposed method is applied and results are discussed. The conclusions are summarized in “Conclusions” section.

Quantitative estimation principle and methods

LMD process

LMD is essentially demodulation process of a multi-component signal. LMD adaptively decomposes a complex multi-component signal into a number of PF components with a physical meaning of instantaneous frequency, each of the PF component is composed of an envelope signal multiplied a pure frequency modulation signal. The instantaneous amplitude is representative of the amplitude modulation information of the PF component. The instantaneous frequency is representative of the frequency modulation of the PF component.

For an arbitrary signal \(x\)(t), it can be decomposed into the sum of \(PF_p \) component and a monotonic function \(u_k \) as follows:

Figure 1 is an alternate current square wave welding current signal \(x\)(t) and the denoising results, Fig. 2 is the decomposition results by LMD.

We can see from Fig. 2, the decomposed component of \(PF_{1}\), \(PF_{2}, {\ldots }PF_{5}\) correspond to the different frequency signal, representing the real physical information within the welding current signal, the monotonic function \(u_5\) is the rule AC square wave. Each PF represents the distortion components of AC square wave current waveform with different frequencies and amplitude diversification in the time scale, the original signal characteristics become visible in different resolutions. The amplitudes of the PF components vary greatly. When welding technology specification changes, the energy distribution of PF component of arc energy signal will change accordingly, which directly affect arc stability and weld formation quality. Based on decomposition of LMD, the distribution of the energy calculated can be used to characterize the welding process state. In order to extract arc feature, the PF components of energy entropy are selected to characterize the differences in quality of the welding process.

Hilbert transform for PFs

According to (1), Hilbert transform of every PF is performed, (2) can be represented as below.

The analytic signal \(z_i (t)\) is constructed by (3)

where the amplitude function \(a_i (t)\) and phase function \(\phi _i (t)\) are represented as (4) and (5)

The instantaneous frequency \(f_i (t)\) can be further represented as follows.

In this way, the \(x(t)\) can be represented as

where RP is real part. (7) is defined as Hilbert spectrum and can be represented as

(8) describes the accurate changing law of time and frequency of signal amplitude in the whole frequency ranges. The signal amplitude can be depicted by contour line of time–frequency plane, can also be expressed as function of time and instantaneous frequency in the three dimensions space.

Energy entropy for Hilbert spectrum

In order to quantify the welding arc energy Characteristics at different welding parameters, the energy entropy is introduced to be calculated based on the Hilbert spectrum of the welding current signal. The method of energy entropy introduced into time–frequency analysis is to divide time–frequency plane into \(N\) equal area blocks, and each block energy is supposed as \(W_i (i=1,2,\ldots ,N)\), the total energy of the time–frequency plane is \(A\). Each block energy is normalized by \(q_i =W_i /A\), thus \(\sum _{i=1}^N {q_i }=1\), which corresponds with initial normalization condition of information entropy calculation. Based on the formula of information entropy, the formula of time–frequency entropy \(s(q)\) based on PF Hilbert transformation can be written as (9),

According to the basic property of information entropy, the distribution of \(q_i \) is more uniform, the calculated value of energy entropy \(s(q)\) is smaller. the distribution of is less uniform, the calculated value of energy entropy is larger.

Figure 3 shows the joint distribution of the time and frequency after Hilbert transform for the welding current signal \(x\)(t) demodulated by LMD. We can see from Fig. 3, that the main frequency components is basically around 50 Hz, accompanying other frequency components fluctuating around the main frequency over time, which meets the variation of instantaneous frequency and amplitude of the 50 Hz AC square wave submerged arc welding current signal. It accurately reflects the variation rule of signal’s frequency, amplitude with high time–frequency resolution and concentration.

The welding quality classifier based on support vector machine

Support vector machine classifier (Ekici 2012; Çaydaş and Ekici 2012; Brezak et al. 2012; Manupati et al. 2013)

Two types of linearly separable sample are set as \((x_i ,y_i )\), \(i=1,\ldots ,l,x_i \in R^{n},y\in \{+1,-1\}, l\) is the number of samples, \(n\) is inputting dimension. General form of the linear discriminated function is \(f(x)=\omega x+b\), the equation of classification plane is:

where \(\omega =[\omega _1 ,\omega _2 ,\ldots ,\omega _n ]\) is a hyperplane weight vector, \(b\) are constants.

Since SVM is binary classifiers, the multivariate classifier must be established by the binary SVM. In order to distinguish welding formation state between normal, undercut and hump, only two classifiers should be designed. In SVM1, \(f(\hbox {x}) = +1\) is defined by undercut, \(f(\hbox {x}) = -1\) indicates a normal or hump, so the undercut can be separated by SVM1. In SVM2, \(f(\hbox {x}) = +1\) is defined by normal, \(f(\hbox {x}) =-1\) indicates the hump, so the hump can be separated by SVM2. In classification test, the testing data sample of feature vectors are inputted into SVM1, if \(f(\hbox {x}) = +1\), welding formation state is recognized as undercut, otherwise the rests are inputted into the SVM2 automatically, if \(f (\hbox {x}) = +1\), welding formation state is recognized as normal, if \(f(\hbox {x}) = -1\), welding formation state is recognized as hump.

Taken the calculated PF component energy entropy of arc current signal as the characteristic parameters, the three common welding seam forms of normal, undercut and hump as the status identification of welding quality, the welding quality classifier based on support vector machine is shown in Fig. 4.

The selection of kernel function (Keerthi and Lin 2003; Chapelle and Vapnik 2002)

The data sample of welding process is nonlinear. For nonlinear classification issues, if the optimal classifier surface in the original space can not be satisfied with the results, we can make the mapping of the original sample space to high dimensional linear separable feature space F by nonlinear mapping \(\phi :R^{n}\rightarrow F,x\rightarrow \phi (x)\), thus the classified samples are changed into \(\{\phi (x_1 ),\phi (x_2 ),\ldots ,\phi (x_n )\}\). It is difficult to solve non-linear mapping in the general case, but the ingenious solution can be introduced to this problem by the kernel function. The optimal hyperplane in the feature space is constructed by:

By choosing the different kernel function, different support vector machine classifier can be constructed.

Kernel function has good local area to facilitate the extension of to the unknown target classification. Different support vector machine can be established by choosing kernel function. In the commonly used kernel function, the linear and gaussian kernel functions have been widely used. The gaussian kernel function is most widely used with good learning ability, has a wide domain of convergence, is the ideal classification function, the gaussian kernel function is as follows:

where \(\sigma \) is kernel parameter.

The principle and method of quantitative estimation for welding quality

The principle and method of quantitative estimation for welding quality is shown in Fig. 5, the quantitative estimation method steps are as follows:

-

(1)

Welding experiments are done by the given welding process parameters under orthogonal experimental program, and conduct welding arc current signal data acquisition, the welding current is sampled real time for 10 s at a sample rate of 25 kHz. From the total samples, 10,000 data points are extracted randomly to be the training and testing samples.

-

(2)

Decompose welding arc current signal data into \(N\) PF components by LMD, each PF component corresponds to a data sample {\(x_{pt} \)}, \(p\) = 1, 2,..., \(n\), \(t\) = 1, 2,..., \(N\), and the new time series are obtained by energy normalized{\(\mathop {x_{pt} }\limits ^\wedge \)}, =1, 2,.... The object of data normalized is to eliminate the original sampled signal amplitude affecting characterized parameter extraction of the system state.

-

3)

Divide each of the data samples {} into m-segment acooding to the length of data, calculating the total energy \(E_{i}\) of each piece of data, and the energy \(E_{1}\), \(E_{2}\), ..., \(E_{m}\) of each PF component are obtained.

-

4)

Based on the formula of energy entropy (9), each PF component is written as Eq. (13),

$$\begin{aligned} S_p (q)=-\sum _{i=1}^m {q_i } \hbox {In}q_i \end{aligned}$$(13)where \(q_i =E_i /E\) represents the proportion of the energy of the \(i\) segment data in the total energy \(E=\sum _{i=1}^m {E_i }\) in each PF component. According to the basic property of information entropy, the more uniform is the distribution, the smaller is the value of energy entropy, while the less uniform is the distribution, and the larger is the value of energy entropy.

-

(5)

The energy eigenvector matrix of each arc current data samples can be constructed as an \(n\)-dimensional \(T=[S_{1},S_{2}{\ldots },S_{n}]\), which are inputted into support vector machine as a feature vector.

-

(6)

The arc energy eigenvectors \(T\) are inputted into support vector machine for training to be welding molding quality classifier.

-

(7)

Within the scope of the setting process parameters, welding experiments are done, arc current signal data are collected as the testing sample form the feature vector \(T\) in accordance with step (2), (3), (4), (5), then input feature vector \(T\) into the SVM classifier to identify the rationality of welding process, arc stability and welding molding quality.

Experiment and results

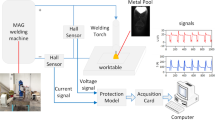

The experimental condition

With objects of experiments and analysis to the AC square wave submerged arc welding, welding arc current and voltage signal are collected by the current sensors, Ethernet data acquisition, industrial control computer, and the experimental platform is shown in Fig. 6. The collected welding current, voltage signal are transported to industrial control computer by cable transmission. The collected signal are analyzed and processed by Matlab.

Experiments are done by alternating current square wave submerged arc welding machine MZE1000. The material of work piece is low carbon steel Q235 with slab thickness of 20 mm, the welding wire trademark is H08A with diameter of 4.0 mm, and welding flux is HJ431.

Results and discussion

In order to ensure the integrity of information of experimental samples with the reasonable number of experiments, the orthogonal design experiment is introduced. Five factors and three levels of orthogonal experiment are designed, the currents are set by 400, 500, 600 A, the voltages are set by 36, 38 and 40 V. The frequency of current waveform are set by 50, 80 and 100 Hz, The duty cycle of current waveform are set by 0.3, 0.5 and 0.8. Welding speed are set by 0.6, 1.0 and 1.4 m/min.

Alternating current square wave submerged arc welding experiments are done by the given welding process parameters, and conduct arc current signal data acquisition, the testing program and results are shown in Table 1. The welding molding situation of the experiments are normal (welding seam surface is neat and smooth), undercut (welding seam surface is corner, irregular and depression) and hump (welding seam surface is obvious rugged, uncontinuous and depression). The actual pictures for between normal, undercut, and hump is shown in Fig. 7.

PF component eigenvectors are constructed after decomposing collected arc current signal by LMD in each experiment. Figure 8a, (b), (c) are the LMD decomposed results of the collected arc current signal of experiments sequence number 1, 7 and 14, respectively. Table 2 lists the calculated PF component eigenvectorsm of the experiments 1, 7 and 14. As can be seen from the Table 2, corresponding to different welding parameters and welding molding, PF component energy entropy values after the decomposition of the LMD are vary, which illustrate the energy entropy of the PF components can quantitatively estimate the time–frequency energy distribution characteristics of the welding arc current signal at different welding parameters and welding formation quality, so it can be inputted into support vector machine as a feature vector.

Arc current signal of experiment sequence number. 1, 7, 14 and the LMD decomposition results. a Arc current signal of experiment sequence number 1 and the LMD decomposition result. b Arc current signal of experiment sequence number 7 and the LMD decomposition result. c Arc current signal of experiment sequence number 14 and the LMD decomposition result

The training samples used to identify the welding process and welding quality are feature vectors of corresponding calculated PF components with regard to welding parameters and welding formation. The training samples from Table 1 are inputted to the two support vector machine classifier of welding quality.

At the same time, the testing experimental program is designed to test the performance of classification. The boundaries of each welding parameters for testing experimental program depend on the upper and lower values of welding parameters in experiment, the boundaries of each welding parameters are as following: the boundary of currents is 400–600 A, the boundary of voltages is 36–40 V, the boundary of frequency of current waveform is 50 A–100 Hz, the boundary of duty cycle of current waveform is 0.3–0.8, the boundary of welding speed is 0.6–1.4 m/min. The calculated eigenvectors at each testing experimental program are used to verify support vector machines for welding quality pattern recognition. The recognition results are shown in Table 3. As can be seen from Table 3, the proposed support vector machine has a high correct recognition rate by 94.4 % to the testing sample, which illustrate the proposed welding quality testing methods are effective based on the energy entropy of PF component and SVM.

Conclusions

Based on local mean decomposition and support vector machine, we have presented an quantitative estimation technique for welding quality, whic have been applied to estimate welding quality in alternating current square wave submerged arc welding, and also obtained the following conclusions:

-

(1)

The LMD combining with energy entropy can quantitatively estimate the time–frequency energy distribution characteristics of the welding arc current signal related to the rationality of welding parameters and welding formation quality.Welding arc current signal is adaptively decomposied by LMD, and a number of real physical significance PF component are obtained, and the energy entropy of each PF component also are calculated, eigenvectors constructed by energy entropy of each PF components can be used as arc characteristics information of the arc stability and welding formation quality.

-

(2)

Based on the arc eigenvectors constructed by the energy entropy of PF components, the pattern recognition of welding molding type has been achieved by support vector machine. The proposed method can effectively quantitative estimate the rationality of the welding parameters and weld formation quality, and has a high correct recognition rate by 94.4 % to the testing sample, which illustrate the proposed welding quality testing methods are effective based on the energy entropy of PF component and SVM.

References

Absi Alfaro, S. C., Carvalho, G. C., & da Cunhab, F. R. (2006). A statistical approach for monitoring stochastic welding processes. Journal of Materials Processing Technology, 175(2006), 4–14.

Brezak, D., Majetic, D., Udiljak, T., & Kasac, J. (2012). Tool wear estimation using an analytic fuzzy classifier and support vector machines. Journal of Intelligent Manufacturing, 23(2012), 797–809.

Çaydaş, U., & Ekici, S. (2012). Support vector machines models for surface roughness prediction in CNC turning of AISI 304 austenitic stainless steel. Journal of Intelligent Manufacturing, 23(2012), 639–650.

Chapelle, O., & Vapnik, V. (2002). Choosing multiple parameters for support vector machines. Machine Learning, 46(2002), 131–159.

Chatterjee, S., Chatterjee, R., Pal, S., Pal, K., & Pal, S. K. (2012). Adaptive chirplet transform for sensitive and accurate monitoring of pulsed gas metal arc welding process. The International Journal of Advanced Manufacturing Technology, 60(2012), 111–125.

Cho, Y., & Rhee, S. (2000). New technology for measuring dynamic resistance and estimating strength in resistance spot welding. Measurement Science and Technology, 11(2000), 1173–1178.

Chokkalingham, S., Chandrasekhar, N., & Vasudevan, M. (2012). Predicting the depth of penetration and weld bead width from the infra red thermal image of the weld pool using artificial neural network modeling. Journal of Intelligent Manufacturing, 23(2012), 1995–2001.

Cullen, J. D., Athi, N., Al-Jader, M., Johnson, P., Al-Shamma’a, A. I., & Shaw, A. (2008). Multisensor fusion for on line monitoring of the quality of spot welding in automotive industry. Measurement, 41(2008), 412–423.

Dickinson, D. W., Franklin, J. E., & Stanya, A. (1980). Characterization of spot welding behavior by dynamic electrical parameter monitoring. Welding Journal, 59(1980), 170s–176s.

Ekici, S. (2012). Support vector machines for classification and locating faults on transmission lines. Applied Soft Computing, 12(2012), 1650–1658.

Flandrin, P., Amin, M., McLaughlin, S., & Torresani, B. (2013). Time–frequency analysis and applications. IEEE Signal Processing Magazine, 30(2013), 19–150.

He, K., Zhang, Z., Xiao, S., & Li, X. (2013). Feature extraction of AC square wave SAW arc characteristics using improved Hilbert–Huang transformation and energy entropy. Measurement, 46(2013), 1385–1392.

He, K. F., Li, Q., & Chen, J. (2013). An arc stability evaluation approach for SW AC SAW based on Lyapunov exponent of welding current. Measurement, 46(1), 272–278.

He, K. F., Wu, J. G., & Wang, G. B. (2011). Time–frequency entropy analysis of alternating current square wave current signal in submerged arc welding. Journal of Computers, 6(2011), 2092–2097.

Hsu, W., Chiou, D., Chen, C., Liu, M., Chiang, W., & Huang, P. (2013). Sensitivity of initial damage detection for steel structures using the Hilbert–Huang transforms method. Journal of Vibration and Control, 19(2013), 857–878.

Huang, W., & Kovacevic, R. (2011). A neural network and multiple regression method for the characterization of the depth of weld penetration in laser welding based on acoustic signatures. Journal of Intelligent Manufacturing, 22(2011), 131–143.

Keerthi, S. S., & Lin, C. J. (2003). Asymptotic behaviors of support vector machines with Gaussian kernel. Neural Computation, 15(2003), 1667–1689.

Li, R. X. (2012). Quality monitoring of resistance spot welding based on process parameters. Energy Procedia, 14(2012), 925–930.

Manupati, V. K., Rohit Anand, J. J., Thakkar, Lyes Benyoucef, Garsia, Fausto P., & Tiwari, M. K. (2013). Adaptive production control system for a flexible manufacturing cell using support vector machine-based approach. The International Journal of Advanced Manufacturing Technology, 67(2013), 969–981.

Pal, S., Pal, S. K., & Samantaray, A. K. (2008). Neurowavelet packet analysis based on current signature for weld joint strength prediction in pulsed metal inert gas welding process. Science and Technology of Welding and Joining, 13(2008), 638–645.

Smith, J. S. (2005). The localmean decomposition and its application to EEG perception date. Journal of the Royal Society Interface, 2(2005), 443–454.

Sun, Y., Bai, P., Sun, H-y, & Zhou, P. (2005). Real-time automatic detection of weld defects in steel pipe. NDT & E International, 38(2005), 522–528.

Wu, C., & Tung, P. (2008). Application of genetic algorithm to external noise cancellation and compensation in automatic arc welding system. Journal of Intelligent Manufacturing, 19(2008), 249–256.

Zhang, Z., Wang, Y., & Wang, K. (2013). Fault diagnosis and prognosis using wavelet packet decomposition, Fourier transform and artificial neural network. Journal of Intelligent Manufacturing, 24(2013), 1213–1227.

Zhiyong, L., Qiang, Z., Yan, L., & Xiaocheng, Y. (2013). An analysis of gas metal arc welding using the Lyapunov exponent. Materials and Manufacturing Processes, 28(2013), 213–219.

Acknowledgments

This work is supported by National Natural Science Foundation of China (51005073) and Hunan Provincial Natural Science Foundation of China (11JJ2027) are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

He, K., Li, X. A quantitative estimation technique for welding quality using local mean decomposition and support vector machine. J Intell Manuf 27, 525–533 (2016). https://doi.org/10.1007/s10845-014-0885-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-014-0885-8