Abstract

There is an urgent need for diversifying livelihood of low-income artisanal fishermen due to rapidly dwindling fishery resources. CSIR-Central Salt and Marine Chemicals Research Institute takes pride in being first for pioneering Kappaphycus alvarezii cultivation, heralding an era of commercial seaweed farming in India. The invention of liquefying fresh seaweed biomass to obtain two products in an integrated manner, one being a granular residue rich in κ-carrageenan and the other being sap rich in potash and micronutrients (ca. 2 % w/v), with proven efficacy has provided a boost to commercial farming. The production has been substantially increased from 21 dry tonnes in 2001 to 1490 dry tonnes in 2013 with concomitant purchase value of <4.5 to 35 Rs kg−1 (dry). India is fast emerging as important production center in Southeast Asia for K. alvarezii production with estimated 765,000 man-days of employment, having annual turnover of around Rs 2 billion. At present, commercial farming is carried out following three techniques, namely floating bamboo raft, tube net, and longline method of which former two are widely practiced. The cultivation activity is well established in southern state of Tamil Nadu and progressing rapidly to other areas namely Gujarat, Andhra Pradesh, and Maharashtra. The socioeconomic benefits accrued in this project are overwhelmingly positive, but evidence-based policies are required for addressing prevailing environmental issues. The steps toward developing value-added products with niche applications coupled with biotechnological interventions aimed at seed production through tissue culture for developing elite germplasm, etc. could further improve the prospects of taking this project to pan India level. The present review provides a detailed account of developments of commercial farming that has witnessed successful diversification of livelihood consistently for the last 10 years.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Carrageenan, by virtue of its distinctive gelling properties, is used as an emulsifier and thickener in diverse commodity products such as toothpaste, cosmetics, ice cream, pet foods, beverages, pharmaceutical, personal care, and dairy industry. The fact that ascertained its utility as an alternative to agar has dramatically improved commercial prospects of carageenophytes post–World War II. Chemically, three major carrageenan types are recognized, namely beta produced by Betaphycus gelatinae (gelatinae of the trade), “iota” by Eucheuma denticulatum (spinosum of the trade), and “kappa” by several species of the genus Kappaphycus (cottonii of the trade). The global red seaweed production through farming has increased from 2 million fr. t in 2000 (21 % of the production of all cultivated seaweeds) to almost 9 million fr. t in 2010 (47 %). Nevertheless, business centric farming in tropical waters has resulted in enhanced production of Kappaphycus and Eucheuma from 0.94 million fr. t in 2000 (48 % of total red seaweed cultivation) to 5.6 million fr. t in 2010 (63 %) (Cai et al. 2013). This was due to expansion of cultivation in the countries where carrageenan seaweed industry is well established (Msuya et al. 2014; Hurtado et al. 2015) and largely to the fast expanding commercial grounds in Mexico, Solomon Islands, and India (Periyasami et al. 2014.

In India, exploitation of seaweeds has been traditionally carried out along the southeastern coast for industrial processing of biomass for agar and alginate (Subba Rao and Mantri 2006). However, continuous, indiscriminate, and unorganized harvesting has resulted into depletion of natural resources, thereby closing several seaweed processing units. The Food and Agriculture Organization of United Nations (FAO) under Bay of Bengal Programme (BOBP) with the Swedish International Development Agency, Overseas Development Administration of United Kingdom, and Department of Fisheries, Government of Tamil Nadu, initiated trials of Gracilaria edulis farming along southeastern coast of Tamil Nadu. However, the project could not be proven commercially viable due to technical impediments. The Central Salt and Marine Chemicals Research Institute (CSMCRI), a constituent R & D laboratory of Council of Scientific and Industrial Research, Ministry of Science and Technology, New Delhi, through its ongoing research has contributed to the advancement of the seaweed industry in India. The development of indigenous processes enabling recovery of an array of products of commercial value from fresh algal biomass has indeed boosted seaweed farming in the country. Seaweed mariculture is now considered as a promising activity for improving the socioeconomic status of low-income artisanal fishermen. India is fast emerging as an important center in Southeast Asia for Kappaphycus alvarezii production with estimated 765,000 man-days of employment, having annual turnover of around Rs 2 billion (Aquaculture Foundation of India 2008) (Rs 100 ≈ US$1.5). This review describes genesis and successes in achieving diversification of livelihood through commercial farming of K. alvarezii in India and issues pertaining to farming and future prospects.

Genesis of commercial farming

Prof. Maxwell Doty of the University of Hawaii with Marine Colloids Corporation attempted cultivation of K. alvarezii in the Philippines in the latter half of the 1960s. His rigorous selection of cultivar and meticulous culture methodologies culminated in achieving successful farming of this alga and other commercial eucheumoids as well. This accomplishment followed introduction of several varieties to over 31 countries for research and commercial farming (Ask et al. 2001). Nevertheless, only five of these counties (Indonesia, Philippines, Malaysia, United Republic of Tanzania, China) commercially produced over 5599 fr. t biomass in 2010 (Cai et al. 2013). The entire commercial farming in India has emanated from a strain of Philippine origin acquired by CSMCRI from Japan in 1984, following procedures of introduction and quarantine for experimental, research, and cultivation (c.f. Mandal et al. 2010). Although the parent thallus perished during acclimatization experiments, asexual propagules formed survived and acted as stock for commercial faming (Mairh and Tewari 1994). There has been a debate on the occurrence of this species from Indian waters. Nevertheless, literature amply supports its occurrence from India. The earliest record dates back to the nineteenth century (c.f. Silva et al. 1996), while subsequently, it was also reported from Port Okha (Krishnamurthy and Joshi 1970–as Eucheuma spinosum) and Red Skin Island, Andaman (Rao and Rao 1999–as Kappaphycus cottonii).

The initial outdoor culture and out-planting experiments were carried during 1989–1996 at Port Okha (Mairh et al. 1995), while the subsequent field trials were extended at Mandapam from 1995 to 1997 (Eswaran et al. 2002). The cultivation was carried out only experimentally until November 2000, when M/s. Pepsi Foods Ltd. (a subsidiary of PepsiCo India Holdings Ltd.) showed interest in carragenophytes. PepsiCo India Holdings Ltd. sponsored a project to CSMCRI for farming of Hypnea musciformis in the Gulf of Mannar. The sample from the first batch (50 kg dry) produced in December 2000 reported inferior carrageenan. This led to explore the farming of K. alvarezii at the hectare scale. Two modes were tested, namely shrimp culture pond and open sea cultivation. The daily growth rate in the former was reported to be about 1 %, while that of latter was 3.88 %, confirming the economic viability of open sea cultivation. Thereafter, cultivation technology was transfer to PepsiCo India Holdings Ltd. in 2001. The company under its corporate social responsibility (CSR) initiated large-scale farming along Palk Bay side of Mandapam coast. Eventually, farming business rights were transferred by PepsiCo Holdings India Ltd. in August 2008, to M/s. Aquagri Processing Pvt. Ltd.—a company formed by group of entrepreneurs led by a former PepsiCo executive in a tripartite agreement. The newly formed company continues to honor buyback commitment made to self-help groups (SHGs) and further acquired the technology for processing the fresh biomass. It was successful in expanding cultivation in Tamil Nadu while maintaining its focus on agricultural by-products in the form of plant growth stimulant (sap) from fresh seaweed biomass (Agarwal et al. 2016; Singh 2016a, b). The farming system has evolved in conjunction with innovations in biomass processing. The timeline of the project implementation is given in Table 1. To date, farming has been tested or practiced at 30 locations along the Indian coast (Fig. 1). The bioeconomic analysis for individual and artisanal culture of K. alvarezii in India reported positive net present value at an internal return rate of 210 % after 6 months of business inception (Jara and Riffo 2016). This analysis showed that farming can be taken up for diversification of livelihood where livelihood opportunities are limited.

Map of India depicting locations of Kappaphycus alvarezii farming (experimental or commercial). 1, Beyt Dwarka, Gujarat (R, 3.64–9.35); 2, Port Okha, Gujarat (R, 3.86–13.98); 3, Mithapur, Gujarat (R, 3.93–9.80); 4, Miyani, Porbadar, Gujarat; 5, Madvad; Gujarat; 6, Diu (Union Territory); 7, Simar, Gujarat; 8, Sarkeswar, Jafrabad, Gujarat (R, 6.57–7.65); 9, Palshet, Guhagar, Maharashtra (R, 5.20); 10, Padanna backwaters, Kasaragod, Kerala; 11, Vizhinjam Harbour, Kerala (R, 4.69–6.91); 12, Muttam, Tamil Nadu (R, 3.21); 13, Kulasekarapattinam, Tamil Nadu (M, 3.86); 14, Tiruchendur, Tamil Nadu (M, 3.2); 15, Tuticorin, Tamil Nadu (R and M, 3.04); 16, Olaikuda, Tamil Nadu (R and M, 3.2); 17, Thonithurai, Tamil Nadu (R, 3.4); 18, Munaikadu, Tamil Nadu (R, 3.69); 19, Jegathapattinam, Tamil Nadu (M, 4); 20, Kottaipattinam, Tamil Nadu (M, 4.23); 21, Athiramapattinam, Tamil Nadu (M, 4.2); 22, Bapatla, Andrha Pradesh; 23, Mypadu, Andhra Pradesh; 24, Humsladevi, Andhra Pradesh; 25, Sorlagondi, Andhra Pradesh; 26, Nagayalanka, Andrha Pradesh; 27, Visakhapattinam, Andhra Pradesh; 28, Gokharkuda, Odhisa (R, 3.6–4.9); 29, Purunabandha, Odhisa (R, 3.4–5.8). Source: Periyasami et al. (2014a, 2015), Bindu (2011), Subba Rao et al. (2008), Padhi et al. (2008), The Hindu, September 19, 2015. Values in parentheses refer to the methods of cultivation and daily growth rate (% day–1). R raft, M monoline, TN tube net

National priorities and policies for encouraging seaweed cultivation and utilization

India, although recording over 600,000 fr. t seaweed standing crop (Subba Rao and Mantri 2006), still imports over 2000 t of carrageenan annually. Self-sufficiency in this important commodity will reduce foreign exchange requirements considerably on one hand, while enabling the diversifying livelihood of coastal populations on the other. Guidelines are in place at the regional level pertaining to seaweed collection (Immanuel and Sathiadhas 2004), but unlike other Southeast Asian countries such as Indonesia and Philippines, national policies for seaweed research, farming, harvesting, and business are lacking. The Indian government has recently identified seaweed cultivation as a priority area and is likely to give it more emphasis in the forthcoming renewed National Aquaculture Policy. Nevertheless, the National Academy of Agricultural Sciences has already produced a strategy document pertaining to commercial farming and processing of seaweeds in the country (Anon 2003). It recommended establishing a special unit in the Ministry of Agriculture—on the lines of the Bureau of Aquatic and Fisheries Resources, in Philippines and Indonesia—which can implement large-scale commercial cultivation program and effectively liaise between ministries. Biomass, both fresh and dried, obtained through aquaculture is considered as agriculture produce for the purpose of all kinds of fiscal levies to promote seaweed farming. The integrated cultivation of shrimp and marine fishes with seaweed is encouraged since seaweeds act as scrubbers to reduce nutrients.

More conscious efforts for implementing the project through the SHG model have yielded better coordination and productivity. This was initiated through the Kutumbam (family) model of cultivation (KMC). In the KMC, members of SHGs normally belong to the same family but may also include members from the same community as well (Krishnan and Narayanakumar 2010). National financial institutions like the State Bank of India (SBI) and the National Bank for Agriculture and Rural Development (NABARD) support commercial farming by providing loans. The Department of Biotechnology (DBT), Ministry of Science and Technology, spent Rs 9 million to rehabilitate tsunami-affected fishers, and the funds were routed through the Aquaculture Foundation of India, responsible for the floating of 12,000 rafts.

Long-term sustainability of the project is ensured by introducing a unique scheme named “Growers Investment Program (GIP)” by M/s. Aquagri Processing Ltd. in April 2009. The company deducts 5 % income of the SHG member/farmer; this is equally matched by the company, and this contribution is deposited in a bank, which facilitates a microcredit lending program. In another initiative, the access and benefit sharing (ABS) agreement implemented by the National Biodiversity Authority of India has realized Rp 3.7 million revenue through commercial farming activities for social well-being of the local community involved in farming (Prathapan and Rajan 2011). Further, there is ample scope for linking seaweed farming with popular government schemes such as the “Mahatma Gandhi National Rural Employment Guarantee Act” which is aimed at enhancing livelihood security of rural people. The technology has further achieved two prestigious national awards from Council of Scientific and Industrial Research, Ministry of Science and Technology, in 2001 and 2013, respectively, for its innovative and scientific approach for societal development. Nevertheless, involvement of stakeholder in policy-making, planning, and management is critical for effective implementation of these initiatives.

Methods adopted for commercial farming

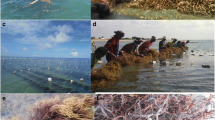

Hayashi et al. (2010) listed 13 techniques employed for K. alvarezii farming. However, off-bottom monoline, or fixed-off bottom, broadcast, floating bamboo, net system, and tubular net are common for shallow waters (Hurtado and Yasir 2014). Deeper water cultivation is carried out by multiple raft longline, spider web, hanging basket, and free-swing methods (c.f. Hurtado et al. 2014). Although several methods have been adopted globally, only the tie-tie system has been used in the form of fixed-off bottom, floating longline, and rafts. The subsequently developed “loop” technique greatly reduced planting labor, thereby also eliminating contamination by raffia. The farming in India also has undergone gradual changes; floating bamboo raft, longline or monoline, and tube net have been practiced for biomass production, while perforated polythene bag, net bag and floating bamboo basket methods have been utilized for conserving biomass during lean periods or for protection from grazing (Supplementary Figs. 1, 2, and 3). This section describes the most common methods of farming in India.

Floating bamboo raft method

A bamboo raft (8–10 cm in diameter and 3 × 3 m) is used as the main frame for cultivation. The angular portions are diagonally fixed with the help of supporting bamboos (≈120 cm long) for keeping it intact. The rafts in clusters are tied with an anchor to fix them and maintaining their buoyancy. Bottom netting is provided to avoid drifting of material as well as to minimize grazing. Total 20 plantings of about 100–150 g fresh weight each are planted on polypropylene ropes (3 mm) at regular intervals by raffia or braider. The seeded ropes are tied parallel to each other at 15-cm intervals at both the ends to opposite bamboo. Each raft with 20 such ropes thus will have an initial seeding weight of 60 kg fresh wt (Fig. 2a). The seeding is carried out on shore and seeded rafts are transplanted into the open sea subsequently. Harvesting is generally carried out after 45 days. This method is recommended where the water moment is gentle and popularly adopted in areas such as the North Ramanathapuram district of Tamil Nadu.

Longline or monoline method

This is modified traditional off-bottom farming, having few similarities with the raft method. Seedlings of about 100–150 g fresh weight are attached to a rope by raffia or braider between anchors. The main rope is 6 to 8 mm in diameter and about 20 m in length. The longline ropes are kept afloat in water with the help of floats tied at regular intervals and anchoring is done on both ends. Timber of casuarina, eucalyptus, bamboo, etc. is used for anchoring. Poles are erected at 3-m interval in a square manner and 12-mm polypropylene rope is tied in any two parallel directions (depending upon tidal current). The seeded ropes (3 mm) are then tied in 10-cm intervals. Care needs to be taken to ensure that the seaweed always remains submerged (0.5 m below the surface) and receives sufficient sunlight (Fig. 2b). Generally, seeding in this case is done in the water itself to avoid seedling loss which may occur if ropes are seeded on the shore and dragged into the sea. This farming technique is recommended for moderate wave action and particularly in areas with low density of grazers. It is popularly adopted in South Ramanathapuram, Pudukkottai, and Tuticorin districts of Tamil Nadu.

Tube net method

Higher wave action may cause drifting of germlings in the early growth phase or considerable crop loss in the preharvest stage where seeding attains highest weight. Thus, the tube net method (de Góes and Reis 2012) holds great promise. The tube nets (15-cm diameter; mesh size of 2.0 cm) of 25-m length are held floating in the water column below the surface with an appropriate number and size of floats at regular intervals. Anchor stones (about 30 kg) are used at each end to hold the tube nets steady in the water column; if required, additional anchors of appropriate size and weight can be fixed intermediately. The seed material of 20 kg fresh wt is loaded into the tubes with the aid of a 1.0- or 1.5 m long plastic pipe acting as a funnel or a hopper. The pipe diameter should be little less than that of tube net for efficient seeding. The plastic pipe is inserted into the tube, and the entire tube is pulled down, so that the mouth of plastic pipe stands out of the tube. The tube net is pulled down from the bottom of the plastic pipe carefully, in such a way that seedling material gets loaded into the tube sequentially leaving no gap between the seedlings. This process is continued till the entire tube net is seeded with algal biomass. The tubes are closed at both ends with rope to prevent material being lost (Fig. 2c; Supplementary Fig. 4). A mechanical harvester has recently been designed and tested for harvesting the biomass from the tubes (Ghosh et al. 2015).

In terms of productivity of the system pertaining to length of farming line, the floating raft system seems to be the best (Cai et al. 2013). The floating bamboo raft technique provides ease of maintenance and harvesting. The other advantage includes enabling relocation with minimum effort during incidences of infestation or disease. The impediments faced by other bottom culture techniques in site selection (such as water depth, nature of underwater terrain, etc.) can be avoided. Further, high productivity of this system is directly linked to its high economic efficiency. The advantages and disadvantages of the two popular methods, namely raft and tube net, are discussed in Table 2.

Production trend in commercially farmed biomass

The extension of K. alvarezii cultivation in newer areas of tropical waters has resulted in rapid production from 944,000 fr. t in 2000 to 5.6 million fr. t in 2010. This corresponds to an over 63 % increase in total red seaweed cultivation (Cai et al. 2013). Nationally, it has registered an impressive 489 % increase from over 20 t dry weight in 2001 to about 1046 t in 2011 (Fig. 3; Supplementary Table 1). The corresponding values for major carrageenan seaweed farming countries were a 164 % increase for Philippines; 1625 % for Indonesia, and 159 % for Tanzania for the corresponding decade (computed from the data given in Cai et al. (2013)). The commercial production in India has reached 7187 dry t biomass worth Rs 140 million farm gate values in a decade between 2005 and 2015. Although most of the biomass has been exported initially (gradually increasing from 20 t dry in 2001 to 700 t dry in 2013), this trend has been subsequently reversed, due to innovative method enabling production of two value-added products from the fresh biomass (explained in other section). The average annual production trend was found to be 69.37 %, while for farm gate price, it was a 19.42 % increment (Supplementary Table 1). The highest yearly production of 1490 dry t was achieved in 2013, which sharply declined in the subsequent year due to mass mortality. The production that has been achieved in current year till June 2016 was 181 dry t worth Rs 6,335,000. Commercial production is advancing in six coastal districts in Tamil Nadu, while expansion is underway in Gujarat, where commercial activities commenced as recently as 2014. The number of seaweed growers in Tamil Nadu has risen from a mere 6 in 2001 to 950 in 2013. The cultivation is mostly undertaken by women-dominated SHGs; however, enrollment of male members is not uncommon. There are over 50 SHGs currently engaged in seaweed farming in Tamil Nadu. The production trend by 44 progressive SHGs from Ramanathapuram district based on their produce procured by processing industry is presented in Table 3. These groups typically have 5–12 members and supported by CSMCRI along with prominent institutions like the Ramanathapuram District Development Agency (RDDA), the Aquaculture Foundation of India (AFI), the Tamil Nadu State Department of Fisheries (TNDoF), and the DBT. The production of 822,140 kg dry wt in 2011, 887,080 kg dry wt in 2012 and 627,690 kg dry wt in 2013. The average biomass production ranged between 1350 and 25,767 kg dry wt, while the 3-year average was 778,996 kg dry wt. Export has also reported a steady increase over the years; however, in a few instances, quantity of exported biomass exceeded production, and additional demand was met through biomass available from harvest of previous year (Supplementary Table 1). It might also be noted that few SHGs have progressive and proactive members, which is reflected in their higher production than others. Furthermore, certain areas allow the growers to have more cultivation cycles due to their location advantage which accounts for their higher production.

A production of 236.05 ± 2.36 kg fr. wt, with average growth rate of 5.20 ± 0.05 % day−1 for 45 days growth cycle was reported during November 2012 to January 2013 from Palshet, Maharashtra, using 2 × 2-m rafts (Kavale et al. 2016). A growth rate of 4.69 to 6.91 % day−1 was recorded in 45 days during November 2005 to March 2007 at Vizhinjam, Kerala, using 3 × 3-m rafts (Bindu 2011). Experimental farming has also been carried out by the Aquaculture Foundation of India at Chepala Thimmapuram and Mangamaripeta (Visakhapatnam district) and at Mukkam, Yerra Musalayapalam, and Neelagaddapetta (Vizianagram district), Andhra Pradesh, during April to September 2015. A maximum biomass of 47.82 ± 2.23 kg fr. wt per 10 m line and 56.25 ± 3.13 kg. fr. wt per 10 m line were obtained by the tube net and net bag methods, respectively (c.f. Kaliaperumal and Chennubhotla 2015). Feasibility experiments were also carried out during April 16 to June 11, 2008, at Purunabandha and Gokharakuda, Odisha. A growth rate of 3.6 to 4.9 and 3.4 to 5.8 % day−1 was recorded at these places, respectively, over 8 weeks (Padhi et al. 2008).

Nevertheless, large-scale farming is happening only along Tamil Nadu and Gujarat coast. CSIR-CSMCRI has undertaken a survey along the Tamil Nadu and Gujarat coast to record environmental parameters, bathymetry, natural seaweed growth, etc. Table 4 shows the current status and potential of seaweed farming in these states. Although the highest expansion so far has occurred in the Ramanathapuram and Tuticorin districts, further extension in these areas has limitation due to presence of marine protected area under the Gulf of Mannar Marine National Park. The more productive and nutrient-rich waters of Gujarat provides ample opportunities to enhance production.

Economics of cultivation

Economics of seaweed farming has been evaluated with respect to raft and tube nets (Table 5). The relative low capital investment, simple and non-cumbersome plantation has resulted in the participation of low-income artisanal fishermen in seaweed farming. The nonrecurring cost comes in the form of infrastructure, namely bamboos, anchors, ropes, and tube nets. Although requirement of thatched roof adds to this value, the multipurpose use of available infrastructure is wiser. The necessity of small boats depends upon farm location, while for calculating economics, we only included raft and tube net cost as most of the farms in Tamil Nadu and some in Gujarat are located near shore. The option of bank loans and subsidy under different government schemes are already available in Tamil Nadu, and other states are trying to evolve their own system to fund infrastructure. Nevertheless, in most of the cases, a set of infrastructure along with partial daily financial assistance is provided to farmers until first crop harvest to encourage them. They can continue a few crop cycles from this infrastructure based on the shelf life of material (bamboo have lower shelf life than tubes). The production per unit of raft or tubes is considered at a minimum of 150 and 100 kg, respectively, for computational purpose (which is certainly less than the yield reported earlier at various places and our own experience in Gujarat). The calculations are carried out considering that the farming is undertaken by a group of 15 farmers. The profit is likely to be more than Rs 9540 per month for raft and Rs 8490 per month for tube net. The international carrageenanophyte prices are volatile and always fluctuate; however, a steady increase in dry weed value in India has been recorded over the past decade (Fig. 3). This is essentially due to use of produce in the domestic sector along with value addition efforts (described later).

Deep sea farming experiment

It is essential to realize the potential of the marine environment especially the ocean for the production of seaweed biomass for food as well as for feed stock for biofuel. The deep sea areas are unpolluted, underutilized, and have higher carrying capacity. In India, at some locations along Tamil Nadu coast where commercial farming has been continuously happening for the last decade or so, the intertidal areas are intensely farmed and there is no vacant space left for further expansion. The deep sea waters are also rich and more productive due to nutrient upwelling.

The technoeconomical feasibility of deep sea farming (at about 8 m depth) was ascertained by scientists of CSMCRI–Marine Algal Research Station during 2010–2012 over 170 floating rafts of 2 × 2 m dimension along the Palk Bay coast of Mandapam, Tamil Nadu, India, under a Ministry of New Renewable Energy sponsored project. The growth differed substantially during the experiments where 22.5 kg fr. wt yielded 127.5 kg fr wt, achieving a 3.85 % day−1 growth rate in a 45-day cultivation cycle in near shore waters, whereas similar biomass yielded 219 kg fr. wt achieving 5.05 % day−1 growth rate during the same cultivation period in deep sea waters (CSMCRI 2010). Nevertheless, structures for deep sea farming require novel designs which are simple, expandable, maneuverable, need no specialized skills for assembly, and could be easily practiced at individual cultivator level. CSMCRI in association with CSIR–Structural Research Engineering Center, Chennai, India, is undertaking cultivation trials of octagonal rafts with various degree of inclination (Fig. 4). The inclination facilitates free passage for seawater that replenishes nutrient supply. The maintenance as well as drift and silt mitigation is easier than for conventional flat rafts.

The real technical challenge is to develop a robust aquaculture system with permanent anchoring that is strong at the same time also remain or flexible to withstand harsh oceanographic conditions. We propose a mooring farm for deep sea farming. The farm would be 500 m long and 25 m wide. The farm is held intact within the water column with the support of anchors and floats of appropriate size adequate enough to give required stability, buoyancy, and intactness to the entire structure. A pair of primary anchors (800 kg) is lowered and kept apart at 500-m distance with a similar pair in parallel at 25-m width to setup a rectangular shape farm. To enhance stability, extra anchors of same capacity are provided between two primary anchors on either side. These anchors are fastened with chain to vertically floating buoy. The buoys running through 500-m length are further connected with another steel chain and held it in water column about 30 cm below the surface. To give adequate buoyancy to this line, several floats are also tied at equal distance. In fact, the seeded tube nets of 25-m length with small floats at equal distance are tied between these two chains. Basically, these two chains which are held at 25 m apart and tied with anchors at the bottom form a solid supporting frame for fastening several 25-m length tube nets in parallel at 1-m distance. It is desired that the farm is oriented in a direction propelling waves, so that current impact is bare minimum. The above proposed farm can have 500 tube nets of 25-m length in parallel at 1-m distance. Each tube seeded with about 20 kg of biomass and is expected to yield 100–125 kg in a 40–45-day growth cycle. A prototype has been installed at Simar, Gujarat, and studies are in progress for ascertaining its stability, biomass production potential, and suitable harvesting mechanism (Supplementary Fig. 5).

Developing value-added products from cultivated biomass

The seaweed hydrocolloid industry is commodity product based. Kappaphycus alvarezii is conventionally utilized for preparation of carrageenan. The energy-efficient and low-capital investment-driven process of obtaining semirefined carrageenan in the Philippines has gradually replaced the use of refined carrageenan in canned meat and pet foods. It also offers considerable flexibility in developing competitive low-cost products having targeted applications. The carrageenan use in dairy applications has declined (40 to 31 %) while the market share for meat processing has increased (33 to 41 %) over the last decade (Bixler and Porse 2011). The facility of M/s. Aquagri Processing Pvt. Ltd. located at Manamaduari in Southern Tamil Nadu produces 50 t semirefined carrageenan annually, and majority of this polysaccharide goes to domestic beverage industry as a clarifying agent (Supplementary Fig. 6). R & D efforts of CSMCRI have led to the development of a few value-added products to make seaweed farming more profitable. Most of these inventions are protected by intellectual property rights (Table 6). The following noteworthy products developed from algal biomass, namely plant biostimulant, biodegradable thin films for packaging applications, hard capsule shells of nonanimal gelatin formulations, health drink, and low sodium salt, are described briefly.

Technology for production of plant biostimulant (sap) and carrageenan-rich raw material has evolved due to the necessity of reducing transportation cost. The sap contains macronutrients and micronutrients besides plant growth hormones such as indole 3-acetic acid, gibberellin GA3, kinetin, and zeatin (Supplementary Fig. 7, Table 2). Their estimated concentrations are 56.04 ± 8.68, 77.20 ± 17.38, and 128.42 ± 9.98 ppm for total auxins, cytokinins, and gibberellins, respectively (Prasad et al. 2010). A recent study also confirmed choline (60.71 mg L−1) and glycine betaine (78.47 mg L−1) in pristine sap which imparts abiotic stress resistance to crops (Mondal et al. 2015). The seaweed sap is organic and improved grain and biomass yield in wide range of crops across varied agroecological locations ascertained through pan India trials (20 states) conducted by 43 agriculture centers (Supplementary Tables 3 and 4). Sap production of M/s. Aquagri Processing Pvt. Ltd. has escalated from 5.25 kL in 2008 to 1875 kL in 2015 (Fig. 5). The US Agency for International Development (USAID) has supported its promotion in Africa, while it is being marketed under the brand name “Paras” domestically (Supplementary Fig. 7a). The Union Minister of Science and Technology, Government of India, on Technology Day (May 11, 2016) released yet another plant biostimulant, based on CSIR-CSMCRI technology under the brand name “Sagarika,” which will be soon marketed by Indian Farmers Fertilizer Cooperative Limited (IFFCO) (Supplementary Fig. 7b). Life cycle impact assessment evaluation confirmed the environmental sustainability of plant biostimulant production having a low carbon foot print of 118.6 kg CO2 equivalents per kiloliter of its production at factory gate. It was observed that transport through sea or rail is more environmentally friendly (Ghosh et al. 2015).

A biodegradable thin film from semirefined carrageenan has been prepared (Supplementary Fig. 8a). These films are 50–2000 μm in thickness having tensile strength of 100–1000 kg cm−2 with 50–350 % elongation ability. The water vapor permeability is 0.01–0.15 kg m−2 h−1 bar−1 (Ghosh et al. 2006). Pouches prepared by heat sealing the film can store nonaqueous edible fluids such as vegetable oils. Hard capsule shells of nonanimal gelatine formulations have also been prepared from semirefined carrageenan, and their performance is under evaluation (Supplementary Fig. 8b).

A nutritious and affordable health drink has been prepared from fresh K. alvarezii. It is rich in potassium (2500–5000 mg L−1) with adequate quantity of iodine (1000–2000 mg L−1) and other minerals namely sodium (150–200 mg L−1), magnesium (750–1250 mg L−1), calcium (250–350 mg L−1), zinc (3–6 mg L−1), phosphorous (25–35 mg L−1), iron (50–210 mg L−1), and manganese (1.5–2.5 mg L−1). It also contains 0.2–0.3 ppm thiamine, 0.1–0.2 ppm riboflavin, and only traces of fat with total energy content of 70–100 kcal L−1. It also has low concentrations of toxic metals such as lead (<6 μg L−1) and chromium (<40 μg L−1) (Ghosh et al. 2008).

The low sodium salt is derived by mixing salts from two biological sources, namely K. alvarezii and the halophyte Salicornia. The naturally free-flowing salt obtained contains 35 to 80 % w/w potassium chloride, 20 to 30 % w/w sodium chloride, 0.02 to 0.5 % w/w calcium, 0.02 to 1.2 % w/w magnesium, and 0.0005 to 0.0007 % w/w iodine, and the rest are nutrients and good for people having hypertension (Ghosh et al. 2005). The salt is marketed under the brand name “Saloni K” by our licensee M/s. N M S Pharma, Bhavnagar, India (Supplementary Fig. 9).

An innovative stand-alone method of obtaining 5-hydroxymethyl furfural (HMF) (fuel intermediate), potassium sulfate (K2SO4) (agricultural nutrient), and pure water in an integrated manner has been developed from fresh biomass (Mondal et al. 2013). Furthermore, biodegradable hydrophobic ropes with numerous domestic applications including seaweed cultivation in the open sea also have been prepared (Chaudhary et al. 2015). It has also been reported that grafting of carbohydrate polymers with different substrates exhibit improved properties and functions. The functional modification of carrageenan is yet another area for developing newer material with wider applications. The cross-linked blend of agar and kappa-carrageeenan with natural cross-linker genipin in aqueous medium exhibited higher viscosity, thermal stability, and swelling ability as well as low weight loss ratio. This presents immense potential as superabsorbent, food applications, sustained release formulation in biomedical and in other pH-specific applications (Meena et al. 2007, 2009). The array of products obtained from Kappaphycus is shown in Supplementary Fig. 10. With the success in achieving product diversification, the institute is working on developing simple and integrated approach to recover multiple products (biorefinery) for efficient utilization of fresh algal biomass (Baghel et al. 2015; Trivedi et al. 2016). A few recent studies have also demonstrated beneficial properties of this alga in preventing diabetes (Cyriac and Eswaran 2016) and ability of its dietary fibers to bind mutagenic amines (Raman and Dhobale 2014). Thus, farmed biomass could be additionally utilized for developing low-cost drugs in the near future.

Somatic embryogenesis and plantlet production through tissue culture to aid farming

Developing in vitro cell culture techniques is crucial to seaweed industry as it facilitates year-round mass proliferation of biomass under controlled conditions. These techniques are useful in crop improvement programs aimed at inducing genetic variability in germplasm pool. Clonal propagation—which is the most simple and common approach used for improving the performance of cultivar—was attempted for the first time in K. alvarezii (Supplementary Fig. 11). In vitro somatic embryogenesis and regeneration of somatic embryos to whole plants through micropropagules was successfully achieved from pigmented uniseriate filamentous callus in axenic cultures (Reddy et al. 2003). A protocol has been established for callus induction, subculture, and micropropagule production through somatic embryogenesis. The plants regenerated through this were out-planted, and their growth performance was recorded against the wild plants. The improvement in growth (over 1.5–1.8 % day−1) by tissue cultured plants over the seven subsequent crop cycles offers a promise for commercial farming. Further, it is imperative to establish homozygous lines for agronomically important traits such as growth and carrageenan yield to realize benefits of in vitro cell manipulation for commercial-scale production. With the advent of new tissue culture protocols, it would be realistic to believe that this can help to generate improved strain in near future (Yeong et al. 2014). It is worth mentioning that the Southeast Asian Fisheries Development Center (SEAFDEC) is proposing tissue culture methodologies for developing fast-growing strain to reignite dwindling production in the Philippines (Philstar Gobal Business 2016). Therefore, such efforts, if initiated in India, would certainly have far reaching positive effects for the development of commercial farming.

Socioeconomic profile of seaweed farmers involved in commercial cultivation

The commercial farming of K. alvarezii is the best example of community-based coastal resource management offering diversified livelihood to coastal inhabitants (Msuya et al. 2014; Poeloengasih et al. 2014). It being labor intensive provides both direct and indirect employment besides enhances community cohesion and cooperation. The production cycles are rapid, spanning over only 45 days; thus, economic returns on farming are high as compared to other aquaculture and land-based agriculture. The engagement of women in tying seedlings, preparation of planting material, assistance in harvesting, drying, cleaning, and sorting biomass enables them to achieve economic independency.

The results of a survey carried out by our team during 2013–2014 are provided in Tables 7, 8, and 9. Parameters such as composition for gender, age and education profile, experience in farming, income status, occupational profile, and mode of spending were covered. The survey covered 236 farming household heads of South Ramanathapuram, North Ramanathapuram, Pudukkottai, and Tuticorin. It emerged that most seaweed farmers (53.12–86.04 %) were under the age group of 30–50, more productive and open to adopt alternative livelihood while a lower percentage was recorded for young as well as older age groups. The survey pertaining to educational profile showed highest percentage of respondents at the literacy level of primarily education (30–67.44 %), while lowest with graduate and above (0–10 %). It might be interesting to note that about 2.65–30 % of respondents were illiterate. Given the fact that there is low literacy level in the area due to poor educational facilities coupled with meager self-employability, seaweed farming is paving the way for young entrepreneurs. The majority of the fisher folk engaged in cultivation were found to be associated with seaweed farming alone (34.44–81.40 %), while the remaining either have fishing as their main occupation supplemented with seaweed farming (13.95–70 %) or other fishing-related activities as their main occupation supplemented with seaweed farming (0–21.87 %) to augment their income. It was also found that most of these seaweed growers have taken up this occupation to diversify their livelihood. The monthly income by higher number of seaweed growers (34.44–80 %) was found to be Rs 30,000. Earnings were spend on children’s education (10–51.16 %), construction of house (0–6.98 %), marriage (0–6.25 %), jewels (0–5.97 %), and other daily needs (0–3.12 %), besides saving (20–71.88 %). The study confirms improvement in socioeconomic status of coastal inhabitants engaging in commercial seaweed farming.

Environmental issues pertaining to seaweed farming

In their recent review, Bindu and Levine (2011) discussed commercial farming of K. alvarezii through application of biotechnological tools, ecological interactions with endemic ecosystems, and cultivation potentials in Asia, Africa, and the Pacific. Although global introduction of this species to nonendemic locations has created concerns, it has been successfully introduced to quite a few countries where commercial farming is taking place with no immediate environmental implications (Ask 2001). Woo et al. (1989) were the first to report its ecological interaction with native Hawaiian taxa while subsequent studies termed this species invasive (Smith 2003; Barrios 2005; Chandrasekaran et al. 2008).

Although negative reports of farming in India have been documented in magazines as well as scientific journals, our studies for the past 7 years have confirmed that the fears of invasion are exaggerated. Secondly, its occurrence being scientifically established from Indian waters means that the term “exotic” needs reconsideration. Large-scale cultivation was undertaken soon after field trials commenced under DBT-sponsored program in 2000. As the part of follow-up of technology transfer, an Environmental Impact Assessment (EIA) study was carried out by CSMCRI. An independent EIA was also carried out by the Center of Advance Study in Botany, Madras University, Chennai, India. No significant adverse effects on the ecosystem were observed except for temporary depletion of nutrients in the immediate vicinity of seedlings (Tewari et al. 2006). The sea being dynamic system means that depleted of nutrients are replenished quickly during next immediate high tide. We believe that a synchronous seeding and cultivation cycle might help in restoring healthy nutrient flow in the commercial farm, where all the seedlings will be of different growth stages.

After the report by Chandrasekarn et al. (2008), CSMCRI planned long-term monitoring of the Krusadai Island site where the populations were reported in the wild including other islands of the Gulf of Mannar as well. The survey was divided into two parts: (1) random survey, to understand the extent of algal establishment in and around Kurusadai Island including the mainland coast (initiated in 2008 and extended up to December 2014), and (2) rigorous survey, to know the lateral spread of this alga at Kurusadai and other islands. All the 21 islands consisting of the Kilakarai, Vemvar, and Tuticorin group of islands were surveyed including studying macroalgal diversity to ascertain establishment of nonfarmed populations, if any during January 2013 to December 2014. In order to cover as much spatial extent as possible, 49 sampling locations were randomly covered from Kurusadai Island, Pully Island, Pully Vassal Island, and main land coast of both Palk Bay and Gulf of Mannar. Being the place of reported invasion, a rigorous survey was conducted for Kurusadai Island. The details of this study are given in Mandal et al. (2010). Nevertheless, subsequent initiative by Tamil Nadu State Forest Department of harvesting algal biomass hindered record keeping in want of actual coverage expanse. During our survey, few drift fragments were reported from Mulli Island. These might have originated from commercial farms located in Tuticorin where monoline cultivation is being practiced which is more prone to drifting of seedlings. The results obtained through studies on diversity and distribution of local seaweed flora conducted during February to August 2013 are shown in Supplementary Table 5. It was found that there is no considerable difference in the seaweed flora of sites which are within a 10-km radius and away from commercial cultivation (CSMCRI unpublished data). The studies were also carried out to understand the response of drift fragments under various salinity and temperature regimes, along with survival efficiency due to bioavailability of nutrients and regeneration capacity. It was found that lower nutrient availability and higher surface seawater temperature at farm sites coupled with dominance of microbial decomposer communities do not allow the drift fragments to establish in the wild (Mandal et al. 2015).

Background and model for implementing seaweed farming in Gujarat

The population in coastal India continues to grow, while marine resources are alarmingly dwindling. This makes the livelihood issue complex, forcing locals to migrate in search of better opportunities to nearby cities. Although seaweed farming has been successfully implemented along the Tamil Nadu coast, the biggest challenge yet is to expand it to other maritime states for diversifying the livelihood. Nevertheless, the success pertaining to its implementation would depend on needs, aspiration, and socioeconomic background of the targeted communities. The experience of Tamil Nadu is quintessential in implementing strategies at micro and macro level. However, executing it exactly in the same manner in other states might not be feasible and several variants to the original implementation strategy need to be developed based on circumstances and issues.

After the preliminary trial in late 1980s, pilot-scale cultivation was attempted at Beyt Dwarka, Port Okha, and Mithapurunder during 2004–2005. The growth rates ranged between 3.64 and 13.98 % day−1confirming suitability of Gujarat waters to undertake commercial farming (SubbaRao et al. 2008). Nevertheless, large-scale cultivation was never attempted before 2012. Ms. Anju Sharma, IAS, Mission Director, National Rural Health Mission, and In-charge Collector, Amreli District, was instrumental in initiating “Pre-feasibility study to ascertain the growth of K. alvarezii along the Amereli, Kathiawar peninsula of Western India” through CSMCRI in association with the Fisheries Department, Government of Gujarat. Simar (Gir-Somnath District), Sarkeshwar (Amreli District), and Waraswarup (Amreli District) hold potential of over 5000, 1000, and 500 rafts (or equivalent), respectively. The preliminary trials using bamboo rafts (2 × 2 m) reported 6.57 % day−1 growth for 45 days during November 2011–May 2012. This study provided impetus to the state government to come up with a much larger concept of implementing farming as livelihood option for the fishers. After attempting cultivation over 50 rafts during March to June 2013, Madvad (Gir-SomnathDistrict) and Miyani (Porbandar District) were also added as the potential sites for commencing commercial farming. The project “Sagar Lakshmi (Wealth from Ocean)” was formally launched on October 2, 2012. Twenty training programs were organized for capacity building of local fisherwomen in seaweed farming. A biomass of over 8 fr. t was produced during trial cultivation at these sites in the first year. The tubular net method was thereafter adopted for commercial farming to overcome dislodgment of rafts in high water currents. At the time of writing, this review biomass production of 45 fr. t was already achieved in Gujarat during 2015–2016.

The model used here is typically a cooperative stakeholder type, where all primary stakeholders and government agencies work together as partners in decision-making and implementing the program, while CSMCRI plays a consultative role. The beneficiaries based on their economic status and need were identified at village level by state government agencies. Clusters of appropriate number of beneficiaries were established, from which a “Master Trainer” has been identified. The master trainer was taught preparation of rafts, tubes, seeding, anchoring, and maintenance; he then imparts training to individual beneficiaries. Each beneficiary is given set of 45 tubes, floats, ropes, anchors, and viable seed material. Each group at village level is further governed by “Cluster Coordinator.” Cluster Coordinator reports to “Taluka Livelihood Manager” who manages the overall monitoring of project (Fig. 6). The farming is conducted by members of SHGs, while financial support and buyback guarantee is provided by state government agencies. It may be noted that formulation of structure to involve stakeholders does not always comply and ensure their participation in meaningful ways.

SWOT analysis for commercial seaweed farming

The most apparent strength is the long coastline for undertaking commercial activity at pan India level. Successful implementation of farming in Tamil Nadu and the most recent initiative in Gujarat can be replicated in other maritime states. The methods are simple, noncumbersome, and cost-effective, while infrastructure needs are minimal. The manpower is readily available at village level for cultivation and processing. The multiple products derived from fresh biomass can give economic impetus. There is an established domestic market for products developed from fresh biomass; being an agriculture-based economy, plant growth stimulant (liquid fertilizer) is in high demand. The indigenous production of carrageenan can reduce its import considerably contributing saving foreign exchange. This is in line with “Make in India” initiative of the current government. Seaweed farming provides valuable ecological services. It also helps in preserving and enhancing fisheries (in a manner similar to “fish aggregating devices”), thus becoming an essential component of an integrated approach to coastal community development.

The weakness of technology is complete absence of mechanical intervention and thus is an intensive labor resource. Nevertheless, lackadaisical and skeptical approach by few seaweed growers in new areas influence the decision making of the entire community or village, hampering expansion. The absence of scientific knowledge and expertise in event of mass mortality hinders the revival of farming in the areas where such events have occurred in the past (Tamil Nadu in August 2013). A detailed and systematic policy from the government to boost farming is urgently required. In the possible scenario of senescence of existing germplasm—which is of Philippine origin—replenishing of seed with new progeny would not be possible due to absence of natural populations of the same stain. The bamboos used in the raft cultivation gradually accumulate salts and lose buoyancy. This could be averted using reinforcement of bamboos with several cost-effective materials such as marine gypsum to increase its shelf life.

The project has several exciting opportunities and the most significant one is empowering rural populations, especially women. Financial adequacy is gained due to their involvement in seaweed farming without negating their traditional responsibility toward household chores. The women in Tamil Nadu, being the first and primary adopters of this initiative, accrue financial benefits. The farming activity brings more stable and assured income; this is well evident from socioeconomic study. Besides cultivation, the value chain also generates jobs invarious downstream sectors. Integrated multitrophic aquaculture (IMTA) is yet another opportunity for sustainability of the overall aquaculture system (Rodrigueza and Montano 2007); it also reduces risk through diversification (Supplementary Fig. 12). CO2 sequestration as a result of photosynthesis and carbon credit potentially can be earned through large-scale seaweed farming. The new applications for fuel and fertilizer can be envisaged commensurate with massive expansion in cultivation that is feasible (Meinita et al. 2012).

The major threat perceived is environmental concerns such as its perceived invasive potential, and the issue of reduced nutrients. The lack of functional reproductive cycle, low fecundity, low spore viability, and the absence of microscopic phases in the life cycle of this alga coupled with abundant presence of herbivores, has restricted the distribution nonfarmed population from Krusadai Island expanding further. Therefore, it would be premature to term its establishment as invasion. Another important aspect is economic loss incurred due to disease which was responsible for declining production in the Philippines (Hurtado et al. 2013) as well as grazing. Although the former is not prevalent in India, the future expansion needs better combating strategies. There is a need to make cultivation less vulnerable to the vagaries of nature such as cyclone and strong currents (Asian tsunami 2004 or Phailin cyclone 2013).

Future prospective

It is evident from the literature that socioeconomic benefits accrued from Kappaphycus farming in India are overwhelmingly positive. This is essentially because farming is family centric or being implemented by SHGs, rather than plantation style corporate farms. The country is on the brink of urban revolution and recently reported 2.38 % increase in urbanized population. The substantial increase in consumption of processed food is inevitable that shall directly boost domestic carrageenan demand. The sustainable development of seaweed cultivation entails equal involvement of nongovernment organizations (NGOs) and state government agencies (SGAs). The development of new methods of farming; high-quality, fast-growing, and improved disease-resistant germplasm through genetic manipulation; and grafting could hold the key for further development (Sahu et al. 2011). The establishment of nurseries to cater to the need of expanding activity is crucial for the success of the project. The integration of remote sensing (RS) and geographical information systems (GIS) in mapping potential cultivation sites is essential. Government efforts, although encouraging, still require more detailed synthesis and holistic planning. A special unit needs to be established at national level for clearance and implementation of all seaweed cultivation projects. This step would help in better coordination between the Department of Fisheries and the Department of Environment and Forests to carry out the commercial activity with high degree of confidence, trust, and efficiency. Commercial cultivation could also be integrated with ecotourism to improve the local economy.

A few companies have already brought out value added products in the domestic market based on R & D efforts of CSMCRI and our institute has demonstrated proof of concept for several others. Nevertheless, these applications will require millions of tons of biomass. The national R & D Enterprise must work on visionary projects and take forward deep sea farming that can improve productivity, scalability, and environmental acceptability.

The potential risks are extensively debated and deliberated. The government should frame policies where working protocols need to be adopted for expansion of this project, like the one in the Cuban Archipelago, the tropical Western Atlantic (Mallea et al. 2014). It is estimated that K. alvarezii sequesters 17–20 t of CO2 ha−1 year−1 (c.f. Mondal et al. 2013). Carbon credits, emission allowance, etc. need to be defined for the seaweed processing industries which are also involved in commercial cultivation. The states where commercial seaweed farming is established should also provide insurance in the event of natural calamities, diseases, pest attacks, etc. Cooperative societies need to be established for entire program that involves cultivation and value addition.

Conclusions

The successful implementation of commercial cultivation of K. alvarezii has shown that scientific innovations can benefit coastal rural populations which lack alternative economic opportunities. The continued advancement in both farming methods as well as integrated product development is crucial for attracting business entrepreneurs. The geographical expansion of commercial farming is inevitable in the foreseeable future despite some environmental concerns and social challenges. The government is expected to boost R & D funding toward deep sea and offshore farming, which requires more focused efforts from the engineering side for developing robust designs of cultivation systems and anchoring. International market fluctuations seldom impact local growers in India as the entire produce is consumed domestically. The higher and more stable income to fisher women has improved living standards of their family, education to the children, health, and accessibility to better amenities. These accrued benefits would attract more participation and offer opportunities for economic empowerment of women contributing positively toward reducing gender bias. The rural economy not only will be boosted though commercial seaweed cultivation but also by employing liquid and solid fertilizers produced from the algal biomass. The pan India multi-institutional trials have recorded a 15–40 % increase in yield of several cash crops. The selective accumulation of potash (KCl 30–35 % on dry weight basis) by this alga has opened up a new avenue for realizing the full potential of biomass through production of liquid fertilizer, generating energy by gasifying the granules and pelleting ash for obtaining chip potassic fertilizer. The marine capture fisheries are fast depleting, and agencies involved in commercial cultivation are likely to take advantage of IMTA. This will help them in sharing benefits pertaining to resources, infrastructure, and labor. The population expansion leading to unemployment persuades migration of younger generation in search of better livelihood prospects. Establishment of seaweed farming in rural areas would help to reduce emigration trends.

References

Agarwal P, Patel K, Das AK, Ghosh A, Agarwal PK (2016) Insights into the role of seaweed Kappaphycus alvarezii sap towards phytohormone signalling and regulating defence responsive genes in Lycopersicon esculentum. J Appl Phycol 28:2529–2537

Anon (2003) Seaweed cultivation and utilization. National Academy of Agricultural Sciences, vol 22. Policy Paper, India, p. pp 5

Aquaculture Foundation of India (2008) Final report of the DBT project: seaweed farming to rehabilitate tsunami affected coastal communities in Tamil Nadu. Department of Biotechnology, Ministry of Science and Technology, New Delhi, Government of India, p. 41

Ask EI, Batibasaga A, Zertuche-González JA, de San M (2001) Three decades of Kappaphycus alvarezii (Rhodophyta) introduction to non-endemic locations. In: Chapman ARO, Anderson RJ, Vreeland VJ, Davison IR (eds) Proceedings, 17th international Seaweed Symposium. Oxford University Press, Oxford, pp. 49–57

Baghel RS, Trivedi N, Gupta V, Neori A, Reddy CRK, Lali A, Jha B (2015) Biorefining of marine macroalgal biomass for production of biofuel and commodity chemicals. Green Chem 17:2436–2443

Barrios JE (2005) Spread of exotic algae Kappaphycus alvarezii (Gigartinales: Rhodophyta) in the northeast region of Venezuela. Bol Inst Oceanogr Venez 44:29–34

Bindu MS (2011) Empowerment of coastal communities in cultivation and processing of Kappaphycus alvarezii—a case study at Vizhinjam village, Kerala, India. J Appl Phycol 23:157–163

Bindu MS, Levine IA (2011) The commercial red seaweed Kappaphycus alvarezii—an overview on farming and environment. J Appl Phycol 23:789–796

Bixler HJ, Porse H (2011) A decade of change in the seaweed hydrocolloids industry. J Appl Phycol 23:321–335

Cai J, Hishamunda N, Ridler N (2013) Social and economic dimensions of carrageenan seaweed farming: a global synthesis. In: Valderrama D, Cai J, Hishamunda N, Ridler N (eds) Social and economic dimensions of carrageenan seaweed farming, pp 5–59 Fisheries and Aquaculture Technical Paper No. 580. Rome, FAO. 204 pp

Chandrasekaran S, Nagendran NA, Pandiaraja D, Krishnankutty N, Kamalakannan B (2008) Bioinvasion of Kappaphycus alvarezii on corals in the Gulf of Mannar, India. Curr Sci 94:1167–1172

Chaudhary JP, Chejara DR, Eswaran K, Meena R, Ghosh PK (2015) Seaweed-derived polymeric materials for multi applications including marine algal cultivation. RSC Adv 5:19426–19431

CMFRI (2015) Annual Report 2014–2015, Mariculture: Trial on Integrated Multi Trophic Aquaculture (IMTA) in a participatory mode, p. 219; Kochi, India http://eprints.cmfri.org.in/10461/1/CMFRI%20Annual%20Report%202014-15.pdf as accessed on August 11, 2016.

Conklin EJ, Smith JE (2005) Abundance and spread of the invasive red algae, Kappaphycus spp. in Kane’ohe bay, Hawai’i and experimental assessment of management options. Biol Invasions 7:1029–1039

CSMCRI (2002) Biennial report Central Salt and Marine Chemicals Research Institute 2000–2002, Marine Algae: Seaweed Cultivation and value addition, p. 59–60; Bhavnagar, India http://www.csmcri.org/Files/Biennial_00-02.pdf as accessed on August 11, 2016.

CSMCRI (2004) Biennial report Central Salt and Marine Chemicals Research Institute 2002–2004, Algal Products: Preparation of biodegradable thin films derived from seaweed polysaccharide, p. 106; Bhavnagar, India http://www.csmcri.org/Files/Biennial_02-04.pdf as accessed on August 11, 2016.

CSMCRI (2006) Biennial report Central Salt and Marine Chemicals Research Institute 2004–2006, Natural Products and Value addition: Yield improvements using Kappaphycus sap, p. 102; Bhavnagar, India http://www.csmcri.org/Files/Biennial_04-06.pdf as accessed on August 11, 2016.

Cyriac B, Eswaran K (2016) Anti- hyperglycemic effect of aqueous extract of Kappaphycus alvarezii (Doty) Doty ex. P. Silva in alloxan-induced diabetic rats. J Appl Phycol 28:2507–2513

de Góes HG, Reis RP (2011) An initial comparison of tubular netting versus tie–tie methods of cultivation for Kappaphycus alvarezii (Rhodophyta, Solieriaceae) on the south coast of Rio de Janeiro State, Brazil. J Appl Phycol 23:607–613

Eswaran K, Ghosh PK, Mairh OP (2002) Experimental field cultivation of Kappaphycus alvarezii (Doty) Doty ex Silva at Mandapam region. Seaweed Res Utilin 24:67–72

Eswaran K, Ghosh PK, Siddhanta AK, Patolia JS, Periyasami C, Mehta AS, Mody KH, Ramavat BK, Prasad K, Rajyaguru MR, Reddy CRK, Pandya JB, Tewari A (2004) Integrated method for production of carrageenan and liquid fertilizer from fresh sea weeds US patent 6983479B2.

Ghosh PK, Mody KH, Reddy MP, Patolia JS, Eswaran K, Shah R, Barot B, Gandhi MR, Mehta AS, Bhatt AM, Reddy AVR (2005) Low sodium salt of botanic origin. US patent, US20050220975A1

Ghosh PK, Siddhanta AK, Prasad K, Meena R, Bhattacharya A (2006) Process of preparation of biodegradable films from semi refined kappa carrageenan. US patent US7067568B1

Ghosh PK, Rajyaguru MR, Patolia JS, Eswaran K, Subbarao PV, Shah MT, Zodape ST, Joshi SV, Reddy AVR, Vithaldas DC, Bandyopadhyay S, Sahoo GC, Devmurari CV, Joshi MSV, Alamuru VRR, Sibdas B (2008) Preparation a refreshing drink from marine algae Kappaphycus alvarezii. US patent 8252359B2

Ghosh PK, Ghosh A, Mondal D, Prasad K, Agarwal PK, Agarwal P, Zodape ST, Vijay Anand KG (2014a) Gibberellic acid (GA3) free Kappaphycus alvareziisap and its application thereof. PCT patent application WO2014167583A1

Ghosh PK, Mondal D, Maiti P, Prasad K, Maiti S, Shah BG, Siddhanta AK (2014b) Process for improved seaweed biomass conversion for fuel intermediates and fertilizer. PCT patent application WO2014027368A3

Ghosh A, Vijay Anand KG, Seth A (2015a) Life cycle impact assessment of seaweed based bio-stimulant production from onshore cultivated Kappaphycus alvarezii (Doty) Doty ex Silva—is it environmentally sustainable? Algal Res 12:513–521

Ghosh PK, Mantri VA, Pothal JK, Veeragurunatahn V, Thiruppathi S (2015b) A device for efficient and cost-effective seaweed harvesting for large-scale commercial application. PCT patent application WO2015/087356A1.

Hayashi L, Hurtado AQ, Msuya F, Bleicher-Lhonneur G, Critchley AT (2010) A review of kappaphycus farming: Prospects and constraints. In: Israel A, Einav R, Seckback J (eds) Seaweeds and their role in globally changing environments. Springer Science, Dordrecht pp 251–283

Hurtado AQ, Montaño MNE, Martinez-Goss MR (2013) Commercial production of carrageenophytes in the Philippines: ensuring long-term sustainability for the industry. J Appl Phycol 25:733–742

Hurtado AQ, Neish IC, Critchley AT (2015) Developments in production technology of Kappaphycus in the Philippines: more than four decades of farming. J Appl Phycol 27:1945–1961

HurtadoAQ GGS, YasirS CAT (2014) Cultivation of tropical red seaweeds in the BIMP-EAGA region. J Appl Phycol 26:707–718

Immanuel S, Sathiadhas R (2004) Employment potential of fisherwomen in the collection and post harvest operations of seaweeds in India. Seaweed Res Util 26:209–215

Jara SZ, Riffo MM (2016) Bioeconomic analysis of small-scale cultures of Kappaphycus alvarezii (Doty) Doty in India. J Appl Phycol 28:1133–1143

Kavale MG, Sreenadhan N, Singh VV (2016) Cultivation of Kappaphycus alvarezii (Doty) Doty ex P. C. Silva along the coast of Palshet, Guhagar, Maharashtra. Ind J Geo Mar Sci. In press.

Kaliaperumal N, Chennubhotla VSK (2015) Studies on marine algae of Andhra Pradesh: a review. Seaweed Res. Util. 37:63–75

Krishnamurthy V, Joshi HV (1970) Central Salt and Marine Chemicals Research Institute. In: A check-list of Indian marine algae. Bhavnagar, India, p. 36

Krishnan M, Narayanakumar R (2010) Socio-economics of seaweed farming in India. Central Marine Fisheries Research Institute, Kochi, India, Special Bulletin No 104:103

Mairh OP, Tewari A (1994) Studies on a new asexual propagules of Kappaphycus striatum (Solieriaceae, Rhodophyta. Phycologia 33:62–64

Mairh OP, Zodape ST, Tewari A, Rajyaguru MR (1995) Culture of marine red algae Kappaphycus striatum (Schmitz) Doty on the Saurashtra region, west coast of India. Indian. J Mar Sci 24:24–31

Mallea AJA, Villanueva FCA, Bernardi J, Cabrera R (2014) Ecological risk assessment of the introduction of exotic carrageenophytes in the tropical Western Atlantic. J Appl Phycol 26:2055–2063

Mandal SK, Mantri VA, Haldar S, Eswran K, Ganesan M (2010) Invasive potential of Kappaphycus alvarezii on corals at Kurusadai Island, Gulf of Mannar, India. Algae 25:205–216

Mandal SK, Ajay G, Monish N, Malarvizhi J, Temkar G, Mantri VA (2015) Differential response of varying temperature and salinity regimeson nutrient uptake of drifting fragments of Kappaphycus alvarezii: implication on survival and growth. J Appl Phycol 27:1571–1581

Meena R, Prasad K, Siddhanta AK (2007) Effect of genipin, on the properties of kappa-carrageenan. Int J Biol Macromol 41:94–101

Meena R, Prasad K, Siddhanta AK (2009) Development of a stable hydrogel network based on agar–kappa-carrageenan blend cross-linked with genipin. Food Hydrocolloid 23:497–509

Meinita MDN, Kang J-Y, Jeong G-T, Koo HM, Park SM, Hong Y-K (2012) Bioethanol production from the acid hydrolysate of the carrageenophyte Kappaphycus alvarezii (cottonii). J Appl Phycol 24:857–862

Mody KH, Ghosh PK, Barindra S, Gnanasekaran G, Shukla AD, Eswaran K (2012) A process for integrated production of ethanol and seaweed sap from Kappaphycus alvarezii. European Patent EP2475776 A1

Mondal D, Sharma M, Maiti P, Prasad K, Meena M, Siddhanta AK, Bhatt P, Ijardar S, Mohandas VP, Ghosh A, Eswaran K, Shah BG, Ghosh PK (2013) Fuel intermediates, agricultural nutrients and pure water from Kappaphycus alvarezii seaweed. RSC Adv 3:17989–17997

Mondal D, Ghosh A, Prasad K, Singh S, Bhatt N, Zodape ST, Chaudhary JP, Chaudhari J, Chatterjee PB, Seth A, Ghosh PK (2015) Elimination of gibberellin from Kappaphycus alvarezii seaweed sap foliar spray enhances corn stover production without compromising the grain yield advantage. Plant Growth Regul 75:657–666

Msuya FE, Buriyo A, Omar I, Pascal B, Narrain K, Ravina JJM, Mrabu E, Wakibia JG (2014) Cultivation and utilisation of red seaweeds in the Western Indian Ocean (WIO) Region. J Appl Phycol 26:699–705

Padhi SB, Swain PK, Behera SK, Nayak L, Panigrahi H, Samantray SM (2008) Feasibility study for the cultivation of Kappaphycus alvarezii (Doty) Doty ex. Silva in the coastal area of Ganjam district (Orissa). Ind Hydrobiol 11:297–301

Periyasami C, Anantharaman P, Balasubramanian ST, SubbaRao PV (2014a) Seasonal variation in growth and carrageenan yield in cultivated Kappaphycus alvarezii (Doty) Doty on the coastal waters of Ramanathapuram district, Tamil Nadu. J Appl Phycol 26:803–810

Periyasami C, Anantharaman P, Balasubramanian T (2014b) Social upliftment of coastal fisher women through seaweed (Kappaphycus alvarezii (Doty) Doty) farming in Tamil Nadu, India. J Appl Phycol 26:775–781

Periyasami C, Anantharaman P, Subba Rao PV (2015) Experimental farming of Kappaphycus alvarezii (Doty) Doty with income estimates at different sites in the Mandapam region, Palk Bay, southeast coast of India. J Appl Phycol 27:935–944

Philstar Gobal Business (2016) http://www.philstar.com/agriculture/2016/04/03/1568707/reigniting-growth-philippines-seaweed-industry. Accessed on August 11, 2016.

Poeloengasih CD, Bardant TB, Rosyida VT, Maryana R, Wahono SK (2014) Coastal community empowerment in processing Kappaphycus alvarezii: a case study in Ceningan Island, Bali, Indonesia. J Appl Phycol 26:1539–1546

Prasad K, Das AK, Oza MD, Brahmbhatt H, Siddhanta AK, Meena R, Eswaran K, Rajyaguru MR, Ghosh PK (2010) Detection and quantification of some plant growth regulators in a seaweed-based foliar spray employing a mass spectrometric technique sans chromatographic separation. J Agric Food Chem 58:4594–4601

Prasad K, Sharma M, Mondal D, Saha A, Singh N (2015a) A novel method for the production of graphene sheets with tunable functionalities from seaweeds using deep eutectic solvents. Indian Patent Application, 1520 /DEL/2015.

Prasad K, Sharma M, Mondal D, Singh N, Bhatt J (2015b) A scalable process for liquid phase exfoliation of graphite to graphene using biomass derived solvents. Indian Patent Application, 4344/DEL/2015.

Prathapan KD, Rajan PD (2011) Biodiversity access and benefit-sharing: weaving a rope of sand. Curr Sci 100:290–293

Raman M, Dobale M (2014) Physicochemical and structural characterization of marine algae Kappaphycus alvarezii and the ability of its dietary fibres to bind mutagenic amines. J Appl Phycol 26:2183–2191

Rao PSN, Rao UM (1999) On a species of Kappaphycus (Solieriaceae, Gigartinales) form Andaman and Nicobar Island, India. Phykos 38:93–96

Reddy CRK, Kumar GRK, Siddhanta AK, Tewari AK (2003) In vitro somatic embryogenesis and regeneration of somatic embryos from pigmented callus of Kappaphycus alvarezii (Doty) Doty (Rhodophyta, Gigartinales. J Phycol 39:610–616

Reddy CRK, Mairh OP, Krishna Kumar GR, Eswaran K, SubbaRao PV, Mody KH, Ghosh PK (2005) Process of cultivation of algae. US Patent 6858430B1

Rodrigueza MRC, Montaño MNE (2007) Bioremediation potential of three carrageenophytes cultivated in tanks with seawater from fish farms. J Appl Phycol 19:755–762

Sahu N, Meena R, Ganesan M (2011) Effect of grafting on the properties of kappa-carrageenan of the red seaweed Kappaphycus alvarezii (Doty) Doty ex Silva. Carbohyd Polym 84:584–592

Silva PC, Basson PW, Moe RL (1996) Catalogue of the benthic marine algae of the Indian Ocean. University of California Press, Berkley, p. 1259

Singh S, Singh MK, Pal SK, Trivedi K, Yesuraj D, Singh CS, Anand KGV, Chandramohan M, Patidar R, Kubavat D, Zodape ST, Ghosh A (2016a) Sustainable enhancement in yield and quality of rain-fed maize through Gracilaria edulis and Kappaphycus alvarezii seaweed sap. J Appl Phycol 28:2099–2112

Singh S, Singh MK, Pal SK, Trivedi K, Yesuraj D, Singh CS, Anand KGV, Chandramohan M, Patidar R, Kubavat D, Zodape ST, Ghosh A (2016b) Erratum to: sustainable enhancement in yield and quality of rain-fed maize through Gracilaria edulis and Kappaphycus alvarezii seaweed sap. J Appl Phycol 28:2113

Smith JE (2003) Invasive macroalgae on tropical reefs: impacts, interactions, mechanisms and management. J Phycol 39(S1):53

Subba Rao PV, Mantri VA (2006) Indian seaweed resources and sustainable utilisation: scenario at the dawn of new century. Curr Sci 91:164–174

SubbaRao PV, Suresh Kumar K, Ganesan K, Thakur MC (2008) Feasibility of cultivation of Kappaphycus alvarezii (Doty) Doty at different localities on the northwest coast of India. Aquac Res 39:1107–1114

The Hindu (2015) Algae cultivation potential not fully tapped, http://www.thehindu.com/news/national/other-states/algae-cultivation-potential-not-fully-tapped/article7666363.ece. Accessed on August 11, 2016.

Tewari A, Basha S, Trivedi RH, Raghunathan C, Sravan Kumar VG, Khambhaty Y, Joshi HV, Kotiwar OS (2006) Recent advances on applied aspects of Indian marine algae with reference to global scenario, In: Tewari A (ed) Environmental impact assessment of Kappaphycus cultivation in India in context to global scenario, vol 1, Central Salt and Marine Chemicals Research Institute pp. 262–287

Trivedi N, Baghel RS, Bothwell J, Reddy CRK, Lali A, Jha B (2016) An integrated process for the extraction of fuel and chemicals from marine macroalgal biomass. Sci Rep 6:1–8

Woo M, Smith C, Smith W (1989) Ecological interactions and impacts of invasive Kappaphycus striatum in Kaneohe Bay. Proceedings, First National Conference, Tropical Reef Marine Bioinvasions, 186–231.http://nsgl.gso.uri.edu/mit/mitw99004/mitw99004_part6.pdf accessed on August 11, 2016.

Yeong HY, Phang SM, Reddy CRK, Khalid N (2014) Production of clonal planting materials from Gracilaria changii and Kappaphycus alvarezii through tissue culture and culture of G. changii explants in airlift photobioreactors. J Appl Phycol 26:729–746

Acknowledgments

We would like to thank the present and past employees of CSIR-CSMCRI and M/s. Aquagri Processing Private Limited for their vital contributions in taking forward Kappaphycus alvarezii cultivation as well as value addition work to the present state. The farming industry of this alga in Indian waters took place due to the pioneering efforts of Dr. OP Mairh in establishing the germplasm; Dr. PV Subba Rao for initiating scaled-up farming. The work carried out by Dr. AK Siddhanta and his group on bioprospection and Dr. Arup Ghosh and his collaborators on sap trials have indirectly encouraged commercial farming. The authors would like to thank Dr. PK Ghosh for his farsightedness in conceptualizing the commercial cultivation and his keen involvement in the project. He has suggested to prepare case study which is culminated into present publication. Thanks are also due to Dr. Subir K. Mandal for his association during the survey of islands in Gulf of Mannar and Dr. J. Rajasankar, Chief Scientist, CSIR-SERC, for suggesting inclined raft designs for deep water farming. We are indebted to Dr. Junning Cai, Aquaculture Officer, FAO Fisheries and Aquaculture Department, Rome, Italy; three anonymous reviewers; and handling editor for their valuable comments that improved the publication. We acknowledge the help rendered by our research scholars during socioeconomic survey. We are grateful to Council of Scientific and Industrial Research, New Delhi; Department of Biotechnology, New Delhi; Ministry of New Renewable Energy, New Delhi; Gujarat State Biotechnology Mission, Gandhinagar; Gujarat Livelihood Promotion Company Ltd., Gandhinagar; National Centre for Sustainable Coastal Management, Ministry of Environment and Forest, Chennai, and our licensees as well as other funding agencies for R & D support. We would take this opportunity to thank Dr. Amitava Das, Director, CSMCRI, for encouragement. This manuscript has PRIS registration number 023/2016.

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Fig S1

(DOCX 35 kb)

Fig S2

(DOCX 185 kb)

Fig S3

(DOCX 123 kb)

Fig S4

(DOCX 784 kb)

Fig S5

(DOCX 852 kb)

Fig S6

(DOCX 372 kb)

Fig S7

(DOCX 305 kb)

Fig S8

(DOCX 13 kb)

Fig S9

(DOCX 298 kb)

Fig S10

(DOCX 1337 kb)

Fig S11

(DOCX 3032 kb)

Fig S12

(DOCX 461 kb)

Table S1

(DOCX 18 kb)

Table S2

(DOCX 15.7 kb)

Table S3

(DOCX 16 kb)

Table S4

(DOCX 15 kb)

Table S5

(DOCX 18 kb)

Rights and permissions

About this article

Cite this article

Mantri, V.A., Eswaran, K., Shanmugam, M. et al. An appraisal on commercial farming of Kappaphycus alvarezii in India: success in diversification of livelihood and prospects. J Appl Phycol 29, 335–357 (2017). https://doi.org/10.1007/s10811-016-0948-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-016-0948-7