Abstract

The aimed modification of expanded graphite electrodes (EG) was divided into two independent parts consisting of chemical treatment in the mixture of concentrated H2SO4/HNO3 and subsequent heat treatment performed at elevated temperature in air. The electrochemical features of modified samples were examined in the model process of phenol electrooxidation which was realized in alkaline medium by the cyclic voltammetry technique. Taking into account the charges of anodic peaks corresponding to the phenol oxidation it was found that a two-step treatment of EG brought about over two-fold improvement of its electrochemical activity as compared to the initial cycle of regarded process. The reason for such a behavior can be ascribed to the changes in chemical composition of the EG surface as well as the changes in porous structure including almost a two-fold development of specific surface area and by a four-fold increase of the sample volume affected by the thermal treatment. According to the X-ray photoelectron spectroscopy and Fourier transform infrared spectroscopy data, the modification of EG resulted in a significant increase of the surface oxygen groups containing C–O.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

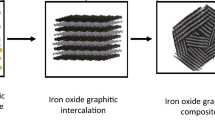

Expanded graphites (EGs) are the products of exfoliation of graphite intercalation compounds (GICs). As a result of exfoliation even 300 times expansion of graphite along the c-axis occurs. When the intercalate or its part persists within the graphite structure after the process of exfoliation, the achieved material is named as exfoliated graphite intercalation compound (EG-GIC). The physicochemical features of EG and EG-GIC are very specific and generally are created during the process of its formation. A developed porous structure, high adsorption capacity, low density, and high thermal resistivity of EG make possible its application in many technical fields, for example as heavy oil sorbent [1, 2] and composite filler [3]. On much less scale EG has found application as a material for the generation and storage of energy in fuel cells [4], supercapacitors [5], and for the hydrogen sorption/desorption [6]. In order to extend the range of the EG potential application, various types of its modification were attempted. Among them, the oxidative treatment resulting in the enrichment of existing functional groups as well as the formation of novel ones on the EG surface seems to be the most useful. In practice, the processes of oxidative modification of chemical composition of the EG surface is realized by chemical [7–9], thermal [10], and electrochemical methods [11]. The advanced oxidation of graphite materials including expanded graphite in some cases leads to the formation of graphite oxide (GO). Since, GO contains enriched amount of chemically bounded oxygen within the oxygen containing surface functionalities it can be regarded as active electrode material [12].

Owing to oxidative modifications, EG reaches capability, for example, of electrochemical oxidation of phenol [11, 13–16]. Besides EG, the process of phenol electrooxidation has also been performed with the use of glassy carbon [17, 18], carbon fibers [18], carbon black [19], and diamond [20] as carbon electrode material. Electrochemical methods allow the entire transformation of phenol into final products, water, and CO2, through some intermediate products. However, to complete mineralization of phenol the application of a suitable experimental conditions as well as electrode exhibiting high electrochemical activity are necessary. Besides soluble intermediate products, such as benzoquinone, fumaric and maleic acids, insoluble, and oligomeric by-products are formed on the surface of electrode material during the process of electrochemical oxidation of phenol. Owing to its features (insufficient electrochemical activity and very low electrical conductivity, high adhesion), oligomer layer causes the electrode inactivation [11, 13–19, 21]. In consequence, the process of phenol electrooxidation is inhibited and the formation of the final products of oxidation is difficult to achieve.

The purpose of this study is to modify the structural and chemical properties of expanded graphite to improve its electrochemical activity in the process of phenol oxidation. The process of EG modification was composed of two steps. During the first one, EG was chemically treated in the mixture of concentrated acids H2SO4/HNO3, whereupon such a modified EG was subjected to the heat treatment in air. The electrochemical results were discussed in term of the data of surface area measurements and XPS and FTIR analyses.

2 Experimental

2.1 Preparation of expanded graphite

EG subjected to the modification process was prepared by the thermal exfoliation of stage 4 graphite intercalation compound with sulfuric acid (H2SO4-GIC). The process of exfoliation was carried out at 800 °C for 5 min in air. H2SO4-GIC was synthesized by anodic oxidation of flaky graphite (with diameter ranging from 32 to 71 μm) in 18 M H2SO4, according to the previously described procedure [22].

2.2 Conditions of modification

The modification process of expanded graphite was consisted of two steps. During the first one, EG was chemically treated in the mixture of the concentrated H2SO4/HNO3 (3:1 by volume) at the temperature of 100 °C followed by washing the product with deionized water until the pH = 7 was achieved and drying in air. Thus, modified material was denoted as EG-c. The next step of modification consisted in heat treatment of sample EG-c at 800 °C for 5 min in air. Expanded graphite received after the second step of modification was marked as EG-c-t.

2.3 Preparation of electrode and electrochemical measurements

The electrochemical properties of the investigated samples were studied in 0.1 M solution of phenol in 0.5 M KOH by cyclic voltammetry (CV) technique. CV measurements were carried out in a three-electrode system, in which the powder type material was a working electrode. The particular description of the electrode preparation as well as the construction of electrochemical cell can be found in our previous articles [15, 16]. All the potentials on the presented voltammograms are referred to the Hg/HgO/0.5 M KOH as a reference electrode. The reference electrode was connected to the solution under investigation by a Luggin capillary. The graphite rod (5 mm in diameter) played a role of a counter electrode. CV measurements were performed with scan rate equal to 0.1 mV/s in the potential range from the rest potential of electrode (E R) to 0.8 V. In order to gain an insight into the cathodic reactions arising from the reduction of surface functional groups originally present on the EG surface before and after the two-step modification, CV measurements in the electrolyte free of phenol were performed. In this case, the potential range was disposed on E R → −0.95 V → 0.8 V → E R. Prior to each measurement the electrode was kept in the investigated electrolyte for 30 min to stabilize the potential. The mass of working electrode was equal to 15 mg. Electrochemical studies were performed using an AUTOLAB potentiostat–galvanostat (model PGSTAT 30). Phenol used as reagent was purchased from LACHEMA (puriss. >99.5 wt%).

2.4 Analysis and equipment

The changes of specific surface area effected by a two-step modification were determined from the isotherms measured by N2 adsorption at 77 K with ASAP 2010 apparatus. The surface chemical composition of the original and modified EG was estimated by the XPS and FTIR analysis. The X-ray photoelectron spectroscopy (XPS) measurements were realized with ESCALAB 210 spectrometer (VG Scientific, East Grinstead, UK) using a non-monochromatized Al Kα radiation (1486.6 eV). The attained XPS spectra were analyzed by performing Shirley-type background subtraction and using Gaussian–Lorentzian mix function of 70%/30% ratio. The binding energy scale was corrected by referring to the graphitic peak at 284.5 eV. FTIR measurements were performed with BRUKER-model 113V IR spectrometer using the KBr technique.

3 Results and discussion

3.1 Electrochemical oxidation of phenol

In order to know the degree of improvement of electrochemical activity of EG affected by its two steps of modification, the preliminary oxidation of phenol was carried out at electrode made of original EG.

3.1.1 Electrochemical oxidation of phenol on original EG

Figure 1 displays cyclic voltammograms recorded during the process of phenol electrooxidation at the electrode made of the original EG. The well defined anodic peak at the potential of 0.43 V can be seen for the first cycle of oxidation. Based on our knowledge, this peak can be ascribed to the reaction of phenol oxidation [11, 13–16]. For the second and third cycle the intensities as well as current charges of the regarded peak markedly fell down. There is no doubt that the oligomeric products formed on the surface of EG electrode during the initial cycle of phenol oxidation are responsible for the significant diminution in intensity of anodic peaks. The passive, nonactive layer of insoluble oligomer, hindering an access of phenol molecules to the active sites located at the surface of EG electrode [11, 13–16], is responsible for the worsening of electrochemical activity of EG and, as a consequence, for the inhibition of the phenol electrooxidation reaction in the subsequent cycles.

The comparison of current charges calculated for the anodic peaks during the consecutive cycles of phenol oxidation provides evidence for electrode inactivation. For the first cycle the peak charge was equal to 5.58 C, whereas, for the second and third cycle the charges fell down dramatically to 0.93 and 0.77 C, respectively. The peak charges for all the investigated electrodes are displayed in Table 1. Since, the anodic peak noted for the second cycle is very close to that for the third one, it means that the process of phenol electrooxidation within the second and third cycle proceeds at the EG surface covered with oligomeric layer. It should be emphasized that for the second and third cycle the process starts at higher potential and the maxima of anodic peaks are shifted toward the less positive potentials. After the first oxidation cycle, the surface of investigated electrode being almost entirely covered by oligomeric layer is characterized by a four-fold decrease of surface area [15]. Considerably reduced surface area accompanied by the changes in chemical composition of the EG surface coated by oligomer film, examined by the FTIR, XPS, and SEM techniques [16, 21], convincingly indicates that during the consecutive cycles the process of phenol oxidation proceeds on appreciably different electrode material as compared to that involved in the first cycle. Such changes suggest that the mechanism of phenol oxidation is altered as compared to that of the first cycle.

3.1.2 Electrochemical oxidation of phenol on EG after its chemical modification

In order to overcome the problem of the abrupt worsening of electrode activity due to the fouling of electrode surface by oligomeric products, the further investigations were focused on the improvement of electrochemical activity and the protection of EG against its inactivation. In order to achieve this goal, chemical modification of EG in the mixture of concentric H2SO4/HNO3 was performed.

Figure 2 presents CV curves recorded in 0.1 M solution of phenol in 0.5 M KOH for chemically treated EG similar to the original EG (Fig. 1), the reaction of phenol oxidation is shown as irreversible anodic peak recorded during the forward scanning. As can be seen in Fig. 2, the regarded peak is about 30 mV shifted toward the less positive potentials suggesting that kinetics of the phenol oxidation process at electrode made of modified EG is slightly altered as compared to the process occurring at the original electrode. In searching for the reasons for such a behavior the following issues are worthy of recalling. The mixture of concentrated H2SO4 and HNO3 used for chemical modification of expanded graphite is well known as a very reactive agent exhibiting a strong oxidative action. Among the main effects of the reaction between the considered acid mixture and amorphous as well as graphitic materials, there are the changes in both chemical structure of the carbon surface due to the formation of different types of surface functional groups and crystalline structure due to the creation of structural defects in the graphitic materials. The contact of graphitic materials, not excluding EG, with concentrated H2SO4/HNO3 at elevated temperature leads to their transformation into graphite intercalation compounds with sulfuric acid (H2SO4-GIC) and nitric acid (HNO3-GIC) [25]. All the mentioned effects involve significant changes in the physicochemical as well as electrochemical properties of chemically treated materials. Taking this into account it is reasonable to assume that the properties of modified EG (sample EG-c) differ from those of the original EG and the considerable enhancement of electrochemical activity as well as the potential shift observed on the respective voltammograms for EG-c (Fig. 2) can be attributed to the effects of chemical modification of EG.

Taking into account the charge value of anodic peak ascribed to phenol oxidation as a criterion of electrochemical activity, it can be pointed out that the chemical treatment of EG results in significant improvement (over 60%) of electrode activity for sample EG-c (Table 1). However, similar to the original EG (Fig. 1), the intensities of anodic peaks rapidly decrease upon cycling due to the blocking of the graphite surface by oligomer products formed during the first cycle of phenol oxidation. From a particular comparison of the peak charges measured during the second and third cycle for the original and modified EG one can infer that the degree of electrode inactivation for chemically treated EG is much less pronounced (Table 1). The enhancement of electrochemical activity of chemically treated EG is not limited to anodic peak only at the potential of 0.43 V. As can be seen in Fig. 2, on continuing the anodic oxidation at the potentials higher than 0.6 V one can observe a rapid rise of anodic currents. After the reversal of polarization at 0.8 V, the current loop emerges with the maximum at 0.78 V. It is likely that both effects are associated with the successive oxidation reactions and/or the products of its previous oxidation. It is worth to note that the considered increase of electrochemical activity noted for electrode EG-c within the potential range of 0.6–0.8 V occurs not only for the first but also for the consecutive scans.

On the basis of the obtained results it should be emphasized that chemical treatment of EG markedly improves its electrochemical activity toward the process of phenol electrooxidation. Until now it is difficult to explain comprehensively the reasons for such a behavior. However, based on the literature one can assume that chemical treatment of EG in the mixture of H2SO4/HNO3 gives rise to enrichment of the expanded graphite surface with some types of functional groups [8, 9]. It is also known that the oxidative treatment of graphitic materials in concentrated H2SO4 admix with oxidant (e.g. KMnO4, HNO3) can lead to the formation of graphite oxide [9, 23, 24]. As a consequence, the degree of oxidation of graphite material is enhanced owing to the existence of oxygen complexes such as hydroxyl, carbonyl, and carboxyl [12]. The formation of EG-graphite oxide compound of enriched amount of surface oxygen groups may have a great influence on the improvement of electrochemical activity noted during the process of phenol oxidation. On the other hand, the mixture of H2SO4 and HNO3 with volume ratio of 3:1 is widely applied for the chemical preparation of graphite intercalation compound with sulfuric acid (H2SO4-GIC) [8, 9, 25]. The product of such a process can easily be transformed into expanded graphite by heat treatment at elevated temperature. Taking this fact into consideration, one cannot exclude that chemical treatment performed under given conditions resulted partially in secondary intercalation of H2SO4 into EG structure. In order to verify the mentioned hypothesis, sample EG-c was heated for 4 min at 800 °C in air and the physicochemical and electrochemical effects of such a treatment were examined.

3.1.3 Electrochemical oxidation of phenol on EG after its chemical modification and subsequent thermal treatment

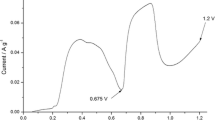

Figure 3 depicts voltammetric curves recorded in electrolyte containing 0.1 M of phenol for sample EG-c-t after a two-step modification (chemical treatment followed by heating). From the presented curves, one can observe that electrochemical activity of EG toward the process of phenol electrooxidation was further improved by additional heat treatment. The intensities of anodic peaks associated with the phenol oxidation increased considerably after such a treatment as compared to that of chemically modified EG (sample EG-c) (Fig. 2). The charge of anodic peak calculated for sample EG-c-t during the first cycle is over 2.5 times higher than that for unmodified EG and of about 60% higher as compared to sample EG-c (Table 1). However, an undesirable inactivation of sample EG-c-t is still observed on cycling (Fig. 3). Contrary to CV curves obtained for electrodes made of the original and chemically modified EG (Figs. 1 and 2), in the case of heat treated sample (EG-c-t), a small prepeak at 0.25 V appears before the huge anodic peak. This effect observed merely on the curve recorded during the first oxidation cycle is related to the initial step of phenol oxidation. The appearance of prepeak accompanied by the shift of the main peak toward higher potentials clearly indicates that not only kinetics but also the mechanism of phenol oxidation are markedly altered due to heat treatment of sample EG-c. On taking into account the fact that chemical modification of expanded graphite performed in the mixture of concentrated H2SO4/HNO3 can result in intercalation of sulfuric ions into the structure of EG, it seems very justified that thermal treatment of such intercalated EG brings about its secondary exfoliation (sample EG-c-t). The comparison of sample EG-c before and after heating at 800 °C showed that thermal treatment resulted in over a four-fold increase in the sample volume of sample. This fact confirms that the intercalation of H2SO4 into the EG structure takes place on soaking EG in the mixture of concentrated acids H2SO4/HNO3. In consequence, during the subsequent heating of sample EG-c an abrupt removal of intercalate from the interlayer spacing of graphite leads to a large expansion of the sample volume due to exfoliation of the graphite flakes. Owing to exfoliation, the porosity of sample EG-c-t increased considerably following the increase in specific surface to 59.8 m2/g as compared to 34.7 m2/g for the starting EG. These changes in the EG structure gave rise to the improvement of adsorptive capability. As a consequence of the secondary exfoliation the EG surface was also enriched in both functional groups and defects, playing a role of active sites in the reaction of phenol oxidation. The above-mentioned effects of thermal treatment of sample EG-c to give sample EG-c-t are very likely responsible for both the changes in the mechanism of electrochemical oxidation of phenol and the kinetics of the reaction. The enhancement of electrochemical activity of sample EG-c-t, noticed by comparing CV curves shown in Figs. 2 and 3, is summarized in Table 1.

3.2 Electrochemical investigations of original and modified EG in the electrolyte free of phenol

In order to evaluate an important role of the two-stage treatment of EG in the generation of chemical and structural properties contributing positively to electrochemical properties, CV measurement in electrolyte free of phenol was performed.

Figure 4 presents CV curves recorded for EG before (sample EG) and after chemical/thermal modification (sample EG-c-t) during the first cycle in 0.5 M KOH. In order to avoid the anodic formation of functional groups on the electrode surface, the measurement was started from the rest potential of electrode (E R) toward the negative potentials. Such a mode of measurement allowed the examination of the cathodic effects related to the reduction of surface oxygen complexes originally present on the EG surface and those chemically and thermally produced on the EG-c-t surface. Some differences in shapes and intensities of the peaks are observed on CV curves presented in Fig. 4. On each voltammogram, two cathodic peaks are seen during the cathodic polarization but their location is markedly different, depending on the sample examined. The pair of cathodic peaks is positioned at the potentials of −0.16 and −0.52 V for the original and at –0.2 and −0.8 V for modified EG. There is no doubt that all of the cathodic peaks are related to the reduction reaction of surface functional groups. On the other hand, a distinct divergence in their locations suggests that some novel surface complexes are formed on the surface of EG as a consequence of a two-step treatment, especially due to thermal treatment proceeding at 800 °C in air. The above assumption is confirmed concerning CV curve recorded for electrode EG-c-t during the backward scanning. After the reversal of polarization (−0.95 V), the asymmetric anodic peak emerges at the potential of about −0.72 V. This peak probably arises from oxidation reactions of EG surface modified due to two-step treatments.

3.3 Study of chemical composition of modified EG

The information arising from CV measurements about chemical composition of the EG surface after its two-step modification are supported by the XPS and FTIR data.

3.3.1 XPS measurements

Figure 5a–d displays deconvoluted XPS spectra of O 1s and C 1s regions recorded for the original and modified EG (samples EG and EG-c-t, respectively). The preliminary comparison of the presented spectra reveals essential differences in the chemical composition of surfaces of both investigated samples. The most pronounced features observed on O 1s spectra, as effect of the EG modification are the presence of peak with binding energy of 535.9 eV (peak D) (Fig. 5c) and disappearance of signal at 534.8 eV, recorded for the original EG (peak C) (Fig. 5a). The former peak seems to correspond to the occluded CO or CO2 [26], whereas, the latter one derives from chemisorbed water or oxygen on the surface of the original EG [27, 28]. The existence of peak D can be presumably attributed to a partial pyrolysis of EG yielding CO or CO2. Another important result of EG modification seen on O 1s spectra is related to the increase in intensity of peak B (Fig. 5b) corresponding to the C–O bond in ether, phenolic, or alcoholic groups [26, 28, 29]. As compared to the original EG, the area of the regarded peak grows up to about 35% after the chemical and subsequent thermal treatment. It is worth to note that enhancement of C–O bond concentration at the surface of EG-c-t goes along with the diminution of C=O bond. The area of peak B for sample EG-c-t (Fig. 5c) is about 60% lower than the analogous peak for the original EG (Fig. 5a). These relations for 1 s spectra are consistent with data presented on the deconvoluted C 1s spectra recorded for the original EG (Fig. 5b) and EG-c-t (Fig. 5d). On both spectra, one can observe the appearance of peak D assigned to C–O bond pertaining to ether, phenolic, or alcoholic groups [7, 9, 29]. The area of regarded peak for modified sample (Fig. 5d) is over 31% higher as compared to the peak for the original EG (Fig. 5b). A two-step modification of EG also resulted in enhanced contribution of peaks at the binding energies of 284.4 (peak B) and 285.0 eV (peak C) in the entire surface carbon effect. The mentioned peaks were aligned to graphitic carbon and aliphatic bond C–C, respectively [9, 30, 31, 32]. Disappearing of carbon signals at the binding energies of 288.4 (peak E) and 290.9 eV (peak F) (C=O bond in carboxylic, ester, and/or carbonyl groups [7, 9, 28, 31]) on C 1s spectrum for EG-c-t can be presumably ascribed to a partial pyrolysis yielding CO or CO2.

Summarizing, from the viewpoint of EG activity toward phenol electrooxidation, the most important results of a two-step modification are the enrichment of C–O bond on the surface of modified EG. Till now there is no enough information to point out which of functional group (ether, alcoholic, or phenolic) consisting of C–O bonds are generated on the EG surface through its chemical and subsequent heat treatment.

3.3.2 FTIR measurements

Nevertheless, the higher concentration of the C–O bond identified on the surface of modified EG by XPS measurements is in a good accordance with the results of FTIR analysis. The FTIR spectra recorded for EG before and after a two-step modification are shown in Fig. 6. As can be seen in this figure, the used modification of EG brought about the appearance of a new band at 1,107 cm−1 (spectrum b). According to the literature data, the regarded signal may be assigned to the stretching vibrations of C–O bands pertaining to ether groups [5, 8, 9]. The above observation agrees also with aforementioned conclusions derived from both CV measurements performed in the electrolyte free of phenol and the XPS data.

4 Conclusions

The two-step modification of EG consisting of chemical treatment in the mixture of concentrated H2SO4/HNO3 and subsequent heat treatment at 800 °C in air considerably improves its electrochemical activity in the process of phenol electrooxidation. Over two-fold enhancement of activity, estimated by comparing the peak charges calculated during the initial cycle of phenol oxidation, has been accomplished for the modified EG electrode. The results of investigations applying electrochemical measurements, XPS, and FTIR analysis allow the conclusion that two factors exert influence on the improvement of electrochemical activity of modified EG electrode: (i) the formation of the surface functional groups containing C–O bonds (e.g., ether, phenolic, or alcoholic groups), (ii) a two-fold increase of specific surface area accompanied with a four-fold expansion of the EG volume due to thermal treatment. The obtained results make an assumption plausible that, during chemical treatment of EG in a mixture of concentrated acids, a secondary intercalation of H2SO4 into EG structure takes place and the subsequent heat treatment at 800 °C leads again to reexfoliation resulting in a significant increase of the EG volume. Despite the considerable increase of activity in the first cycle of phenol oxidation, the unwanted behavior associated with the inactivation of electrode upon cycling was not successively prevented. The current charges measured for the second and third cycle rapidly fall down due to the formation of non-active oligomeric by-products. In order to examine the particular influence of the two-step modification of EG on its activity toward the process of phenol electrooxidation, the additional investigations involving qualitative as well as quantitative analysis of intermediate and final products of considered reaction are necessary.

References

Tryba B, Kaleńczuk RJ, Kang F et al (2000) Mol Cryst Liq Cryst 340:113

Toyoda M, Inagaki M (2000) Carbon 38:199

Celzard A, McRae E, Marache JF et al (1996) J Phys Chem Solids 57:715

Bhattacharya A, Hazra A, Chatterjee S et al (2004) J Power Sources 136:208

Mitra S, Sampath S (2004) Electrochem Solid-State Let 7:A264

Lueking AD, Pan L, Narayanan DL (2005) J Phys Chem B 109:12710

Ramesh P, Sampath S (2001) Analyst 126:1872

Ramesh P, Sivakumar P, Sampath S (2003) Electroanalysis 15:1850

Ramesh P, Bhagyalakshmi S, Sampath S (2004) J Colloid Int Sci 274:95

Fukushima H, Drzal LT, Rook BP, Rich MJ (2006) J Therm Anal Calorim 85:235

Krawczyk P, Skowroński JM (2006) Przem Chem 85(8–9):1198

Stankovich S, Dikin DA, Piner RD et al (2007) Carbon 45:1558

Skowroński JM, Krawczyk P (2000) In: Proceedings of the 51st Annual meeting of International Society of Electrochemistry, Warszawa, Poland, p 218

Skowroński JM, Krawczyk P (2003) In: Eurocarbon conference, Oviedo, Spain (CD-ROM)

Skowroński JM, Krawczyk P (2004) J Solid State Electrochem 8:442

Skowroński JM, Krawczyk P (2007) J Solid State Electrochem 11:223

Ureta-Zañartu MS, Bustos P, Berríos et al (2001) Electrochim Acta 46:2399

Kuramitz H, Nakata Y, Kawasaki M, Tanaka S (2001) Chemosphere 45:37

Boudenne JL, Cercilier O, Galea J, Van der Vlist E (1996) Appl Catal Environ 143:185

Canizares P, Garcia-Gomez J, Saez C, Rodrigo MA (2004) J Appl Electrochem 34:917

Krawczyk P, Skowroński JM (2009) Chem Eng J. doi:10.1016/j.cej.2009.05.009

Skowroński JM, Jurewicz K (1991) Synth Met 40:161

Nakajima T, Mabuchi A, Hagiwara R (1988) Carbon 26:357

Hirata M, Gotom T, Horiuchi S et al (2004) Carbon 42:2929

Skowroński JM (1997) In: Nalva HS (ed) Handbook of organic conductive molecules and polymers. Wiley, New York, p 621

Terzyk AP (2001) Colloids surf A Physicochem Eng Aspects 177:23

Biniak S, Szymański G, Siedlewski J, Świątkowski A (1997) Carbon 35:1799

László K, Tombácz E, Josepovits K (2001) Carbon 39:1217

Świątkowski A, Pakuła M, Biniak S, Walczyk M (2004) Carbon 42:3057

Wu YP, Jiang C, Wan C, Holze R (2003) Electrochim Acta 48:867

Okpalugo TIT, Papakonstantinou P, Murphy H et al (2005) Carbon 43:153

Hontoria-Lucas C, López-Peinado AJ, De J et al (1995) Carbon 33:1585

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Krawczyk, P., Skowroński, J.M. Modification of expanded graphite resulting in enhancement of electrochemical activity in the process of phenol oxidation. J Appl Electrochem 40, 91–98 (2010). https://doi.org/10.1007/s10800-009-9984-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-009-9984-1