Abstract

In the presented paper, we report on electrochemical oxidation of phenol occurring at exfoliated graphite (EG) in alkaline solution. The mechanism of the electrocatalytic reaction of phenol oxidation was modified on adding methanol to the phenol-containing electrolyte. Using the voltammetry method, the influence of methanol additive on cyclic behavior of EG electrode was examined. A particular attention has been paid to the first two cycles when an abrupt decrease in electrocatalytic activity of various electrode materials has been observed. The results obtained showed that in the presence of methanol EG, electrode preserves its electrocatalytic activity for a longer time of phenol oxidation. In the absence of methanol in a phenol/KOH electrolyte, the charge of phenol oxidation peaks decreases sharply on cycling, whereas in the presence of methanol, the observed drop is considerably inhibited. The anodic charge attained for the 15th cycle of phenol oxidation in methanol-admixed electrolyte is the same as that for the third cycle recorded in methanol-free electrolyte. The thermogravimetric analysis (TG), Fourier-transformed infrared spectroscopy (FTIR), and X-ray photoelectron spectroscopy (XPS) data showed that an improved electrocatalytic activity of EG can be accounted for by new chemical composition of oligomer film built on the EG surface with the participation of methanol and/or the products of its oxidation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Many industrial processes, e.g., petrochemical refineries, pharmaceutical, chemical etc., generate effluents consisting of phenol and its derivatives. In literature, one can find works dealing with physical [1], chemical [2], photochemical [3], biochemical [4], and electrochemical [5–24] procedures of phenol deactivation. Most of them have been focused on achieving a high efficiency of phenol elimination from water solutions involving only one pollutant at a time. In practice, a variety of contaminants pertaining to the different chemical classes coexist within wastewater, which make the processes of water purification much more complicated.

Low costs, effectivity, and controlling of the regarded process make the electrochemical elimination of phenol from water especially worthy of interest. Generally, the electrochemical methods of electrochemical oxidation of phenol are realized directly at the electrode materials or/and due to mediation by inorganic oxidants such as oxygen or hydroxyl radicals, generated at the surface of electrode [11, 12].

A variety of electrode materials have been examined in the process of phenol oxidation. Electrodes made of noble metals (e.g., Pt and Au) [5, 7, 13] and electrodes based on metal oxides, such as SnO2 [14], PbO2 [15], TiO2 [16], and IrO2 [14], are commonly used, but carbon materials are also applicable in this area. Typical examples of carbon anodes suitable to the electrochemical oxidation of phenolic compounds are diamond [17], glassy carbon [6, 9], carbon fibers [8], and activated carbon [10].

From the ecological point of view, methods dealing with phenol elimination from the aqueous media should ensure its conversion into CO2 and water. It is well known that electrochemical techniques can accomplish the established task. The complete electrochemical conversion of phenol may proceed through the formation of aromatic (hydroquinone and benzoquinone) and aliphatic (maleic, fumaric, and oxalic acids) intermediates. Depending on the pH of electrolyte, the beginning of the process of phenol oxidation includes the generation of phenoxy radicals in acidic solution and phenolate ions in alkaline media. It must be emphasized that during the process of phenol electrooxidation, an unwanted phenomenon consisting in the formation of polymeric products may also occur through the dimerization reactions. Because the formation of strongly adhesive, nonactive polymer products may be dominant, the inactivation of anode due to fouling of electrode materials takes place and results in the interruption of the process of phenol oxidation. Such a scenario is reported not only for electrochemical treatment but also for all the methods of phenol elimination. Therefore, numerous techniques have been developed to overcome the problem of surface fouling, e.g., electrochemical treatment [25] and laser activation [26]. Our previous work on oxidation of phenol at electrode made of exfoliated graphite (EG), using cyclic voltammetry technique, shows that it is possible to restore and even improve the electrochemical activity of graphite electrode covered with the oligomer products of phenol oxidation [20]. As compared to the starting electrode, almost threefold enhancement of electrochemical activity of exhausted EG electrode was attained after its thermal regeneration at 500°C in air.

A new approach to the problem of electrode inactivation during the electrooxidation of phenol was used by Andreescu et al. [13]. They reported that during the electrochemical oxidation of phenol carried out on Pt electrode in a mixture of phosphate buffer (pH 6.5)/methanol, the deposition of polymer products of phenol oxidation is followed by the reactive layer formation of products of methanol oxidation. In consequence, instead of a current drop, the increase in anodic current was observed during the consecutive potential scans due to the appearance of a new type of phenolic polymer on the surface of platinum electrode.

The purpose of this work is to investigate the possibility of using the electrolyte modification as a way to counteract the inactivation of the EG electrode induced by the passive oligomer products of phenol electrooxidation. This paper endeavors to explain how the addition of methanol to the electrolyte containing phenol changes the course of the process of phenol electrooxidation, its kinetic, and mechanism upon the electrode cycling. The electrochemical oxidation of phenol has been investigated in potassium hydroxide medium by cyclic voltammetry technique. The results of electrochemical measurements are discussed in relation to the thermogravimetric analysis (TG), Fourier-transformed infrared spectroscopy (FTIR), and X-ray photoelectron spectroscopy (XPS) data.

Experimental

Graphite composed of particles with diameters ranging from 32 to 71 μm was used as a host material to obtain graphite intercalation compound (GIC). H2SO4–GIC was synthesized by the galvanostatic oxidation of host graphite in 18 M H2SO4 according to the procedure described earlier [27]. GIC, thus prepared, was thermally exfoliated in muffle furnace at temperature 800°C in air for 5 min. The electrochemical investigations of phenol electrooxidation on EG electrode were performed by cyclic voltammetry (CV) in 0.5 M aqueous solution of KOH containing 0.05 M of phenol. To examine how the presence of methanol affects the reaction of phenol electrooxidation, especially the magnitude of electrode inactivation, 0.05 M of methanol was added to a solution of KOH/phenol. Except for two measurements (Figs. 7 and 8), the cyclic voltammetry measurements were performed in the potential range from the rest potential of electrode (E R) to 0.8 V with a scan rate of 0.1 mV/s. To reveal the influence of methanol oxidation on the kinetics of phenol oxidation, the potential range was reduced to 0.5 V (Fig. 7), and during another experiment, the potential range was extended to 1.1 V (Fig. 8). Before each measurement, the electrode was kept in the investigated electrolyte for 30 min. In each case, the mass of working electrode was equal to 30 mg. All the potentials on the presented voltammograms are referred to the Hg/HgO/0.5 M KOH electrode. The reference electrode was connected to the solution under investigation by a Luggin capillary.

The powder-type working electrodes were prepared according to the following procedure. Exfoliated graphite was placed in a pocket made of porous polymer material, in which graphite rod (5 mm in diameter), playing a role of current collector, was beforehand inserted. The contribution of graphite rod to the oxidation charge of phenol is negligibly small as compared to that of complete electrode containing the EG particles. A similar graphite rod was used as a counter electrode [18–20].

Electrochemical measurements were performed using an AUTOLAB potentiostat–galvanostat (model PGSTAT 30). Phenol, used as reagent, was purchased from Lachema (puriss. > 99.5 wt%).

TG was done in air at a rate of 5°C/min with SETSYS TG-DSC 12 (Setaram) apparatus. FTIR measurements were performed with BRUKER-model 113V IR spectrometer using the potassium bromide technique. The surface chemical compositions of the samples were determined with an XPS (ESCALAB 210 spectrometer, VG Scientific, East Grinstead, UK) using a nonmonochromatized Al Kα radiation (1,486.6 eV). The attained XPS spectra were analyzed by performing Shirley-type background subtraction and using Gaussian–Lorentzian mix function of 70:30% ratio. The binding energy scale was corrected by referring to the graphitic peak at 284.5 eV.

Results and discussion

Figure 1 illustrates cyclic voltammograms for EG recorded in 0.05-M solution of phenol in 0.5 M KOH. During the first oxidation cycle, the well-defined irreversible anodic peak is observed at the potential around 0.42 V. This peak is associated with the reaction of phenol oxidation to quinone compounds followed by the oligomer film formation [18–20]. Except for the initial steps of phenol oxidation, when the phenoxy radicals are generated in acidic solution and the phenolate ions are formed and subsequently oxidized to phenoxy radicals in alkaline media, the mechanism of phenol oxidation in acidic and alkaline solution is similar [8, 9, 23, 24]. According to this mechanism, further oxidation of phenoxy radicals proceeds through the two competitive pathways, the formation of soluble quinonic compounds and the other one yielding the insoluble oligomer products, which may also involve quinonic species [7–9, 21–24]. The formation of oligomer film on the EG surface determines the consecutive steps of the considered process. Such an assumption is supported by the fact that the intensity of oxidation peak rapidly falls down after the first cycle. The charges of oxidation peaks calculated for all the investigated samples are given in Table 1. The decrease in anodic charges found after the first cycle is associated with the worsening of electrochemical activity of investigated electrode material due to the formation of passive, nonconductive layer of oligomer products of phenol oxidation on its surface [18–20]. Because for the second cycle the maximum of anodic peak, assigned to the phenol oxidation, is significantly shifted towards the lower potentials, it is reasonable to assume that the kinetics of the process is also altered. As shown in Fig. 1, the products of phenol oxidation formed during the first cycle block the electrode surface, hindering further phenol oxidation. Therefore, there was a need to find an effective method for protection of the electrode material against its inactivation. It is obvious that the type of electrolyte, as well as its composition, should play an important role in the process of phenol oxidation. So, before further investigations, the modification of electrolyte by the adding of methanol was attempted.

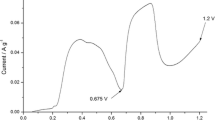

To examine the electrochemical oxidation of methanol within the considered potential range (E R↔0.8 V), the measurement in KOH electrolyte containing methanol in the absence of phenol was performed (Fig. 2). As seen from this figure, an abrupt increase of current associated with methanol oxidation occurs in the potential range starting from 0.48 V. Some irregularities seen in this potential range may be attributed to the successive steps of methanol oxidation. On the other hand, no anodic peak appears in Fig. 2 within the potential range 0↔0.55 V, where phenol oxidation is observed in Fig. 1. This comparison allows the conclusion that the processes of phenol and methanol oxidation will occur consecutively upon scanning the potential from E R to 0.8 V. Figure 3 shows the CV curves recorded for EG in electrolyte containing the same amounts of phenol and methanol. The processes of anodic oxidation recorded on each curve in this figure can be divided into two distinctly separated potential sections. Within the former section (E R to 0.5 V), anodic peak of phenol oxidation appears, whereas the latter section (0.5–0.8 V) displays the process of methanol oxidation. Taking into account the charge of anodic peak associated with phenol oxidation as a criterion of electrochemical activity of EG electrode, it can be pointed out that the activity of the investigated electrode during the successive cycles of phenol oxidation is markedly enhanced owing to methanol present in the electrolyte, as compared to the measurement in the electrolyte free of methanol (Fig. 1). The current charges of phenol oxidation peaks for the second and third cycle, achieved in methanol containing electrolyte (Fig. 3), and over twice higher than the respective charges recorded in the electrolyte free of methanol (Table 1). It is noticeable that the charge of anodic peak measured for the fifteenth cycle of the process of phenol oxidation accompanied by methanol oxidation is very similar to that measured for the third cycle in the electrolyte free of methanol additive. Moreover, from the comparison of curves presented in Figs. 1 and 3, it is seen that the kinetics of phenol oxidation varies significantly under the influence of methanol. The maxima of the phenol oxidation peaks recorded in electrolyte admixed with methanol are more than 100 mV shifted toward less positive potentials as compared to unmodified electrolyte (Fig. 1).

Our results differ in some points from those reported by Andreescu et al. [13] on the influence of methanol on the electrochemical oxidation of phenol. In the present paper, the CV measurements were performed in alkaline solution using the electrode made of exfoliated graphite scanned at 0.1 mV/s, whereas the mentioned authors carried out the process in electrolyte of pH=6.5 using platinum electrode cycled with a scan rate of 100 mV/s. For the phenol/phosphate buffer admixed with methanol, they observed gradual increase in anodic currents on the CV curves up to 50 forward/backward cycles. The process of methanol/phenol oxidation occurred within one oxidation peak. Such a behavior was explained assuming that phenol is not oxidized directly on platinum surface but on the Pt surface covered with the products of methanol oxidation. In contrast, during our investigations, the oxidation reactions for phenol and methanol are markedly separated. As can be seen in Fig. 3, the process of phenol oxidation is represented by anodic peak with maximum at 0.280 V, whereas methanol oxidation proceeds within a broad and multiple peak in the potential range of 0.65–0.8 V.

Contrary to the measurement performed in the electrolyte containing only methanol (Fig. 2), the anodic charge corresponding to methanol oxidation decreases gradually in successive cycles if both methanol and phenol are together present in the electrolyte (Fig. 3). This result is an indication that oligomer products generated on the EG surface due to phenol oxidation are responsible for the worsening of electrode activity toward both the phenol and methanol oxidation. It is likely that the consecutive reactions of phenol oxidation develop in parallel with methanol oxidation in the potential range 0.5–0.8 V. Although this question is yet unanswered, the results obtained allow the conclusion that the presence of methanol in phenol containing alkaline electrolyte gives rise to the preservation of the EG activity in cyclic oxidation of phenol oxidation. It has been found previously [20] that oligomer film generated on the EG surface is the main product of phenol oxidation. Based on the present results, one can assume that physicochemical features of the film are modified due to the reaction with methanol or the products of methanol oxidation.

Such an assumption is supported by the results of the TG analysis. The TG curves recorded for EG covered with oligomer film formed during the reaction of phenol oxidation in the electrolyte free and admixed with methanol are shown in Fig. 4. Difference between the two curves is apparently visible. As compared to the curve recorded for EG oxidized in the phenol/methanol mixture (Fig. 4a), TG curve corresponding to EG taking part in the process occurring in the absence of methanol (Fig. 4b) is distinctly shifted toward lower temperatures. These results show that oligomer formed on the EG surface with the participation of the products of methanol oxidation exhibits higher thermal resistance than oligomer in which such products are not incorporated. The TG curve recorded for the original EG (Fig. 4c) differs markedly from those presented in Fig. 4a,b. The main feature of the original EG is its higher thermal resistance. The host EG starts to decompose at a temperature of more than 600°C, when the samples of EG covered with oligomer film are almost completely combusted.

Besides the differences in thermal behavior of oligomer film deposited on the EG surface during electrochemical oxidation of phenol with and without the participation of the reaction of methanol oxidation, some differences in the chemical nature of the film are also noted. Tentative information is provided by the FTIR analysis. On the FTIR spectra presented in Fig. 5a,b, one can find bands assigned to oligomer products of phenol oxidation. The most important are the bands corresponding to ether bonds, which are observed in the region of 1,300–1,100 cm−1, aromatic carbon–carbon stretching vibrations in the region of 1,800–1,630 cm−1 [5, 7]. It is reasonable to assume that phenol oxidation occurring along with methanol oxidation results in a modification of chemical structure of the oligomer film. In comparison with EG oxidized in the absence of methanol (Fig. 5b) on the FTIR spectrum recorded for EG oxidized in the presence of methanol (Fig. 5a), some new effects, especially in the region of 1,500–800 cm−1, appear. Two of them are the bands at 1,088 and 1,053 cm−1, which are probably derived from the vibration of C–O pertaining to methanol molecule [28] or to double bridging methoxy species [29]. Other new bands can be observed at the regions of 1,400–1,300 and 1,000–800 cm−1. The former may be due to CH3 bending vibrations, whereas the latter to ether O–C–O bond [29]. Both bands might be related to the decomposition of methanol. As compared to the above-mentioned spectra a and b, a considerably different FTIR spectrum was recorded for EG before its use in the reaction of phenol oxidation (Fig. 5c). It is important from the point of view of phenol oxidation that within the region associated with the presence of oligomer, no distinct bands are observed on the spectrum for the original EG. Simultaneously, the bands’ characteristic of the original EG does not exist on the spectra for EG examined after phenol oxidation (Fig. 5a, b). The reason for such a behavior is the oligomer layer masking the EG surface. From the other hand, spectrum c presents some bands typical for exfoliated graphite arising from the carboxylic functional groups (1,660, 1,580 cm−1), and alcoholic or phenolic functional groups (1,115 cm−1), which are generated on the graphite surface during the process of thermal exfoliation [30, 31].

The XPS studies made for the EG electrodes after electrochemical oxidation of phenol with and without competitive oxidation of methanol provided further information about the chemical structure of the EG surface. The O1s spectra recorded for both investigated samples are essentially similar (Fig. 6d,e). The O1s spectra are composed of two peaks corresponding to C–OH and C=O groups [32, 33]. The only difference is that the binding energies (BE) for the sample examined in the methanol-admixed electrolyte are somewhat higher (BEC–OH=533.6 eV, BEC=O=531.9 eV) (Fig. 6e) compared to those of the sample examined in the alcohol-free electrolyte (BEC–OH=533.3 eV, BEC=O=531.6 eV) (Fig. 6d). The modifying influence of methanol on the chemical structure of the carbon surface examined after phenol oxidation can be deduced from the C1s spectra (Fig. 6a,b). Four peaks in the deconvoluted C1s spectra are common for both samples: peak A (BE=284.5 eV, graphitic carbon), peak B (BE=285.7–286.3 eV; carbon present in alcohol, polyphenol, or ether groups), peak C (BE=288.3–288.8 eV, carbonyl or quinone group), and peak D (BE=290.3–290.8 eV, shake-up satellite peaks due to π–π* transitions in aromatic rings) [32–37]. A new peak E (BE=287.1 eV) revealed for EG examined after the reaction in electrolyte containing a phenol/methanol couple can be ascribed to formate groups (Fig. 6b) [38–40]. Peak B for this sample with BE=285.7 eV, somewhat lower than that for EG used in a phenol/KOH electrolyte (BE=286.3 eV), might also be ascribed to methoxy groups [40–43]. The existence of methoxy and formate groups on the EG surface can be understood as the effect of methanol oxidation.

XPS carbon 1s spectra for EG covered with oligomer film formed during phenol electrooxidation in 0.5 M KOH containing 0.05 M phenol (a), a mixture of 0.05 M phenol/0.05 M methanol (b), for the original EG (c), XPS oxygen 1s spectra for EG covered with oligomer film formed during phenol electrooxidation in 0.5 M KOH containing 0.05 M phenol (d), a mixture of 0.05 M phenol/0.05 M methanol (e), and for the original EG (f)

Another consequence of the existence of methanol in a phenol/KOH solution is the almost twice-lower ratio of the graphitic peak to the other C1s peaks. The result indicates that the surface activity of graphite is enriched in oxygen groups produced due to alcohol oxidation. The XPS spectra recorded for the original EG are shown in Fig. 6c,f. The significant differences can be found on comparing these spectra with those obtained for EG covered with oligomer film (Fig. 6a,b,d,e). The deconvolution of the O1s region of the original EG (Fig. 6f) reveals a new peak C with BE=534.8 eV (corresponding to O–H in water molecule), not existing on the O1s spectra for electrochemically treated EG electrodes (Fig. 6d,e). Contrary to spectra for EGs covered with oligomer film, where peak A is dominating, in the case of the original EG, peak B (BEC=O=532.0 eV) is considerably higher than peak A (BEC–O=533.4 eV). The most pronounced difference between the XPS data obtained for the original EG and EG covered with the products of phenol oxidation is that the amount of oxygen in the surface composition of the original EG is much lower. The atomic ratio of O to C for not electrochemically treated EG is equal to 0.024, whereas the ratios for EGs examined in phenol-containing electrolyte with and without methanol are found to be 0.208 and 0.197, respectively. Such a low O to C ratio for original EG, which is in a good agreement with the literature data reported for exfoliated graphite [44], can be simultaneously associated with an increased amount of graphitic carbon. The above relations are clearly confirmed by the deconvoluted C1s spectra, shown in Fig. 6c, composed of five peaks. Four of them, with insignificant shifts in binding energies and different contribution to the integrated C1s components, exist on spectra for EGs covered with oligomer film (Fig. 6a,b). The four peaks in Fig. 6c are as follows: peak A (BE=284.4 eV, graphitic carbon), peak B (BE=286.3 eV, carbon present in alcohol), peak C (BE=288.4 eV, carboxyl), and peak D (BE=290.9 eV, shake-up satellite peaks due to π–π* transitions in aromatic rings [32–37, 44, 45]. A new peak F (BE=285.0 eV), corresponding to C–H [45] in hydrocarbons, is observed in Fig. 6c for the original EG. It is worth to note that the peak arising from the graphitic carbon (A) is considerably much pronounced for the original EG as compared to electrochemically treated samples of EG.

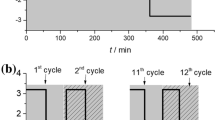

To evaluate how the lack of the methanol oxidation reactions influences the mechanism of phenol oxidation, the potential range was reduced to E R↔0.5 V (Fig. 7). Similar to voltammograms shown in Fig. 3, the intensity of anodic peak corresponding to phenol oxidation decreases suddenly after the first cycle. As shown in Table 1, the charges of anodic peaks of phenol oxidation measured in a shortened potential range for electrolyte admixed with methanol (Fig. 7) are close to those obtained in a wider range for electrolyte free of methanol (Fig. 1). From this comparison, one can infer that the products of methanol oxidation making oligomer film of phenol oxidation rich in active species are necessary to enhance the electrochemical activity of EG in the process of phenol oxidation.

To ascertain the role of methanol oxidation in the process of phenol oxidation, particularly to answer a question if an increased amount of intermediate products of methanol oxidation influences electrochemical behavior of EG during the subsequent cycles of phenol oxidation or not, the potential range was markedly extended. Figure 8 shows the CV curves in the potential range E R↔1.1 V obtained for EG examined in electrolyte containing equivalent amounts of phenol and methanol. From the comparison of these curves with those shown in Fig. 3, it is clear that the peak charges attained for the first three cycles in extended potential range are significantly lower (Table 1). A set of small anodic peaks observed in Fig. 8 above the potential of 0.6 V (more pronounced for the first cycle) indicates that the process of methanol oxidation has a multistep character. Some of the peaks disappear upon cycling, which suggests that the mechanism of methanol oxidation is altered at higher potential. Moreover, the intensity of anodic effects corresponding to methanol oxidation considerably decreases during the successive cycles. Based on the results obtained, the conclusion can be drawn that the rate of the EG inactivation during cyclic phenol oxidation decreases in different potential ranges according to the following order: E R↔0.5 V > E R↔1.1 V > E R↔0.8 V (Table 1).

Conclusions

On the basis of the results obtained, one can conclude that some amount of methanol added to alkaline solution of phenol markedly protects EG against inactivation by oligomer products of phenol oxidation. In the absence of methanol in the KOH/phenol electrolyte, the charge of phenol oxidation peaks decreases sharply on cycling, whereas in the presence of methanol the observed drop is considerably inhibited, especially after the first cycle. For the second cycle, the anodic charge of phenol oxidation in electrolyte admixed with methanol exceeds twice more than that measured in unmodified electrolyte. Electrochemical activity of EG during the consecutive cycles of phenol oxidation depends on the potential range. The highest improvement of electrochemical activity of EG was observed for cyclic phenol oxidation in the potential range of E R↔0.8 V. In this case, anodic charge attained for the fifteenth cycle of phenol oxidation in the electrolyte containing methanol additive is even slightly higher than that for the third cycle recorded in electrolyte free of methanol. The TG, FTIR, and XPS data showed that chemical structure of oligomer film formed on the EG surface with the participation of methanol and/or the products of its oxidation differs from that created achieved in electrolyte free of alcohol additive. The role of methoxy and formate groups, produced in the reaction of methanol oxidation, in the improvement of electrochemical activity of EG needs to be examined further.

References

Ayranci E, Conway BE (2001) J Electroanal Chem 513:100

Santos A, Yustos P, Durbán B, García-Ochoa F (2001) Catal Today 66:511

Renzi C, Guillard C, Herrmann J-M, Pichat P, Baldi G (1997) Chemosphere 35:819

Sá CSA, Boaventura RAR (2001) Biochem Eng J 9:211

Lapuente R, Cases F, Garcés P, Morallón E, Vázquez JL (1998) J Electroanal Chem 451:163

Gonçalves D, Faria RC, Yonashiro M, Bulhões LOS (2000) J Electroanal Chem 487:90

Eerskis Z, Jusys Z (2002) J Appl Electrochem 32:755

Kuramitz H, Nakata Y, Kawasaki M, Tanaka S (2001) Chemosphere 45:37

Ureta-Zañartu MS, Bustos P, Berrios C, Diez MC, Mora ML, Gutiérrez C (2002) Electrochim Acta 47:2399

Polcaro AM, Palmas S, Renoldi F, Mascia M (2000) Electrochim Acta 46:389

Johnson DC, Feng J, Houk LL (2000) Electrochim Acta 46:323

Kuramitz H, Saitoh J, Hattori T, Tanaka S (2002) Water Res 36:3323

Andreescu S, Andreescu D, Sadik OA (2003) Electrochem Commun 5:681

Zanta CLPS, Michaud P-A, Comninellis C, Andrade AR, Boodts JFC (2002) J Appl Electrochem 33:1211

Iniesta J, González-García J, Expósito E, Montiel V, Aldaz A (2001) Water Res 35:3291

Feng YJ, Li XY (2003) Water Res 37:2399

Cañizares P, García-Gómez J, Sáez C, Rodrigo MA (2003) J Appl Electrochem Part I 33:917

Skowroński JM, Krawczyk P (2000) Proc 51th Annual Meeting of International Society of Electrochemistry Warszawa (extended abstracts), p 218

Skowroński JM, Krawczyk P (2003) Eurocarbon (extended abstracts), Oviedo

Skowroński JM, Krawczyk P (2004) J Solid State Electrochem 8:242

Glarum SH, Marshal JH, Hellman MY, Taylor GN (1987) J Electrochem Soc 134:81

Gottrell M, Kirk DW (1992) J Electrochem Soc 139:2736

Gottrell M, Kirk DW (1993) J Electrochem Soc 140:903

Ežerskis Z, Jusys Z (2001) J Appl Electrochem Part I 31:1117

Zhang H (2002) Chem Eng J 85:81

Poon M, McCreery RL (1986) Anal Chem 58:2745

Skowroński JM, Jurewicz K (1991) Synth Met 40:161

Orozco G, Pérez MC, Rincón A, Gutiérrez C (2000) J Electroanal Chem 495:71

Zawadzki J, Azambre B, Heintz O, Krztoñ A, Weber J (2000) Carbon 38:509

Ramesh P, Sampath S (2001) Analyst 126:1872

Weng W, Chen G, Wu D, Lin Z, Yan W (2003) Synth Met 139:221

Biniak S, Szamański G, Siedlewski J, Świątkowski A (1997) Carbon 35:1799

László K, Tombácz E, Josepovitz K (2001) Carbon 39:1217

Darmstadt H, Roy C, Kaliaguine S, Choi SJ, Ryoo R (2002) Carbon 40:2673

Świątkowski A, Pakula M, Biniak S, Walczyk M (2004) Carbon 42:3057

Okpalugo TIT, Papakonstantinou P, Murphy H, McLaughlin, Brown NMD (2005) Carbon 43:153

Su F, Lv L, Hui TM, Zhao XS (2005) Carbon 43:1156

Harikumar KR, Rao CNR (1997) Catal Letters 47:265

Edmundts A, Pirug G, Werner J, Bonzel HP (1998) Surf Sci 410:L727

Kulkarni GU, Rao CNR (2003) Top Catal 22:183

Werner H, Herein D, Schultz G, Wild U, Schlögl (1997) Catal Letters 49:109

Bukhtiyarov VI, Prosvirin IP, Tikhomirov EP, Kaichev VV, Sorokin AM, Evstigneev VV (2003) React Kinet Catal Lett 79:181

Prosvirin IP, Tikhomirov EP, Sorokin AM, Kaichev VV, Bukhtiyarov VI (2003) Kinet Catal 44:724

Ramesh P, Bhagyalakshmi S, Sampath S (2004) J Colloid Interface Sci 274:95

Blyth RIR, Buqa H, Netzer FP, Ramey MG, Besenhard JO, Golob P, Winter M (2000) Appl Surf Sci 167:99

Acknowledgement

This work was financially supported by the grant DS 31-084/05.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Skowroński, J.M., Krawczyk, P. Improved electrooxidation of phenol at exfoliated graphite electrodes. J Solid State Electrochem 11, 223–230 (2007). https://doi.org/10.1007/s10008-005-0092-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-005-0092-9