Abstract

Exfoliated graphite (EG) was modified by a two-stage process consisting of electrochemical oxidation followed by the thermal treatment. Within the former one, the process of re-intercalation of H2SO4 into the EG by linear sweep voltammetry was carried out. Thus, obtained re-intercalated EG underwent heat treatment at 800 °C in order to synthesize re-exfoliated EG (re-EG). The electrochemical features of the re-EG were examined in the model process of phenol electrooxidation carried out by cyclic voltammetry technique in alkaline solution with and without phenol addition. Taking into account the anodic charges as a main criterion of electrochemical activity, it was found that the modification of EG caused over twofold improvement of its electrochemical activity. This behavior is related with the changes within the chemical composition of modified EG surface and on much smaller scale with the modification of its structure. The degree of electrochemical activity improvement depends on the conditions under which the processes of re-intercalation and re-exfoliation were performed. The results of Fourier-transform infrared spectroscopy (FTIR) and X-ray photoelectron spectroscopy (XPS) analysis supported by the data of the Brunauer-Emmett-Teller (BET) surface area and scanning electron microscope (SEM) observations allow an understanding of the physicochemical properties of re-exfoliated EG and enhancement of its electrochemical activity.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The exfoliation of graphite intercalated compounds (GICs) may lead to the formation of exfoliated graphites (EGs). As a result of this process, the crystal structure of graphite may be significantly changed. The graphene layers are separated and partially deformed; in consequence, the volume of graphite flakes significantly increases along the c-axis, even 300 times as compared to the starting material. The level of graphite expansion depends on many factors; among them, the type of GIC used for exfoliation and employed method should be recognized as the most important. The processes of exfoliation are commonly realized by thermal [1], chemical [2], or electrochemical method [3]. EG has interesting physicochemical features, such as high specific surface area, developed porous structure, low density, high concentration of edges and surface defects, high thermal and chemical stability, and high adsorption capacity. The above mentioned properties of EG enable its application in many technical fields, for example in flexible graphite foil production [4], as an oil sorbent [5] and plastic filler [6]. Exfoliated graphite is also used as a catalyst support [7], electrode material in fuel cells [8], supercapacitors [9], and for hydrogen sorption [10]. The features of EG can be easily modified by oxidation of its surface using chemical [11], thermal [12, 13], or electrochemical methods [14]. As a result of those modifications, new oxygen functional groups can be created on EG surface increasing the electrochemical activity in oxidation processes.

From the literature data, it is known that EG can be also re-intercalated leading to the formation re-intercalated exfoliated graphite (re-inEG). This process is commonly performed by chemical treatment of the previously formed exfoliated graphite [15–17]. During the re-intercalation, the intercalate penetrates through the free spaces between more or less deformed graphene layers of EG giving re-inEG. Thus, formed re-inEG undergoes re-exfoliation by heat treatment to be transformed into the re-exfoliated exfoliated graphite (re-exEG). The final product of this two-step modification can be recognized as an intermediate product of the process of graphene-sheets preparation [16]. The re-inEG being the product of chemical re-intercalation of sulphuric acid into the EG was rapidly re-exfoliated by heat treatment in 800–900 °C thus forming re-exEG. Within the final step, the suspension of re-exEG in N,N-dimethylformamide (DMF) was ultrasonicated to form graphene-sheets [16]. From our previous work, it is known that the electrochemical activity of re-exEG synthesized on the way of chemical re-intercalation of sulfuric acid into the EG followed by thermal re-exfoliation was significantly higher compared to the pristine EG [15]. This effect was reached due to increased concentration of the surface oxygen functional groups as well as a development of the specific surface area. Tanaike and co-workers [17] have studied the multiply process of bromine intercalation. For this purpose, graphite was treated with bromine vapors yielding Br-GIC; within the subsequent step, the obtained compound underwent exfoliation. The both processes were carried out in vacuum. After the sixth exfoliation, volume of the gathered re-exEG was 250 times higher as compared to the started graphite.

Electrochemical activity of re-exEG can be examined, for example, in the model process of phenol electrooxidation. Phenol can be completely oxidized to the final products, water and CO2, by electrochemical methods [13, 18–21]. A variety of soluble intermediates such as benzoquinone, hydroquinone, fumaric, and maleic acids are formed during the process of phenol electrooxidation. It should be emphasized that during the phenol oxidation, the unwanted behavior associated with the oligomeric film formation is also taking place. Because of its features such as poor solubility, low electrical conductivity, and insufficient electrochemical activity, oligomeric products inhibit the phenol oxidation; in consequence, the formation of the final products is difficult to reach [18–21].

The aim of the present work was to study the process of two-step modification of exfoliated graphite leading to the formation of re-exfoliated EG. The physicochemical properties of re-exfoliated EG were studied by Brunauer-Emmett-Teller (BET), X-ray photoelectron spectroscopy (XPS), and Fourier-transform infrared spectroscopy (FTIR) analysis, whereas its electrochemical properties were investigated in the model process of phenol electrooxidation realized by cyclic voltammetry method.

Experimental

Procedure of EG modification

EG being the product of thermal exfoliation of graphite intercalation compound with sulfuric acid (H2SO4-GIC) was prepared by two-stage synthesis. Within the first one, the graphite intercalation compound with sulfuric acid (H2SO4-GIC) was prepared on the way of anodic oxidation of graphite powder (ranging in diameter from 32 to 71 μm) realized by galvanostatic method in 18 M H2SO4. During the next step, H2SO4-GIC was thermally exfoliated in a muffle furnace at the temperature of 800 °C in air for 4 min giving exfoliated graphite. Such prepared EG was subjected to the two-stage modification composed of re-intercalation and re-exfoliation processes. Within the first step, EG underwent re-intercalation by anodic oxidation in 18 M H2SO4 using two potential ranges 0.675 and 1.2 V. The process was performed by linear sweep voltammetry (LSV) with a scan rate equal to 0.1 mV s−1. Electrochemical re-intercalation was carried out in a three-electrode system with EG as a working electrode and Hg/Hg2SO4/1 M H2SO4 (0.674 V vs. NHE) as a reference electrode. Platinum wire was playing a role of counter electrode. The mass of working electrode was equal to 400 mg. In order to facilitate the penetration of electrolyte through the structure of EG, before the starting the re-intercalation process, EG was ultrasonicated for 10 min. During the second step of modification, previously formed re-intercalated EG was heat treated at the temperature of 800 °C for 4 min in air yielding re-exfoliated EG being the final product of aimed modification. Depending on upper potential of the re-intercalation process, the synthesized samples were denoted as re-EG0.675 and re-EG1.2.

To give the answer if the re-intercalation and re-exfoliation of EG can be recognized as useful methods enabling multiple improving of EG activity, the modification operations were two times repeated. Each modification repetition consists of re-intercalation and re-exfoliation processes carried under above mentioned conditions. The obtained samples were denoted as 2re-EG0.675, 2re-EG1.2 (after the second re-exfoliation), and 2re-EG0.675, 2re-EG1.2 (after the third re-exfoliation).

Material analysis

The changes within the specific surface area of EG due to its two-step modification were determined from the N2 adsorption isotherms measured at 77 K with ASAP 2010 apparatus. Morphological properties of re-exfoliated EG were studied by scanning electron microscopy (SEM) with a S-3400N Hitachi microscope using acceleration voltage of electron beam adjusted to 15 keV. The chemical composition of re-EG surface was investigated by XPS and FTIR analysis. XPS spectra were recorded with an ESCALAB 210 spectrometer using non-monochromatized Al Kα radiation (1486.6 eV) operated at 15 kV. The binding energy scale was corrected by referring to the graphitic peak at 284.5 eV. FTIR measurements were done with a BRUKER model 113 V IR spectrometer using KBr technique.

Electrochemical activity

Electrochemical activity of the re-exfoliated EG was studied in 0.1 M phenol solution in 0.5 M KOH by cyclic voltammetry method. The process of phenol electrooxidation was conducted within the potential range from the rest potential of electrode (E R) to 0.8 V with a scan rate equal to 0.1 mV s−1. Besides the XPS and FTIR analysis, the oxidation stage of re-exfoliated EG was also examined by electrochemical method. In this case, the cyclic voltammetry measurements were carried out in 0.5 M KOH solution within the potential range −0.95 ↔ 0.8 V using a scan rate equal to 0.1 mV s−1. In order to reveal the reduction reactions arising from the functional groups originally exhibited on the electrode surface, the measurements were started from E R towards the less positive potentials. The electrochemical investigations were carried out in the three-electrode system composed of re-EG as a powder type working electrode and Hg/HgO/0.5 M KOH (0.117 V vs. NHE) as a reference electrode. The details of electrode preparation as well as the construction of electrochemical cell can be found in our previous works [11, 13, 15, 21]. In each measurement, the mass of re-EG electrode was equal to 30 mg. All electrochemical investigations were realized using AUTOLAB potentiostat-galvanostat (PGSTAT30 model).

Results and discussion

Modification of EG

The two-stage modification of EG leading to the formation of re-exfoliated EG was composed of two processes: re-intercalation and re-exfoliation. The former process comprises anodic oxidation of EG in 18 M H2SO4. Voltammetric curve depicting the process of EG re-intercalation is shown in Fig. 1. As can be seen, the curve can be divided into two parts. Within the first one, the asymmetric wave with numbers of peaks is observed in the potential range of 0.2–0.675 V. The appearing peaks most likely illustrate filling with intercalate of successive spaces between the damaged graphene layers of EG. The second part of the regarded curve observed between the potentials 0.675 and 1.0 V comprises the huge anodic peak probably associated with the overoxidation of re-intercalated EG. In order to explain the influence of the oxidation stage of re-intercalated EG on the properties of final product (re-exfoliated EG), during the second part of modification were selected two samples of re-intercalated EG which were prepared using the upper potential of 0.675 and 1.2 V. Within the final part of the investigated modification, the previously formed re-intercalated EGs underwent thermal exfoliation yielding re-exfoliated EGs (re-EG0.675 and re-EG1.2).

The measurements of specific surface area and SEM observations of re-exfoliated EG

The calculation of specific surface area of the re-exfoliated EGs has partially confirmed our expectations associated with the modification of EG structure. However, for re-EG0.675 (sample obtained through the re-intercalation with the finishing potential equal to 0.675 V), BET surface slightly decreased (29.1 m2 g−1) as compared to the original EG (30.5 m2 g−1). On the other hand, the BET surface area for sample re-EG1.2 increased to 33.5 m2 g−1. Almost 10 % increase in specific surface area of EG due its two-step modification indicates that the re-introduction of intercalate into the damaged graphitic structure followed by its thermal decomposition and evaporation insignificantly change the porous structure of re-exfoliated EG.

The upper potential of re-intercalation enables the formation of the re-intercalated EG of a higher concentration of intercalate. Therefore, it can be assumed that higher amount of intercalate undergoes transformation due to re-exfoliation process; in consequence, the most pronounced modification of EG structure occurs. The abovementioned assumption agrees with the comparison of BET surface area of both investigated samples (re-EG0.675 and re-EG1.2).

SEM micrographs for original EG and EG after its two-step modification are shown in Fig. 2. As can be seen, the images are very similar, and there is no significant difference between the morphology of original EG (Fig. 2a) and sample EG0.675 (Fig. 2b). On the other hand, some differences can be found by comparing the micrograph for original EG (Fig. 2a) and for sample prepared through the re-intercalation process performed up to the potential of 1.2 V (sample re-EG1.2) (Fig. 2c). It seems that due to re-exfoliation process, the surface of re-EG1.2 is enriched in defects and edges. These observations coincide with the structural changes of the investigated samples.

XPS measurements

Deconvoluted XPS spectra of O 1s and C 1s regions recorded for original EG are shown in Fig. 3, whereas for modified EG are depicted in Fig. 4. The chemical composition of EG surface gathered from the XPS analysis is given in Table 1. The total amount of surface oxygen considerably increases due to EG modification (Table 2). Peak A on the O 1s spectra is the only signal which intensity significantly decreased due to two-stage modification of EG (Figs. 3b, 4a, c). This peak most likely corresponds to the chemisorbed water or oxygen on the surface of EG [22]. As can be seen from Table 1, the two-step modification of EG resulted in significant increment in concentration of C=O bonds pertaining to ester (peak C) and carboxyl groups (peak D) [22]. The concentration of the ester groups is of about 120 % for re-EG0.675 and 75 % for re-EG1.2 higher as compared to the original EG. While an increase in carboxylic groups concentration is more pronounced, it should be emphasized that the amount of C–O bonds (peak B) [24, 25] also significantly increased due to two-step modification. The abovementioned observations are consistent with results of C 1s analysis (Fig. 4b, d). By comparing to the original EG (Fig. 3b), the intensity of peak C associated with C=O bonds in carbonyl groups as well as peak D assigned to C–O bonds slightly increased for modified samples (Fig. 4b, d) [22–25]. New peak at 289.3 eV (peak B) can be observed on C 1s spectra for re-EG0.675 and re-EG1.2 samples (Fig. 4b, d). Most likely, this peak corresponds to C=O bonds in carboxyl or ester groups [22, 24, 25], which are probably created on EG surface during the re-exfoliation process. In contrast, the concentration of graphitic carbon (peak E) as well as π-π* satellite (peak A) significantly decreased due to modification EG (Table 1) [24, 25].

A comparison of Cox/Cgr ratios of carbon atoms in different oxide groups (peaks B, C, and D) and graphitic carbon (peaks A and E) for modified samples re-EG1.2 (0.213) and re-EG0.675 (0.197) and original EG (0.428) shows that the oxidation degree of re-EG surface is considerable increased duo to its two-step modification. The analysis of C 1s spectra indicates that the surface of re-EG1.2 is much more enriched in bonds between C and O atoms as compared to re-EG0.675 (Table 1).

FTIR measurements

FTIR analysis provides an additional information on the changes within the chemical composition of EG surface due to its two-step modification. Figure 5 shows FTIR spectra recorded before (sample EG) and after (samples re-EG0.675 and re-EG1.2). For modified samples, one can observe new bands appearing at 1725, 1580, and 1120 cm−. According to the literature data, band at 1725 cm−1 can be assigned to the stretching vibrations of C=O bonds, whereas the signal at 1580 cm−1 likely corresponds to the aromatic rings coupled to carbonyl groups [23]. The broad band within the frequency range of 1150–1050 cm−1 is associated with the appearance of C–O–C and C–O bonds [23]. New bonds observed on FTIR spectra for modified EG confirms that the surface of EG is significantly modified duo to its two-stage treatment.

The difference in XPS and FTIR results for the two types of re-EG indicates that the amount of intercalate which is introduced into the EG structure during the re-intercalation process partially influences on the amount of oxygen functionalities created during the process of EG re-exfoliation.

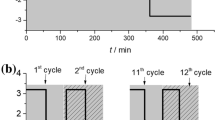

Electrochemical measurements of modified EG in the electrolyte free of phenol

An additional information on chemical composition of EG due to its modification is provided from the electrochemical measurements performed in electrolyte free of phenol. Cyclic voltammograms recorded in 0.5 M KOH for samples re-EG0.675 and re-EG1.2 are shown in Figs. 6 and 7, respectively. To observe the effects arising from the reduction reaction of oxygen functional groups originally present on EG surface, the measurements were started from the rest potential of electrode (E R) towards the less positive potentials. Instantly after starting the measurement, cathodic peaks associated with the reduction reactions of surface functionalities can be observed. Their intensities as well as the positions are dependent on the type of electrode. For sample re-EG0.675 (Fig. 6), three cathodic peaks appear at the potentials of −0.21, −0.36, and −0.52 V. In the case of sample re-EG1.2 (Fig. 7), the first cathodic peak is less pronounced and shifted towards the less negative potentials (−0.16 V) as compared to the sample re-EG0.675 (Fig. 6). Besides the mentioned peak, the rest of cathodic effects recorded during the first cycle for sample re-EG1.2 are significantly more intensive then that noted for sample re-EG0.675 (Fig. 6). Taking into account the assumption that the intensity of cathodic peaks are in coincidence with the concentration of the surface functionalities, the estimation of oxidation stage of examined samples can be possible to perform. Basing on the abovementioned assumption, it can be stated that the oxidation level of re-EG1.2 surface is much higher than the surface of re-EG0.675. This conclusion is consistent with the results gained from the XPS analysis.

Electrochemical oxidation of phenol on modified EG

The CVs depicting the process of electrochemical oxidation of 0.1 M of phenol dissolved in 0.5 M KOH on the electrode made of original EG are shown in Fig. 8. For the first cycle, a small prepeak appears at the potential of 0.18 V, whereas at around 0.38 V, one can observe a huge anodic peak representing reaction of phenol oxidation. Electrochemical activity of EG dramatically declines after the first cycle of the conducted process. For the second cycle, the charge of anodic peak ascribed to the phenol oxidation is of 42 % lower as compared to the first cycle (Table 2). The huge decrease in electrochemical activity is caused by the appearance of an oligomeric film covering the surface of the electrode [11, 13, 15]. The oligomer layer being the product of incomplete oxidation of phenol hinders an access of electrolyte into the active surface of EG electrode thus results in inhibition of the conducted process (Table 2).

Figures 9 and 10 present CVs recorded during the electrochemical oxidation of phenol on re-exfoliated EG prepared through the process of re-intercalation of H2SO4 into the EG performed up to the potential of 0.675 and 1.2 V, respectively. To emphasize the difference in electrochemical activity demonstrated by the investigated samples during the first cycle of phenol electrooxidation, the additional comparison of voltammograms is shown in Fig. 11.

As shown in Table 1, the re-exfoliation process has a major impact on the activity of the EG towards the process of phenol electrooxidation. For the first cycle, the charge of anodic peak associated with the phenol oxidation on electrode made of re-EG0.675 (Fig. 9) is almost 1.8 times higher than that for original EG (Fig. 8). For the consecutive cycles of phenol oxidation, the electrochemical activity of re-exfoliated EG is still considerably higher compared to the starting EG. Taking into account the fact that the specific surface area of the sample re-EG0.675 is closed to the BET surface area calculated for the original EG, it is plausible that the increased concentration of oxygen functional groups for modified EG is responsible for the improvement of its electrochemical activity. Surprisingly, sample re-EG1.2 (Fig. 10) exhibits slightly lower electrochemical activity than this observed for sample re-EG 0.675 (Fig. 9). Charge of phenol oxidation peak is for re-EG 1.2 of around 9 % lower as compared to the sample re-EG 0.675 (Table 2). It should be emphasized that on cycling, the discrepancy in electrochemical activity is less pronounced.

Electrochemical oxidation of phenol on the multi-modified EG

To acquire information if the re-exfoliation of EG can be recognized as useful method enabling multiple increasing of EG activity, the modification operations were two times repeated. Each modification repetition consists of re-intercalation followed by the re-exfoliation carried out under previously applied conditions. The obtained samples were denoted as 2re-EG0.675, 2re-EG1.2 (after the second re-exfoliation) and 2re-EG0.675, 2re-EG1.2 (after the third re-exfoliation). The obtained CVs are not presented, whereas the charge densities of phenol oxidation peaks are given in Table 2.

From the data shown in Table 2, it is clear that the electrochemical activity of double and triple modified exfoliated graphite is still considerably higher compared to the starting material. However, the level as well as the stability of electrochemical activity of the multi-modified EG depends on the upper potential applied during the re-intercalation process. For the first cycle, the charge densities associated with the peak of phenol oxidation for all modified samples dominate over the charge density calculated for original EG. It is worth to note that the described difference in charge density is markedly reduced on cycling. Such tendency can be observed for the sample which was modified through the process of re-intercalation performed up to the potential of 0.675 V. The charges calculated for the forth cycle for samples 2re-EG0.675 and 3re-EG0.675 are very closed to this for original EG. On the other hand, the charges for samples prepared by the re-intercalation occurred up to the potential of 1.2 V (2re-EG1.2 and 3re-EG1.2) are still significantly higher compared to the starting material. By comparing the charge densities of the phenol oxidation peak for EG after the single re-exfoliation (re-EG0.675 and re-EG1.2) with that noted after the second (2re-EG0.675 and 2re-EG1.2) and third (3re-EG0.675 and 3re-EG1.2) re-exfoliation processes, it is seen that the repetition of the modification has a different influence on the electrochemical activity of both types of EG electrodes. In the case of EG prepared by the re-intercalation performed up to the potential 0.675 V, the electrochemical activity decreased with numbers of re-exfoliation cycles, whereas the regarded activity for the samples synthesized through the re-intercalation up to 1.2 V insignificantly increased. It should be emphasized that there is no linearity in the abovementioned increase in peak charges. The scale of activity improvement strongly depends on the numbers of modification repetitions as well as on the cycle of phenol electrooxidation. Such a discrepancy in stability of electrochemical properties demonstrated by the multiple modified EG during the process of phenol electrooxidation likely is related with the invasive character of re-intercalation and re-exfoliation processes. It can be assumed that due to the repetitive intercalation of sulfuric acid into the EG and subsequent thermal exfoliation, graphitic structure can be partially damaged influencing on reduction of not only its electrochemical but also its mechanical stability.

Conclusions

The obtained results indicate that the two-step modification of exfoliated graphite (EG) composed of its electrochemical oxidation in concentrated H2SO4 followed by the heat treatment in air leads to the formation of re-exfoliated EG. Electrochemical activity of EG towards the process of phenol electrooxidation has been considerably improved due to its two-step modification. Current charges associated with the phenol oxidation peak are for re-exfoliated EG of about twice higher as compared to the starting EG. The results of XPS and FTIR analysis indicate that the observed improvement of electrochemical activity is caused by the changes in chemical composition of EG surface. During the aimed modification, the formation of surface oxygen functionalities containing C–O as well as C=O bonds occurs. The O/C atomic ratio, indicating the degree of surface oxidation, calculated from the XPS spectra for modified EG is significantly higher as compared to the original EG. The oxidation level of the re-exfoliated EG depends on the upper potential applied during the of re-intercalation process. It was assumed that anodic oxidation of EG in 18 M H2SO4 performed up to the potential 1.2 V leads to the overoxidation of EG. In consequence, the amount of C–O and C=O bonds increased. Moreover, the SEM observation and BET surface calculation for re-exfoliated EG have revealed that the re-exfoliation process induced some morphological changes as well as modification of EG structure. The latter effect is illustrated by the 10 % developing of its BET surface area. The repetitions of the re-intercalation and re-exfoliation processes result only insignificant improvement of EG electrochemical activity for the sample prepared by re-intercalation performed up to the potential 1.2 V.

References

Chung DDL (1987) J Mater Sci 22:4190

Lee JH, Shin DW, Makotchenko VG, Nazarov AS, Fedorov VE, Kim YH, Choi J, Kim JM, Yoo J (2009) Adv Mater 21:1

Bourelle E, Cloude-Montigny B, Metrot A (1998) Mol Cryst Liq Cryst 310:321

Yakovlev AY, Finaenov AI, Zabud’kov SL, Yakovleva EV (2006) Russ J Appl Chem 79:1741

Toyoda M, Inagaki M (2000) Carbon 38:199

Zheng W, Wong S (2003) Compos Sci Technol 63:225

Li W, Han C, Liu W, Zhang M, Tao K (2007) Catal Today 125:278

Bhattacharya A, Hazra A, Chatterjee S, Sen P, Laha S, Basumallick I (2004) J Power Sources 136:208

Mitra S, Sampath S Electrochem Solid-State Lett 7:A264

Lueking AD, Pan L, Narayanan DL (2005) J Phys Chem B 109:12710

Krawczyk P (2011) Chem Eng J 172:1096

Fukushima H, Drzal LT, Rook BP, Rich MJ (2006) J Therm Anal Calorim 85:235

Skowroński JM, Krawczyk P (2004) J Solid State Electrochem 8:442

Ramesh P, Sampath S (2001) Analyst 126:1872

Krawczyk P, Skowroński JM (2010) J Appl Electrochem 40:91

Dhakate SR, Chauhan N, Sharma S, Tawale J, Singh S, Sahare PD, Mathur RB (2011) Carbon 49:1946

Tanaike O, Yamada Y, Kodama M, Miyajima N (2012) J Phys Chem Solids 73:1420

Gottrell M, Kirk DW (1992) J Electrochem Soc 139:2736

Boudenne JL, Cerclier O, Galéa J, Bianco P (1998) J Electrochem Soc 145:2763

Martinez-Huitle CA, Ferro S (2006) Chem Soc Rev 35:1324

Skowroński JM, Krawczyk P (2007) J Solid State Electrochem 11:223

Świątkowski A, Pakuła M, Biniak S, Walczyk M (2004) Carbon 42:3057

Terzyk AP (2001) Colloids Surf A 177:23

László K, Tombácz E, Josepovits K (2001) Carbon 39:1217

Okpalugo TIT, Papakonstantinou P, Murphy H, McLaughlin J, Brown NMD (2005) Carbon 43:153

Acknowledgments

This work was financially supported by the grant of the Poznan University of Technology No. 03/31/DSPB/0292.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Krawczyk, P., Gurzęda, B. Electrochemical properties of exfoliated graphite affected by its two-step modification. J Solid State Electrochem 20, 361–369 (2016). https://doi.org/10.1007/s10008-015-3051-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-015-3051-0