Abstract

Global businesses are leveraging their analytical capabilities to develop competence over others. This study uses Organization Information Processing Theory (OIPT) in context to explain the relationship between the smart supply chain and information system flexibility to achieve an overall greater supply chain flexibility. Also, this shows that correct deployment of information processing leads to better diffusion of information throughout the system necessary for making the supply chain more adaptive in nature. This study extends the application of OIPT theory and a better understanding of analytical data processing and theoretically grounded guidance to managers in order to achieve a higher degree of flexibility in dynamic conditions. The Partial Least Square Method based on Structural Equation Modeling is used to empirically test the theoretical framework. Results from the analysis of 150 respondents indicate the strong relationship between the components of the smart supply chain and information systems agility. The research shows a positive relationship between the characteristics of smart supply chain management and modules of information system flexibility which leads to the achievement of a high level of supply chain flexibility.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

As businesses are expanding their boundaries to global operations, they are simultaneously thriving to niche down their technological competence. In the era of Factories 4.0 (Zhou et al. 2015) most firms are competing through their supply chain and aspiring to make it inherently smarter than ever before. This has created a need to nurture an understanding of the critical parameters of smart operations. We can use previous research that investigates the new extent of connectivity between the value chain and information system flow. The current requirement has motivated scholars to investigate the new characteristics of smart supply chains. Smart supply chains are engineered to be agile and customized to be adaptive, which makes them responsive when there are challenges and supply chain disruption (Butner 2010). Supply chain flexibility is studied but mostly in the absence of a theory-driven approach or only with a resource-based view (Manders et al. 2017). Pushing the boundaries in outbound directions, companies are looking for concrete evidence of connectivity between the value chain (which is inherently smart in its nature) and information flow (which should be flexible to comply with the operational pace).

Previous research (Dubey et al. 2017a) has shown the relationship between the sustainable supply chain and new age information technologies through strategic supplier collaboration. The relationship between the smart supply chain and information system flexibility is still unknown regarding the extent of their effect when directly proportional. Information asymmetry needs a flexible structure and a proper carrier to flow in an organization. Past studies explicitly convey the importance of digital infrastructure to achieve higher levels of responsiveness (Lee 2004) and an agile supply chain structure which addresses uncertain market conditions. These digital structures facilitate the transformation of colonial boundaries into smart cities. Chatterjee et al. (2018) showcases the importance of big data sources such as the Internet of Things (IoT) in the development of smart cities with the deployment of smart machines.

The current study is dedicated to investigating the direct relationship between the characteristics of the smart supply chain and information system flexibility in the presence of an organization’s information processing capabilities. In their research, Manders et al. (2017) highlight the missing link between supply chain flexibility and operational strategy. Overall supply chain flexibility can be acquired through the systematic and uniform processing of information throughout the system. According to Galbraith (1973, 1977), higher levels of information system flexibility can be achieved by avoiding overload of information on hierarchical communication channels. Higher frequency of information processing results in minimizing traffic at the hierarchical level of decision making and increasing the responsiveness of the decision system (Peng et al. 2014). With the multi-objective of the current piece of work, it also helps to consider information agility as one of the major drivers in the transformation of land boundaries into smarter cities. Past studies (Janssen and van den Hoven 2015; Dwivedi et al. 2017) demonstrate the contribution of big open linked data (BOLD) in bringing innovation to the system which leads to the development of smart cities. Galbraith (1977) emphasizes on this point that firms should develop capabilities to analyze information and that only after investigating the vitality of this information should they invest in the technological capacity required for information processing at organizational level, otherwise they should develop ‘mechanistic’ methods. Insights gained through expanded information processing capacity help to reduce uncertainty, especially in the case of market volatility, and the operational tasks are highly inter-related. Closs et al. (2011) consider environment as one of the critical dimensions for creating flexibility in operations.

This study finds its scope in developing a strong relationship between the smart value chain and information system flexibility to achieve operational excellence, but also in the environmental capabilities of an organization in its information processing. Also, this research further tries to address the limitations (Manders et al. 2017) and will be conducted in the context of a theory-driven approach.

2 Research Objective

This study examines the relationship between and the importance of the characteristics of the smart supply chain and information system agility from the perspective of organization information processing theory to achieve supply chain flexibility. This study also examines the effect of the customer and supplier relationship on achieving a high level of supply chain flexibility. The paper is structured in five sections and follows a set of sequence. Section (2) provides an understanding of existing literature, presented in a systematic manner. Next, section (3) comprehensively discusses the development of the theoretical model according to the research objective by addressing the gap in the existing literature. Section (4) investigates the proposed model and validates it using research tools. Section (5) comprehensively discusses analysis output supported by quantitative figures. Section (6) opens up new possibilities for future research which this work cannot address due to limitations.

3 Theoretical Background

3.1 Organizational Information Processing Theory (OIPT)

Organizations must know how to organize and use their information effectively, which enables them to make decisions involving a high level of uncertainty and risk. According to Galbraith (1973, 1977), a firm should be aware of its information resources and the costs associated with them. The processing capability of a firm is considered to be an asset which can be utilized to compete in the market. But the cost associated with the information and its processing is high, which results in a high risk for the organization if underutilized. Galbraith (1973, 1977) suggests that if an organization does not have means to process the information in the right manner, it should use “mechanistic” methods, and if it wants to optimize the information flow, it needs to nurture and build the technological capacity process and analyze the required information in time. Supporting the argument, Janssen et al. (2012) advocates the use of open data for cost optimization and clarifies the myths associated with this. For instance, Trentin et al. (2012) propose, as cited in Liu et al. (2006), that an organization may enhance its cost-effectiveness and responsiveness of product customization through use of the cross-training theory studies by Hyer and Brown (1999), by means of which operators visually scan all the workstations to respond quickly to hard-pressed situations. This approach was coined as cellular manufacturing.

According to the market environment and organizational orientation, the firm should take advantage of information processing by deploying it in their vertical and horizontal hierarchy of process. This leads to a more agile and adaptive system.

Intelligent information processing leads to smart supply chain decisions allowing an organization to remove problems such as buffer-stock and underutilized inventories, and helps in the decision of capacity planning. Organizations should monitor the frequency of information processing and need to maintain a balance between the inflow and outflow of information in the system (Bensaou and Venkatraman 1995; Peng et al. 2014). Information processing leads to system flexibility which directly reduces response time and helps to achieve higher service levels (Srinivasan and Swink 2017).

3.2 Smart Supply Chain Management

The Council of Logistic Management coined the term Supply Chain Management more than two decades ago (Cooper et al. 1997). Many authors have defined the supply chain in different contexts. In simple terms, a supply chain is a systematic set of monitored activities starting from procurement of raw materials and ending with the delivery of finished goods (Council of Supply Chain 2005). The new age supply chain is expected to be smart enough to respond to abrupt changes in fluctuating market conditions. Koo et al. (2017) while studying the tourism industry advocated that Information & Communication technology (ICT) transforms the supply chain into a smarter version. El-Kassar and Singh (2018) put emphasis on green technological innovations to create a smart supply chain in order to gain a competitive edge and performance. With the increasing complexity of the supply chain, firms are now investing more in creating a siloed (connecting physical capacity with digital infrastructure) supply chain structure. Previously, the supply chain leg of a firm was treated as the operational activity required to fulfil a particular task. Now, in the era of big data and multi-channel information flow, firms are nurturing their supply chains as a competitive resource. Firms are taking bold strategic decisions in their technological investments. Kaur and Singh (2017) explain the importance of flexible but sustainable supply chain activities. Butner (2010) explicitly explains the characteristics of the smart supply chain while keeping in mind its agile and sustainable nature.

3.2.1 Instrumented Supply Chain

One of the key components for achieving agility in the supply chain is the use of instruments. Since technology costs are coming down, newer specialized machines are being deployed into the system which sense information in a minimal expected time. Butner (2010) strongly advocates the need to create visibility in the supply chain by deploying cost-efficient sensor-based technologies. These help the supply chain to experience the events of all operational activities occurring in the real-time flow. As the cost of acquiring and serviceability of sensor-based technology reduces, firms are engaging more in maximum leveraging of the specific features of a wide variety of sensor-based technologies, such as IOTs, to drive various service orientation and production businesses. (Fescioglu-Unver et al. 2015; Ben-Daya et al. 2017).

3.2.2 Interconnected Supply Chain

A supply chain is a consolidation of interconnected events occurring to complete a specific task. The inherent nature of interconnections makes the supply chain more viable to connect on a greater scale of functionality. Multi-echelon supply chain structures are interconnected and are not mutually exclusive. Their functionality exerts an effect on other agents in the echelon. Inter-operability improves by deploying SCOR (APICS 2015) when designing the supply chain (Stephens 2001) in a holistic view. For a higher-level performance, organizations must coordinate and integrate worldwide supply chain networks (Butner 2010). Global supply chain partners are willingly pooling their operations in horizontal business flows and cumulatively sharing information in a vertical manner, saving cost on both information processing and information leak (Zhou and Benton 2007). Vickery et al. (2003) studied the implications of supply chain integration on firms’ performance and customer satisfaction; and managing financial performance by taking joint decisions via supply chain contracts carried by the information flow management system (Arshinder and Deshmukh 2008).

3.2.3 Intelligent Supply Chain

The inherent nature of smart supply chains makes them adapt and react in a stipulated time (Lee 2004). The ability to sync and reconfigure in real time, in such a way that it not only takes decisions based on the current scenario but configures itself for future operations, is the most attentive feature of the smart supply chain. The need for an intelligent supply chain to drive businesses to build a flexible structure for optimum information flow leads to acquiring a higher level of adaptiveness (Lee 2004) in the ever-changing dynamic business environment (Christopher and Holweg 2011). The supply chain architecture is important for information sharing and achieving a reconfigurable supply chain for making smart managerial decisions and increasing service levels (Liu and Kumar 2011). With minimum or no human intervention, a capable, intelligent supply chain takes its own decisions in disruptive conditions and makes use of both the physical and digital infrastructure (Butner 2010). Various applications of smart technologies-enabled supply chains that have revolutionized the business environment, have been studied by scholars (Bendavid and Cassivi 2010; Bowles and Lu 2014).

3.3 Information System Agility

3.3.1 Agile Project Management

The evolution of business strategies has given rise to a whole new avenue of planning called ‘project management’. Since a large stake in operations is governed by information technology, the organization finds a better way to plan, implement and monitor the events occurring in the supply chain. Agents (players in the multi-echelon supply chain) play a crucial role in providing real-time information throughout the supply chain. Agile project management is often leveraged as a tool by managers to simultaneously address customers’ demands and to control the cost component associated with the project (Cockburn 2001). Organizations with smart managers often widen their vision of operations to create agile projects. Simply adopting agile methods does not produce a flexible system; it is the flexibility in information system development which makes the system more responsive as cognition amongst the team members makes the system perform (Chan et al. 2017). Intelligent information sharing brings visibility amongst team members which leads them to perform multi-skilled jobs in an interchanging job environment (Drury-Grogan 2014; Bozionelos and Singh 2017). Rhee et al. (2007) explore the fact that project management can be effectively carried out by services which enhance agility in project management.

3.3.2 Agile Software Development

In the age of open sourcing, even established firms are investing a low fixed cost in software development, as the functionality of software is a function of dynamic change in the market. To respond in minimal time, a complementary structure is needed which should be capable enough to imbibe important information from the external environment. Over the last decade, a growing number of companies have employed agile software development methods (West et al. 2010). These include the subtle but essential control mechanism to manage the progress as well as the quality of the resulting software product (Harris et al. 2009). The high degree of functionality demand is constrained by the lifespan of software and becomes the reason for non-compatible interconnectivity. Highsmith (2002) describes the importance of the ecosystem in bringing agility into software development. High costs of developing and acquiring software create ambiguity when making strategic decisions for both present lines of products as well as future demand. Harris et al. (2009) suggest that software development should be linked to dynamic market demand and should consider uncertainty. Gill et al. (2016) studied the factors required to scale up agility in software development. Software developers require human management skills, such as participating in activities beyond programming for systems analysis and project management. Having such skills likely increases their level of perceived job autonomy and skill or task variety (Tripp et al. 2016).

3.4 Supply Chain Flexibility

Supply chain flexibility (SCF) is the capability of firms to respond to unforeseen changes in customer needs/ ever-changing customer demands and competitors’ moves in the dynamic business environment. Many scholars have defined flexibility as the key to competence and sustainability (Beamon 1999; Duclos et al. 2003; Vickery et al. 1999; Das 2011). Charles et al. (2010) list five dimensions of supply chain agility regarding flexibility, effectiveness, velocity, reliability and visibility. Technology can be acquired, but organizations need to nurture intelligence in their internal environment which equips smart managers to extract critical information out of multidirectional information flow and use it for crucial decision making. Venkatesh (2008) argues that organizations are incapable of assessing and enriching users’ skills making it hard for them to use technology at an optimum level. The information system capability of an organization fosters structural flexibility, which leads to supply chain adaptability to cater to the ever-changing business environment (Christopher and Holweg 2011). Many firms have demonstrated their capacity to introduce a business intelligence model in electricity markets to make the supply chain agile and intelligent (Lukić et al. 2017). The two crucial components for creating more flexible operations are technological changes in the organization and attitudinal changes amongst the people. Information and communication technologies (ICT) have offered many choices and greater speed of interaction, but the additional dimension is the interaction of attitudes with the design and use of technology (Sushil 2015). Further, Manders et al. (2017) worked on the new dimensions of supply chain flexibility. From a broad perspective, supply chain flexibility can be achieved by deploying information technology through flexible structure which gives room to acquire the features of a smart supply chain through the proper processing of information theory.

3.5 Importance of Supply Chain Flexibility and Information Agility in Development of Smart Cities

The diffusion of information technology has already disrupted the way of operationalizing things. One of the major pillars of smart cities is future-ready organizations which promote sustainable performance and economic stability. Popovič et al. (2018) study the contribution of big data analytic capabilities to achieving high firm value and business performance. Smarts cities offer quality of services by providing a competitive ecosystem consisting of a streamlined flow of information and facilitated by emerging technologies/analytical tools. Recent studies in healthcare (Plachkinova et al. 2018) motivate big data technologies to access quality healthcare through smart infrastructure. Gupta et al. (2018a, b) studied and demonstrated the positive relationship between big data and cognitive computing. They further advocated that characteristics of cognitive computing will drive future-ready smart factories. Batty (2013) describes the use of big data with emphasis on short term rather than long term planning, facilitating more functional cities and accelerating them to attain the status of smart cities. Considering the vital role of smart organizations and digital infrastructure as a cornerstone of smart cities, they are expected to transform themselves with the help of digital tools. Grover and Kar (2017) discuss tools such as Big data predictive analysis (BDPA) platforms, data warehouses, programming languages and search tools which complement the digital infrastructure and outperform it when needed.

4 Theoretical Model and Hypothesis Development

Previous research reveals the interdependency of information technology and system flexibility. As an extension of this, a mechanism is needed which steers the flow of information inside and outside the system. Srinivasan and Swink (2017) investigated supply chain flexibility and visibility from the perspective of organizational information processing theory. Extending their work, this study recognizes the importance of the information flow mechanism treated as an ecosystem accommodating the avenues to connect the smart supply chain with the flexible information system, resulting in achieving overall flexibility in supply chain operations. Organization information processing theory (OIPT) cited by Galbraith (1973, 1974), is the best fitting theory to be considered as a mechanism of information flow. Operationalization of constructs can be seen in Table 9 of Appendix 1.

4.1 Direct Relationship of the Smart Supply Chain with Information System Flexibility

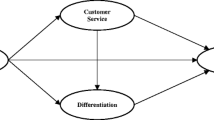

Figure 1 depicts the conceptual model based on the theoretical framework used for this study, with its foundations in organization information processing theory (Galbraith 1974). This model also shows a strong relationship between smart supply chain management and information system flexibility. Strong development and monitoring of both lead to a higher level of supply chain flexibility. The relationship between the smart supply chain and information system agility is not always linear due to the moderating effects of the customer and supplier relationship in the system.

Based on the literature review, we have developed a hypothesis which will be tested empirically in this paper. Smart supply chains equipped with features of instrumented connectivity provide visibility throughout the supply chain and in the context of this study, providing more insight to members of the project management team and helping them to manage their projects flexibly. Chopra and Meindl (2013) express their viewpoint on Internet of Things (IoT) applications from a process-centric viewpoint. In the past, scholars (Ahmed et al. 2017) have studied the role of big data analytics while leveraging the Internet of Things. Rhee et al. (2007) state that correct project management methods increase interoperability amongst heterogeneous information systems as well as supply chain adaptability. According to Galbraith (1973), information must be stored in vertical operational units and shared in laterally connected operations. As an extension of this, this research relates the instrumented supply chain to agile software development, since it gives information on demand from the market in real time, which helps the organization take investment decisions for new software development projects. Fescioglu-Unver et al. (2015) studied the application of RFID in the service industry. Fang et al. (2015) studied the application of technology in the supply chain information flow which is helpful for managing project snowmelt. Based on the above literature review, we have proposed the following hypothesis:

-

H1a: Instrumented supply chain is positively related to agile project management in an organization

-

H1b : Instrumented supply chain is positively related to agile software development in an organization

In the age of sharing production capacity and technology, most organizations share their information through contracts which help them to take decisions jointly in the context of cost saving and to plan risk mitigations in disruptive conditions (Hill and Omar 2006; Arshinder and Deshmukh 2008). Tan et al. (2016) state that the risk associated with information leak could be countered with monitored interconnections between the operational functions of the supply chain. Some information leakage such as individual leakage and organization leakage causes major loss regarding market credibility and brand visibility. Cai et al. (2010) find that trust plays a crucial role in oriental culture and helps in exchanging information in an interconnected supply chain which in turn leads to management of joint projects with more visibility and flexibility. These arguments strongly advocate the next two propositions:

-

H2a: Interconnected supply chain is positively related to agile project management in an organization

-

H2b: Interconnected supply chain is positively related to agile software development in an organization

Electronic Data Interchange (EDI) facilitates information sharing resulting in the rational alignment of operational activities which provides flexibility to the system (Tan et al. 2016). The sensor enables the supply chain to sync with real-time data and reconfigure its operations to take the crucial decision in minimal time. This helps the project management team or software development team to work on new requirements and specifications quickly. In this way, the collaborative strategy helps to cater to the most uncertain disruptive conditions. Real-time information processing capability helps in removing some of the supply chain problems such as the bullwhip effect which creates ambiguity when taking project management decisions. Therefore, the next two propositions are the following:

-

H3a : Intelligent supply chain is positively related to agile project management in an organization

-

H3b : Intelligent supply chain is positively related to agile software development in an organization

4.2 Direct Relationship of Agile Information Systems with Supply Chain Flexibility

-

H4: Agile project management has a positive impact on supply chain flexibility in an organization

-

H5: Agile software development has a positive impact on supply chain flexibility in an organization

4.3 Moderating Effect of Supplier and Customer Relationship on Supply Chain Flexibility

Customers have the most dominant influence on decisions in agile project management teams as well as being a decision maker in their own right (Beck 2000). Information sharing throughout agile project management teams increases visibility, since teams consist of a small number of members with interchanging job roles (Drury-Grogan 2014). Agile adoption does not merely depend on the universal agile methods available. Core agility in information system development is focused on the cognition or mindsets of people involved in project management (Cho and Chan 2015). Mani et al. (2016) examined the weightage of social sustainability and its effect on vendor management. Vendors and customers are an integral part of a social community and a smart supply chain should be flexible enough to provide sustainability. Therefore, their sustainability affects the overall functionality of operations.

-

H6a : Supplier relationship positively moderates the relationship between agile project management and supply chain flexibility in an organization

-

H6b : Supplier relationship positively moderates the relationship between agile software development and supply chain flexibility in an organization

-

H7a : Customer relationship positively moderates the relationship between agile software development and supply chain flexibility in an organization

-

H7b : Customer relationship positively moderates the relationship between agile project management and supply chain flexibility in an organization

5 Research Methodology

5.1 Survey

An online survey technique was used for this study. The respondents are from a diversified domain and all the responses were collected for the year 2018. The distance between any two consecutive parameters was identical and a 5-point Likert Scale (1- strongly disagree, 2- disagree, 3- neutral, 4- agree, and 5- strongly agree) was used for the survey instrument (Hair et al. 2014). The instrument was pre-tested on 12 respondents to ensure the validity, reliability and appropriateness of the questionnaire. The questionnaire was shared with approximately 400 respondents working in the manufacturing sector in South Africa. The response rate was 45% and after critically examining all the survey responses, a total of 150 fully-filled responses were considered for this research. Data was standardized and there was no case of missing data, no zero variance, and no rank-related problems found in the data.

A wide age-range with different levels of academic qualifications is considered since every hierarchy represents positions held by different respondents whose decisions create a scope of flexibility in the system, which is shown in Table 1 below. From a total of respondents, 88%, i.e. 133 respondents belong to the age range of 41 to 60.

Table 2 below provides details of the respondents’ work and their relevant years of experience. For this study, respondents from seven different sectors have been considered, a majority of which, i.e. 83% of respondents, were from ‘Manufacturing / Manufacturing related services’. The respondents were from different geographical ethnicities, and the firm size varies according to their scale of operations.

Table 3 gives the different roles and the total number of employees in that role. Out of the 150 respondents, a majority of the responses were from Directors and Senior Level Managers, i.e. 81%. The reason behind taking a large number of respondents from this particular ‘Role’ is that since they work at middle or senior management level they have authoritative power in the system, which is required to implement supply chain strategies.

5.2 Data Analysis

Structural Equation Modeling (SEM) is deployed amongst a variety of research disciples starting from strategic management, marketing and psychology over a large period of time (Astrachan et al. 2014). Two types of SEM techniques are used – Covariance-based (CB) SEM and Partial Least Squares (PLS) based Structural Equation Modeling (Hair et al. 2014). Partial Least Squares-Structural Equation Modeling is used efficiently when the sample size is comparatively small, and the research is more exploratory in nature. Also, there is no requirement of normally distributed data for Partial Least Square-Structural Equation Modeling (Hair et al. 2011; Kock 2016). Partial Least Square based Structural Equation Modeling is a more effective technique when there is no established relationship between the dependent and independent variables (Hair et al. 2014).

Dubey et al. (2017b) employed Warp PLS to undertake the Partial Least Square-Structural Equation Modeling analysis for their research to examine the role of big data and predictive analytics in improving social and environmental sustainability. We have used Warp PLS software Version 6.0 in our study to analyze the data. When the objective of the study is to predict and explain the target constructs, Partial Least Square-Structural Equation Modeling is a more suitable technique in such case (Hair et al. 2014; Henseler et al. 2014). In case of Partial Least Square-Structural Equation Modeling, the efficiency is higher for parameter estimation, and this enhances the likelihood that any relationship will be considered as significant (Hair et al. 2014; Gupta et al. 2018a, b). In Table 4, the model fit and quality indices can be seen. All values, i.e. Average path coefficient (APC), average R-squared (ARS) are significant as the p value is less than 0.05 and average block VIF (AVIF) value is 4.476 which lies in the acceptable range, where less than 3.3 is an ideal case (Kock 2016).

To conclude the correctness of the model, causality assessment indices are calculated and presented in Table 5. The value of each of the indices ranges from 0 to 1 and acceptable values are above 0.7. In Table 5 below it can be seen that the value of all four of these indices is in the acceptable range.

Cronbach’s alpha is mainly used to assess the internal validity of the scale. Many types of research use it to check the reliability of survey instruments. The accepted value is 0.7 or greater (Nunnally and Bernstein 1994; Tellis et al. 2009). In Table 6 below, most of the values are above the threshold value of 0.7 and reflect the strong reliability of the instrument. According to Hair et al. (2006), the average variance extracted (AVE) should be more than 0.5 which is also seen in the table below.

To check the multicollinearity among the variables, Variance Inflation Factor (VIF) is used and should be less than 5 (Kock and Lynn 2012). Table 6 showcases that the VIF value of all the variables is within the limit. The values of R-squared coefficients show the extent to which the latent variable can be explained by the constructs of each related variable (Gupta et al. 2018a, b). Combined loadings and cross-loadings can be seen in Table 10 of Appendix 2 and the indicator weights of all the factors can be seen in Table 11 of Appendix 3.

In Table 7 a discriminant validity test is employed to locate whether the constructs are linked with the wrong variable. The value of the square root of the average variance extracted for each variable shown diagonally should be more than the construct correlations (Fornell and Larcker 1981; Hair et al. 2006; Gupta et al. 2018a, b).

Table 8 below shows the result and defines which hypotheses are supported and which are not.

6 Discussion and Conclusion

This section explains the findings drawn from the outcome of the data analysis. Also, this shows the validity of constructs in the form of accepted or non-accepted hypotheses. The section is divided into two parts, ‘Theoretical Contribution’ and ‘Managerial Implication’. Table 8 gives a summary of the evidence provided by the study data to support or not support the hypothesis generated in this study. The research findings have theoretical contributions and practical implications and open up a whole new scope for future research in a niche domain.

6.1 Theoretical Contributions

This study uses the perspective of organization information processing theory to explain the relationship between smart supply chain management and information systems agility combined to achieve overall supply chain flexibility. This research is mostly valid in a relatively unstable market, as in a stable environment, organizations mainly opt for conventional supply chain management and information processing tools.

The study uncovers many interesting relationships between the characteristics of the smart supply chain and modules of flexible information systems. Organizations aspiring to achieve the maximum degree of flexibility demonstrate an adaptive nature throughout the system to respond in a minimal time, achieve greater customer serviceability and lower operating costs. Previous research established theories related to use of the information system to achieve the AAA of the supply chain (Lee 2004). This study expands on the established theories related to information system agility and supply chain flexibility.

Butner (2010) and Majeed and Rupasinghe (2017) studied the importance of the instrumented supply chain for the development of a smart operational ecosystem which homes supply chain flexibility. Drury-Grogan (2014) and Tripp et al. (2016) studied the characteristics of agile project management. As an extension of this research, this study shows the positive relationship between the instrumented supply chain and agile project management/ agile software development.

Clegg et al. (1995); Butner (2010) and Ben-Daya et al. (2017) studied the positive side of the interconnected supply chain with IT as a medium of information processing. But this study tries to portray the negative aspect of the interconnected supply chain with information systems agility, since more closely connected supply chains governed through centralized systems result in a delay and pile up of the information at vertical levels. This in turn leads to more stringent processes resulting in hampering supply chain flexibility. Also, information leakage at both vertical and lateral levels creates extra costs which form a barrier to achieving agility.

Digital infrastructure (technology and instruments) needs to be synchronized and deployed in such a way that it supports the organizational structure and strategy. Extensive use of technology strengthens the organization but, on the other hand, leads to underperformance of businesses when the technological infrastructure is unavailable or there are compatibility issues with other businesses, specifically in conditions of uncertainty. Butner (2010), Bendavid and Cassivi (2010), and Bowles and Lu (2014) contribute to the technological aspects of the intelligent supply chain. This study shows the positive outcome regarding supply chain flexibility, conditioning the positive relationship between the intelligent supply chain and information systems modules.

Supply chain visibility can be achieved by developing external lateral relations with customers and suppliers (Srinivasan and Swink 2017). Suppliers and customers do influence the supply chain by their interaction with the organization and sometimes intervene in the optimum operations process. Previous studies (Srinivasan and Swink 2017) use the positive relationship of suppliers/customers with organizations to achieve supply chain visibility. This study examines the moderating effect of these relationships on determining supply chain flexibility.

This study analyzes the fact that the supplier positively moderates the relationship between the modules of information system agility and supply chain flexibility. On the other hand, due to their limited access to the supply chain, customers do not have a high effect on moderating the relationship between agile project management / agile software development and supply chain flexibility.

Overall the study helps to consolidate the fragmented established relationships between the flexible information system, the smart supply chain and supply chain flexibility. Also, the relationship between sustainable organizations and smart cities is well established. The study examines various industries to capture all vertices of direct connections between the technological and core competencies of an organization.

6.2 Managerial Implications

New age business managers always seek optimum deployment of technology and also to harness the internal strength of their organization enabling them to differentiate themselves in a league of technology-dependent organizations. Decision makers are keen to reduce the overall cost of the system while keeping in mind sustainability and the requirement of high service levels and therefore want to strengthen their supply chains in a manner that will be adaptive for dynamic requirements. Based on the findings, the study gives a clear picture of the importance of linking the smart supply chain with information processing strategies, which will help to make the supply chain agile and aligned with cross-departmental operations. This research attempts to empirically test the positive relationship between the characteristics of the smart supply chain and information systems modules and their effects on overall supply chain flexibility.

The implication for managers is to understand the level of smartness they need to incorporate in their supply chain which will complement the information systems with the help of efficient analysis of available data through the available information processing tools. The study looks in depth at the nature of the supplier and customer relationship within organizational growth. The moderating effect of the supplier relationship on information system and supply chain flexibility is analyzed and proved, which should encourage decision makers to implement an incentive mechanism, strengthening the supplier relationship, and support more operations related to flexible information systems.

In the business world, global consumers demand more customized services irrespective of their knowledge of and exposure to technologies. The ability of a manager to maintain the service level and meet customer expectations helps to build an influential relationship between the customer and the business. The study empirically proves that the customer relationship has the least influence on information system agility and supply chain flexibility due to its late penetration in the supply chain.

7 Limitations and Future Scope of Research

Although the present work generates many insights into the significant relationship of supply chain management and information system agility based on Organization Information Processing Theory, some limitations do exist regarding sample populations, since the majority of respondents are from the manufacturing sector and mostly work on a middle or higher hierarchical level. In future, responses can be collected from other industries and also, from lower level managers, since their work is not specialized but they have multi-skills which help them to process information more quickly and share it in an efficient manner. Also, the sample size is one of the limitations which can be increased by extending the reach to more countries for the future purpose. Spillover of information causes massive damage to existing operations. The effect of these leaks can be studied by considering their direct and moderating effect within the proposed theoretical framework.

Finally, Information transaction theory (Daft and Lengel 1986; Huber 1990) can be used as an alternative to organization information processing theory and can be analyzed in the same manner to get more insight into flexible information systems.

References

Ahmed, E., Yaqoob, I., Abaker, I., Hashem, T., Khan, I., Ibrahim, A., & Vasilakos, A. V. (2017). The role of big data analytics in internet of things. Computer Networks, 129, 459–471. https://doi.org/10.1016/j.comnet.2017.06.013.

APICS (2015). Supply chain operations reference model: Quick reference guide, Revision 11.0. http://www.apics.org/docs/default-source/scor-p-toolkits/apics-scc-scor-quick-reference-guide.pdf?sfvrsn=2. Accessed 20 Dec 2018

Arshinder, K. A., & Deshmukh, S. G. (2008). Supply chain coordination: Perspectives, empirical studies and research directions. International Journal of Production Economics, 115(2), 316–335. https://doi.org/10.1016/j.ijpe.2008.05.011.

Astrachan, C. B., Patel, V. K., & Wanzenried, G. (2014). A comparative study of CB-SEM and PLS-SEM for theory development in family firm research. Journal of Family Business Strategy, 5(1), 116–128.

Avittathur, B., & Swamidass, P. (2007). Matching plant flexibility and supplier flexibility: Lessons from small suppliers of US manufacturing plants in India. Journal of Operations Management, 25(3), 717–735.

Batty, M. (2013). Big data, smart cities and city planning. Dialogues in Human Geography, 3(3), 274–279. https://doi.org/10.1177/2043820613513390.

Beamon, B. M. (1999). Measuring supply chain performance. International Journal of Operations & Production Management, 19(3), 275–292. https://doi.org/10.1108/01443579910249714.

Beck, K. (2000). Extreme programming explained: Embrace change. Boston: Addison-Wesley.

Bendavid, Y., & Cassivi, L. (2010). Bridging the gap between RFID/EPC concepts, technological requirements and supply chain e-business processes. Journal of Theoretical and Applied Electronic Commerce Research, 5(3), 1–16. https://doi.org/10.4067/S0718-18762010000300002.

Ben-Daya, M., Hassini, E., & Bahroun, Z. (2017). Internet of things and supply chain management: A literature review. International Journal of Production Research, 7543(November), 1–24. https://doi.org/10.1080/00207543.2017.1402140.

Bensaou, M., & Venkatraman, N. (1995). Configurations of interorganizational relationships: A comparison between U.S. and Japanese automakers. Management Science, 41(9), 1471–1492.

Bowles, M., & Lu, J. (2014). Technological forecasting and social change removing the blinders: A literature review on the potential of nanoscale technologies for the management of supply chains. Technological Forecasting and Social Change, 82, 190–198. https://doi.org/10.1016/j.techfore.2013.10.017.

Bozionelos, N., & Singh, S. K. (2017). The relationships of emotional intelligence with task and contextual performance: More than it meets the linear eyes. Personality and Individual Differences, 116, 206–211.

Butner, K. (2010). The smarter supply chain of the future. Strategy and Leadership, 38(1), 22–23. https://doi.org/10.1108/10878571011009859.

Cai, S., Jun, M., & Yang, Z. (2010). Implementing supply chain information integration in China: The role of institutional forces and trust. Journal of Operations Management, 28(3), 257–268.

Carr, A. S., & Pearson, J. N. (1999). Strategically managed buyer-seller relationships and performance outcomes. Journal of Operations Management, 17(5), 497–519.

Chan, A. T. L., Ngai, E. W. T., & Moon, K. K. L. (2017). The effects of strategic and manufacturing flexibilities and supply chain agility on firm performance in the fashion industry. European Journal of Operational Research. Elsevier B.V., 259(2), 486–499. https://doi.org/10.1016/j.ejor.2016.11.006.

Charles, A., Lauras, M., & Wassenhove, L. V. (2010). A model to define and assess the agility of supply chains: Building on humanitarian experience. International Journal of Physical Distribution & Logistics Management, 40(8/9), 722–741. https://doi.org/10.1108/09600031011079355.

Chatterjee, S., Kar, A. K., & Gupta, M. P. (2018). Success of IoT in smart cities of India: An empirical analysis. Government Information Quarterly, 35(3), 349–361. https://doi.org/10.1016/j.giq.2018.05.002.

Cho, V., & Chan, A. (2015). An integrative framework of comparing SaaS adoption for core and non-core business operations: An empirical study on Hong Kong industries. Information Systems Frontiers, 17(3), 629–644.

Chopra, S. & Meindl, P. (2013). Supply chain management: Strategy, planning and operations, 5th ed. Pearson.

Christopher, M., & Holweg, M. (2011). “Supply chain 2.0”: Managing supply chains in the era of turbulence. International Journal of Physical Distribution and Logistics Management, 41(1), 63–82. https://doi.org/10.1108/09600031111101439.

Clegg, S. R., Hardy, C., & Nord, W. R. (Eds.). (1995). Handbook of organization studies (pp. 440–458). Thousand Oaks: Sage.

Closs, D. J., Speier, C., & Meacham, N. (2011). Sustainability to support end-to-end value chains: The role of supply chain management. Journal of the Academy of Marketing Science 39(1), 101–116. https://doi.org/10.1007/s11747-010-0207-4.

Cockburn, A. (2001), Agile Software Development, Addison Wesley Longman, Glen View, IL.

Cooper, M. C., Douglas, M. L., & Janus, D. P. (1997). Supply chain management: More than a new name for logistics. International Journal of Logistics Management, 8(1), 1–14.

Council of Supply Chain Management Professionals (2005). Supply Chain Management/ Logistics Management Definitions. http://www.cscmp.org/Downloads/Resources/glossary03.pdf. Accessed 20 Dec 2018

Daft, R. L., & Lengel, R. H. (1986). Organizational information requirements, media richness and structural design. Management Science, 32(5), 554–571.

Das, K. (2011). Integrating effective flexibility measures into a strategic supply chain planning model. European Journal of Operational Research, 211(1), 170–183.

Drury-Grogan, M. L. (2014). Performance on agile teams: Relating iteration objectives and critical decisions to project management success factors. Information and Software Technology, 56(5), 506–515. https://doi.org/10.1016/j.infsof.2013.11.003.

Dubey, R., & Bag, S. (2013). Exploring the dimensions of sustainable practices: An empirical study on Indian manufacturing firms. International Journal of Operations and Quantitative Management, 19(2), 123–146.

Dubey, R., Gunasekaran, A., Papadopoulos, T., Childe, S. J., Shibin, K. T., & Fosso Wamba, S. (2017a). Sustainable supply chain management: Framework and further research directions. Journal of Cleaner Production, 142, 1119–1130.

Dubey, R, Gunasekaran, A, Childe, S.J., Papadopoulos, T., Luo, Z, Fosso-Wamba, S. & Roubaud, D. (2017b). Can big data and predictive analytics improve social and environmental sustainability? Technological Forecasting and Social Change, In Press. https://doi.org/10.1016/j.techfore.2017.06.020.

Duclos, L. K., Vokurka, R. J., & Lummus, R. R. (2003). A conceptual model of supply chain flexibility. Industrial Management and Data Systems, 103(6), 446–456.

Dwivedi, Y. K., Janssen, M., Slade, E. L., Rana, N. P., Weerakkody, V., Millard, J., & Snijders, D. (2017). Driving innovation through big open linked data (BOLD): Exploring antecedents using interpretive structural modelling. Information Systems Frontiers, 19, 197–212. https://doi.org/10.1007/s10796-016-9675-5.

El-Kassar, A. & Singh, S.K. (2018). Green innovation and organizational performance: The influence of big data and the moderating role of management commitment and HR practices. Technological Forecasting and Social Change, (Accepted & in Press), https://doi.org/10.1016/j.techfore.2017.12.016.

Fang, S., Xu, L., Zhu, Y., Liu, Y., Liu, Z., Pei, H., Yan, J., & Zhang, H. (2015). An integrated information system for snowmelt flood early-warning based on internet of things. Information Systems Frontiers, 17(2), 321–335. https://doi.org/10.1007/s10796-013-9466-1.

Fescioglu-Unver, N., Choi, S. H., Sheen, D., & Kumara, S. (2015). RFID in production and service systems: Technology, applications and issues. Information Systems Frontiers, 17(6), 1369–1380. https://doi.org/10.1007/s10796-014-9518-1.

Fornell, C., & Larcker, D. F. (1981). Evaluating structural equation models with unobservable variables and measurement error. Journal of Marketing Research, 18(1), 39–50.

Galbraith, J. R. (1973). Designing complex organizations. MA: Addison-Wesley.

Galbraith, J. R. (1974). Organization design: An information processing view. Interfaces (Providence), 4(3), 28–36. https://doi.org/10.1287/inte.4.3.28.

Galbraith, J. R. (1977). Organization design. MA: Addison-Wesley.

Gill, A. Q., Henderson-Sellers, B., & Niazi, M. (2016). Scaling for agility: A reference model for hybrid traditional-agile software development methodologies. Information Systems Frontiers, 20, 1–27. https://doi.org/10.1007/s10796-016-9672-8.

Grover, P., & Kar, A. K. (2017). Big data analytics: A review on theoretical contributions and tools used in literature. Global Journal of Flexible Systems Management, 18(3), 203–229. https://doi.org/10.1007/s40171-017-0159-3.

Gupta, Y. P., & Somers, T. M. (1992). The measurement of manufacturing flexibility. European Journal of Operational Research, 60(2), 166–182.

Gupta, S., Kumar, S., Singh, S. K., Foropon, C., & Chandra, C. (2018a). Role of cloud ERP on the performance of an organization: Contingent resource-based view perspective. The International Journal of Logistics Management, 29(2), 659–675. https://doi.org/10.1108/IJLM-07-2017-0192.

Gupta, S., Kar, A. K., Baabdullah, A., & Al-khowaiter, W. A. A. (2018b). Big data with cognitive computing: A review for the future. International Journal of Information Management, 42, 78–89. https://doi.org/10.1016/j.ijinfomgt.2018.06.005.

Hair, J., Black, W., Babin, B., Anderson, R., & Tatham, R. (2006). Multivariate data analysis (6th ed.). Uppersaddle River: Pearson Prentice Hall.

Hair, J. F., Ringle, C. M., & Sarstedt, M. (2011). PLS-SEM: Indeed a silver bullet. Journal of Marketing Theory and Practice, 19(2), 139–151.

Hair, J.F., Hult, T., Ringle, C.M. & Sarstedt, M. (2014). A primer on partial least squares structural equation modeling (PLS-SEM), Sage, 2nd Edition, ISBN: 9781483377445.

Harris, M. L., Hevner, A. R., & Collins, R. W. (2009). Controls in flexible software development controls in flexible software development. Communications of the Association for Information Systems, 24(June), 757–776.

Heide, J. B., & John, G. (1990). Alliances in industrial purchasing: The determinants of joint action in buyer-supplier relationships. Journal of Marketing Research, 27(1), 24–36.

Henseler, J., Dijkstra, T. K., Sarstedt, M., Ringle, C. M., Diamantopoulos, A., Straub, D. W., & Calantone, R. J. (2014). Common beliefs and reality about PLS: Comments on Rönkkö and Evermann (2013). Organizational Research Methods, 17(2), 182–209.

Highsmith, J. (2002). Agile software development ecosystems. Addison-Wesley Professional. Vol 13.

Hill, R. M., & Omar, M. (2006). Another look at the single-vendor single-buyer integrated production-inventory problem. International Journal of Production Research, 44(4), 791–800. https://doi.org/10.1080/00207540500334285.

Huber, G. P. (1990). A theory of the effects of advanced information technologies on organizational design, intelligence and decision making. The Academy of Management Review, 15(1), 47–71.

Hyer, N. L., & Brown, K. A. (1999). The discipline of real cells. Journal of Operations Management, 17(5), 557–574.

Janssen, M., & van den Hoven, J. (2015). Big and open linked data (BOLD) in government: A challenge to transparency and privacy? Government Information Quarterly, 32(4), 363–368. https://doi.org/10.1016/j.giq.2015.11.007.

Janssen, M., Charalabidis, Y., & Zuiderwijk, A. (2012). Benefits, adoption barriers and myths of open data and open government. Information Systems Management, 29(4), 258–268. https://doi.org/10.1080/10580530.2012.716740.

Kaur, H., & Singh, S. P. (2017). Flexible dynamic sustainable procurement model. Annals of Operations Research, 273, 1–41. https://doi.org/10.1007/s10479-017-2434-2.

Kock, N. (2016). Non-normality propagation among latent variables and indicators in PLS-SEM simulations. Journal of Modern Applied Statistical Methods, 15(1), 299–315.

Kock, N., & Lynn, G. S. (2012). Lateral collinearity and misleading results in variance-based SEM: An illustration and recommendations. Journal of the Association for Information Systems, 13(7), 546–580.

Koo, C., Ricci, F., Cobanoglu, C., & Okumus, F. (2017). Special issue on smart, connected hospitality and tourism. Information Systems Frontiers, 19(4), 699–703. https://doi.org/10.1007/s10796-017-9776-9.

Laaksonen, T., Jarimo, T., & Kulmala, H. I. (2009). Cooperative strategies in customer-supplier relationships: The role of interfirm trust. International Journal of Production Economics, 120(1), 79–87. https://doi.org/10.1016/j.ijpe.2008.07.029.

Lee, H. (2004). The triple-a supply chain. Harvard Business Review., 82(10), 102–112.

Liu, R., & Kumar, A. (2011). Leveraging information sharing to configure supply chains. Information Systems Frontiers, 13(1), 139–151. https://doi.org/10.1007/s10796-009-9222-8.

Liu, G. J., Shah, R., & Schroeder, R. G. (2006). Linking work design to mass customization: A sociotechnical systems perspective. Decision Sciences, 37(4), 519–545.

Lukić, J., Radenković, M., Despotović-Zrakić, M., Labus, A., & Bogdanović, Z. (2017). Supply chain intelligence for electricity markets: A smart grid perspective. Information Systems Frontiers, 19(1), 91–107.

Majeed, M. A. A., & Rupasinghe, T. D. (2017). Internet of things (IoT) embedded future supply chains for industry 4.0: An assessment from an ERP-based fashion apparel and footwear industry. International Journal of Supply Chain Management, 6(1), 25–40.

Manders, J. H. M., Caniëls, M. C. J., & Ghijsen, P. W. T. (2017). Supply chain flexibility: A systematic literature review and identification of directions for future research. The International Journal of Logistics Management, 28(4), 964–1026.

Mani, V., Gunasekaran, A., Papadopoulos, T., Hazend, B., & Dubey, R. (2016). Supply chain social sustainability for developing nations: Evidence from India. Resources, Conservation and Recycling, 111, 42–52.

Modi, S. B., & Mabert, V. A. (2007). Supplier development: Improving supplier performance through knowledge transfer. Journal of Operations Management, 25(1), 42–64. https://doi.org/10.1016/j.jom.2006.02.001.

Moon, K. K-L., Yi, C. Y., & Ngai, E. W. T. (2012). An instrument for measuring supply chain flexibility for the textile and clothing companies. European Journal of Operational Research, 222 (2), 191–203, https://doi.org/10.1016/j.ejor.2012.04.027

Nunnally, J. C., & Bernstein, I. H. (1994). Psychometric theory (3rd ed.). New York: McGraw-Hill Inc.

Peng, D. X., Heim, G. R., & Mallick, D. N. (2014). Collaborative product development: The effect of project complexity on the use of information technology tools and new product development practices. Production and Operation Management, 23(8), 1421–1438.

Plachkinova, M., Vo, A., Bhaskar, R., & Hilton, B. (2018). A conceptual framework for quality healthcare accessibility: A scalable approach for big data technologies. Information Systems Frontiers, 20, 289–302. https://doi.org/10.1007/s10796-016-9726-y.

Popovič, A., Hackney, R., Tassabehji, R., & Castelli, M. (2018). The impact of big data analytics on firms’ high value business performance. Information Systems Frontiers, 20, 209–222. https://doi.org/10.1007/s10796-016-9720-4.

Primo, M. A. M., & Amundson, S. D. (2002). An exploratory study of the effects of supplier relationships on new product development outcomes. Journal of Operations Management., 20(1), 33–52.

Rhee, S. H., Bae, H., & Choi, Y. (2007). Enhancing the efficiency of supply chain processes through web services. Information Systems Frontiers, 9(1), 103–118. https://doi.org/10.1007/s10796-006-9020-5.

Slack, N. (1983). Flexibility as a manufacturing objective. International Journal of Operations & Production Management, 3(3), 4–13. https://doi.org/10.1108/eb054696.

Srinivasan, R., & Swink, M. (2017). An investigation of visibility and flexibility as complements to supply chain analytics: Organizational information processing theory perspective. Production and Operations Management, 27, 1–19. https://doi.org/10.1111/poms.12746.

Stephens, S. (2001). Supply chain operations reference model version 5.0: A new tool to improve supply chain efficiency and achieve best practice. Information Systems Frontiers, 3(4), 471–476. https://doi.org/10.1023/A:1012881006783.

Sushil. (2015). Creating flexibility through technological and attitudinal change. Global Journal of Flexible Systems Management, 16(4), 309–311. https://doi.org/10.1007/s40171-015-0112-2.

Tan, K. H., Wong, W. P., & Chung, L. (2016). Information and knowledge leakage in supply chain. Information Systems Frontiers, 18(3), 621–638. https://doi.org/10.1007/s10796-015-9553-6.

Tellis, G. J., Yin, E., & Bell, S. (2009). Global consumer innovativeness: Cross-country differences and demographic commonalities. Journal of International Marketing, 17(2), 1–22.

Tiwari, A. K., Tiwari, A., & Samuel, C. (2015). Supply chain flexibility: A comprehensive review. Management Research Review, 38(7), 767–792. https://doi.org/10.1108/MRR-08-2013-0194.

Trentin, A., Forza, C., & Perin, E. (2012). Organization design strategies for mass customisation: An information-processing-view perspective. International Journal of Production Research, 50(14), 3860–3877. https://doi.org/10.1080/00207543.2011.597790.

Tripp, J. F., Riemenschneider, C., & Thatcher, J. B. (2016). Development as work redesign. Journal of the Association for Information Systems, 17(4), 267–307.

Venkatesh, A. (2008). Digital home technologies and transformation of households. Information Systems Frontiers, 10(4), 391–395. https://doi.org/10.1007/s10796-008-9097-0.

Vickery, S., Canlantone, R., & Droge, C. (1999). Supply chain flexibility. An empirical study. Journal of Supply Chain Management, 35(1), 16–24.

Vickery, S. K., Jayaram, J., Droge, C., & Calantone, R. (2003). The effects of an integrative supply chain strategy on customer service and financial performance: An analysis of direct versus indirect relationships. Journal of Operations Management, 21(5), 523–539. https://doi.org/10.1016/j.jom.2003.02.002.

West, D., Grant, T, Gerush, M., & D’Silva, D. (2010). Agile development: Mainstream adoption has changed agility. Forrester Research.

Wong, C. W. Y., Lai, K., Cheng, T. C. E., & Lun, Y. H. V. (2015). The role of IT-enabled collaborative decision making in inter-organizational information integration to improve customer service performance. International Journal of Production Economics, 159, 56–65. https://doi.org/10.1016/j.ijpe.2014.02.019.

Wu, Z., Choi, T. Y., & Rungtusanatham, M. J. (2010). Supplier-supplier relationships in buyer-supplier-supplier triads: Implications for supplier performance. Journal of Operations Management, 28(2), 115–123. https://doi.org/10.1016/j.jom.2009.09.002.

Yu, W., Jacobs, M. A., Salisbury, W. D., & Enns, H. (2013). The effects of supply chain integration on customer satisfaction and financial performance: An organizational learning perspective. International Journal of Production Economics, 146(1), 346–358. https://doi.org/10.1016/j.ijpe.2013.07.023.

Zhang, Q., Vonderembse, M. A., & Lim, J.-S. (2003). Manufacturing flexibility: Defining//analyzing relationships among competence, capability, customer satisfaction. Journal of Operations Management, 21(2), 173–191.

Zhou, H., & Benton, W. C. (2007). Supply chain practice and information sharing. Journal of Operations Management, 25(6), 1348–1365. https://doi.org/10.1016/j.jom.2007.01.009.

Zhou, K., T. Liu, & L. Zhou. (2015). Industry 4.0: Towards future industrial opportunities and challenges. In Proceedings of 2015 12th International Conference on Fuzzy Systems and Knowledge Discovery (FSKD), Zhangjiajie, China, 2147–2152.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1

Appendix 2

Appendix 3

Rights and permissions

About this article

Cite this article

Gupta, S., Drave, V.A., Bag, S. et al. Leveraging Smart Supply Chain and Information System Agility for Supply Chain Flexibility. Inf Syst Front 21, 547–564 (2019). https://doi.org/10.1007/s10796-019-09901-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10796-019-09901-5