Abstract

In this study, the effect of two additives, including recycled polypropylene (PP) fibers and Nano magnesium oxide (MgO), was investigated in the improvement of strength characteristics of clay. Some samples of clay, with or without additives, were prepared and strength characteristics were measured by unconfined compression and direct shear tests. The soil was stabilized by adding 0.2%, 0.5% and 1% of PP fiber and/or 0.2%, 0.4%, 0.8% and 1% of nano-MgO by dry weight of the soil. The results of the unconfined compression tests show that nano-MgO can significantly increase the stiffness of the soil and the undrained cohesion of the clay. Adding 0.2% nano-MgO raises the undrained cohesion about 45%. However, the undrained cohesion slows down to a mild slope after adding more nanomaterial. The direct shear test also demonstrates the significant increase of internal friction angle of the samples with PP fibers and implies proper engagement of the PP fibers within the reinforced soil structure. Besides the increase of the stiffness, adding the fibers increases the ductility of the samples and imparts more failure strain. The study of scanning electron microscope also shows that the nanomaterial has significantly turned clay particles from the layered sheet structures into concentrated ones and created a behavior like granules as far as the internal friction of clay is concerned. Moreover, these conditions and development of a hard mass of nano-soil can provide more interlocking with the fibers due to the pressure from compression and surcharge loading. It therefore increases the strength and mass interlocking and controls the strains in the sample.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Clayey soil has some disadvantages like the weakness in bearing capacity, high and long-term settlement, swelling, high moisture absorption, and difficulties in compaction. Ground improvement by stabilization with additives is the most common method for reducing the problems of clayey soil. Traditionally, materials such as cement and lime are used as additives. However, the application of nano powdery materials is proposed as additives for stabilization of clay in the recent decades. Zhang (2007) has conducted microstructural studies on the effect of nanomaterials in physical and mechanical characteristics of soil. In that study, the properties of various nanomaterials were introduced and their effects on soil strength were discussed. Applying nano-SiO2 in improvement of geomechanical behavior of clay (Ahmadi and Shafiee 2019), investigation on the effect of adding nano-clay on plasticity and strength properties of clay (Nohani and Alimakan 2015) are examples of researches conducted to study the effects of nano powdery materials on clay treatments. Majeed and Taha (2012) surveyed three nano materials namely nano-copper oxide, nano-magnesium oxide, and nano-clay for treating the soft soil in the Penang island. The effects of these materials on density, consistency limits and unconfined compressive strength of the soft soil were investigated by utilizing laboratory experiments. In all these cases, liquid limit, plastic limit, and plasticity index of the soil exhibited decrease by adding nanomaterials. Gao et al. (2015, 2018) investigated the effect of nano magnesium oxide on physical and mechanical characteristics of clay. Different nano-MgO contents (0–6% by weight of the soil) were added to the soil samples. According to the results of the tests, the unconfined compressive strength of the soil samples increased owing to the inclusion of nano-MgO. This study revealed that nano-MgO could impart cementation, filling the pores, and give rise augmented water absorption within the soil particles which brought about substantial strengthening effect.

On the other side of the spectrum, the use of waste materials has been broadly considered for stabilization of soils by researchers and practitioner worldwide in recent years. If it could improve the mechanical properties of soils, the utilization of these materials is important and welcomed because of three main reasons. First, since they are wastes, it could be economically attractive and viable. Secondly, it could prevent the massive annual consumption of commonly used building materials such as cement, lime, or bitumen which are traditionally introduced into soil stabilization schemes. Last but not the least, the application of waste materials, especially polymeric waste materials, is environmentally friendly as it is feasible to restrain the accumulation of these waste products in nature and reduce the adverse environmental effects caused by their unsafe disposal. One of the common polymeric materials is the polypropylene (PP) fiber which has been recognized for clay reinforcement. Notable researches have been carried out on the effect of PP fibers reinforcement on shear strength of clays. Cai et al. (2006), Tang et al. (2007), Gümüşer and Şenol (2014), Hamidi and Hooresfand (2013), and Soğancı (2015) are solely examples. According to Cai et al. (2006), the inclusion of PP fibers in clay yields physical interaction between the fibers and soil and also the internal friction angle of the soil mass increases. Tang et al. (2007, 2010) deem the overburden pressure as an influential parameter in reinforcing action and modification of the internal soil friction.

Changizi and Hadad (2015) studied the mutual effects of recycled polyester fibers produced from polyethylene bottles and nano-silica as stabilizer agent for improving the mechanical properties of soils. The results of their study demonstrated that adding the recycled polyester fibers and Nano silica increases the strength of the soil samples. By increasing the content of the recycled polyester fibers and nano-silica in the soil mixture, both shear strength and UCS parameters of the composite material were reported improved. In the present research, the simultaneous contributions of nano magnesium oxide (MgO) and PP fibers in improving the mechanical properties of clayey soil is elaborated. The unconfined compression and direct shear tests are invoked to evaluate the shear strength and mechanical properties of the stabilized clay with different contents of the additives.

2 Materials and Experimental Work

2.1 Materials

2.1.1 Clay

The investigated soil in the present research is the clay soil obtained from City of Rasht which is so-called Rasht clay. This soil consists of different minerals and covers major northern areas of the city in the north of Iran. Extensive studies have been performed to characterize Rasht clay. The studied soil is brownish and its plasticity is not high. The physical properties of the clay under study are shown in Table 1. The elemental analysis of the soil, undertaken by X-Ray Fluorescence (XRF) is presented in Table 2. According to this analysis, the amount of magnesium in the soil is very low (3.6%). Although the clay under study contains noticeable amounts of calcium and aluminum cations which have higher replacement power than the magnesium ion, the small amount of the sodium ions present in the clay under study can be replaced by some alternative cations which have either higher valence or larger non-hydrated radius. Magnesium would potentially supersede the sodium ions.

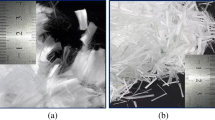

2.1.2 Polypropylene (PP) Fibers

The fibers used for soil reinforcement in the present study are made up of polypropylene. In order to carry out tests under more controllable condition, the fibers, representing recycled PP fibers, were supplied from Beton Pas Chemical Company. The physical and mechanical features of the used fibers are provided in Table 3. It is to be noted that the introduced PP fibers are indeed mechanical elements which, owing to their very high modulus and tensile strength as appear from Table 3, are expected to impart augmented shear strength to the mixture due to possible mobilization of their tensile strength.

2.1.3 Nano Magnesium Oxide

In order to improve the plasticity and strength properties of the original clayey soil, nano magnesium oxide (nano-MgO) is applied in this research. Table 4 presents some features of the nano-MgO utilized in the current study. It is observed that the adopted nanomaterial contains a vast amount of magnesium ion, which makes it a good candidate for ion exchange due to its divalent nature and higher cation exchange capacity (CEC) in comparison to the sodium ions hosted in the original clayey soil. This means that vastly available Mg2+ ions are nominees for isomorphous substitution and snugging in the original clay structure. The particle size of the nano particles is less than 50 nm, they are powdery and white in color, and the density is 3.58 g/cm3.

2.2 Preparation and Tests

2.2.1 Experimental Program

Different combinations of clayey soil, nano-MgO, and PP fibers were tested to investigate the effect of different constituents in improving the mechanical characteristics of the original clay. For this purpose, the nanomaterial in five different contents of 0, 0.2%, 0.4%, 0.8%, and 1% (weight ratio of dry nano-powder to the dry clay) and the PP fibers in four various contents of 0, 0.2%, 0.5%, and 1% (by dry weight of the soil) were mixed with the original clay and tested. To this end, three different scenarios were adopted. Solo nano-MgO, solo PP fibers, and combined nanomaterials and PP fibers are three mixing and inclusion scenarios adopted herewith. The unconfined compression experiments and direct shear tests, at three normal stresses of 100, 200, and 300 kPa were performed on each of the twenty test combinations.

2.2.2 Sample Preparation

In order to prepare samples, the dry original clayey soil is first fully grinded and passed through the sieve #4. The nonmaterial admixture was added to the original clayey soil in pre-specified contents and mixed in five stages by strewing the nanomaterial over it using a mechanical mixer for the duration of 30 min. Due to the possibility of lumpy fibers formation, the PP fibers were introduced into the mixture in ten stages and kneaded for the duration of 10 min. Since it was required to prepare the samples with nanomaterials in five different combinations, in order to create the optimum compaction condition for each inclusion content, the amount of the optimum moisture content of the samples was determined by utilizing the standard proctor compaction test and subsequently the samples were made with the optimum moisture contents. Adding water to the samples was also carried out in five stages and the samples were mixed by a mechanical mixer for the duration of 10 min. Some images of the specimens prepared for the unconfined compressive strength test are shown in Fig. 1.

3 Laboratory Element Tests

3.1 Unconfined Compression Test

The unconfined compression test has been carried out according to ASTM D2166-06. The specimens were 38 mm in diameter and 76 mm in height. All the samples were kept in an insulated container in laboratory temperature condition for 28 days and then were tested. The results of the unconfined compression tests for the samples with 0, 0.2%, 0.5%, and 1% PP fibers are shown in Figs. 2, 3, 4, and 5, respectively. Thus, the variations of the undrained cohesive strength were studied in three different scenarios of solo nano-MgO (for short: NM), solo PP fibers, and combination of nano-MgO and PP fibers, totaling 20 samples.

3.2 Direct Shear Test

The direct shear tests were carried out according to ASTM D3080-11. The samples were 60 × 60 mm in plan and 25 mm in height. The combination of the original clayey soil and the admixtures are similar to the unconfined compression tests as explained earlier. In order to perform the tests with three normal stresses of 100, 200, and 300 kPa, three samples were provided for each combination. Before conducting each test, the mold of the device was filled with water and the sample was kept in water for 24 h. The shearing of the samples was undertaken by the constant shearing rate under drained condition. The results of variations in shear stress versus the horizontal displacement are shown for samples with 0, 0.2%, 0.5%, and 1% PP fibers in Figs. 6, 7, 8, and 9, respectively.

4 Results and Discussion

4.1 Effect of Nano-MgO on Strength and Stiffness of Natural Clay

The effects of nano-MgO and PP fibers were studied in three different scenarios as introduced in prior. In first and second scenarios, the effects of the sole inclusion of the MgO nanomaterial and PP fibers were investigated, respectively on undrained shear strength of the natural clay and in the third case, simultaneous addition of these materials was evaluated. Accordingly, the undrained cohesion of the samples can be determined by the following equation (ASTM D2166–06 2006):

where \({c}_{u}\) refers to the undrained cohesive strength and \({q}_{u}\) represents the unconfined compressive strength of the samples which is the peak point of the stress–strain curves acquired from the unconfined compression tests. The maximum amount of failure strain was presumed 20%. The unconfined compressive strength (UCS) for different samples is illustrated in Fig. 10 acquired from the curves of Figs. 2, 3, 4, and 5. The values of the undrained shear strength (cu) for different specimens are also given in Table 5.

As evident from Fig. 10, in samples without the PP fibers, adding nano-MgO to the original clayey soil dramatically increases the unconfined compressive strength and consequently the undrained shear strength of the samples, so that by adding about 0.2% nano-MgO, about 45.8% increase in the strength of the sample is to be expected. This increase can be attributed to the fact that nano-MgO is teeming with the two-valence magnesium ion. Hence, isomorphous substitution occurs leading to the structural transformation from dispersion to flocculation. This lends support to the contention that introduction of the nano-MgO powder within the sodium clay matter brings about stiffening of the modified soil as inferred from the UCS tests results. By adding more nano-MgO, the ascending trend of the strength growth slows down. In this way, the uniaxial strength of the samples increased by about 13.2% by doubling the MgO nanomaterial from 0.2% to 0.4%. The results of the tests showed that the ascending trend of the \({q}_{u}\) variations continued by increasing the nano-MgO content up to 1%. Comparison of the sample containing 1% nanomaterial with natural clay implies a doubled unconfined compressive strength and so does the undrained cohesion of the clay. Referring to Fig. 2 indicates that adding nano-MgO gives rise to the peak strength value to occur in a lower strain. As evident from the charts, although the natural clay sample was loaded in compression, a conspicuous peak is not exhibited in its stress–strain diagram. However, it reached its maximum strength in about 15% strain. On the other hand, by adding 1% nanomaterial to the original clayey soil, the stabilized sample reached to the peak strength state in a strain of about 10%. This means that the behavior of samples are inclined to be more brittle by increasing the nanomaterial content and it resembles over-consolidated clays in this aspect. The increase in strength of the samples and reduction of the failure strain indicate the stiffening of the samples due to the inclusion of the nanomaterials. In order to investigate the effect of the nanomaterial on the stiffness of the stabilized materials, the secant stiffness modulus at 50% of the failure is reached as below:

where, \({E}_{50}\) refers to the elasticity modulus, \(\Delta \sigma\) represents the variations of the axial stress until achieving 50% of the ultimate strength, and \(\Delta \varepsilon\) is the variations of strain corresponding to the mid-failure state.

Elaborations on the stress–strain variation curves corresponding to different samples have been charted in Fig. 11. This lends support to the contention that increasing the amount of nanomaterials significantly increases the stiffness of the improved soil. To be more specific, adding 0.4% nano-MgO has created a growth of about 58% in the soil stiffness. Nevertheless, the ascending growth rate of \({E}_{50}\) reached to a moderate slope after this extent. The variations of \({E}_{50}\) have been diminished to about 26% for 0.4 to 0.8% nanomaterial inclusion while the variation rate dropped to 5% for having 0.8 to 1% nano-MgO. In Fig. 12, the images of the scanning electron microscope (SEM) illustrate natural clay samples (Fig. 12a) and samples with 1% nano-MgO (Fig. 12b). The comparison of the SEM images shows that adding nano-MgO to clay renders a tangible linkage between the clay particles, and the soil turned from the layered sheet structures into a more concentrated status. An implication is that the nano-MgO material lends itself to be used to impart shear strength and stiffness to the original clayey soil.

According to the apparent similarity between these conditions and granular soils, it is predicted that these changes have a significant influence on the parameter of the internal friction angle of the original soil. Using the results of the direct shear tests and considering the Mohr–Coulomb criterion, shear strength parameters of the samples for various contents of nano-MgO can be extracted from the failure envelopes of Fig. 13. Profiling the slope of the drawn charts in Fig. 13, the variations of the internal friction angle (ϕ) can be presented in Fig. 14 for different nano-MgO and PP fiber contents. The values of shear strength parameters for the tested specimens are also given in Table 5. It is noted that in samples without fiber reinforcement, the internal friction angle had about 24%, 49%, 72%, and 87% growth compared to the natural clay by adding 0.2, 0.4, 0.8, and 1% nano-MgO contents, respectively. For the sample containing 1% nanomaterial, the internal friction angle was about 32° which shows that the clay fabric has gradually transformed from layered sheet structure condition to granules-based behavior. In a similar ground, Naval et al. (2017) demonstrated that adding nano-magnesium to clay significantly reduces the plasticity of the clay and this can be influential in water absorption by clay particles. It is also possible to investigate the cohesion of samples due to adding nanomaterials by considering the ordinate intercepts in the Mohr–Coulomb failure envelopes of Fig. 13. The cohesion intercept values are presented in Fig. 15. According to the failure envelopes of Fig. 13 related to the samples without PP fibers, it is observed that adding 0.2% nano-MgO to the original clayey soil would expectedly bring about 33% increase in the cohesion intercept of the original soil. This increase reaches 95% by adding 1% nano-MgO. Comparison of the results of direct shear and unconfined compression tests shows that there is a unanimous agreement between the results of the cohesive strength estimated from the two test types.

4.2 Effect of Adding PP Fibers

In the second phase of the present research, the effects of adding PP fibers to the original clay soil are investigated. The stress–strain variations of samples possessing 0, 0.2%, 0.5%, and 1% PP fibers are presented in the charts of Figs. 2, 3, 4, and 5 respectively. By adding PP fibers to the samples, reinforcement has been rendered to the samples to some extent and they are geared to being used to augment the shear strength of the samples. The increase in shear strength of clay soils due to adding PP fibers has been seen from Soğancı (2015) as well. In the present research, the growths of 30, 79, 79, and 108% in the undrained shear strength of the clay samples were observed by adding 0.2%, 0.5%, and 1% PP fibers contents, respectively. According to Fig. 11, E50 also underwent an increase of 16, 45, and 61% for the samples with 0.2%, 0.5%, and 1% PP fibers, respectively. An intriguing point about the stress–strain behavior of the samples containing PP fibers is that adding the PP fibers to the clayey soil has given rise to an increase of the samples plasticity, presumably due to the PP fibers extensibility. The SEM images of the samples containing 1% PP fibers (no nanomaterials included) is shown in Fig. 16. According to the SEM images, fibers could properly spread within the clay samples and by intercepting the potential failure surfaces, would create appropriate reinforcement. Indeed, compressing the reinforced clay sample has produced proper confinements of the fibers and entanglement of the clay particles. The reinforcement of the samples and the immense strength of the reinforcing elements not only augment the strength and stiffness of the sample but also are highly effective in the plasticity of the samples. For instance, the strain level of a sample with 1% PP fibers reached to 19.7% at peak strength state. Although the low thickness of the fibers does not allow a complete monotony of fibers distribution in the clay and therefore a regular trend in the increase of strength is not notable, an overall beneficial influence due to the PP fibers inclusion is recognizable. The confinement of the clay mass particles by the PP fibers causes an increase in the aggregate interlocking within the skeleton and hence, it influences the internal friction angle of the soil. Based on the results of the direct shear tests (Fig. 14), the value of the internal friction angle has increased by 27–46% by reinforcing the soil with 0.2–0.5% of the PP fibers. Nevertheless, more increase in the PP fibers content does not have any further notable influence on the internal friction angle of the original clayey soil, indicating an optimum PP fibers content. Such optimum behavior with regard to the PP fibers content can be presumably attributed to the fact that at very high PP fibers contents, densely included PP fibers will form soft spots within the reinforced soil mass and this will evidently prevent proper compaction of the composite, hence yielding less strong mixtures. Indeed, the PP fibers require sufficient compaction and bond length to mobilize their pullout capacity.

The final remark is that waste products made of polypropylene are the most prevailing recycled materials posing added value applications due to their beneficial contribution in soil reinforcement issues as substantiated in the aforesaid discussions. Consequently, applying these materials not only can be economically viable but also can be a pro-environmental practice by eliminating such wastes which are sometimes discarded in the landfill and remained untouched in long run.

4.3 Combined Effect of Nanomaterial and PP Fibers

Tang et al. (2010) conducted a laboratory study on the effect of fibers on the mechanical behavior of clay soil and demonstrates that if a sample contains hard soil particles, then these particles penetrate into fibers by pressure with plastic deformation and produce more anchorage through better interaction between soil and fibers. Therefore, the pull-out capacity of fibers grows and subsequently the engagement between granules and fibers rises. Referring to Fig. 12, it is apparent that the particles have turned from the initial layered/dispersed structure into a relatively flocculated structure; hence becoming more rigid by adding nano-MgO to clay. The comparison of the elasticity modulus of the samples containing nanomaterial indicates an increase in the soil stiffness compared to the natural clay. Hence, it is expected that by adding nano-MgO, the modified soil would exhibit a brittle deformation mode of behavior.

In Fig. 17, SEM images of two soil samples containing the PP fibers and nano-MgO are shown. The comparison of Fig. 17 with the images taken from samples without nanomaterials illustrates that the solidarity between the fibers and soil has improved owing to the presence of the nanomaterial. The soil shown in Fig. 17b contains twofold nano-MgO content compared to the one illustrated in Fig. 17a. It is apparent that the agglomeration of particles increases by introducing more nano-MgO materials and more surface plastic deformation and concavity are observed on the surface of fibers under applied surcharges. Evaluation of the shear strength data of the soil reinforced with fibers indicates that the shear strength of samples containing nano-MgO is more than the one lacking nanomaterials. From Fig. 10, it is observed that the value of the unconfined compressive strength has increased by 26 to 44% by adding 0.2% nanomaterial to the soil reinforced with PP fibers of different contents. A growth of 66 to 86% for UCS is also noted by adding 1% of the nano-MgO to the samples reinforced by PP fibers. According to Fig. 11, the increasing rate of \({E}_{50}\) due to the nano-MgO inclusion in samples containing the PP fibers is more pronounced than the unreinforced samples. Filamentous fibers impart augmented stiffness to the composite clayey soil due to the particles entanglement. Therefore, the strain at failure state declines due to the combined inclusion of the nono-MgO and PP fibers. This means that the microstructure of the improved soil has undergone modifications due to presence of the additives.

Survey of the results of the direct shear tests also shows similar trends of variations. Considering the graphs in Figs. 7, 8, and 9, the shear strength of the composite soil has significantly increased by adding more nanomaterial to the soil under the same surcharge stress and PP fibers content. It is further noted that the samples improved by nanomaterial exhibit more dilative tendency. This behavior is more highlighted, especially in low surcharge levels and a higher PP fibers contents. Besides, the charts of Figs. 14 and 15 show that adding nano-MgO to the PP fibers reinforced soil can bring about a substantial increase in the shear strength parameters. The increasing rate of the shear strength parameters is especially higher in lower additive contents.

5 Conclusion

In this study, the issue of stabilization of clayey soils with additives of mechanical and chemical influences was investigated by making samples of clay mixed with different percentages of polypropylene fibers and Nano-MgO. On the one hand, the PP fibers represent elements of mechanical engagement and, on the other hand, nano-MgO representing very fine and chemically active material, contributes to the enhancement of the original clayey material by altering the structural condition of it. Unconfined compression and direct shear tests were invoked to investigate the strength and stiffness parameters of the clayey soil improved with different contents of the PP fibers and nano-MgO material. Undrained shear strength and stiffness of the composite material was estimated from the unconfined compression tests and the drained strength parameters of the improved soil were yielded from the direct shear tests. Followings are the most important conclusions derived from the comparison of the laboratory element tests results.

- 1.

Adding nano-MgO to the clayey soil causes local aggregation and transformation of the dispersed structure to the flocculated condition leading to the formation of harder granules. In this regards, the stiffness of the improved soil along with the drained and undrained shear strength parameters of the composite soil exhibited substantial increase.

- 2.

The PP fibers, due to their reinforcing influence, impart augmented strength and stiffness characteristics to the improved clayey soil. This effect becomes more pronounced by the increase of the overburden pressure. This behavior can be attributed to the fact that surcharge stress brings about more confinement of the reinforcing elements, hence more advantageous contribution of the PP fibers inclusion is expected.

- 3.

The reinforcing effect of the PP fibers becomes resonated by adding nano-MgO powdery material to the reinforced clay. This has risen due to the stiffened clay material and the improved parameters of the interface between the reinforcing elements and surrounding clay modified by nano-MgO. This means that the combined effect of the PP fibers and nano-MgO is rewarding.

- 4.

Although the ascending trend of variation of the mechanical parameters of the soil improved mutually by the addition of the PP fibers and nano-MgO powder continued by adding both materials in the scope of tests, the highest rate of increase due to the effect of the additives is recognizable in the range of 0.2–0.4%.

- 5.

However although the strength and mechanical properties of the clayey soil mixed with both the PP fibers and nano-MgO material, have proven to increase, the produced composite material bears lower failure strain corresponding to the peak stress value. This is translated in form of the augmented brittleness imparted to the original clay material mixed with nanomaterial and PP fibers, mutually and individually.

Overall, the current study endeavored to demonstrate the positive consequences of mechanical and chemical additives when mixed with non-compliant local soils. However, the materials presented herewith are considered some typical inclusions which can potentially add to the deformation and strength properties of untreated soils. Therefore, their influences can be collectively exhaustive, depending on the level of improvement sought. Moreover, a cost-benefit analysis, while deemed equally important, was left for future refinements to compare their usage as soil improvement solution with other traditional alternatives.

References

Ahmadi H, Shafiee O (2019) Experimental comparative study on the performance of nano-SiO2 and microsilica in stabilization of clay. Eur Phys J Plus 134(9):1–14

ASTM D2166–06 (2006) Standard test method for unconfined compressive strength of cohesive soil. ASTM International, West Conshohocken

ASTM D3080, D3080M-11 (2011) Standard test method for direct shear test of soils under consolidated drained conditions. ASTM International, West Conshohocken

Cai Y, Shi B, Ng CWW, Tang CS (2006) Effect of polypropylene fibre and lime admixture on engineering properties of clayey soil. Eng Geol 87:230–240

Changizi F, Haddad A (2015) Strength properties of soft clay treated with mixture of nano-SiO2 and recycled polyester fiber. J Rock Mech Geotech Eng 7:367–378

Gao L, Ren K, Ren Z, Yu X (2015) Experimental study of nanometer magnesium oxide-modified clay. Soil Mech Found Eng 52(4):218–224

Gao L, Ren K, Ren Z, Yu X (2018) Study on the shear property of nano-MgO-modified soil. Mar Georesour Geotechnol 36:465–470

Gümüşer C, Şenol A (2014) Effect of fly ash and different lengths of polypropylene fibers content on the soft soils. Int J Civil Eng 12(2):134–145

Hamidi A, Hooresfand M (2013) Effect of fiber reinforcement on triaxial shear behavior of cement treated sand. Geotext Geomembr 36:1–9

Majeed ZH, Taha MR (2012) Effect of nanomaterial treatment on geotechnical properties of a Penang soft soil. J Asian Sci Res 2(11):587–592

Naval S, Chandan K, Sharma D (2017) Stabilization of expansive soil using nanomaterials. In: International interdisciplinary conference on science technology engineering management pharmacy and humanities. Nanyang Technological University, Singapore, 432–439

Nohani E, Alimakan E (2015) The effect of nanoparticles on geotechnical properties of clay. Int J Life Sci 9(4):25–27

Soğancı S (2015) The effect of polypropylene fiber in the stabilization of expansive soils. Int J Geol Environ Eng 9(8):994–997

Tang C, Shi B, Gao W, Chen F, Cai Y (2007) Strength and mechanical behavior of short polypropylene fiber reinforced and cement stabilized clayey soil. Geotext Geomembr 25(3):194–202

Tang CS, Shi B, Zhao LZ (2010) Interfacial shear strength of fiber reinforced soil. Geotext Geomembr 28(1):54–62

Zhang G (2007) Soil nanoparticles and their influence on engineering properties of soils, GSP 173 Advances in Measurement and Modeling of Soil Behavior. ASCE, Geo-Denver, Colorado, pp 1–13

Funding

The authors would like to address that no funding was received to carry out this research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Human and Animal Rights

No human/animal rights issue is relevant herewith.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ahmadi, H., Janati, S. & Jamshidi Chenari, R. Strength Parameters of Stabilized Clay Using Polypropylene Fibers and Nano-MgO: An Experimental Study. Geotech Geol Eng 38, 2845–2858 (2020). https://doi.org/10.1007/s10706-020-01191-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-020-01191-y