Abstract

The current study presents the laboratory investigation on the use of nano-silica (0.2, 0.4, 0.8 and 1.0%) and polypropylene fiber (0.25, 0.50, 0.75 and 1.0%) in problematic clayey soil to enhance the shear strength and compaction characteristics. From the Transmission electron microscopy (TEM) analysis, it is observed that the diameter of nano-particles used in this study was in the range of 10–20 nm. The nano-particles have a spherical shape and amorphous in nature. Extensive laboratory tests such as the standard Proctor compaction test and unconfined compressive strength test have been conducted on untreated and polypropylene fiber along with nano-silica treated clayey soil. The outcomes showed that the addition of polypropylene fiber in poor soil, increase the maximum dry density and reduce the optimum moisture content of the soil. Whereas, the addition of nano-silica to the clay soil results in reduced maximum dry density and increased optimum moisture content. Unconfined compressive strength of clay soil is increased with the addition of polypropylene fiber and nano-silica to the clay soil. The optimum dosage of polypropylene fiber and nano-silica added to the poor soil was 0.75% and 0.8%, respectively. The Young’s modulus of clay soil was increased with the addition of polypropylene fiber and nano-silica. The microscopic analysis confirmed that C–S–H gel was the main cementitious product, and the inclusion of nano-silica can contribute to a denser packing of soil particles.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Due to increasing urbanization, land for construction is getting limited, and now, it is vital to utilize even the undesirable land [15]. In addition, the construction of pavement generally pacts with issues linked to the deficient resource of large-quality materials for pavement structure (subgrade, sub-base and base) at construction field that creates a hike in transportation cost [23]. For centuries, humankind shocking at the weakness of earth materials, especially clay soil with poor soil properties. Clay soils are hard in summer or dry seasons, and they are weak in winter or rainy seasons. Clay soils always make the problem for moderately loaded superstructures by changing volumetrically along with seasonal moisture variations. Ground alteration due to the combined swelling and shrinkage of clay soil create severe damage to the structures constructed on such soils which include pavements, basement, foundations, etc., Even when attempts are developed to enhance clay soil, the inadequacy of convenient technology sometimes results in volumetric change that is liable for huge dollars devastation each year. A wide area of Central and South India has been masked with swelling soils [24, 30]. To enhance the engineering behavior of clay soils, the most viable solution is the soil stabilization technique [7, 8, 26]. Soil stabilization methods are generally done by adding chemicals, recycled materials, natural binding materials and solid wastes to soils [3], 14, 24, 25.

Changizi and Haddad [7] summarized that the inclusion of recycled fiber enhances the shear strength of soils. Shear strength and stiffness, ductility and the crack minimization capacity of the clay soil improve significantly with the addition of fiber reinforcement [16]. When fiber is added to the problematic soil, swelling, settlement, and volume change behavior of clay soil are also found to reduce [22, 27]. Fiber-reinforced soil tends to improve the compressive and tensile strength of the soil [2, 6]. The flexural property of soil improves with increment in polypropylene fiber addition [18]. Tang [29] explained that the reinforcing effect of fibers could offer more contribution in cemented soil rather than regular soil.

Foad Buazar [5] observed that the conventional soil stabilization methods such as lime, flyash and cement stabilization have several permanent disadvantages like a huge cost for maintenance, poor soil structure, secondary chemical pollution and unfavorable environmental impacts related to construction. Therefore, nano-particles due to their unique properties were proposed as an effective alternative stabilizer to overcome the detriments of conventional soil stabilization methods. From the past research studies, it can be concluded that nano-particles lead to observable changes to physical, chemical and mechanical properties of stabilized soil. For example, Ferric Oxide nano-particle is engaged as filling material to pack the soil void spaces and strengthen soil and concrete. And also, Ferric Oxide nano-particle along with fly ash cementing material enhances the mechanical properties of concrete. In addition to that, inorganic nanomaterials such as Aluminium oxide, Copper oxide and clay nano-powder efficiently enhanced the engineering properties of the problematic soils. Foad Buazar [5] demonstrated that increasing SiO2 nano-particles improves unconfined compressive strength and generates denser packing of cured loess soil. Silica nano-agents were encouraging prospective material for problematic soil stabilization due to cost-effectiveness, high durability characteristics and reliable stabilization. With the inclusion of nano-silica, the maximum dry density and shear strength of soil was improved [8]. The shear strength of clay soils is comparatively less due to their shrinkage and swelling behavior. In addition, with the usage of nanomaterials, the swelling and shrinkage strain is reduced. Thus, a conclusive influence on the swelling and shrinkage behavior of the clay soil is supported by a handful of studies with the inclusion of nano-material [28]. Pham and Nguyen [21] conducted a series of laboratory tests on clay soils by mixing nano-materials and concluded that the inclusion of nano-materials reduces the swelling index of soil.

Table 1 lists the previous studies involving nano-materials for soil stabilization. It is clear that the studies are mainly focused on the stabilization of low compressible clayey (CL) soil using nano-materials. In this current research, the admixtures like polypropylene fiber and nano-silica are used as additives to stabilize high compressible clayey soil. The experimental test variables were the type of admixtures and dosage of admixtures added to the clay soils. The standard Proctor compaction and unconfined compression strength tests were carried out for both untreated and treated soil specimens and the experimental results were compared.

Materials and methods

Material properties

Soil sample

Soil particles used in this current study was extracted from Kolapparakadu, Meenakshipuram Post, Chittur Taluk, Palakkad District, Kerala at a depth of 2 m. The collected soil was air-dried and processed to conduct the basic tests. The geotechnical characteristics of soil samples were decided by Indian standard (IS) codes and the test results are listed in Table 2. Based on the laboratory test results, the soil sample was classified as high compressible clay (CH) as per the Indian soil classification system (ISCS). In addition, the presence of the chemical compounds in the soil sample was evaluated and their amount in the soil are listed in Table 3.

Nano-silica

Nano-silica used in this research was commercially purchased from Modern Scientific Chemicals, Coimbatore, India. The basic characteristics of nano-silica were evaluated and reported in Table 4. In addition, the pictorial view of nano-silica along with the soil sample is shown in Fig. 1.

Polypropylene fiber

Polypropylene fibers were used due to their chemically inert nature and hydrophobic, which does not consume or perform with soil moisture or leachate. The fiber utilized in this current study was commercially available polypropylene (PP) fiber of length-10-mm and diameter-37-micron meter. The polypropylene fiber was purchased from Kalyani Polymers Pvt. Ltd, Bangalore, India. Figure 2 shows the photographic view of the polypropylene fiber used in this study. The physical properties of polypropylene fiber are listed in Table 5.

Test details

Compaction test

Standard Proctor compaction test was executed as per Indian Standard of IS 2720-Part 7 (1980). Proctor compaction test was implemented to discover the inter-relationship between optimum moisture content (OMC) and maximum dry density (MDD) of treated and untreated soil specimens. Firstly, the compaction test was carried out to determine the OMC and MDD of the untreated clay soil. Secondly, the clay soil was treated with various admixtures such as nano-silica and polypropylene fiber to carry out the compaction tests. In the sample preparation process, the soil and admixtures were thoroughly mixed until the mixture has a uniform color. After that, the water was added to the soil-admixture sample to expedite the mixing and compaction processes.

Unconfined compressive strength test

The Unconfined Compressive Strength (UCS) test of clay soil was carried out following IS 2720-Part 10. The test specimens were prepared as per the following procedures mentioned in the standard guidelines. First, the soil sample was air-dried at room temperature, and the admixtures were mixed thoroughly with the dry soil. Then, the OMC (corresponding to the mix proportion) amount of water was added to the soil and properly mixed to get a uniform paste. The UCS soil samples were prepared by making the sample preparation on the dry side of optimum to attain 95% of MDD. The prepared soil samples had a length to diameter ratio of 2.0 with a diameter of 38 mm and a length of 76 mm. The vertical load was enforced at a fixed rate of 1.25 mm/min applied on the soil specimens.

Microstructural study

Transmission Electron Microscopy (TEM) is a technique that uses an electron beam to image a nano-particle sample, giving much higher resolution than other light-based imaging techniques. TEM analysis of nano-silica was presented in Fig. 3a, b. TEM analysis certified that the nano-particles used in this study have a spherical shape. In addition to that, the nano-particles were found to be amorphous. Most of the nano-silica particles have an average particle size of 20 nm. Taking into account the high surface energy, the silica nanoparticles exhibit arbitrary aggregations, thus leading to the generation of larger particle clusters with poor dispersivity. In addition to that, the XRD analysis for nano-silica particles was done. The XRD test result was shown in Fig. 4. XRD analysis is used to determine the crystallographic structure of a material. By the interpretation of XRD analysis, it was identified that the intensity of O and Si elements were in a higher percentage since they are the main elements in nano-silica particles. The percentage of Oxygen and Silica components in the nano-silica particles was 37.45% and 18.6%.

In addition, the microstructure of clay soils was determined using Scanning Electron Microscope (SEM) analysis. At room temperature, the soil samples were dried and gold coated with the arc discharge method. Then, the prepared samples were tested at accelerating voltages 20 kV by scanning electron microscope for both treated and untreated soil samples.

Results and discussions

Effect of compaction on nano-silica treated soil

The effect of compaction on the various dosages of nano-silica treated soil samples is shown in Fig. 5. The addition of nano-silica to the clay soil was done in various percentages such as 0.2%, 0.4%, 0.8% and 1.0% to the total weight of the dry soil. From Table 6, it has been found that the OMC improves with increment in dosage of nano-silica up to optimum level and after that, it decreases. The MDD reduces with increment in the percentage of the nano-silica to the soil up to optimum level and after that, it increases. The clay soil mixed with different dosages of nano-silica powder has a high specific surface area, and the water absorption capacity of nano-silica was high. The water absorption capacity of nano-silica was high which increases the OMC of soil if the dosage of nano-silica mixed into the soil increases. Due to the low specific weight of nano-silica, the combination of clay soil treated with different dosages of nano-silica decreases the MDD upon increasing the dosage of nano-silica added to the soil.

Kalhor et al. [12] concluded that low compressible clayey soil treated with 1%, 2%, 3% and 4% of nano-SiO2, the OMC of clay soil enhances with increasing the nano-SiO2 content whereas the MDD of clay soil decreases with increasing the nano-SiO2 content. The current study agrees with the statement given by Kalhor et al. [12]. In the current study, increasing the nano-silica content increases the OMC and reduces the MDD of high compressible clay soil.

Effect of compaction on polypropylene fiber mixed soil

The effect of compaction on the various dosage of polypropylene fiber mixed clay soil is shown in Fig. 6. From the graph, it can be noted that the MDD of clay soil increases with increment in polypropylene fiber and decreases the OMC of clay soil by increasing the polypropylene fiber content. The reason behind that was the pore spaces of soil particles gets filled with help of water which results in soil particles bonds together in closer packing responsible for increasing the dry density. After OMC, further addition of water content is not responsible for decreasing the air voids but increase the total voids which ultimately decrease the overall weight of soil. Thus, the dry density of the soil reduces gradually with the increment in fiber content.

From the Table 5, it has been found that the OMC decreases with increment in the percentage of polypropylene fiber up to optimum level and after that, it increases. The reason behind that was the water holding or water absorption capacity of polypropylene fiber is less, therefore the OMC decreases with an increase in polypropylene fiber content. It is noticed that beyond 0.75% inclusion of polypropylene fiber to the clay soil increases the water content of the soil. Hence, the optimum dosage of polypropylene fiber was identified as 0.75% in this compaction behavior.

Meena et al. [19] examined that increasing the wheat straw fiber content decreases the MDD and improves the OMC of intermediate compressible clay soil, but the result variations are marginal only. In the current research, it was noticed that enhancing the polypropylene fiber content reduces the OMC and increases the dry density of high compressible clay soil. The difference could be due to the higher moisture consumption capacity of natural fiber (wheat straw) when compared to polypropylene fiber.

Unconfined compressive strength of nano-silica treated soil

The effect of nano-silica on the unconfined compressive strength of clay soil is shown in Fig. 7. Four different proportions of nano-silica (0.2%, 0.4%, 0.8% and 1.0% by dry weight of soil) were mixed into the clay soil. When comparing the different percentages of nano-silica added to the soil sample, 0.8% inclusion of nano-silica gives higher shear strength of 226 kPa than other dosages of nano-silica. It was observed that up to 0.8% of nano-silica to the clay soil, the unconfined compressive strength gradually increases. With the further addition of nano-silica to the clay soil, the strength decreases. The maximum strength improvement attained for 0.8% nano-silica is 2.52 times higher than the strength of untreated soil. Accordingly, 0.8% nano-silica was the optimum dosage to enhance the unconfined compressive strength of clay soil.

From the Fig. 7, it is also observed that, at a fixed amount of moisture content added to the soil, due to the consumption of water by nano-silica, the clay soil becomes less compressible which was deteriorated by improving the nano-silica content. This can be the inference for the clay soil having less strength with 1.0% nano-silica in comparison with clay treated with 0.8% nano-silica. In addition, when nano-silica was mixed into the soil, due to cation exchange capacity and pozzolanic reaction the soil samples undergo flocculated structure and build larger particles compared to raw soil particles.

Changizi and Haddad [7] reported that the low compressible clay soil treated with 0.7% nano-SiO2 grants the maximum UC strength of 1.1 MPa. In the current study, the high compressible clay soil treated with 0.8% nano-silica grants the maximum unconfined compressive strength of 226 kPa. This variation in results could be attributed to the difference in soil type, treatment procedure and difference in nano-silica. Similarly, Choobbasti and Kutanaei [9] reported that the Babolsar sand treated with 8% nano-silica particles and cement grants the maximum unconfined strength of 880 kPa, for 7 days of curing. When compared with the current study, the high compressible clay soil treated with 0.8% nano-silica grants the unconfined compressive strength of 226 kPa, for 7 days of curing period. The difference was caused mainly because of the variation in the soil type and admixtures used in both studies.

Unconfined compressive strength of polypropylene fiber mixed soil

The variation in unconfined compressive strength of clay soil mixed with various dosages of polypropylene fiber is shown in Fig. 8. Four different dosages of polypropylene fiber (0.25%, 0.5%, 0.75% and 1% by dry weight of soil) were mixed into the oven-dried clay soil. From the graph, it is found that the 0.75% inclusion of polypropylene fiber to the soil, gives a higher compressive strength of 174.24 kPa than other dosages of fibers to the clay soil. It was observed that, up to 0.75% inclusion of polypropylene fiber, the compressive strength of soil sample gradually increases and beyond that, it decreases. The strength improvement attained for 0.75% content of polypropylene fiber is 1.94 times higher than the compressive strength of untreated soil. Therefore, 0.75% polypropylene fiber was the optimum dosage to enhance the unconfined compressive strength of clay soil. It was indicated that usage of more than a convinced amount of fibers results in a decrement of the effectiveness of the increase in unconfined compressive strength. This peculiarity can account for the reason that, with enhancing the polypropylene fiber content, the fiber merges to one another and cannot interact with soil particles effectively.

Tang et al. [29] investigated that low compressible clay soil treated with 0.05%, 0.15% and 0.25% of fiber content gives the maximum unconfined compressive strength in the range of 0.25 MPa, 0.26 MPa and 0.29 MPa, respectively, for the curing time of 28 days. In the present study, the high compressible clay soil treated with a polypropylene fiber content of 0.25%, 0.50%, 0.75% and 1.00% gives the maximum strength of 125.10 kPa, 161.39 kPa, 174.24 kPa and 135.66 kPa, respectively, for 7 days of curing period. The slight difference caused in strength mainly due to soil type and strength of fiber used in both the studies was not the same.

Changizi and Haddad [7] expressed that the low compressible clay soil treated with a recycled fiber content of 0.1%, 0.3% and 0.5% grants the maximum unconfined compressive strength in the range of 110 kPa, 122 kPa and 130 kPa, respectively. In addition, Changizi and Haddad [7] examined that the optimum content of fiber to treat the soil was 0.3%. In the present study, the high compressible clay soil treated with a polypropylene fiber content of 0.25%, 0.50%, 0.75% and 1.00% grants the maximum unconfined compressive strength of 125 kPa, 161.4 kPa, 174.2 kPa and 135.7 kPa, respectively. The optimum dosage of fiber content in the present study was 0.75%. A slight inequality of strength improvement occurred in both studies due to the reason that the fiber and type of soil used in both studies were different. Hence, it could be reasonable to study the 0.75% polypropylene fiber mixed in the different dosages of nano-silica on the clay soil.

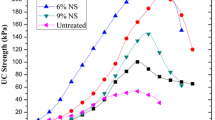

Unconfined compressive strength of polypropylene fiber and nano silica mixed soil

The unconfined compressive strength of 0.75% polypropylene fiber with various percentages of nano-silica is shown in Fig. 9. The optimum percentage of polypropylene fiber which is 0.75% by dry weight of the soil and four different dosages of nano-silica (0.2%, 0.4%, 0.8% and 1.0% by dry weight of the soil) was added to the clay soil individually and the uniform mix was carried out. It was observed that up to 0.75% PP Fiber + 0.8% nano-silica content, the unconfined compressive strength gradually increases and beyond that, it decreases. The maximum unconfined compressive strength obtained in this study was 249 kPa when the clay soil was treated with 0.75% PP Fiber + 0.8% nano-silica. The strength improvement was 2.78 times higher than the unconfined compressive strength of untreated soil. Therefore, 0.8% addition of nano-silica to 0.75% PP Fiber was the optimum dosage to enhance the unconfined compressive strength of clay soil. It may be notable that an increment in polypropylene fiber content is correlated with a reduction in brittleness of stabilized clay soils. By mixing nano-silica, the failure of clay soils took place suddenly, but with improving the content of polypropylene fiber, the failure mechanism of stabilized clay soil specimen has changed from brittle to ductile behavior.

Changizi and Haddad [7] declared that the low compressible clay soil treated with 0.3% recycled fiber content and 1% nano-silica content grants the maximum unconfined compressive strength of 2.0 MPa. In the present study, the high compressible clay soil treated with 0.75% polypropylene fiber content and 0.8% nano-silica grants the maximum unconfined compressive strength of 249 kPa. The difference pertained in both studies may be due to the difference in soil type and also the untreated strength of clay soil used in the current study was 89.54 kPa and in Changizi and Haddad [7] study the untreated strength of clay soil used was 0.7 MPa.

Young’s modulus of treated soil

The Young's modulus of high compressible clay soil treated with different dosages of nano-silica (0.2%, 0.4%, 0.8% and 1.0%) was in the range of 2880 kPa to 5120 kPa which is shown in Fig. 10a. Changizi and Haddad [7] reported that the Young's modulus of low compressible clay soil treated with 0.5%, 0.7% and 1% nano-silica particles were in the range of 12.3 MPa, 14 MPa and 18.9 MPa, respectively. The difference identified in both these cases were the type of soil used and the admixture dosage added to the soil. In the present study, high compressible clay soil was used and in Changizi and Haddad [7] study, low compressible clay soil was used. In addition to that, Oluwatuyi et al. [20] concluded that low compressible clay soil stabilized with cement-lime content 5% to 20% the Young's modulus values increased from 3.12 MPa to 3.8 MPa. Oluwatuyi et al. [20] study give slightly less Young's modulus value when compared to the current study due to the fact that the type of soil, type of admixture and amount of admixture added to the soil was different.

The Young’s modulus of high compressible clay soil treated with 0.25% to 1.00% of polypropylene fibers was in the range of 2700 kPa to 4690 kPa which is presented in Fig. 10b. Changizi and Haddad [7] recorded that the Young's modulus of low compressible clay soil mixed with 0.1% to 0.5% recycled fibers was in the range of 10.8 MPa to 11.5 MPa. The difference was generated due to the reason that the strength of fibers used in both these studies was not the same. In the present study, the tensile strength of fibers used was 400 MPa and in Changizi and Haddad [7] study, the tensile strength of fibers used was 200–400 MPa.

The Young's modulus of high compressible clay soil treated with a fixed amount of 0.75% polypropylene fibers and different dosage of nano-silica (0.2% to 1.0%) was in the range of 2600 kPa to 5770 kPa which is shown in Fig. 10c. [7] investigated that the maximum Young’s modulus of low compressible clay soil treated with 0.5% recycled fibers and 1% nano-silica was 35 MPa. Choobbasti et al. [10] studied that low compressible clay soil stabilized with nano calcium carbonate of different dosages (0.4% to 1.2%) along with a constant amount of 0.2% carpet waste fibers gives the Young’s modulus in the range of 37 MPa to 55 MPa. The differences caused in the present study, Changizi and Haddad [7] and Choobbasti et al. [10] was mainly due to the strength of fibers, type of soil and dosage of admixtures used in these studies were different. Amini and Ghasemi [1] demonstrated that clayey sand stabilized with a constant dosage of 20% magnesium slag along with a different dosage of cement content in the range of 2% to 6% gives the Young's modulus of 4.3 MPa to 6 MPa. While comparing Amini and Ghasemi [1] and current studies almost similar results were found.

Microstructural analysis

The microstructure of untreated and nano-silica treated clay soil was demonstrated by the help of scanning electron images which is shown in Fig. 11a, b, respectively. The untreated clay soil sample SEM photograph shows the smaller particle packing (see Fig. 11a). By comparing the SEM photograph of untreated and treated clay soil, the crystals developed on the surface of the treated soil particles were more uniform, larger and more compact than those observed in untreated clay soils and the bonding structures were stronger after cementation. The treated clayey soil (see Fig. 11b) with nano-silica and optimum amount of water, the clay soil particles bonded together because of water as well as the nano-silica, results in the formation of large particle packs and compacted soil matrix.

Conclusions

This research aims to identify the influence of nano-silica and polypropylene fiber on the strength characteristics of clay soil. The effects of nano-silica and polypropylene fiber on clayey soil were studied based on the unconfined compressive strength test results. From the experimental results presented in this research, the following conclusions can be drawn:

The OMC of clay soil is decreased with increasing polypropylene fiber, and OMC of soil is increased with increasing nano-silica. In addition to that, the MDD of soil is increased with increasing polypropylene fiber and the MDD of soil is decreased with increasing nano-silica.

The unconfined compressive strength of high compressible clay soil was improved with the inclusion of nano-silica materials. The optimum dosage and maximum strength achieved in nano-silica treated clay soil was 0.8% and 226 kPa, respectively. The strength improvement was 2.52 times greater than untreated soil.

With the inclusion of polypropylene fiber in high compressible clay soil, the strength of the soil was improved. The optimum percentage and maximum unconfined compressive strength identified in polypropylene fiber treated soil was 0.75% and 174 kPa, respectively. The strength improvement was 1.94 times higher than untreated soil.

The addition of both polypropylene fiber and nano-silica to clay soil enhances the strength of high compressible clay soil. The maximum unconfined compressive strength achieved in polypropylene fiber and nano-silica treated clay soil was 249 kPa when the clay soil stabilized with 0.75% PP fiber + 0.8% nano-silica and the strength improvement was 2.78 times greater than untreated soil.

The maximum Young’s modulus of high compressible clay soil was attained as 5770 kPa when the soil stabilized with 0.75% PP fiber mixed with 0.8% nano-silica.

From this research, it was concluded that the method of clay stabilized with nano-silica and polypropylene fiber could be significantly adopted as a technique for soil improvement that enhances the strength and Young’s modulus of clay soil. Based on this, it enhances the stability of pavement structures and lightly loaded infrastructures on the clay soil. So, this soil treatment method can be adopted as a technique for the stabilization of clay soil in pavement projects with practical considerations.

Availability of data and material

The data that guide the results of this research will be available openly.

References

Amini O, Ghasemi M (2019) Laboratory study of the effects of using magnesium slag on the geotechnical properties of cement stabilized soil. Constr Build Mater 223:409–420

Anggraini V, Asadi A, Huat BB, Nahazanan H (2015) Effects of coir fibers on tensile and compressive strength of lime treated soft soil. Measurement 59:372–381

Sharmila B, Bhuvaneshwari S, Landlin G (2021) Application of lignosulphonate—a sustainable approach towards strength improvement and swell management of expansive soils. Bull Eng Geol Environ 80:6395–6413. https://doi.org/10.1007/s10064-021-02323-1

Bahmani SH, Huat BBK, Asadi A, Farzadnia N (2014) Stabilization of residual soil using SiO2 nanoparticles and cement. Constr Build Mater 64:350–359

Buazar F (2019) Impact of biocompatible nanosilica on green stabilization of subgrade soil. Sci Rep 9:15147

Cai Y, Shi B, Ng CW, Tang CS (2006) Effect of polypropylene fiber and lime admixture on engineering properties of clayey soil. Eng Geol 87:230–240

Changizi F, Haddad A (2015) Effect of nano-SiO2 on the geotechnical properties of cohesive soil. Geotech Geol Eng 34:725–733

Changizi F, Haddad A (2015) Strength properties of soft clay treated with mixture of nano-SiO2 and recycled polyester fiber. J Rock Mech Geotech Eng 7:367–378

Choobbasti AJ, Kutanaei SS (2017) Microstructure characteristics of cement-stabilized sandy soil using nanosilica. J Rock Mech Geotech Eng 9:981–988

Choobbasti AJ, Samakoosh MA, Kutanaei SS (2019) Mechanical properties soil stabilized with nano calcium carbonate and reinforced with carpet waste fibers. Constr Build Mater 211:1094–1104

Ghavami S, Naseri H, Jahanbakhsh H, Nejad FM (2021) The impacts of nano-SiO2 and silica fume on cement kiln dust treated soil as a sustainable cement-free stabilizer. Constr Build Mater 285:1–14

Kalhor A, Ghazavi M, Roustaei M, Mirhosseini SM (2019) Influence of nano-SiO2 on geotechnical properties of fine soils subjected to freeze-thaw cycles. Cold Reg Sci Technol 161:129–136

Karande SD, Jadhav SA, Garud HB, Kalantre VA, Burungale SH, Patil PS (2021) Green and sustainable synthesis of silica nanoparticles. Nanotechnol Environ Eng 6:1–14

Kulanthaivel P, Soundara B, Das A (2020) Performance study on stabilization of fine grained clay soils using calcium source producing microbes. KSCE J Civ Eng 24:2631–2642

Kulanthaivel P, Soundara B, Velmurugan S, Naveenraj V (2021) Experimental investigation on stabilization of clay soil using nano-materials and white cement. Mater Today Proc 45:507–511

Kumar A, Gupta D (2016) Behavior of cement-stabilized fiber-reinforced pond ash, rice husk ash–soil mixtures. Geotext Geomembr 44:466–474

Lang L, Chen B, Duan H (2021) Modification of nanoparticles for the strength enhancing of cement-stabilized dredged sludge. J Rock Mech Geotech Eng 13:694–704

Li J, Tang C, Wang D, Pei X, Shi B (2014) Effect of discrete fiber reinforcement on soil tensile strength. J Rock Mech Geotech Eng 6:133–137

Meena SK, Sahu R, Ayothiraman R (2019) Utilization of waste wheat straw fibers for improving the strength characteristics of clay. J Nat Fibers. https://doi.org/10.1080/15440478.2019.1691116

Oluwatuyi OE, Ojuri OO, Khoshghalb A (2020) Cement-lime stabilization of crude oil contaminated kaolin clay. J Rock Mech Geotech Eng 12:160–167

Pham H, Nguyen QP (2014) Effect of silica nanoparticles on clay swelling and aqueous stability of nanoparticle dispersions. J Nanopart Res 16:2137

Phanikumar BR, Singla R (2016) Swell-consolidation characteristics of fiber-reinforced clay soils. Soils Found 56:138–143

Pongsivasathit S, Horpibulsuk S, Piyaphipat S (2019) Assessment of mechanical properties of cement stabilized soils. Case Stud Construct Mater 11:e00301

Selvakumar S, Soundara B (2019) Expanded polystyrene (EPS) geofoam columns in expansive soil: preliminary swelling characteristics evaluation. In: Arellano D, Özer A, Bartlett S, Vaslestad J (eds) 5th International conference on geofoam blocks in construction applications. Springer, Cham

Selvakumar S, Soundara B (2019) Swelling behaviour of expansive soils with recycled geofoam granules column inclusion. Geotext Geomembr 47(1):1–11

Soundara B, Selvakumar S (2020) Experimental Investigation on the swelling behavior of expansive soils with EPS geofoam inclusion. Indian Geotech J 50(4):519–530

Soundara B, Selvakumar S, Bhuvaneshwari S (2020) Laboratory study on natural fibre amended fly ash as an expansive soil stabilizer. Geotech Eng J SEAGS AGSSEA 51(4):1–6

Taha MR, Taha OME (2012) Influence of nano-material on the clay and shrinkage soil behavior. J Nanopart Res 14:1190

Tang C, Shi B, Gao W, Chen F, Cai Y (2007) Strength and mechanical behavior of short polypropylene fiber reinforced and cement stabilized clayey soil. Geotext Geomembr 25:194–202

Tiwari N, Satyam N (2020) An experimental study on the behavior of lime and silica fume treated coir geotextile reinforced clay soil subgrade. Eng Sci Technol Int J. https://doi.org/10.1016/j.jestch.2019.12.006

Acknowledgements

The authors convey thanks to the Nanotechnology Research Centre (NRC) of SRM Institute of Science and Technology (SRMIST) for providing the research facilities. Also, the authors acknowledge the Hi-Resolution Transmission Electron Microscope (HRTEM) Facility at SRMIST set up with support from MNRE (Project No. 31/03/2014-15/PVSE-R&D), Government of India.

Funding

The authors collected no financial support from any government/private agencies.

Author information

Authors and Affiliations

Contributions

PK conceptualized the presented idea, derived the methodology, designed and performed the experiments and writing original draft. SS developed the theory, supervised the findings, supported in writing review and editing. BS article drafting and contributed to the final version of the manuscript. VSK contributed to final version of the manuscript. SB contributed to the microstructural analysis and final version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Informed consent

Informed consent was gathered from all individual participants involved in the study.

Consent for publication

I give my consent for the publication that the research details in the paper to be published in this Journal.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kulanthaivel, P., Selvakumar, S., Soundara, B. et al. Combined effect of nano-silica and randomly distributed fibers on the strength behavior of clay soil. Nanotechnol. Environ. Eng. 7, 23–34 (2022). https://doi.org/10.1007/s41204-021-00176-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41204-021-00176-3