Abstract

In this paper, the splitting testing for the Yellow Rust Granite were performed to obtained 14 rock profiles. Based on the Barton’s method, the JRC values of the rock profiles with four different directions were calculated, it is interesting to find that the JRC values of rock profiles are different when tilt directions are different, suggesting that the JRC values presents the characteristics of anisotropy. The traditional empirical formula for estimating the JRC values mainly focused on the two dimensional rock profile and the anisotropy of JRC values are ignored in most studies. For considering the anisotropy of the rock surfaces, this paper presents an empirical formula to evaluate the JRC values, the empirical formula is \(JRC = 1.319(1 + 2.862\tan \beta )D_{f}\).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

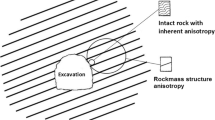

In rock engineering, the joints and faults have significant influence on stability. Liu (2014) found that the joint spacing, joint state and joints direction can affect the rock mass stability. A new rock mass rating evaluation method was carried out to evaluate the rock mass stability. Wang’s study (2014) reckoned that the joints weaken the intactness of the rock and the joints distribution can influence the rock slope stability. Some other researchers’ results indicated that the joints influence the rock mass engineering stability greatly (He et al. 2013; Zhang et al. 2012; Grenon and Hadjigeorgiou 2012). Due to the important role of joint in rock mass engineering stability, the study on characteristics of joints have attracted much attention. The roughness of rock joints has been one of the hot topics.

It is widely accepted that the shear strength of rock joints is strongly influenced by the rock joint surface morphology (Jang et al. 2015; Xia et al. 2014; Grasselli 2006). In the earlier time, Barton and Choubey (1977) estimated the joint roughness coefficient (JRC) value by comparing the appearance of a discontinuity surface with standard profiles. However, it is subjective to determine JRC value of a profile by visual comparison (Hsiung et al. 1993; Beer et al. 2002). To calculate the JRC value more accurately, Tse and Cruden (1979) proposed an empirical formula to estimate the JRC value of a rock profile by the equation:

where, \(Z_{2} = \left[ {\frac{1}{L}\int\limits_{0}^{L} {\left( {\frac{{{\text{d}}z}}{{{\text{d}}x}}} \right)^{2} {\text{d}}x} } \right]^{2}\) and sampling interval dx in the Eq. (1) is 0.5 mm. From analysis of Eq. (1), the empirical formula proposed by Tse and Cruden is dependent on the sampling interval dx. To overcome this problem, thereafter, Yu and Vayssade (1991)modified the empirical formula by considering the influence of sample interval:

Meanwhile, a useful tool was carried out to determine the roughness of rock profile: fractal dimension (Giri et al. 2013; Pi et al. 2010; Xie et al. 2011). The fractal geometry has been invented by the French mathematician Benoit Mandelbrot (1982) and it can be used to describe the phenomena of scale invariance. The relationship between JRC values and fractal dimensions was investigated and some empirical formulas were proposed [Eq. (3) by Lee et al. (1990), Eq. (4) by Wakabayashi and Fukushigi (1992), Eq. (5) by Manouchehr et al. (2015)]:

The related studies mentioned above are mainly focused on the JRC values of two dimension rock profiles. There are still many other researchers who made contributions to the roughness of 2 dimensional rock profiles (Li et al. 2015; Sanei et al. 2015; Zhang et al. 2014). However, the natural rock surface is 3 dimensional. Therefore, the research on the JRC value of 3 dimensional rock surfaces is more practical and meaningful. Ge et al. (2014) used the modified 2-D divider and variogram methods to quantify natural rock joint roughness in 3-D and 2-D. Zhao et al. (2015) proposed a model for the three-dimensional fractal distribution of the number of rock-mass fracture surfaces. While the anisotropy of JRC values were ignored in the aforesaid empirical formula, namely, the JRC values are different when the direction were different. Kulatilake et al. (1995, 2006, 1997, 1999) proposed some new approaches to study the anisotropy characteristics of the 3-D dimensional surface and some results were obtained. However, the corresponding empirical formula of JRC values considering anisotropy have not been reported so far. Thereof, the study on the JRC anisotropy of 3 dimensional rock surfaces and its empirical formula need to be further studied.

In this paper, the splitting testing was applied to obtain the Yellow Rust Granite surfaces. The tilt testing of the 3 dimensional surfaces were performed with four different directions. The rebound hammer testing of the surfaces was conducted to determine the joint compressive strength (JCS). Due to the difficulty of determining the JRC values of the surfaces by the traditional way, an empirical formula is established to estimate the JRC values of surfaces by considering the anisotropy.

2 JRC Values Calculation

2.1 Rock Surfaces Preparation

In the experiments, the splitting testing (shown in Fig. 1) of 14 Yellow Rust Granite with size of 70 mm × 70 mm × 70 mm were conducted, and these 14 specimens were marked as S1, S2,… S14. The loading speed of the splitting testing was 100 N/s in these experiments, which were performed by adopting two small diameter steel rods (Komurlu et al. 2016). The friction between these two steel rods and the specimens were ignored. Therefore, totally 28 rock surfaces were obtained, as shown in Fig. 1.

2.2 JRC Values Calculation

Based on the study by Barton et al. (1985), the JRC value can be denoted as:

where \(\alpha\) is the tilt angle when sliding occurs, \(\phi_{\text{r}}\) is the residual friction angle, JCS is the joint wall compression strength, \(\sigma^{\prime}_{{\text{no}}}\) is the corresponding value of effective normal stress when sliding occurs.

To estimate JRC values of rock surfaces, the related parameters tilt angle \(\alpha\), residual friction angle \(\phi_{\text{r}}\), JCS and \(\sigma^{\prime}_{{\text{no}}}\) should be calculated as follow.

2.2.1 Residual Friction Angle \(\phi_{\text{r}}\)

The residual friction angle \(\phi_{\text{r}}\) can be calculated by an empirical formula (Barton and Choubey 1977):

where \(\phi_{\text{b}}\) is the basic friction angle, which can be obtained by the three cores testing that will be introduced in the following; r is the weathered and saturated joint wall rebound by using the Schmidt hammer; R stands for the rebound of unweathered and dry rock.

The Schmidt hammer (Fig. 2) was utilized to obtained the rebound value of the rock or joint wall. During the testing, the Schmidt hammer should be vertical to the measured surface. Besides, to obtain accurate the rebound value, more than 10 times rebound hammer testing should be conducted for the each measured surface, and the mean value is taken as the final result.

100 Schmidt hammer rebound testing were conducted on the unweathered, dry rock (rebound R) and the weathered, saturated joint (rebound r) of Yellow Rust Granite by using the Schmidt hammer, respectively. The mean value of r/R was calculated. The basic friction angle \(\phi_{\text{b}}\) was determined by the three rock cores testing (Stimpson 1977) (the size of rock cores is \(\varPhi 50\;\text{mm } \times \text{ 100}\;\text{mm}\)), illustrated in Fig. 3.

As shown in the Fig. 3, the core B and C are contacted and fixed in the base. The core A located on the top of core B and C. By keep increasing of the rotation angle of the base, the core A will slide when the tilt angle reaches a certain angle \(\varphi\).

The friction angle between A, B and C is the so call basic friction angle \(\phi_{\text{b}}\). Based on the limit equilibrium method, it can be concluded that:

where w is the weight of the rock core, \(\theta = 30^{ \circ }\).

Based on Eq. (8), the basic friction angle can be written as:

Based on the Eqs. (7), (8) and (9), the residual friction angle \(\phi_{\text{r}}\) of Yellow Rust Granite is \(30.95^{ \circ }\).

2.2.2 JCS Evaluation

Based on the study by Miller (Deere and Miller 1966; Hardin 1965), the joint compression strength (JCS) can be expressed as:

where \(\gamma\) is the bulk density of rock, R is the Schmidt rebound value of unweathered, dry rock.

On basis of this method, the JCS value of the rock surface is 85.55 MPa (uniaxial compressive strength (UCS) of the Yellow Rust Granite is 126.3 MPa). The value of JCS/UCS is 0.67, which is in a good agreement with the study by Barton and Choubey (1977) (JCS/UCS values range from 0.53 to 0.71).

2.2.3 Laboratory Tilt Testing

In these experiments, the tilt testing of the rock surfaces were performed with four different directions in laboratory, displayed in Fig. 4. Before the tilt testing, the four directions should be determined. In this paper, the rock surfaces can be termed as a square from the top view of the rock surfaces. For convenience of the tilt testing, the four directions are perpendicular to the square side (Fig. 4), the direction 1 is chosen randomly at the first, then the direction 2–4 can be determined on clockwise. And the direction number and tilt testing direction were marked before the tilt testing, hence the four directions for the rock surfaces were determined.

As shown in Fig. 4, the four tilt testing with four different directions for each surfaces were performed. The corresponding tilt angles were recorded, shown in Fig. 5.

The corresponding value of effective normal stress \(\sigma^{\prime}_{{\text{no}}}\) when sliding occurs in the tilt testing were calculated for each specimen with four directions, which can be denoted as:.

where \(w_{{\text{up}}}\) is the weight of upper sample, \(\alpha\) is the tilt angle, \(A_{\text{j}}\) is the measurement area of joint surface, the measurement area of the joint surfaces were calculated, displayed in Fig. 6.

Based on the Figs. 5, 6 and Eq. (6), the JRC values of the surfaces with four directions were calculated, illustrated in Fig. 7.

From analysis of Fig. 7, it is interesting to note that the JRC values for the rock surfaces are different when the tilt directions are different. In other words, the JRC values of the surfaces are not only influenced by the geometry of rock surface but also the tilt direction, which is can be described as the anisotropy of the joint surface JRC values. For example, as for the specimen S11, the tilt angles of the joint surface with four directions are 52°, 61°, 66°, 57° and the corresponding JRC values are 2.14, 3.03, 3.51 and 2.64, respectively. It is observed that the same variation for the other surfaces occurs as well. Obviously, the tilt directions affect the JRC values of the surfaces greatly and the influence of directions to JRC values cannot be ignored. However, the anisotropy of JRC value of rock surface has not been studied in most previous researches. Through analysis of the experiments results, it is indicated that the influence of the tilt directions to the JRC value of rock joints surface should be considered. Accordingly, an empirical formula for calculating JRC values of surfaces should take the anisotropy of the joint surfaces into account, which would be illustrated in the following.

3 Empirical Formula of JRC Value

As mentioned above, the JRC value of the surfaces is influenced by the tilt directions. Moreover, the traditional JRC calculation method of rock surface is complicated and time-consuming. In this paper, an improved empirical formula has been proposed for calculating JRC value by considering the fractal dimension and the tilt directions. The fractal dimension is utilized to quantify the fluctuation of surfaces and the direction angle is used for quantifying the anisotropy of the JRC values, which is demonstrated detailedly in the following.

3.1 Fractal Dimension Calculation

Due to the natural joints surface are three dimensional, the related study on three dimensional rock joints can be more practical and useful than the two dimensional. In this study, the fractal dimension was used to measure the fluctuation of the joints surface. The fractal dimension is used to characterize and quantify the complexity of rock profile, it is important that the fractal dimension is not influenced by the scale effect and sampling intervals, moreover it is widely used in describing the 3-D rock profile (Xie et al. 1999; Jiang et al. 2006).

In order to estimate the fractal dimensions of the surfaces, both the Talysurf CLI 2000 scanner and Talymap Gold software were utilized. The morphology of the rock surfaces were scanned by Talysurf CLI 2000 testing machine (Fig. 8). This machine offers both the advantages of high precision and good repeatability (Chen et al. 2010, 2014). The maximum measurement size of Talysurf CLI 2000 is about 200 mm × 200 mm × 200 mm and the maximum mass of a specimen is 30 kg. The accuracy of this machine is up to 0.5 μm (x, y and z directions), which can guarantee the precision of results. In addition, the maximum scanning speed is 30 mm/s and the scanner can pick lots of points along the scanning direction by manual setting.

By combining the scanning results from Talysurf TLI 2000 scanner, the fractal dimensions of the surfaces were estimated with the aid of Talymap Gold software via the box counting method (Ai et al. 2014; Liu et al. 2014; Jaya et al. 2014). The box counting method consists of enclosing each section of a 3 dimensional profile by a box of width \(\varepsilon\) and calculating the area \({\text{A}}\varepsilon\) of the boxes endorsing the whole profile, this procedure is iterated with boxes of different widths to build a graph \({\text{ln(A}}\varepsilon )/\ln (\varepsilon )\), then the slope for the line \({\text{ln(A}}\varepsilon )/\ln (\varepsilon )\) would be the fractal dimension of the rock profile. Based on the box counting method, the fractal dimension for the joint surfaces were calculated, listed in Table 1. However, the anisotropy of JRC values can not be reflected by the fractal dimension (The JRC values are different when the tilt direction are different), therefore, another variation needed to describe the anisotropy.

3.2 Direction Angle Evaluation

To quantify the anisotropy the surface JRC values (the JRC values of the surfaces were different when the tilt directions were different), the direction angle was introduced. The calculation of direction angles of the surfaces were illustrated in the following.

-

1.

The trend plane of the surfaces was obtained via the regression method by using the x, y, z coordinates of the picked points on the surfaces (these coordinates of the points were obtained by the Talysurf scanning machine), which can be expressed by the following equation.

$$\left\{ \begin{aligned}& \left[ {\begin{array}{*{20}c} {\sum {x_{i}^{2} } } & {\sum {x_{i} y_{i} } } & {\sum {x_{i} } } \\ {\sum {x_{i} y_{i} } } & {\sum {y_{i}^{2} } } & {\sum {y_{i} } } \\ {\sum {x_{i} } } & {\sum {y_{i} } } & n \\ \end{array} } \right]\left[ \begin{aligned} a_{0} \hfill \\ a_{1} \hfill \\ a_{2} \hfill \\ \end{aligned} \right] = \left[ \begin{aligned} \sum {x_{i} z_{i} } \hfill \\ \sum {y_{i} z_{i} } \hfill \\ \sum {z_{i} } \hfill \\ \end{aligned} \right] \hfill \\ &z = a_{0} x + a_{1} y + a_{2} \hfill \\ \end{aligned} \right.$$(12)where, a 0, a 1 and a 2 are the fitting parameters; n is the total number of the picked points of the joint surfaces; \(z = a_{0} x + a_{1} y + a_{2}\) is the trend plane.

-

2.

The direction angles of different directions can be calculated on basis of the trend plane and the tilt directions, displayed in Fig. 9.

As illustrated in Fig. 9, the tilt direction vector (CB d, CA d) was firstly confirmed, the tilt direction vector is paralleled to the xy-plane and parallel to y-axis or x-axis, which represents the directions. On the other hand, the plane vector CB y and CA x are on the trend plane, further these vectors are paralleled to the yz-plane and xz-plane, separately. The direction angles would be the angles \(\angle B_{\text{d}} CB_{\text{y}}\) (\(\beta_{1}\)) and \(\angle A_{\text{d}} CA_{\text{x}}\) (\(\beta_{2}\)). When the tilt direction vector is up on the plane vector (CA d is above CA x), the corresponding direction angle is negative. On the contrary, while the direction vector is below the corresponding plane vector (CB d is below CB y), the corresponding direction angle would be positive. According to the method mentioned above, direction angles of the rock surfaces were calculated, listed in Table 2. In Table 2, it is found that the direction angles were different when the directions are different, which can reflect the anisotropy of the rock joints surface JRC values well.

3.3 Empirical Formula of JRC Value

To establish the relation between JRC values, fractal dimension and the direction angles, a set of experimental data set should be confirmed. In this paper, JRC values and the directions angles of four directions of a rock are different when the tile directions are different, but the fractal dimension are the same. For example, the fractal dimension for the four directions of the rock surfaces is 2.16, while the direction angles for the direction 1, 2, 3 and four are −5.09°, 0.99°, 5.09° and −0.99°, separately. Meanwhile, the JRC values of the four directions for the rock surface S11 are 2.14, 3.03, 3.53 and 2.64, respectively. By this method, the fitting data for establishing the relation between JRC values, directions angles and the fractal dimension were determined.

Combined the experimental data of Fig. 7 (JRC values), Table 1 (fractal dimension) and Table 2 (direction angle), the empirical formula among JRC values, fractal dimension and the directions angles were constructed by the least square fitting. By trying different fitting function, it is found that the Eq. (13) has the best fitting effect. The corresponding fitting parameter R2 is 0.8967, which is close to 1 (The closer the value of R2 to 1, the better the fit of the empirical equation to the shear test data.). To further investigate the validity of the fitting equation, the Analysis of Variance (ANOVA) was conducted, which is listed in Table 3. In the Table 3, the Prob > F equates 0, which indicates that the fitting equation can be accepted.

where \(JRC\) represents the JRC values of the joint surfaces, \(\beta\) stands for the direction angle of the joints surfaces and \(D_{\text{f}}\) stands for the fractal dimensions of joints surfaces.

From analysis of Eq. (13), it is suggested that the JRC values of the surfaces are positively correlated with the direction angle \(\beta\) and the fractal dimension \(D_{\text{f}}\). Additionally, the empirical formula proposed by this paper can reflect the influence of the tilt direction to the JRC values of surfaces. It is indicated the JRC value would increase as the direction angle \(\beta\) increases for the same surfaces. The empirical formula, considering the influence of the tilt directions to the JRC values, can present different JRC values when directions are different even for the same rock surface. Moreover, the proposed empirical formula is much simpler than Eq. (6). The previous studies (Lee et al. 1990; Wakabayashi and Fukushigi 1992; Manouchehr et al. 2015) mainly focused on the relation between the JRC values and fractal dimensions of the two dimensional joints. However, the rock joint in nature are three dimensional, the relation between JRC values and fractal dimension were established in this paper, and the results can be more reliable in practical use.

4 Discussion

According to previous research, the JRC values of joints were mainly calculated by the empirical formula for two dimensional joints, that is, the joints were simplified as two dimensional problems. Regarding the study of JRC value of two-dimensional joints, a large number of empirical formula, based on laboratory testing, were proposed. Barton’s method has been widely used practically in recent years, however, it is noted that there are some disadvantages: complicated procedure, hard-conducting and time-consuming. It is necessary to propose a more simpler empirical formula.

Since the rock joints in nature are usually in type of three dimensional, the study on the JRC value of two dimensional rock joints has limited use for rock engineering. Hence, it is necessary to investigate the JRC values of three dimensional rock joints surface. For the 3D rock joints surface, the fractal dimension and the direction angles were utilized to measure the JRC values in this paper.

In order to research the JRC values of three dimensional joints surfaces, Yellow Rust Granite were used in this study, the three dimensional joints surfaces were obtained by the splitting testing. Subsequently, the JRC values were calculated based on the experiments results: the tilt angle \(\alpha\) when sliding occurs, the residual friction angle \(\phi_{\text{r}}\), the joint wall compression strength JCS, et al. It is interesting to note that the tilt angles for the joints surface are different when the tilt directions are different, and the JRC values of joints surface are different as well. The testing results indicate that the JRC values are influenced by the directions, the JRC values of the rock joint surfaces have the characteristics of anisotropy. Nevertheless, the anisotropy of the JRC values were ignored in most references. Thus, it is meaningful to consider the influence of anisotropy to the JRC values. Moreover, due to the influence of the direction to the JRC values of the rock surfaces, hence, to obtain the JRC values of the rock surfaces, the tilt directions can not be selected randomly but should be carefully chosen based on the engineering practice, which is important to obtain the proper JRC values of the rock surfaces.

To consider the anisotropy of JRC values of the three dimensional joints rock surface, the direction angle was used in this paper. Furthermore, the fluctuation of the rock joints surface was measured via the fractal dimension. Combined the JRC values of the joints surface from four different directions obtained by the Barton’s method, a new JRC empirical formula was proposed by using the fractal dimension and the direction angle via the least square method. This proposed empirical formula can be used to estimate the JRC values with fractal dimension and direction angle, and the calculation procedure is quite simple. The R-square for the fitting results is 0.8967 (close to 1), which suggests that the empirical formula can predict the laboratory testing results well.

5 Conclusions

In this paper, 14 Yellow Rust Granite specimens were utilized to perform a series of laboratory testing. The rock surfaces were obtained by the splitting testing and the JRC values were calculated accordingly. Furthermore, an empirical formula was proposed, which can reflect the anisotropy of the JRC values of rock surfaces. The main conclusions in this paper are as follows.

-

1.

Based on the study by Barton, the JRC values of the Yellow Rust Granite surfaces were calculated. It is interesting to note that, for the same surface, the JRC values are different when the tilt directions are different. As matter of fact, the study on influence of directions to the JRC values is less. Hence, it is meaningful to investigate the anisotropy of the JRC values of surfaces. By adopting the fractal dimension and direction angle, an empirical formula for calculating the JRC values of the surfaces was proposed. The proposed formula can verify the original data well. Both the experimental data and the empirical formula results indicate that the JRC values are positively correlated with the fractal dimension and the direction angle. Moreover, for the same rock surface, the JRC values of the surfaces increases as the increasing direction angles.

-

2.

In the experiments, only the Yellow Rust Granite was used in the experiments. Whether the proposed empirical formula is suitable for other kinds of rock surfaces need to be further investigated. There may be some errors when the proposed empirical formula is applied to measure the JRC value of the joints surface for other kinds of rock. It is necessary to perform the experiments of the other kinds of rock joints surface, which can make the results more accurate and practical. In brief, this paper suggests that the anisotropy of the JRC values cannot be ignored, and the empirical formula for estimating the JRC value should include the influence of the direction.

References

Ai T, Zhang R, Zhou HW et al (2014) Box-counting methods to directly estimate the fractal dimension of a rock surface. Appl Surf Sci 314:610–621

Barton N, Choubey V (1977) The shear strength of rock joints in theory and practice[J]. Rock Mech Rock Eng 10(1–2):1–54

Barton N, Bandis S, Bakhtar K (1985) Strength, deformation and conductivity coupling of rock joints. Int J Rock Mech Min Sci Geomech Abstr 22(85):121–140

Beer AJ, Stead D, Coggan JS (2002) Estimation of the joint roughness coefficient (JRC) by visual comparison. Rock Mech Rock Eng 35:65–74

Chen Y, Cao P, Chen R et al (2010) Effect of water-rock interaction on the morphology of a rock surface. Int J Rock Mech Min 47(5):816–822

Chen Y, Cao P, Mao D et al (2014) Morphological analysis of sheared rock with water-rock interaction effect. Int J Rock Mech Min 70:264–272

Deere DU, Miller RP (1966) Engineering classification and index properties for intact rock. (Technical report no. AFNL-TR-65-116). New Mexico: Air Force Weapons Laboratory

Ge YF, Kulatilake PHSW, Tang HM et al (2014) Investigation of natural rock joint roughness. Comput Geotech 55:290–305

Giri A, Tarafdar S, Gouze P et al (2013) Fractal geometry of sedimentary rocks: simulation in 3-D using a relaxed bidisperse ballistic deposition model. Geophys J Int 192(3):1059–1069

Grasselli G (2006) Manuel Rocha Medal recipient-shear strength of rock joints based on quantified surface description. Rock Mech Rock Eng 39(4):295–314

Grenon M, Hadjigeorgiou J (2012) Applications of fracture system models (FSM) in mining and civil rock engineering design. Int J Min Reclam Environ 26(1):55–73

Hardin RP (1965) Engineering classification and index properties for intact rock. Ph.D. Univ. of Illinois: 332

He L, An XM, Zhao XB et al (2013) Investigation on strength and stability of jointed rock mass using three-dimensional numerical manifold method. Int J Numer Anal Methods Geomech 37(14):2348–2366

Hsiung SM, Ghosh A, Ahola MP et al (1993) Assessment of conventional methodologies for joint roughness coefficient determination. Int J Rock Mech Min Sci Geomech Abstr 30:825–829

Jang HS, Jang BA (2015) New method for shear strength determination of unfilled, unweathered rock joint. Rock Mech Rock Eng 48(4):1515–1534

Jaya V, Raghukanth STG, Mohan SS (2014) Estimating fractal dimension of lineaments using box counting method for the Indian landmass. Geocarto Int 29(3):314–331

Jiang YJ, Li B, Yosihiko T (2006) Estimating the relation between surface roughness and mechanical properties of rock joints. Int J Rock Mech Min 43(6):837–846

Komurlu E, Kesimal A, Demir S (2016) Experimental and numerical analyses on determination of indirect (splitting) tensile strength of cemneted paste backfill materials under different loading apparatus. Geomech Eng 10(6):775–791

Kulatilake PHSW, Um J (1999) Requirements for accurate quantification of self-affine roughness using the roughness-length method. Int J Rock Mech Min 36(1):5–18

Kulatilake PHSW, Shou G, Huang TM et al (1995) New peak shear strength criteria for anisotropic rock joints. Int J Rock Mech Min Sci Geomech Abstr 32:673–697

Kulatilake PHSW, Um J, Pan G (1997) Requirements for accurate estimation of fractal parameters for self-affine roughness profiles using the line scaling method. Rock Mech and Rock Eng 30(4):181–206

Kulatilake PHSW, Balasingam P, Park J et al (2006) Natural rock joint roughness quantification through fractal techniques. Geotech Geol Eng 24:1181–1202

Lee YH, Carr JR, Bars DJ et al (1990) The fractal dimension as a measure of the roughness of rock discontinuity profiles. Int J Rock Mech Min Sci Geomech Abstr 27:453–464

Li YR, Huang RQ (2015) Relationship between joint roughness coefficient and fractal dimension of rock fracture surfaces. Int J Rock Mech Min 75:15–22

Liu ZX, Dang WG (2014) Rock quality classification and stability evaluation of undersea deposit based on M-IRMR. Tunn Undergr Space Technol 40:95–101

Liu Y, Chen LY, Wang HM et al (2014) An improved differential box-counting method to estimate fractal dimensions of gray-level images. J Vis Commun Image Represent 25(5):1102–1111

Mandelbrot BB (1982) The fractal geometry of nature. W. H. Freeman and Company, New York

Manouchehr S, Lohrasb F, Ahmad F et al (2015) Shear strength of discontinuities in sedimentary rock masses based on direct shear tests. Int J Rock Mech Min 75:119–131

Pi WL, Dai GF (2010) Research on periodical damage of roof rock-mass and its fractal character. Disaster Adv 3(4):459–461

Sanei MFL, Goli S, Fahimifar A et al (2015) Development of a new equation for joint roughness coefficient (JRC) with fractal dimension: a case study of Bakhtiary Dam site in Iran. Arab J Geosci 8(1):465–475

Stimpson B (1977) Technical note: a suggested technique for determining the basic friction angle of rock surfaces using core. Int J Rock Mech Min Sci Geomech Abstr 8:63–65

Tse R, Cruden DM (1979) Estimating joint roughness coefficients. Int J Rock Mech Min Sci Geomech Abstr 16(5):303–307

Wakabayashi N, Fukushigi I (1992) Experimental study on the relation between fractal dimension and shear strength. In: Proceedings of international symposium for fractured and jointed rock masses, Berkeley, pp 101–110

Wang SH, Ni PP (2014) Application of block theory modeling on spatial block toplogical identification to rock slope stability analysis. Int J Comp Methods 11(1):1350044

Xia CC, Tang ZC, Xiao WM et al (2014) New peak shear strength criterion of rock joints based on quantified surface description. Rock Mech Rock Eng 47(2):387–400

Xie HP, Wang JA, Kwasniewski MA (1999) Multifractal characterization of rock fracture surfaces. Int J Rock Mech Min 36(1):19–27

Xie HP, Liu JF, Ju Y et al (2011) Fractal property of spatial distribution of acoustic emissions during the failure process of bedded rock salt. Int J Rock Mech Min 48(8):1344–1351

Yu X, Vayssade B (1991) Joint profiles and their roughness parameters. Int J Rock Mech Min Sci Geomech Abstr 28(4):333–336

Zhang YT, Ding XL, Huang SL et al (2012) Stability evaluation of rock blocks in jointed rock masses considering earthquake impacts. Disaster Adv 5(4):127–132

Zhang GC, Karakus M, Tang HM et al (2014) A new method estimating the 2D joint roughness coefficient for discontinuity surfaces in rock masses. Int J Rock Mech Min 72:191–198

Zhao YS, Feng ZC, Yang D et al (2015) Three-dimensional fractal distribution of the number of rock-mass fracture surfaces and its simulation technology. Comput Geotech 65:136–146

Acknowledgements

This study was funded by the Open Research Fund Program of Hunan Provincial Key Laboratory of Shale Gas Resource Utilization; Hunan University of Science and Technology (Grant No. E21527); the Fundamental Research Funds for the Central universities of Central South University (Grant No. 2015zzts077).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interests regarding the publication of this paper.

Rights and permissions

About this article

Cite this article

Wang, M., Cao, P. & Chen, Y. Anisotropy of Rock Profile JRC Values and Its Empirical Formula: A Case Study on Yellow Rust Granite. Geotech Geol Eng 35, 1645–1655 (2017). https://doi.org/10.1007/s10706-017-0199-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-017-0199-7