Methods for predicting creep processes of synthetic sewing materials used for devices of personal protection from mechanical impacts are reviewed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

An example of use of synthetic clothing materials in devices of individual protection is their use as inner linings of protective helmets for guarding the head of the person from injury, for example, during construction works.

Clothing materials and structures therefrom must have specific elastic and viscoelastic properties. In view of this, a pressing task is to predict the creep of synthetic clothing materials or structures therefrom under various conditions of force action.

Examples of such conditions could be various types of deformation-recovery processes under both full and partial loads. The simplest loading condition is the deformation process with a constant rate of deformation [1].

This process is described experimentally using tensile-test diagram, which could serve as a means of control of accuracy of prediction of elastic and more intricate conditions of deformation.

The methods of determination of creep characteristics of synthetic clothing materials are based on use of mathematical models that approximate experimental “families” of creep curves via normalized functions. Let us analyze one of the variants of such method [2].

The stress-strain state of synthetic clothing material in the domain of nondestructive loads is described by Boltzmann-Volterra integral equation for creep process

where \( {D}_{\upsigma s}^{\prime }=\partial {D}_{\upsigma s}/\partial s \) is the creep kernel expressing force-time analogy, σt is the stress, εt is the strain (deformation), D0 is the initial compliance, D∞ is the ultimate equilibrium compliance, and t is the time.

Let us approximate compliance Dσt by the normalized function φσt [3]; Dσt = D0 + (D∞ − D0)φσt, which we will put as

Where

is the structural-force-time argument-functional, t1 is the fixed base time, τσ is the delay time, and bpσ is the structure coefficient.

The normalized logarithmic creep kernel has the form [4]

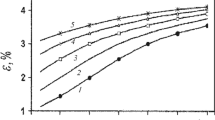

Let us analyze the method of processing of the “family” of creep curves (Fig. 1) using the example of cloak fabric used in impact-protective helmets with a breaking deformation value of 45%.

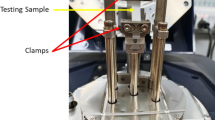

Instead of the stress σ = const, let us consider the force magnitudes P = σF, where F = const is the area of the fabric sample cross-section calculated with due regard for the density of interweaving of yarns [5].

The kernel rσt attains its extreme value \( {\overline{r}}_{\upsigma t}=\left(1/{b}_{n\upsigma}\right)\cdot \left(1/\uppi \right) \) at t = τσ, which corresponds to Wτ = 0, φτ = 0.5, Dτ = 0.5(D0 + D∞).

This fact enables us to determine the creep process intensity parameter [6]

the force-time function [7]

and the asymptotic values of D0 and D∞.

In our case, the calculated value of the creep process intensity was 1/bpσ = 0.216 and the asymptotic compliance values were D0/F = 37.531/kg and D∞/F = 20.469/kg. The curve of force-time function [7] is shown in Fig. 2.

Thus, by calculating the creep parameter using the described method we can predict the desired deformation conditions on the basis of integral equation (1) [8].

The process of deformation of cloak fabric with a constant deformation rate ε = 0.00083/sec is illustrated in Fig. 3, where experimental and calculated tensile-test diagrams are shown. As evident from their comparison, the extension process is calculated with a relative error of not more than 10 %, which is technically admissible [9].

References

A. S. Gorshkov, A. G. Makarov, et al., Mag. Civil Eng., 44, No. 9, 76-83 and 103-104 (2013). https://doi.org/10.5862/MCE.44.10

P. P. Rymkevich, A. A. Romanova, et al., Macromol. Sci., Pt. B: Phys., 52, No. 12, 1829-1847 (2013). https://doi.org/10.1080/00222348.2013.808906

A. V. Demidov, A. G. Makarov, and A. M. Stalevich, Izv. Vuz. Ser. Tekhnol. Text. Prom., 298, No. 3, 11-14 (2007). eid=2-s2.0-34648822922

V. V. Golovina, P. P. Rymkevich, et al., Izv. Vuz. Tekhnol. Legk. Prom., 33, No. 3, 14-20 (2016).

A. A. Askadskii, Structure and Properties of Heat Resistant Polymers [in Russian], Khimiya, Moscow (2001), p. 320.

A. A. Askadskii, Deformation of Polymers [in Russian], Khimiya, Moscow (1999), p. 449.

G. M. Bertenev and Yu. V. Zelenev, Physics and Mechanics of Polymers [in Russian], Vysshaya Shkola, Moscow (1999), p. 392.

A. M. Stalevich, Deformation of Highly Oriented Polymers, 4.2: Theory of Nonlinear Viscoelasticity [in Russian], St. Petersburg (1997).

A. M. Stalevich and L. E. Root, Probl. Prochn., No. 1, 43-45 (1984).

The study was financed within the ambit of fulfilment of the Russian Federation Presidential Grant No. MK-1210.2020.8 and Russian Federation Presidential Stipend No. SP-3895.2021.5.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimicheskie Volokna, No. 3, pp. 15-17, May-June 2021

Rights and permissions

About this article

Cite this article

Kozlov, A.A., Egorova, M.A. & Egorov, I.M. Prediction of Creep of Synthetic Protective Clothing Materials. Fibre Chem 53, 163–165 (2021). https://doi.org/10.1007/s10692-021-10259-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10692-021-10259-1